Have you ever watched a metal lathe spin and create amazing shapes? It’s like watching magic happen in your workshop! Many hobbyists enjoy using metal lathes for their projects. But what if you could make that experience even better? That’s where hobbyist metal lathe automation comes in.

Imagine transforming your manual lathe into a smart machine. This means you can set it up and let it work on its own while you relax or focus on other tasks. Sounds exciting, right? With the right tools and techniques, you can automate your lathing process.

Did you know that many creative people have turned simple lathes into automated marvels? They have made their projects faster and more precise. By automating your hobbyist metal lathe, you can join them and make your creations shine even brighter.

This article will explore how you can dive into hobbyist metal lathe automation. Get ready to discover tips, tricks, and fun ideas that will transform your projects and have you crafting like a pro!

Hobbyist Metal Lathe Automation: Elevate Your Crafting Skills

Hobbyist Metal Lathe Automation

Hobbyist metal lathe automation lets makers create precise parts easily. Imagine using a machine that can work while you relax! Automating your lathe can save time and reduce mistakes. You learn how to set up programs and choose tools. It’s like giving your machine superpowers! Many enthusiasts find joy in making custom projects with less hassle. This way, your creativity shines brighter without getting bogged down by repetitive tasks. So, why not explore this exciting world of possibilities?Benefits of Automating Your Hobbyist Metal Lathe

Increased efficiency and productivity. Improved precision and consistency in machining.Automating your hobbyist metal lathe can feel like giving it a trusty robot sidekick. This partnership boosts efficiency and productivity, allowing you to create more parts in less time. Imagine finishing your project while still having time for a snack break! Moreover, automation ensures improved precision and consistency in machining. Your cuts will be sharper than a newly sharpened pencil, leading to better results every time. So, what’s not to love about a little help in the workshop?

| Benefits | Details |

|---|---|

| Increased Efficiency | Complete tasks quicker, leaving time for other fun hobbies! |

| Better Precision | Perfect cuts every time—less chance of mistakes! |

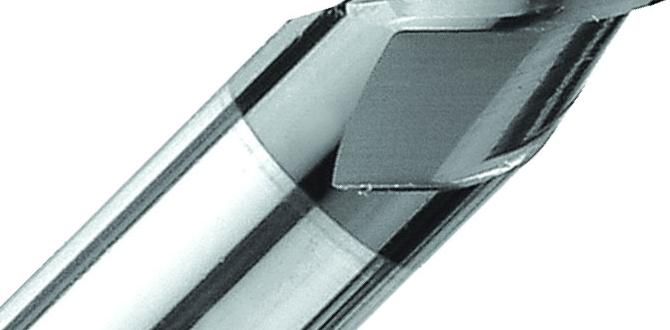

Types of Automation for Hobbyist Metal Lathes

Manual vs. CNC (Computer Numerical Control) automation. Pros and cons of each automation type.Hobbyist metal lathes can be manually operated or automated with CNC. Manual lathes rely on the operator’s skills to shape metal. They are simple and cost-effective but require practice. CNC lathes use a computer for precise cuts. They save time and reduce errors but are more expensive and complex. Below are the pros and cons of each type:

- Manual Lathes:

- Pros: Less upfront cost, hands-on experience.

- Cons: Slower, requires skill and patience.

- CNC Lathes:

- Pros: Fast, accurate, great for complex designs.

- Cons: Higher cost, needs computer knowledge.

Both types have unique benefits. Choosing depends on your budget and comfort with technology. Which one will you pick for your metalworking adventures?

What is CNC automation?

CNC automation stands for Computer Numerical Control. It uses computers to control machines for high accuracy.

What are the benefits of wooden lathes?

Wooden lathes are great for beginners. They are affordable and easy to control. Plus, they allow hands-on learning which is beneficial!

Essential Components for Automation

Key hardware components required for automation. Software considerations for programming and control.For automating a metal lathe, you need some essential hardware. First, look at stepper motors and controllers. These help move the lathe parts smoothly, like dancers in a party! Next, consider limit switches. They prevent your tool from going too far, much like a friendly bouncer at a club.

On the software side, you’ll need a user-friendly program for control and programming. Look for options that allow easy adjustments. It’s like finding just the right pizza topping: everyone has their favorite! Without good software, even the best hardware will be as useful as a chocolate teapot.

| Component | Function |

|---|---|

| Stepper Motors | Control movement |

| Limit Switches | Prevent over-travel |

| Controller Board | Manage commands |

| Software Program | Program lathe operation |

Setting Up Your Automated Metal Lathe

Stepbystep guide for installation of automation systems. Calibration and testing procedures for optimal performance.To set up your automated metal lathe, follow these steps. First, install the automation system according to the manual’s instructions. Make sure everything is securely attached. Next, connect the power supply and test the controls. This ensures your machine runs smoothly.

