Have you ever watched those amazing machines turn metal into beautiful parts? Metal lathes can do just that. For hobbyists, using a lathe can feel like magic. But what if you want to take it a step further? That’s where a CNC retrofit comes in. Imagine being able to control your lathe with a computer. Sounds cool, right?

Many people start with manual lathes. They learn the ropes and enjoy crafting with metal. However, as they grow, they dream of more precision and creativity. A hobbyist metal lathe CNC retrofit offers that chance. It’s like giving your machine a superpower!

Did you know that many hobbyists have transformed their old lathes into high-tech machines? It’s true! Upgrading can change how you create and help you learn. So why not explore this exciting journey together?

Hobbyist Metal Lathe Cnc Retrofit: Enhancing Your Machining Skills

Hobbyist Metal Lathe CNC Retrofit

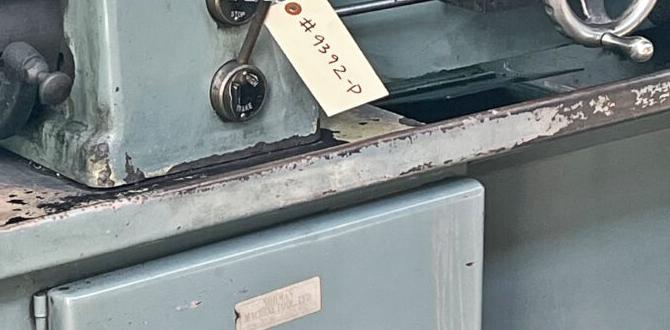

A hobbyist metal lathe CNC retrofit allows makers to upgrade their machines for added precision and control. This process involves installing CNC (computer numerical control) components. Imagine turning raw metal into precise parts with a few clicks! It’s like transforming a simple sewing machine into a high-tech embroidery device. This upgrade not only enhances skill but opens up endless creative possibilities. Did you know some retrofitted lathes can create intricate designs that would baffle even experienced machinists?Understanding CNC Retrofit

Definition and purpose of CNC retrofit for metal lathes. Benefits of retrofitting hobbyist lathes with CNC technology.CNC retrofit is a process that upgrades metal lathes. It adds computer control to machines, making them more precise and efficient. This upgrade helps hobbyists work faster and with greater detail. Retrofitting a lathe with CNC technology can offer many benefits:

- Increased accuracy in cutting.

- Ability to create complex shapes easily.

- Less manual effort, saving time.

- Higher quality finished products.

With CNC, hobbyists unlock better performance and creativity in their metalworking projects.

What is the purpose of CNC retrofit?

The main purpose of CNC retrofit is to improve the performance of older lathes. It transforms them into modern tools. This upgrade makes precise cuts and complex designs easier.

How does it benefit hobbyists?

Benefits include:

- Time-saving through automation.

- Consistent results with less effort.

- Opportunity to learn advanced skills.

Choosing the Right CNC Kit

Factors to consider when selecting a CNC retrofit kit. Popular CNC retrofit kits for hobbyist metal lathes.Picking the right CNC kit is like choosing a pet; you want one that fits your home and lifestyle. First, consider the size and power of your lathe. It needs to match your projects. Next, think about the complexity. Some kits are as easy as pie, while others require a PhD in engineering! Popular options include the X-Carve and Shapeoko, known for their user-friendly features. Here’s a quick view of some top kits:

| Kit Name | Best For | Price Range |

|---|---|---|

| X-Carve | Beginners | $$ |

| Shapeoko | Advanced users | $$$ |

| MillRight | Budget friendly | $ |

Choose wisely, or you might end up with a kit that’s more trouble than a cat in a bathtub!

Tools and Equipment Needed

Essential tools for the retrofit process. Additional equipment that may enhance the retrofitting experience.Getting ready for a hobbyist metal lathe CNC retrofit? You’ll need some essential tools to make this process smooth, almost as smooth as butter on a hot pancake! Start with a sturdy wrench set and screwdrivers for assembly. Don’t forget your trusty digital caliper for precise measurements. A drill press can add neat holes where they’re needed. And for the cherry on top, consider a laser cutter to spice up your design! Here’s a simple table of what you might want:

