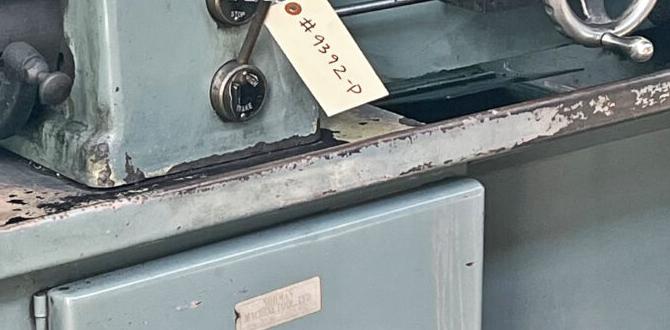

Imagine walking into a workshop filled with the hum of machines. Among all the tools, the heavy duty metal lathe stands out. This powerful machine helps create amazing things from metal. But what makes it work so well? The answer lies in its drive system.

A heavy duty metal lathe drive system is like the heart of the machine. It translates power from the motor to the lathe, allowing it to spin and shape metal. Have you ever wondered what happens when this system doesn’t work? The entire lathe can stop, causing delays and extra costs.

Did you know that the right drive system can make a lathe more efficient? It’s true! An efficient drive system can even increase the lifespan of the lathe. This means fewer repairs and more time for creating. Isn’t that fascinating?

As we explore the heavy duty metal lathe drive system, you’ll learn about its parts, benefits, and tips for choosing the best one. Let’s dive into this mechanical marvel and see how it transforms metalworking!

Heavy Duty Metal Lathe Drive System: Power And Precision

Heavy Duty Metal Lathe Drive System

A heavy duty metal lathe drive system powers machines for tough jobs. These systems let you shape and cut metal easily, making them essential for workshops. With strong motors and durable parts, they provide reliability and precision. Did you know that heavy duty lathes can handle materials like steel and aluminum? This makes them perfect for industries like automotive and aerospace. Choosing the right system boosts productivity and ensures quality work. Have you considered how this tool could enhance your projects?What is a Heavy Duty Metal Lathe Drive System?

Definition and purpose of heavyduty metal lathe drive systems. Key components that make up the drive system.A heavy-duty metal lathe drive system is a powerful tool used to shape metal with precision. Its main purpose is to rotate the material and allow for cutting, sanding, or drilling. This makes it essential in workshops and factories. Key components include the motor, gears, and belts, all working together like a well-rehearsed dance team. If one part goes rogue, the whole system can trip over its own feet!

| Component | Function |

|---|---|

| Motor | Supplies power for rotation |

| Gears | Control speed and torque |

| Belt | Transmits power from the motor |

In short, a heavy-duty metal lathe drive system is the unsung hero of machining! It shapes metal into amazing things like tools, car parts, and more. Remember, without it, we’re all just stuck with a bunch of metal scraps!

Types of Heavy Duty Metal Lathe Drive Systems

Direct drive vs. belt drive systems. Advantages and disadvantages of each type.Metal lathes can use two main drive systems: direct drive and belt drive. Each type has its own perks and downsides. Direct drive connects the motor directly to the spindle. This provides strong power but can be pricier. Belt drive uses belts for power transfer. It’s cheaper and quieter but can slip sometimes. This is how they compare:

- Direct Drive: More powerful; less maintenance; higher cost.

- Belt Drive: Easier to fix; quieter; can lose power.

What is better: direct drive or belt drive?

It depends on your needs. Direct drive is best for heavy work. Belt drive works well for lighter tasks.

Key Features to Consider

Torque and horsepower ratings. Speed range and adjustability. Durability and material construction.When you pick a heavy duty metal lathe drive system, remember a few things that can make your work easier. First, check the torque and horsepower ratings—like your lathe’s muscle power! You want it to spin faster than your favorite roller coaster, so look for a wide speed range and adjustability. Finally, ensure it’s built tough with quality materials—no one wants a lathe that goes “oops” after a heavy project. Here’s a handy table summarizing these features:

| Feature | What to Look For |

|---|---|

| Torque & Horsepower | High ratings for heavy jobs |

| Speed Range | Wide range with easy adjustability |

| Durability | Strong materials for long-lasting use |

Benefits of Using Heavy Duty Metal Lathe Drive Systems

Enhanced precision and accuracy in machining. Increased efficiency and productivity. Longevity and reduced maintenance costs.Using heavy-duty metal lathe drive systems can be a game changer for any workshop. First, they provide enhanced precision and accuracy in machining, meaning your parts will fit like a glove. Second, these systems boost efficiency and productivity, allowing you to churn out items faster than a rabbit on a sugar rush! Plus, their sturdy design offers longevity and reduced maintenance costs, so you won’t have to spend a fortune on repairs. Who knew metalworking could be this easy?

