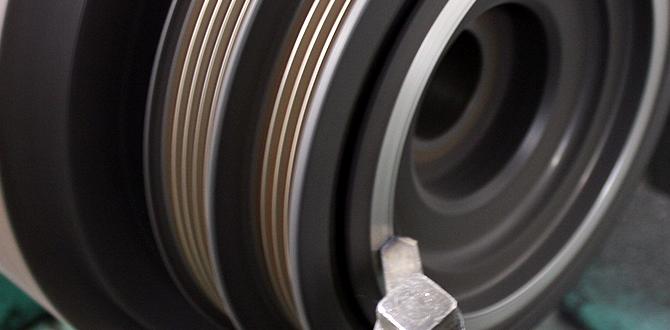

Have you ever wondered how workshops create amazing metal pieces? One key tool is the heavy duty metal lathe pulley. This simple part plays a big role in making lathes work smoothly. Imagine a workshop filled with the sounds of spinning metal and the smell of fresh shavings. Exciting, right?

Using a lathe can be fun, especially when you see the results. But without a solid pulley, you can run into problems. A heavy duty metal lathe pulley helps keep everything running well. It connects the motor to the lathe and helps control the speed. With the right pulley, metalworking becomes easier and more precise.

Did you know that lathes have been around for thousands of years? They are one of the oldest machines we use today! From small DIY projects to large industrial jobs, the heavy duty metal lathe pulley is essential for success.

Heavy Duty Metal Lathe Pulley: Essential Guide And Insights

Understanding Heavy Duty Metal Lathe Pulleys

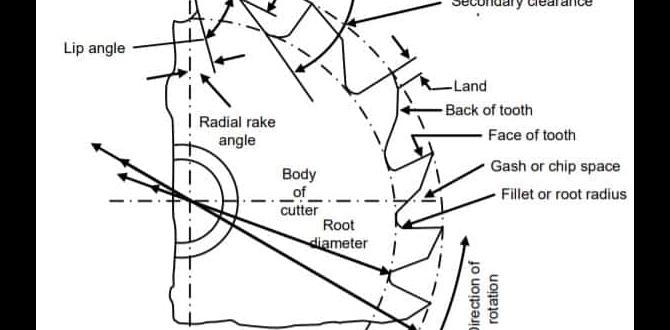

Heavy duty metal lathe pulleys are vital for machine operations. They help control speed and torque, making metalworking efficient. Did you know a well-maintained pulley can extend the life of your lathe? Properly selecting a pulley boosts performance, ensuring smooth cuts. Different sizes and materials play a role in effectiveness. When working on projects, using the right pulley enhances your results significantly. Keep your lathe running smoothly to enjoy exceptional metal crafting!What is a Heavy Duty Metal Lathe Pulley?

Definition and purpose of a metal lathe pulley.. Distinction between heavy duty and standard pulleys..A heavy duty metal lathe pulley is a strong component found in metalworking lathes. Its main job is to help transfer power from the motor to the lathe. This makes cutting and shaping metal easier and more efficient, kind of like how a pizza cutter gets your pizza slices just right!

Heavy duty pulleys are built to handle bigger jobs compared to standard pulleys. They can support more weight and endure higher stress without breaking a sweat. Think of it like a bodybuilder versus a couch potato—one’s ready for a heavy lift while the other prefers snacks on the sofa!

| Feature | Heavy Duty Pulley | Standard Pulley |

|---|---|---|

| Weight Limit | Higher | Lower |

| Durability | Very Strong | Standard |

| Usage | Heavy Materials | Light Tasks |

Benefits of Using a Heavy Duty Metal Lathe Pulley

Enhanced durability and performance in machining applications.. Improved precision and efficiency in lathe operations..Using a heavy duty metal lathe pulley brings many perks, making your machine work like a charm. First, it offers enhanced durability, so you won’t be worried about breakage when things get tough. Think of it as the superhero in your workshop! This strong pulley allows for improved precision and efficiency in your lathe operations, meaning less time fixing errors and more time creating masterpieces. It’s like trading a tricycle for a race car; the difference in speed and style is incredible!

