Imagine standing in a workshop filled with the hum of machines. In the corner, a heavy-duty metal lathe shines under bright lights. It’s not just a tool; it’s a piece of art in action. Have you ever wondered how such powerful machines are designed? The answer lies in CAD design.

Computer-Aided Design, or CAD, helps engineers draw up plans for machines like heavy-duty metal lathes. With CAD, they can create detailed and exact designs. This makes building these machines faster and more accurate. It’s like having a magic pen that brings ideas to life!

Did you know that lathes have been around for thousands of years? They have evolved from simple wooden tools to the robust metal machines we see today. Designers use smart software to make these upgrades possible. They ensure each part fits perfectly and works flawlessly.

So, why should you care? Understanding heavy-duty metal lathe CAD design can open doors to innovation. It can make you think about how machines shape our world. Let’s dive deeper into this fascinating topic and explore how it all comes together!

Heavy Duty Metal Lathe Cad Design: A Comprehensive Guide

Understanding Heavy Duty Metal Lathe CAD Design

Heavy duty metal lathes are powerful machines used in manufacturing. They shape and finish metal parts. Using CAD design for these lathes makes their creation easier and more precise. Imagine being able to design a complex part on your computer and then watch it come to life! CAD design helps in visualizing dimensions and optimizing efficiency. Knowing how to utilize this technology is essential for modern machinists, ensuring high-quality outputs with less waste.Understanding Heavy Duty Metal Lathes

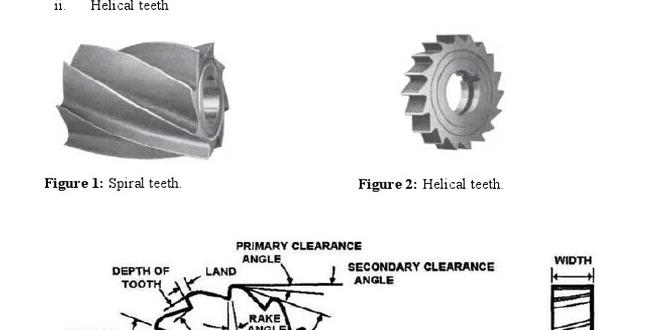

Definition and applications of heavy duty metal lathes. Key features differentiating them from standard lathes.Heavy duty metal lathes are machines that shape large pieces of metal. They spin the metal while cutting tools carve out various shapes. These lathes are essential in big industries like aerospace and automotive. Unlike standard lathes, heavy duty lathes can handle more weight and pressure. They offer strong performance for tough jobs. Key features include:

- High durability: Made for tough materials.

- Large spindle sizes: Can fit bigger workpieces.

- Advanced controls: Easy to operate for precise cuts.

What are the applications of heavy duty metal lathes?

Heavy duty metal lathes are used for producing parts in industries like construction and manufacturing. They help create critical components that need to be accurate and strong.Importance of CAD in Metal Lathe Design

Benefits of utilizing CAD software in designing lathes. Comparison of traditional design methods vs. CAD.Using CAD software for metal lathe design provides many benefits. CAD helps create precise models and save time. It also allows easy changes to designs. Traditional methods can be slow and messy. In contrast, CAD gives clear and neat designs. Here are some key benefits of using CAD:

- Speed: CAD makes designing faster.

- Accuracy: CAD provides precise measurements.

- Flexibility: Changes are easy to make.

- Visualization: 3D models help see finished products.

This software is a game-changer for makers. It merges creativity and technology. Why craft in a messy way when you can design with ease?

Why is CAD important for metal lathe design?

CAD improves design speed, accuracy, and flexibility, making it essential for modern metal lathe development.