| Essential Tools | Additional Equipment |

|---|---|

| Wrench Set | Laser Cutter |

| Screwdrivers | Extra Bits |

| Digital Caliper | Drill Press |

Step-by-Step Retrofit Process

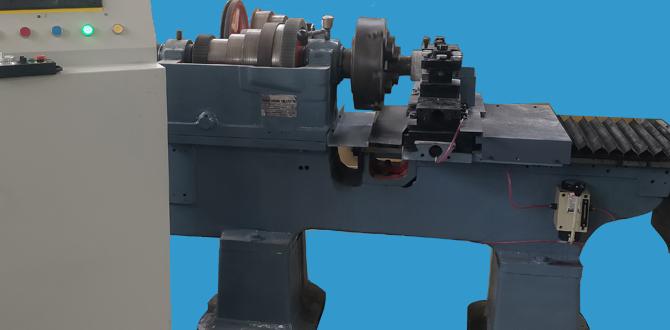

Preparing the metal lathe for retrofit. Installing CNC components: stepbystep guide.Before starting the retrofit, prepare your metal lathe. Clean it well to remove dust and grease. Check for wear on parts. Tighten loose screws to ensure everything is secure.

Next, follow these steps for installing CNC components:

- Remove the old motor and controls.

- Install the CNC stepper motors.

- Attach the control board securely.

- Connect power and signal wires carefully.

- Test all connections for safety.

Once done, your metal lathe will be ready for CNC use. Enjoy transforming your lathe into a high-tech tool!

How do I retrofit my metal lathe?

You retrofit a metal lathe by cleaning it first, installing new CNC components, and ensuring wires are connected properly. Following these steps makes the process smooth and fun!

Common Challenges and Solutions

Typical issues faced during retrofitting. Effective problemsolving techniques for hobbyists.Retrofitting a metal lathe can feel like trying to teach a cat to fetch. You might hit some bumps along the way! Common issues include misalignment and software glitches. Don’t let these hiccups slow you down! To tackle problems, double-check your setup and consult online forums. Fellow hobbyists often share tips that can save you time. Remember, every challenge is just a chance to learn—like realizing your cat prefers napping over fetching.

| Issue | Solution |

|---|---|

| Misalignment | Check your machine setup! |

| Software Glitches | Consult online forums for help! |

Post-Retrofit Maintenance and Troubleshooting

Regular maintenance tips to keep the CNC lathe running smoothly. Troubleshooting common retrofitting issues.Keeping your CNC lathe in good shape is important for smooth operation. Regularly check the oil levels and clean the machine to prevent dust buildup. Tighten any loose screws and ensure belts are adjusted. This can help avoid major repairs later. If something seems off, try these common solutions:

- Check the power source if the machine won’t start.

- Inspect for loose wires or connections.

- Look for unusual sounds that may indicate wear.

- Always refer to your manual for specific troubleshooting advice.

What should I check regularly on my CNC lathe?

Focus on oil levels, cleanliness, and loose parts. Regular checks keep your lathe running well and prevent breakdowns.

Real-World Applications and Projects

Examples of projects that can be accomplished with a CNC retrofitted lathe. User stories and testimonials from hobbyists.With a CNC retrofitted lathe, hobbyists can create amazing projects. Imagine crafting precision parts for your bike or even making custom jewelry. One user, Tom, turned his dreams into reality by making unique desk ornaments. He said, “It’s like magic to watch metal turn into something beautiful!”

| Project | Description |

|---|---|

| Bike Parts | Create custom gears and components. |

| Jewelry Making | Design stunning custom pieces. |

| Furniture Hardware | Craft unique knobs and handles. |

Many hobbyists have shared their success stories and gained confidence through these exciting projects. So, if you want to play with metal, a CNC lathe is the ticket! Think of it as a treasure map that leads to shiny goodies.

Community and Support Resources

Online forums and communities for CNC hobbyists. Recommended resources for continued learning and support.Connect with fellow CNC hobbyists online! There are many lively forums where you can ask questions, share your projects, and learn new tricks. Websites like CNCZone and Reddit’s r/CNC are perfect for finding advice and support. Plus, you’ll get to enjoy some funny memes about our love for machines! Remember, sharing is caring—so bring your best metal lathe jokes. For continued learning, check out video tutorials on YouTube or join local maker groups. They can turn your hobby into a fun community adventure!