| Benefit | Description |

|---|---|

| Precision | Parts fit perfectly every time. |

| Efficiency | Produce items faster. |

| Longevity | Less money spent on repairs. |

Common Applications of Heavy Duty Metal Lathe Drive Systems

Industries that utilize heavyduty lathes (e.g., manufacturing, aerospace). Specific machining tasks suitable for heavyduty systems.Many industries rely on heavy-duty lathes for their work. The manufacturing sector uses these machines to craft everything from car parts to kitchen utensils. In aerospace, they play a vital role in shaping precision components. Heavy-duty lathes are perfect for heavy cutting, bar turning, and creating complex shapes. It’s like making a pizza! First, you flatten the dough, then add your favorite toppings, all while avoiding the cheese slide! These machines truly help create amazing products.

| Industry | Common Tasks |

|---|---|

| Manufacturing | Part production, metal shaping |

| Aerospace | Precision component creation |

Maintenance and Troubleshooting

Routine maintenance tips for optimal performance. Common issues and how to resolve them.Keeping your heavy-duty metal lathe running smoothly is no laughing matter, but a bit of upkeep can go a long way. For optimal performance, check the oil levels regularly and clean the gears often—think of it as giving your machine a spa day!

Common issues include strange noises or slipping belts. If you hear a grinding sound, it might mean bearings need replacing. Don’t worry—tightening the belt usually solves slipping problems. Here’s a handy table for quick fixes:

| Issue | Solution |

|---|---|

| Grinding Noise | Check and replace bearings |

| Slipping Belt | Tighten or replace the belt |

| Overheating | Inspect cooling system |

A little maintenance goes a long way! Keep your lathe in top shape, and it will reward you with fine craftsmanship. After all, who needs tools that act like divas?

Comparing Popular Brands and Models

Top brands known for heavyduty metal lathe drive systems. Comparison of specifications and user reviews.Many brands shine in the heavy-duty metal lathe drive system market. Each has its perks, making it tough to choose. Popular names include Grizzly, Jet, and Baileigh. These brands offer solid machines that users rave about. Grizzly is often praised for durability, while Jet stands out for ease of use. Baileigh gets points for modern features. Here’s a quick comparison:

| Brand | Known For | User Rating |

|---|---|---|

| Grizzly | Durability | 4.7/5 |

| Jet | Ease of Use | 4.5/5 |

| Baileigh | Modern Features | 4.6/5 |

Users appreciate how these machines handle tough jobs. So, whether you’re a hobbyist or a professional, knowing your options can make a big difference!

Future Trends in Heavy Duty Metal Lathe Drive Systems

Technological advancements influencing drive systems. The impact of automation and smart technology on lathe operation.New tech is changing how heavy duty metal lathe drive systems work. Automation makes machines smarter. They can run faster and more accurately. This helps factories produce better products. Smart technology lets operators control lathes remotely. With sensors in place, machines can alert operators if something is wrong. This means less downtime and more safety. In the future, we can expect:

- More robots working with lathes.

- Advanced software for better control.

- Less energy use thanks to efficient designs.

What are the benefits of automation in lathe operations?

Automation boosts efficiency, improves accuracy, and ensures safety in lathe operations. This leads to faster production and less waste.

Conclusion

In conclusion, a heavy duty metal lathe drive system is essential for strong and reliable performance. It helps you create precise shapes and sizes in metalwork. Understanding its features will improve your projects. We encourage you to explore different models and read reviews. This will help you choose the best drive system for your work. Happy crafting!FAQs

Sure! Here Are Five Questions Related To Heavy-Duty Metal Lathe Drive Systems:Sure! Here are five questions we can think about related to heavy-duty metal lathe drive systems: 1. What is a heavy-duty lathe? 2. How does a lathe work? 3. What makes a lathe “heavy-duty”? 4. Why do we need drive systems in lathes? 5. How do you keep a lathe safe to use? If you want answers to any specific questions, just let me know!

Sure! Please go ahead and ask your question. I’m here to help!

