Have you ever wondered how a heavy-duty metal lathe works? These machines can create beautiful shapes from metal. But to do that, they need to be wired correctly. Understanding a heavy-duty metal lathe wiring diagram can help you make the right connections.

Imagine standing in a workshop, ready to start your next project. You see the lathe glistening under the lights, full of potential. But what if the wiring isn’t right? It can lead to frustrating problems and even accidents.

In this article, we will explore the important parts of a wiring diagram. We will break it down step by step. You’ll learn how to understand these diagrams, making your projects run smoothly. Plus, we might share a fun fact about metal lathes that you didn’t know!

So, if you’re eager to dive into the world of metalworking, let’s get started. Your next great creation awaits with the help of a well-understood wiring diagram!

Heavy Duty Metal Lathe Wiring Diagram: A Comprehensive Guide

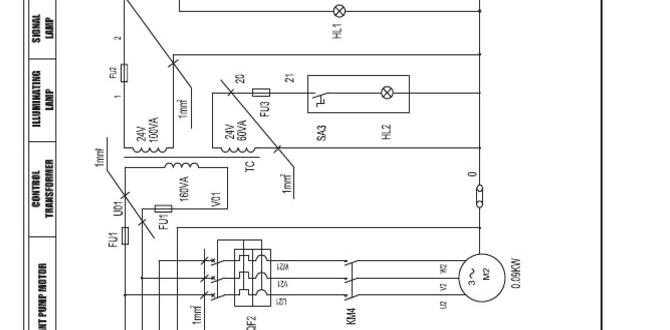

Heavy Duty Metal Lathe Wiring Diagram

A heavy duty metal lathe wiring diagram shows how to connect various parts safely. It highlights essential components like the motor, power supply, and control switches. Understanding this diagram is crucial for anyone setting up a lathe. Did you know that improper wiring can lead to equipment damage? Following the correct wiring specifications ensures a safe and efficient workspace. A well-connected lathe runs smoother and lasts longer, making your projects more successful!Safety Precautions for Metal Lathe Wiring

Importance of safety in wiring and operation. Essential safety gear and practices during installation.Wiring a metal lathe safely is very important. It helps prevent accidents and injuries. Always wear proper safety gear like gloves, goggles, and ear protection. This gear keeps you safe from flying debris and loud noises. Check the wiring diagram carefully. Make sure connections are secure. Always work in a dry area to avoid electrical shocks. If you feel unsure, ask an expert for help. Remember, safety first!

What safety gear should I use?

Use gloves, safety goggles, and earplugs when working with a metal lathe.

Essential safety practices:

- Keep your workspace clean.

- Know the emergency shut-off.

- Never wear loose clothing.

Components of a Heavy Duty Metal Lathe Wiring Diagram

Description of major electrical components (motors, switches, etc.). Explanation of wiring symbols and conventions.Understanding a heavy-duty metal lathe wiring diagram begins with its key parts. First, we have the motor, which drives the lathe like a tiny superhero. Then come the switches, which help control everything. They’re like the traffic lights, telling the current when to go or stop. Let’s not forget the wiring symbols! They’re the secret codes of the lathe world. Each symbol plays a role, making sure everything connects just right. Below, you’ll find a handy table that explains some common components:

| Component | Description |

|---|---|

| Motor | Powers the lathe’s movement |

| Switch | Controls on/off functions |

| Wires | Carry electric current |

| Relays | Act like little helpers in switching |

Step-by-Step Wiring Instructions

Detailed wiring process for connecting the main components. Tips for ensuring secure and reliable connections.Wiring a heavy duty metal lathe can seem tricky, but it’s simple with clear steps. Start by matching the main components to their correct positions. Use tools like wire strippers and pliers. Make sure each connection is tight to avoid problems later. Check your work twice for safety.

- Strip wires to expose enough copper.

- Connect wires securely with screws.

- Use electrical tape for extra safety.

Always follow the manual for specific details. Take your time, and you’ll have a safe setup!

What is the first step for wiring my lathe?

The first step is to read the wiring diagram carefully. This helps you understand where each wire goes. Prepare your tools and gather all parts before starting. This will make things smoother.

