Have you ever stared at a machine and wondered how it works? A metal lathe is one of those fascinating tools. It spins metal while cutting it into different shapes. But what happens when you want to set one up? That’s where a gearhead metal lathe wiring diagram comes into play.

A wiring diagram can feel like a puzzle. It shows where each wire goes and how power flows. Imagine trying to ride a bike without knowing how to steer. That’s how tricky it can be without a good diagram.

Did you know that even a small mistake in wiring can cause big problems? You could blow a fuse or even damage your lathe. That’s why understanding these diagrams is super important. Don’t let confusion hold you back from creating amazing projects!

Getting to know your gearhead metal lathe can open doors to endless possibilities. Whether you want to make custom parts or cool projects, the journey starts with understanding how to wire it right!

Gearhead Metal Lathe Wiring Diagram Explained Simply

Understanding Gearhead Metal Lathe Wiring Diagrams

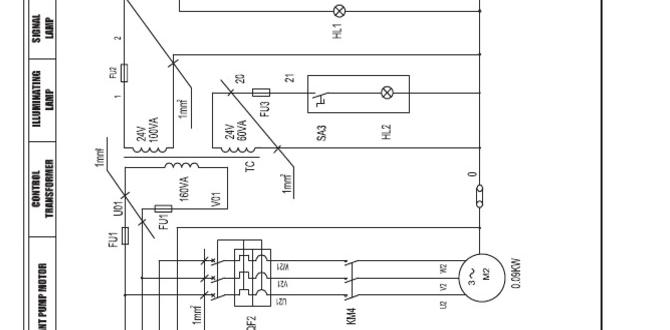

A gearhead metal lathe wiring diagram helps users connect their machines safely. These diagrams show how to wire motors, switches, and controls. Ever wondered how to avoid short circuits? The diagram makes sure you hook everything up correctly. Imagine turning raw metal into a masterpiece! Clear wiring is crucial for smooth operation. Plus, knowing the diagram can save you from costly mistakes. Dive into the world of metalwork with confidence!Understanding Gearhead Metal Lathes

Definition and functionality of gearhead metal lathes. Key components and their roles in the lathe operation.Gearhead metal lathes are magical machines that spin metal, helping to create cool shapes and parts. They work by holding the metal still while a tool cuts into it. Key components like the chuck, spindle, and tailstock play vital roles. The chuck grips the metal like a hungry mouth, the spindle spins it faster than a roller coaster, and the tailstock helps with precise cutting. Each part must work well together for the lathe to shine. Isn’t metalworking fun?

| Component | Function |

|---|---|

| Chuck | Holds the metal in place. |

| Spindle | Spins the metal for cutting. |

| Tailstock | Supports tools for accuracy. |

Importance of Wiring Diagrams in Metal Lathes

How wiring diagrams enhance safety and efficiency. Common issues that may arise from incorrect wiring.Wiring diagrams play a huge role in keeping metal lathes safe and efficient. They show how to connect everything, which means fewer mishaps. Without them, wires might cross like confused snakes, leading to messy problems. A little miswiring can cause machines to stop or, yikes, even spark! Using a diagram helps avoid this chaos, ensuring the lathe runs smoothly. Safety first, fun later! Here’s a quick overview of common issues from incorrect wiring:

| Problem | Result |

|---|---|

| Short Circuits | Equipment damage |

| Incorrect Voltage | Overheating |

| Loose Connections | Intermittent Operation |

Following a wiring diagram keeps everything organized and running like a charm! So, grab that diagram, and let’s keep the metal spinning smoothly!