| Resource Type | Recommended Links |

|---|---|

| Online Forum | CNCZone |

| Subreddit | r/CNC |

| YouTube Channel | YouTube CNC Tutorials |

| Maker Group | Local Maker Spaces |

Conclusion

In conclusion, a hobbyist metal lathe CNC retrofit can enhance your machining projects significantly. It allows you to automate tasks and improve precision. By upgrading your lathe, you can unlock new possibilities in metalworking. If you’re interested, check online resources and guides to learn how to start your retrofit journey. Let’s explore the exciting world of CNC together!FAQs

What Are The Essential Components Needed For A Successful Cnc Retrofit Of A Hobbyist Metal Lathe?To make a hobby metal lathe work with CNC (Computer Numerical Control), you need a few key parts. First, you need stepper motors to move the tools. Then, you need a computer or controller to tell the motors what to do. You’ll also need software to design your projects. Finally, don’t forget the power supply to give everything energy!

How Can I Determine The Appropriate Stepper Motors And Drivers For My Lathe Retrofit Project?To choose the right stepper motors for your lathe, first, think about how much power you need. Measure the size and weight of your lathe parts. Next, look for drivers that match your motors. Make sure the drivers can handle the power your motors require. Finally, ask for help from hobbyist forums or stores if you get stuck.

What Software Options Are Compatible With Hobbyist Metal Lathe Cnc Retrofits For Designing And Controlling Machining Operations?For hobbyist metal lathe CNC retrofits, you can use several software options. One popular choice is Fusion 360, which helps you design parts and plan machining. Another good option is Mach3, which controls the lathe while you work. You can also try CNCjs for easy control using a web browser. All these tools make it easier for you to create and manage your projects!

What Safety Precautions Should I Follow While Retrofitting My Metal Lathe For Cnc Operation?When retrofitting your metal lathe for CNC operation, you should always wear safety glasses to protect your eyes. Keep your hair and loose clothes away from moving parts to avoid getting caught. Make sure your work area is clean and free of clutter. Double-check all electrical connections to prevent shocks or fires. Lastly, never work alone; have someone nearby in case you need help.

How Can I Troubleshoot Common Issues Encountered During The Cnc Retrofit Process Of A Hobbyist Metal Lathe?To fix problems during CNC (Computer Numerical Control) upgrades on your metal lathe, start by checking the wires. Make sure all connections are tight and in the right places. If something doesn’t work, restart the computer and the machine. You can also read the manuals for help. Lastly, ask friends online for tips—they might have faced the same issues!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Components Needed For A Successful Cnc Retrofit Of A Hobbyist Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a hobby metal lathe work with CNC (Computer Numerical Control), you need a few key parts. First, you need stepper motors to move the tools. Then, you need a computer or controller to tell the motors what to do. You’ll also need software to design your projects. Finally, don’t forget the power supply to give everything energy!”}},{“@type”: “Question”,”name”: “How Can I Determine The Appropriate Stepper Motors And Drivers For My Lathe Retrofit Project? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right stepper motors for your lathe, first, think about how much power you need. Measure the size and weight of your lathe parts. Next, look for drivers that match your motors. Make sure the drivers can handle the power your motors require. Finally, ask for help from hobbyist forums or stores if you get stuck.”}},{“@type”: “Question”,”name”: “What Software Options Are Compatible With Hobbyist Metal Lathe Cnc Retrofits For Designing And Controlling Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For hobbyist metal lathe CNC retrofits, you can use several software options. One popular choice is Fusion 360, which helps you design parts and plan machining. Another good option is Mach3, which controls the lathe while you work. You can also try CNCjs for easy control using a web browser. All these tools make it easier for you to create and manage your projects!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should I Follow While Retrofitting My Metal Lathe For Cnc Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When retrofitting your metal lathe for CNC operation, you should always wear safety glasses to protect your eyes. Keep your hair and loose clothes away from moving parts to avoid getting caught. Make sure your work area is clean and free of clutter. Double-check all electrical connections to prevent shocks or fires. Lastly, never work alone; have someone nearby in case you need help.”}},{“@type”: “Question”,”name”: “How Can I Troubleshoot Common Issues Encountered During The Cnc Retrofit Process Of A Hobbyist Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems during CNC (Computer Numerical Control) upgrades on your metal lathe, start by checking the wires. Make sure all connections are tight and in the right places. If something doesn’t work, restart the computer and the machine. You can also read the manuals for help. Lastly, ask friends online for tips—they might have faced the same issues!”}}]}