What Types Of Drive Systems Are Commonly Used In Heavy-Duty Metal Lathes, And What Are Their Respective Advantages And Disadvantages?Heavy-duty metal lathes usually use belt drive systems or direct drive systems. Belt drives are quiet and easy to repair, but they can slip and wear out. Direct drives are strong and precise, but they can be more expensive and harder to fix. Each type has good points and not-so-good points, so you can choose what works best for your job!

How Do The Power Requirements Of A Heavy-Duty Metal Lathe’S Drive System Influence Its Performance And Efficiency During Machining Operations?The heavy-duty metal lathe needs a good amount of power to work well. This power helps the lathe turn metal quickly and smoothly. If it doesn’t get enough power, it might slow down or not cut right. So, having the right power makes the machine work better and saves time. We want our machines to be strong and efficient to finish our projects faster!

What Maintenance Practices Are Essential To Ensure The Longevity And Reliability Of A Heavy-Duty Metal Lathe Drive System?To take good care of a heavy-duty metal lathe, you should follow some easy steps. First, keep it clean. Dust and grease can hurt the machine. Next, check the oil and add more if it’s low. Regularly tighten loose parts to prevent problems. Finally, look for any wear or damage and fix it right away. This helps your lathe work well for a long time.

How Do Variable Speed Drive Systems Enhance The Versatility And Functionality Of Heavy-Duty Metal Lathes?Variable speed drive systems let heavy-duty metal lathes change their speed easily. This helps you work on different materials and shapes. You can go slow for careful tasks or fast for quick ones. With this flexibility, lathes can do more types of jobs. You can get better results and finish projects faster!

What Are The Key Factors To Consider When Selecting A Drive System For A Heavy-Duty Metal Lathe Based On The Intended Machining Applications?When choosing a drive system for a heavy-duty metal lathe, think about a few important things. First, consider how much power you need. More power helps for tougher jobs. Next, think about the speed you need for different tasks. Lastly, make sure the system is durable. A strong drive system lasts longer and can handle heavy work better.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Heavy-Duty Metal Lathe Drive Systems:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions we can think about related to heavy-duty metal lathe drive systems: 1. What is a heavy-duty lathe? 2. How does a lathe work? 3. What makes a lathe heavy-duty? 4. Why do we need drive systems in lathes? 5. How do you keep a lathe safe to use? If you want answers to any specific questions, just let me know!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question. I’m here to help!”}},{“@type”: “Question”,”name”: “What Types Of Drive Systems Are Commonly Used In Heavy-Duty Metal Lathes, And What Are Their Respective Advantages And Disadvantages?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Heavy-duty metal lathes usually use belt drive systems or direct drive systems. Belt drives are quiet and easy to repair, but they can slip and wear out. Direct drives are strong and precise, but they can be more expensive and harder to fix. Each type has good points and not-so-good points, so you can choose what works best for your job!”}},{“@type”: “Question”,”name”: “How Do The Power Requirements Of A Heavy-Duty Metal Lathe’S Drive System Influence Its Performance And Efficiency During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The heavy-duty metal lathe needs a good amount of power to work well. This power helps the lathe turn metal quickly and smoothly. If it doesn’t get enough power, it might slow down or not cut right. So, having the right power makes the machine work better and saves time. We want our machines to be strong and efficient to finish our projects faster!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential To Ensure The Longevity And Reliability Of A Heavy-Duty Metal Lathe Drive System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take good care of a heavy-duty metal lathe, you should follow some easy steps. First, keep it clean. Dust and grease can hurt the machine. Next, check the oil and add more if it’s low. Regularly tighten loose parts to prevent problems. Finally, look for any wear or damage and fix it right away. This helps your lathe work well for a long time.”}},{“@type”: “Question”,”name”: “How Do Variable Speed Drive Systems Enhance The Versatility And Functionality Of Heavy-Duty Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Variable speed drive systems let heavy-duty metal lathes change their speed easily. This helps you work on different materials and shapes. You can go slow for careful tasks or fast for quick ones. With this flexibility, lathes can do more types of jobs. You can get better results and finish projects faster!”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting A Drive System For A Heavy-Duty Metal Lathe Based On The Intended Machining Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a drive system for a heavy-duty metal lathe, think about a few important things. First, consider how much power you need. More power helps for tougher jobs. Next, think about the speed you need for different tasks. Lastly, make sure the system is durable. A strong drive system lasts longer and can handle heavy work better.”}}]}