Components of a Gearhead Metal Lathe Wiring Diagram

Description of circuit elements included in the diagrams. Importance of each component (motors, switches, controls).Understanding the wiring diagram of a gearhead metal lathe is like knowing how to bake a cake. You need the right ingredients! Key components include motors, switches, and controls. Motors are the heart, making the lathe spin and whir. Switches are like traffic lights, directing power where it needs to go. Controls give you the power to decide how fast or slow. Without these parts, your lathe would be like a car without an engine— not much fun!

| Component | Description | Importance |

|---|---|---|

| Motors | These power the spindle. | They make everything move! |

| Switches | Control the flow of electricity. | They keep things safe and functioning! |

| Controls | Adjust speed and settings. | Your personal driving instructor! |

Step-by-Step Guide to Reading Wiring Diagrams

How to interpret symbols and notations in wiring diagrams. Tips for understanding connections between components.Reading a wiring diagram can feel tricky, but it’s easier when you know the symbols. Each symbol stands for a part, like a wire or a switch. These are often drawn simply, like circles or lines. Connections show how parts link together. Here are some tips:

- Look for bold lines to find power paths.

- Check notes beside symbols for extra details.

- Follow the path to see how the electricity flows.

Understanding these points helps you read the diagram easily. It’s like solving a puzzle!

What should I know about symbols in wiring diagrams?

Each symbol represents a specific electrical component, which makes diagrams clear and organized. You can find these symbols on the diagram key. They help identify parts quickly. Using symbols allows for easy understanding of wiring layouts.

Common Wiring Configurations for Gearhead Lathes

Examples of standard wiring setups for different models. Variations based on manufacturer specifications.Many gearhead lathes have different wiring setups. Here are some common examples:

- Model A: Standard connection for 120V operation.

- Model B: Uses a specific switch for reversing direction.

- Model C: Features a built-in safety circuit.

Each model may vary based on the manufacturer. It’s important to check the manual for specific wiring details. Understanding your lathe’s unique requirements helps ensure safety and proper function.

What are common wiring configurations for gearhead lathes?

Common wiring setups vary based on the model and manufacturer. Always refer to your lathe’s manual for correct wiring instructions. Each setup ensures safe and effective operation.

Troubleshooting Wiring Issues

Common wiring problems encountered with metal lathes. Steps to identify and resolve wiring faults.Wiring problems can cause frustration with metal lathes. Some common issues include loose connections, damaged wires, or burnt switches. To fix these, follow these steps:

- Check every connection: Look for loose wires.

- Inspect wires: Look for cuts or nicks.

- Test components: Check switches and plugs for faults.

Start by turning off the machine and unplugging it. This keeps you safe. Regular checks can help prevent problems. Keeping your lathe in good shape is key!

What are signs of wiring issues?

Common signs include unusual sounds, weird smells, and machine not starting.

Safety Precautions when Working with Wiring Diagrams

Best practices to avoid electrical hazards. Recommended tools and protective gear for wiring tasks.Before diving into wiring diagrams, it’s important to take some safety steps. Always wear gloves and goggles. These protect you from shocks and bits of flying wires. Make sure your workspace is dry. Water and electricity are like oil and water—they don’t mix! Use the right tools: a screwdriver, wire stripper, and a multimeter can help you avoid nasty surprises. Remember, safety first; no one enjoys a shocking experience!

| Recommended Tools | Protective Gear |

|---|---|

| Wire Stripper | Gloves |

| Screwdriver | Safety Goggles |

| Multimeter | Insulated Shoes |

Resources for Gearhead Metal Lathe Wiring Diagrams

Where to find reliable wiring diagrams online. Recommended books and materials for further learning.Finding good wiring diagrams for your gearhead metal lathe is easy. You can check out several online resources. Websites like *YouTube*, *Instructables*, and forums like *Reddit* provide valuable images and guides. Recommended books also help with detailed wiring instructions. Try these:

- *The Complete Guide to Metalworking*

- *DIY Lathe Projects*

- *Electric Lathes and Their Uses*

These materials will boost your understanding of wiring and safety. Start exploring the wealth of knowledge available!

Where can I find wiring diagrams for a metal lathe?

Look for reliable info on wiring diagrams through YouTube and dedicated hobbyist websites. Forums are also helpful for tips and shared experiences.