Troubleshooting Common Wiring Issues

Identification of common problems with wiring. Solutions for addressing wiring faults and malfunctions.Wiring problems can be tricky, but spotting them is easy. Look for signs like flickering lights or strange noises. These can mean there’s a fault. Common issues include:

- Broken connections

- Frayed wires

- Short circuits

To fix these, check connections first. Replace any damaged wires. If there’s a short circuit, find where it happens and repair it. Always ensure your wiring matches your heavy duty metal lathe wiring diagram. By being careful, you can keep your machine running smoothly.

What are typical wire problems in heavy duty metal lathes?

Common wire problems include broken connections, frayed wires, and short circuits. Regular checks can help spot these issues early.

Maintenance Tips for Longevity of Wiring System

Regular checks and maintenance practices to prevent issues. Importance of keeping wiring clean and protected from damage.Taking care of your wiring system helps it last longer. Regular checks can spot problems before they get worse. It’s important to keep wires clean and safe. Dirt and damage can cause issues. Here are some simple tips:

- Inspect wires often for wear and tear.

- Clean dust off wiring regularly.

- Keep wires away from sharp edges.

- Use protective covers where needed.

Following these steps can keep your heavy-duty metal lathe wiring in great shape.

How often should I check my wiring system?

Check your wiring system at least once a month to ensure it is in good condition. Regular checks can help you avoid future problems.

Resources for Further Learning

Recommended books, online courses, and forums for deeper understanding. Useful tools and software for creating and interpreting wiring diagrams.Learning more about metal lathe wiring can be fun and exciting! Books can provide in-depth knowledge, while online courses offer hands-on experience. Check out forums where experts share tips and tricks. It’s a great place to ask questions, too!

| Resource Type | Examples |

|---|---|

| Books | The Complete Guide to Metalworking |

| Online Courses | Udemy Metalworking Class |

| Forums | Metalworking Zone |

For designing wiring diagrams, tools and software like AutoCAD can be invaluable. With these resources, you’ll twist and turn wires like a pro. Remember, mastering wiring is a skill worth flaunting! Happy learning!

Conclusion

In summary, understanding a heavy duty metal lathe wiring diagram is important for safe and effective use. It helps you connect wires correctly, avoiding mistakes. Always follow the diagram closely. If you want to learn more, check out guides and tutorials online. Practicing with real diagrams can boost your confidence and skills in metalworking. Keep exploring and happy crafting!FAQs

What Are The Key Components Typically Found In The Wiring Diagram Of A Heavy-Duty Metal Lathe?In a heavy-duty metal lathe, you will find several key components in the wiring diagram. There are power switches that turn the machine on and off. You’ll also see motors that help move the lathe parts. Wires connect everything, helping electricity flow. Lastly, there are control panels where you can adjust the settings.

How Do You Interpret The Wiring Diagram To Troubleshoot Electrical Issues In A Heavy-Duty Metal Lathe?To read a wiring diagram for a heavy-duty metal lathe, look for colors and symbols. Each wire has a different color that shows where it goes. Follow the lines from one part to another to see how they connect. If a part isn’t working, find it on the diagram and check the wires. This helps us see if there’s a break or a short circuit.

What Safety Precautions Should Be Considered When Wiring Or Rewiring A Heavy-Duty Metal Lathe?When wiring a heavy-duty metal lathe, you should first unplug it to avoid shocks. Wear rubber gloves to keep your hands safe. Use the right tools to avoid accidents. Make sure all wires are connected tightly and check for any damage. Lastly, always follow the instructions and ask for help if you’re unsure.

Are There Specific Wiring Configurations For Different Horsepower Ratings In Heavy-Duty Metal Lathes?Yes, different horsepower ratings in heavy-duty metal lathes do require special wiring setups. The way we connect the wires depends on how much power the machine needs. Higher horsepower lathes often need thicker wires to handle the extra power safely. So, you need to be careful and follow the instructions for your specific lathe. Always make sure to check the manual!

What Types Of Connectors And Cables Are Recommended For Use In Heavy-Duty Metal Lathe Wiring Applications?For heavy-duty metal lathe wiring, you should use connectors and cables that are strong and safe. Look for connectors made of metal with good insulation. Use thick cables that can handle a lot of power. Make sure they can resist heat and damage. Always follow safety rules to keep everything working well.