Imagine stepping into your garage and feeling the excitement of creating something amazing. For many hobbyists, a metal lathe brings that dream to life. It’s a powerful tool that spins metal to shape it into various parts. But have you thought about how a control panel plays a big role in this process?

The hobbyist metal lathe control panel is like the brain of your machine. It helps you control speed and movement. This means you can make fine adjustments for any project you have in mind. Learning how to use this control panel can take your crafting to the next level!

Did you know that one of the first lathes was invented over 2,000 years ago? Since then, they have evolved a lot. Today’s hobbyists can use a simple control panel to perform tasks that once needed a skilled artisan.

So, if you’re curious about how to maximize your metalworking skills, stick around. This article will dig into the features of hobbyist metal lathe control panels and why they are essential for every project.

Hobbyist Metal Lathe Control Panel: Essential Features & Tips

Hobbyist Metal Lathe Control Panel

Hobbyist metal lathe control panels are essential for anyone looking to create precise metalwork. These panels offer users control over speed and settings, making machining more efficient. Did you know you can customize your control panel features based on your projects? Understanding its layout and functions can boost your crafting skills. Plus, knowing how to troubleshoot common issues can save time! Get ready to take your metalworking hobby to the next level with the right control panel!Understanding the Basics of Metal Lathe Control Panels

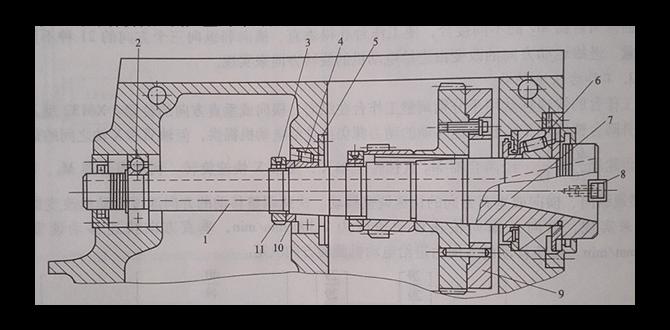

Definition and purpose of metal lathe control panels. Key components and their functions.A metal lathe control panel lets users operate a lathe machine efficiently. It helps in managing the speed and direction of the lathe. Understanding its key components is essential for safe and effective use. Here are some main parts:

- Power Switch: Turns the machine on and off.

- Speed Control: Adjusts how fast the lathe spins.

- Direction Switch: Changes the rotation direction.

- Emergency Stop: Quickly halts the machine for safety.

Knowing these parts helps hobbyists work safely and productively. Metal lathe control panels ensure smooth operation and aid in creating precise designs.

What is a metal lathe control panel?

A metal lathe control panel is a device that manages and controls the operation of a lathe machine. It enhances safety and allows for precise machining tasks.

Essential Features to Look for in a Hobbyist Metal Lathe Control Panel

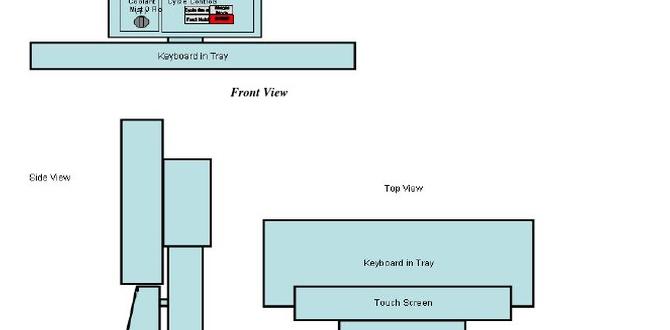

User interface and ease of use. Safety features and emergency stop functions. Compatibility with various lathe models.When choosing a hobbyist metal lathe control panel, consider these key features:

- User Interface: Look for buttons and displays that are easy to understand. A clear layout helps you work faster and more accurately.

- Safety Features: Emergency stop functions are crucial. This feature stops the machine quickly in case of trouble.