Conclusion

In summary, the gearhead metal lathe wiring diagram is essential for safe and effective operation. It shows how to connect wires properly. Understanding this diagram helps you troubleshoot and maintain your lathe. You can enhance your skills and confidence by studying the wiring further. So, check out more resources or experiment with your own lathe setup today!FAQs

What Are The Essential Components Needed For Wiring A Gearhead Metal Lathe?To wire a Gearhead metal lathe, you need a power supply, some wires, a switch, and a motor. The power supply gives electricity to the lathe. Wires help connect everything together. The switch lets you turn the lathe on and off easily. Finally, the motor makes the lathe spin to work on metal.

How Do You Interpret The Wiring Diagram For A Gearhead Metal Lathe?To read the wiring diagram for a Gearhead metal lathe, start by looking at the main parts. You’ll see lines that connect different pieces. Each line shows how electricity flows. The symbols represent things like power switches and motors. By following the lines, you can understand how everything works together.

What Safety Precautions Should Be Taken While Wiring A Gearhead Metal Lathe?When wiring a Gearhead metal lathe, you should always turn off the power first. Make sure to wear safety glasses to protect your eyes. Use insulated tools to avoid electric shocks. Keep your workspace clean and organized to prevent accidents. Finally, ask a grown-up for help if you are unsure about anything.

Can The Wiring Diagram For A Specific Gearhead Metal Lathe Model Be Found Online, And Where?Yes, you can often find the wiring diagram for your Gearhead metal lathe online. Search for the model number of your lathe followed by “wiring diagram.” You can check websites like the manufacturer’s site, forums, or even YouTube. Sometimes, helpful people share diagrams on these sites. Just make sure to look carefully to find the right one!

What Common Issues Might Arise During The Wiring Process Of A Gearhead Metal Lathe, And How Can They Be Resolved?When wiring a Gearhead metal lathe, you might see loose wires, wrong connections, or shorts. To fix loose wires, check if they’re tightly connected. If you’ve connected something wrong, double-check the instructions to see where it should go. For shorts, look for wires touching each other and separate them. Always make sure the power is off while you work for safety!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Needed For Wiring A Gearhead Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To wire a Gearhead metal lathe, you need a power supply, some wires, a switch, and a motor. The power supply gives electricity to the lathe. Wires help connect everything together. The switch lets you turn the lathe on and off easily. Finally, the motor makes the lathe spin to work on metal.”}},{“@type”: “Question”,”name”: “How Do You Interpret The Wiring Diagram For A Gearhead Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To read the wiring diagram for a Gearhead metal lathe, start by looking at the main parts. You’ll see lines that connect different pieces. Each line shows how electricity flows. The symbols represent things like power switches and motors. By following the lines, you can understand how everything works together.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken While Wiring A Gearhead Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a Gearhead metal lathe, you should always turn off the power first. Make sure to wear safety glasses to protect your eyes. Use insulated tools to avoid electric shocks. Keep your workspace clean and organized to prevent accidents. Finally, ask a grown-up for help if you are unsure about anything.”}},{“@type”: “Question”,”name”: “Can The Wiring Diagram For A Specific Gearhead Metal Lathe Model Be Found Online, And Where? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can often find the wiring diagram for your Gearhead metal lathe online. Search for the model number of your lathe followed by “wiring diagram.” You can check websites like the manufacturer’s site, forums, or even YouTube. Sometimes, helpful people share diagrams on these sites. Just make sure to look carefully to find the right one!”}},{“@type”: “Question”,”name”: “What Common Issues Might Arise During The Wiring Process Of A Gearhead Metal Lathe, And How Can They Be Resolved? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a Gearhead metal lathe, you might see loose wires, wrong connections, or shorts. To fix loose wires, check if they’re tightly connected. If you’ve connected something wrong, double-check the instructions to see where it should go. For shorts, look for wires touching each other and separate them. Always make sure the power is off while you work for safety!”}}]}