Calibration is critical. Adjust the settings for accuracy and check the measurements for precision. Finally, conduct a performance test. Run a sample part and inspect its quality. This ensures your lathe works perfectly.

- Install automation system

- Connect power supply

- Calibrate settings

- Test performance

How do I ensure my automated metal lathe works well?

Regularly calibrate and test your lathe. This helps maintain optimal performance and accuracy. Check it often for any adjustments needed.

Common Challenges in Automating Metal Lathes

Technical issues and troubleshooting tips. Overcoming learning curves and operational hurdles.Automating metal lathes can feel like trying to teach a cat to dance. Many face technical issues, like software glitches or compatibility problems that pop up like a jack-in-the-box. Troubleshooting these may seem tricky, but fear not! A good tip is to keep your manuals close and a cup of coffee handy. Learning new skills might feel like climbing a mountain, but every expert was once a beginner. Embrace the challenges; they will make your successes even sweeter!

| Challenge | Tip |

|---|---|

| Technical Glitches | Check software updates regularly. |

| Learning New Skills | Take baby steps and practice. |

| Operational Hurdles | Test your setup often to fix issues early. |

Maintenance Tips for Automated Metal Lathes

Regular upkeep practices to ensure longevity. Signs that indicate the need for servicing or upgrades.Keeping your automated metal lathe in top shape is key for smooth operations and long life. Regular checks can catch problems early. Look out for strange noises or irregular cutting; these signs might scream, “Help me!” If your lathe stands still more than you do at a dance party, it’s time for a tune-up. Always clean and lubricate parts, just like you’d polish your favorite toy.

| Maintenance Tip | Signs of Trouble |

|---|---|

| Regular Cleaning | Strange Noises |

| Frequent Lubrication | Unusual Vibration |

| Check for Wear | Poor Cutting Quality |

Remember, a well-maintained lathe not only runs better but is also safer. Who wouldn’t want a happy machine at their side?

Resources and Communities for Hobbyist Metal Lathe Automation

Recommended online forums and groups for support. Valuable books and tutorials for further learning.Joining the right online spaces can make your hobbyist metal lathe automation journey smoother and more fun! There are many forums and groups where you can ask questions and share ideas. Try out the “Machinists’ Corner” and “CNCZone” for expert tips and friendly chats. For more learning, books like “The Metal Lathe” by Ernie Conover and free tutorials on YouTube are gold mines! Remember, a great metalworker is never too shy to ask for help—just like a lost squirrel looking for acorns!

| Resource Type | Recommended |

|---|---|

| Online Forum | Machinists’ Corner |

| Online Forum | CNCZone |

| Book | The Metal Lathe by Ernie Conover |

| Tutorials | YouTube CNC Videos |

Conclusion

In summary, hobbyist metal lathe automation makes your projects easier and more efficient. You save time and improve precision. With tools like CNC systems, you can create amazing designs. Explore different automation options and find what works best for you. Start small, practice, and enjoy the process! For more tips, check out online resources and communities. Happy crafting!FAQs

What Are The Essential Features To Look For In A Metal Lathe For Hobbyist Automation Projects?When choosing a metal lathe for your projects, look for a sturdy frame. This helps keep the machine steady while you work. A good size is important too; it should fit your workspace. Make sure it has easy controls so you can change settings quickly. Finally, check for safety features like guards to keep you safe while using it.

How Can I Integrate A Cnc Controller With My Existing Manual Metal Lathe To Achieve Automation?To automate your manual metal lathe, you can add a CNC controller. First, you will need to choose a CNC kit that fits your lathe. Next, you’ll connect the motors to the lathe’s moving parts. Then, you can use a computer to program the lathe. This setup allows you to make precise cuts automatically!

What Are Some Beginner-Friendly Projects To Automate Using A Hobbyist Metal Lathe?You can start with simple projects like making small knobs for toys. You could also create simple tools, like a handle for a screwdriver. Another fun idea is making custom pencil holders. You could even try making parts for a small robot. These projects are easy and let you practice using the lathe.

What Safety Precautions Should Be Taken When Automating A Metal Lathe For Hobbyist Use?When using a metal lathe, we should always wear safety goggles to protect our eyes. You should keep long hair tied back and wear tight clothing to avoid getting caught. Make sure the area is clean and free of clutter to prevent accidents. Always check that the machine is turned off before making any adjustments. Lastly, read the instructions carefully and ask for help if you’re unsure.

What Software Options Are Available For Programming Automated Operations On A Hobbyist Metal Lathe?You can use some fun software to program your hobbyist metal lathe. One example is **GRBL**, which is free and easy to use. Another option is **Mach3**, which has more features but costs money. **Fusion 360** is also great for designing parts and can help with programming. These programs make it easier to run your lathe and create cool projects!