| Benefits | Description |

|---|---|

| Durability | Withstands heavy use |

| Performance | Improved operation speed |

| Precision | Higher accuracy in cuts |

| Efficiency | Less downtime for repairs |

How to Choose the Right Heavy Duty Metal Lathe Pulley

Factors to consider: size, weight capacity, and compatibility.. Importance of matching the pulley to specific lathe models..Choosing the right pulley for a lathe is important. Three main factors matter: size, weight capacity, and compatibility. First, ensure the size matches your machine. Next, check how much weight it can handle. Lastly, confirm it fits your specific lathe model. Picking the wrong pulley can cause problems or even damage your lathe. So, take time to choose wisely.

What is the importance of matching the pulley to specific lathe models?

The right heavy duty metal lathe pulley helps your machine work better and safer. Using an incorrect pulley can lead to issues, like poor performance or wear. Always match the pulley to your lathe’s model to keep everything running smoothly.

Key Factors to Consider:

- Size: Choose a pulley that fits your lathe.

- Weight Capacity: Make sure it can handle your workload.

- Compatibility: Verify it works with your specific lathe model.

Installation Guide for Heavy Duty Metal Lathe Pulleys

Stepbystep instructions for proper installation.. Tools required for installation and maintenance..Ready to install your heavy-duty metal lathe pulley? First, gather your tools. You’ll need a wrench, a screwdriver, and maybe a few strong words for motivation! Follow these simple steps for installation:

- Start by turning off the lathe and unplugging it. Safety first!

- Next, remove the old pulley with your wrench.

- Attach the new pulley and tighten it snugly.

- Finally, plug it back in and test it out. Voila!

Regular maintenance is key. Check that all bolts are tight and clean the pulley often. For easy reference, here’s a quick tool checklist:

| Tool | Purpose |

|---|---|

| Wrench | Tighten bolts |

| Screwdriver | Remove old pulley |

| Cleaning cloth | Keep things tidy |

Happy lathe-ing! Remember, with great power (like a lathe) comes great responsibility—not to mention a lot of fun!

Common Issues and Solutions with Heavy Duty Metal Lathe Pulleys

Troubleshooting frequent problems: slippage, noise, and wear.. Maintenance tips to ensure longevity and optimal performance..Heavy duty metal lathe pulleys can face common issues. Slippage can happen when belts aren’t tight enough. This affects performance and safety. Noise might indicate wear or misalignment. Regular checks help catch problems early. For maintenance, keep everything clean. Lubricate parts to prevent rust. Regularly inspect belts for damage. These steps ensure long life and smooth operation.

What is slippage in lathe pulleys?

Slippage occurs when the belt loses grip on the pulley. This can lead to uneven cutting and inefficient work.

Common Problems and Maintenance Tips:

- Slippage: Check for proper tension.

- Noise: Look for wear or loose parts.

- Wear: Inspect belts regularly.

Comparing Heavy Duty Metal Lathe Pulleys from Different Brands

Review of leading brands in the market.. Analysis of features, pricing, and customer feedback..There are many brands offering heavy duty metal lathe pulleys, each claiming to be the best. Some popular names include Brand X, Brand Y, and Brand Z. A fun fact? You might actually get a workout just trying to choose between them! These brands differ in features like strength and design.

Pricing varies too. Brand X’s pulley could cost you $150, while Brand Y may be around $120. Customers often praise Brand Z for durability but complain about the weight. Here’s a quick look:

| Brand | Price | Features | Feedback |

|---|---|---|---|

| Brand X | $150 | High strength, lightweight | Great reviews! |

| Brand Y | $120 | Versatile, easy to install | Positive feedback |

| Brand Z | $130 | Durable, heavy | Mixed reviews |

Choosing the right pulley is important. You’ll want one that fits your needs and your budget. Happy lathe-ing!