Fundamentals of Metal Lathe CAD Design

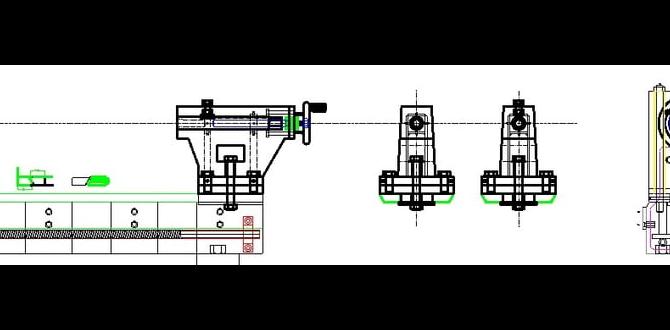

Essential components to include in a lathe design. Best practices for creating accurate and functional designs.Creating a metal lathe design is like building a giant puzzle. You need all the right pieces to make it work smoothly. Important parts include the headstock, tailstock, and carriage. Each part plays a special role, just like characters in a movie!

| Component | Function |

|---|---|

| Headstock | Holds and rotates the workpiece |

| Tailstock | Stabilizes the other end of the workpiece |

| Carriage | Moves the cutting tool across the workpiece |

For those designing a lathe, following best practices is key! Be accurate and double-check your measurements. Keep designs simple, because nobody likes a clunky lathe. Remember, even a lathe has to stay in shape—you wouldn’t want it to go to “lathe” school, would you?

Step-by-Step Process for Designing a Heavy Duty Metal Lathe

Initial design concepts and planning stages. Detailing and refining the CAD model.Designing a heavy duty metal lathe begins with bright ideas and planning. Start by sketching your initial design concepts. Think about what features your lathe needs, like sturdiness and precision. Then, dive into creating a refined CAD model. This is where your dreams take shape! You can use fancy software to add details, like knobs and levers. Remember, the goal is to make it look great and work like a dream!

| Step | Description |

|---|---|

| Initial Concepts | Sketch ideas and key features |

| Refinement | Detail and finalize CAD design |

Common Challenges in Metal Lathe CAD Design

Identifying potential pitfalls during the design process. Solutions and tips for overcoming these challenges.Metal lathe CAD design can be tricky. Designers face issues like choosing the wrong materials or miscalculating dimensions. These slip-ups can be costly—nobody wants a machine that ends up looking like a banana instead of a tool! To avoid these blunders, double-check your work and measure twice. Using software tools that highlight errors can save you from major headaches. And hey, don’t forget to consult a buddy; two heads are better than one! Here are some common challenges and helpful tips:

| Challenge | Solution |

|---|---|

| Poor material selection | Research and choose wisely! |

| Incorrect dimensions | Measure twice, check three times! |

Case Studies: Successful Heavy Duty Metal Lathe Designs

Examples of notable designs and their applications. Lessons learned from case studies in the industry.Heavy-duty metal lathes have led to amazing innovations and real success stories. For instance, a company used a unique design to create custom parts for airplanes. This design cut production time by 30%! Another case showcased a lathe that helped make precise tools for medical devices. Talk about a lifesaver! Each example teaches us about important features, like stability and precision. These qualities are key for reliable performance.

| Design Example | Application | Lesson Learned |

|---|---|---|

| Aircraft Part Lathe | Airplane Components | Efficiency matters! |

| Medical Device Lathe | Surgery Tools | Precision is crucial! |

The Future of Metal Lathe Design with CAD Technology

Emerging trends in CAD for heavy duty metal lathes. Predictions for advancements in lathe design and manufacturing technology.CAD technology is changing how we design heavy-duty metal lathes. Instead of drawing by hand, engineers can now create 3D models easily. This lets them see how everything fits together before building. Imagine building a Lego tower without the fear of it toppling over! Trends like automation and smart technology are also on the rise. These tools make lathes faster and more efficient. The future is bright, and who knows, maybe your lathe will have a built-in coffee maker!

| Emerging Trends | Predictions |

|---|---|

| 3D Modeling | More efficient designs |

| Automation | Speedy production |

| Smart Technology | Enhanced user interaction |

Conclusion

In conclusion, heavy duty metal lathe CAD design helps you create strong and precise tools. You can design parts easily for various projects. Understanding this design process empowers you to build better machines. Start by exploring online resources and practice your skills. With more knowledge, you’ll be ready for exciting hands-on projects in metalworking!FAQs

What Are The Key Design Specifications To Consider When Creating A Cad Model For A Heavy Duty Metal Lathe?When making a computer model of a heavy-duty metal lathe, think about size first. It needs to be big and strong to work with heavy metal pieces. Next, consider the materials, like tough steel, so it lasts long. You should also design parts that move easily, like the cutting tool and the bed. Finally, make sure it can hold heavy weights safely.