Real-World Applications of Heavy Duty Metal Lathe Pulleys

Examples of industries utilizing heavy duty metal lathe pulleys.. Case studies showcasing performance improvements..Many industries rely on heavy duty metal lathe pulleys for efficient operations. For example:

- Manufacturing: Factories use these pulleys to power machines.

- Aerospace: Pulleys help in shaping parts for planes.

- Automotive: They are vital for engine components.

Case studies show that businesses using heavy duty metal lathe pulleys can see a 20% increase in production speed. This change leads to better quality products and saved costs. Companies report smoother operations and less downtime. Such outcomes highlight the importance of these tools in various fields.

How do heavy duty metal lathe pulleys improve performance?

Heavy duty metal lathe pulleys enhance performance by providing reliable power transfer. They reduce wear and tear on machines, leading to longer lifespans. Also, they can adjust speeds for different tasks, improving efficiency.

Future Trends in Heavy Duty Metal Lathe Pulley Design

Innovations and technologies shaping the future of lathe pulleys.. Impact of automation and advanced materials on pulley development..New designs for heavy duty metal lathe pulleys are changing fast. Innovations like advanced materials make them stronger and lighter. Automation tools speed up production and improve precision.

Companies now use smart technology in their processes. This means less waste and better quality products. These changes make pulleys more effective for everyone.

- Use of composite materials for strength

- Smart tech for better production

- Automation for speed and accuracy

What are the future innovations in lathe pulley design?

Future design innovations include using smarter materials and automated manufacturing techniques. These advances will lead to stronger, lighter, and more precise pulleys.

Conclusion

In conclusion, a heavy-duty metal lathe pulley is essential for smooth operations. It boosts performance and durability. You can easily find one that suits your needs. Think about how it can improve your projects. To learn more, explore guides or ask experts. Start enhancing your lathe today and enjoy better results in your work!FAQs

What Materials Are Commonly Used In The Construction Of Heavy Duty Metal Lathe Pulleys, And How Do They Affect Performance And Durability?Heavy duty metal lathe pulleys are often made from materials like steel and aluminum. Steel is strong and lasts a long time, which makes it great for heavy work. Aluminum is lighter and helps machines run faster. Both materials help pulleys work well and stay durable over time.

How Do Different Pulley Sizes And Designs Impact The Speed And Torque Of A Heavy Duty Metal Lathe?Different pulley sizes change how fast a metal lathe spins. A big pulley makes the lathe go faster, but it gives less torque, which is the strength to do heavy work. A small pulley moves slower but gives more torque, helping cut tough metal. The design of the pulleys also matters; some shapes can help transfer power better. So, by changing pulley sizes and shapes, we can control speed and strength.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Optimal Performance Of Heavy Duty Metal Lathe Pulleys?To keep heavy-duty metal lathe pulleys working well, you should check them regularly. Clean any dust or grease on the pulleys. Make sure the belts are tight and not worn out. Lubricate the moving parts to reduce friction. Lastly, store the lathe in a dry place to prevent rust.

How Can The Proper Alignment Of Pulleys Influence The Overall Efficiency And Accuracy Of A Metal Lathe Operation?When we align the pulleys correctly on a metal lathe, it helps everything move smoothly. This makes the machine work faster and more accurately. If the pulleys are not lined up, the lathe can shake or make mistakes. So, proper alignment means better results for our metal work!

What Are The Common Problems Associated With Heavy Duty Metal Lathe Pulleys, And How Can They Be Diagnosed And Resolved?Heavy duty metal lathe pulleys can have a few common problems. First, they might get worn or damaged over time. You can check for cracks or breaks when inspecting them. Second, the pulleys might not turn smoothly. To fix this, make sure they are properly lubricated and not too tight. Lastly, they can get misaligned, making loud noises. You can fix this by adjusting their position correctly.