How Can Cad Software Help Optimize The Structural Integrity Of A Heavy Duty Metal Lathe During The Design Phase?CAD stands for Computer-Aided Design. It helps us draw and plan machines like a heavy-duty metal lathe. With CAD, you can test designs on the computer before making them in real life. This lets us see if the machine will be strong enough. We can fix problems early, so the lathe stays safe and works well.

What Materials Are Commonly Used In The Construction Of Heavy Duty Metal Lathes, And How Can Cad Assist In Selecting The Appropriate Material?Heavy-duty metal lathes are usually made from strong materials like cast iron and steel. These metals are tough and help the lathes work well. We can use Computer-Aided Design (CAD) to choose the right materials. CAD lets us see how different metals will look and act. This helps us make smart choices for building the lathe.

How Can You Integrate Advanced Features, Such As Cnc Capabilities, Into A Cad Design For A Heavy Duty Metal Lathe?To add advanced features like CNC, or Computer Numerical Control, to a CAD design for a heavy-duty metal lathe, you first need to plan your design carefully. You can use special software to create the 3D model of your lathe. Then, you write instructions that tell the computer how to move the lathe’s parts. Finally, you test the design to make sure everything works well together. This way, you can make strong and precise metal pieces!

What Are Some Best Practices For Creating Assembly Drawings And Parts Lists For Heavy Duty Metal Lathes In Cad Software?When you make assembly drawings for heavy-duty metal lathes in CAD software, start with clear labels. Use simple shapes and lines to show each part. Number the parts and create a list with names next to the numbers. Keep everything organized so it’s easy to read. Finally, double-check your work to catch any mistakes.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Design Specifications To Consider When Creating A Cad Model For A Heavy Duty Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making a computer model of a heavy-duty metal lathe, think about size first. It needs to be big and strong to work with heavy metal pieces. Next, consider the materials, like tough steel, so it lasts long. You should also design parts that move easily, like the cutting tool and the bed. Finally, make sure it can hold heavy weights safely.”}},{“@type”: “Question”,”name”: “How Can Cad Software Help Optimize The Structural Integrity Of A Heavy Duty Metal Lathe During The Design Phase?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CAD stands for Computer-Aided Design. It helps us draw and plan machines like a heavy-duty metal lathe. With CAD, you can test designs on the computer before making them in real life. This lets us see if the machine will be strong enough. We can fix problems early, so the lathe stays safe and works well.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used In The Construction Of Heavy Duty Metal Lathes, And How Can Cad Assist In Selecting The Appropriate Material?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Heavy-duty metal lathes are usually made from strong materials like cast iron and steel. These metals are tough and help the lathes work well. We can use Computer-Aided Design (CAD) to choose the right materials. CAD lets us see how different metals will look and act. This helps us make smart choices for building the lathe.”}},{“@type”: “Question”,”name”: “How Can You Integrate Advanced Features, Such As Cnc Capabilities, Into A Cad Design For A Heavy Duty Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To add advanced features like CNC, or Computer Numerical Control, to a CAD design for a heavy-duty metal lathe, you first need to plan your design carefully. You can use special software to create the 3D model of your lathe. Then, you write instructions that tell the computer how to move the lathe’s parts. Finally, you test the design to make sure everything works well together. This way, you can make strong and precise metal pieces!”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Creating Assembly Drawings And Parts Lists For Heavy Duty Metal Lathes In Cad Software?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you make assembly drawings for heavy-duty metal lathes in CAD software, start with clear labels. Use simple shapes and lines to show each part. Number the parts and create a list with names next to the numbers. Keep everything organized so it’s easy to read. Finally, double-check your work to catch any mistakes.”}}]}