- Compatibility: Ensure the panel works with different lathe models. Versatile panels save you from buying new ones later.

These features make your lathe experience safe and enjoyable. A good control panel helps you create amazing projects with ease.

What should I look for in a hobbyist metal lathe control panel?

Key features include an easy-to-use interface, strong safety features, and compatibility with various lathe models.

DIY vs. Pre-built Control Panels: Pros and Cons

Benefits of building your own control panel. Common challenges and considerations. Comparison with purchasing readymade options.Building your own control panel can be exciting. It lets you personalize features to fit your needs. Plus, you might save money. However, there are challenges. You need tools, skills, and time. Sometimes, you might make mistakes that cost more. Buying a ready-made panel is easier, but it may lack some personal touches. Here’s a quick look at the pros and cons:

- DIY Control Panel: Customizable, often cheaper, rewarding experience.

- Ready-Made Panel: Quick setup, professional design, less risk of errors.

What are the benefits of building your own control panel?

Building your own control panel allows for customization and learning opportunities. You can tailor it to your unique needs.

Common challenges of a DIY project

- Requires specific tools and materials.

- May involve trial and error.

- Needs time for assembly and testing.

Top Brands and Models of Hobbyist Metal Lathe Control Panels

Review of popular brands available. Analysis of features and pricing.Many brands shine in the world of hobbyist metal lathe control panels. Brands like Sherline, Taig, and Grizzly have loyal fans. They offer great features and solid performance without breaking the bank. For example, Sherline’s control panel is known for its user-friendly design. Grizzly, on the other hand, offers great value with a variety of features at a reasonable price. Check out the table below for quick comparisons!

| Brand | Features | Price Range |

|---|---|---|

| Sherline | User-friendly design, compact size | $300-$500 |

| Taig | Durable construction, precision control | $400-$600 |

| Grizzly | Good value, multiple features | $250-$450 |

Each of these panels has its highlights, making it easier to pick one that suits you best. Who knew a lathe could be so friendly? Just remember, it’s not the size of your lathe that counts, but how you use it!

Installation and Setup of Metal Lathe Control Panels

Stepbystep installation guide. Common troubleshooting tips during setup.Setting up your metal lathe control panel can feel like assembling a puzzle with your eyes closed, but it doesn’t have to be that tricky! Start by reading the instructions carefully and gather your tools. Remember, the only tool that should get lost is your sense of humor! Follow these steps:

| Step | Action |

|---|---|

| 1 | Connect the power supply. |

| 2 | Attach motor wires. |

| 3 | Calibrate settings. |

If something goes wrong, don’t panic! Common issues include wiring mistakes or power problems. If your lathe doesn’t turn on, check that everything is plugged in properly. Remember, a tight connection is key—just like that last piece of cake at a party! Troubleshooting can be simple and fun if you take it step by step.

Maintaining and Troubleshooting Your Metal Lathe Control Panel

Routine maintenance tips for longevity. Common issues and how to resolve them.Keeping your metal lathe control panel happy requires regular check-ups. Picture it like a puppy; it needs a little love! Start by cleaning dust and grime. A quick wipe keeps it smiling. Also, check the wiring for any loose connections—it’s a panel, not a magic trick!

Common hiccups include unresponsive buttons or flickering screens. If that happens, reset it by turning it off for a minute. Still acting goofy? It might be time to check the settings. Remember, an unhappy lathe won’t make shiny things!

| Issue | Solution |

|---|---|

| Unresponsive buttons | Reset the panel |

| Flickering screen | Check connections |

So, keep an eye on your panel, and it will help you shape metal masterpieces for years to come! After all, your metal lathe is like a trusty sidekick in your hobby adventures!

Community and Resources for Hobbyist Metal Lathe Enthusiasts

Online forums and support groups. Recommended books and tutorials for further learning.Finding a community of metal lathe lovers is easier than spotting a squirrel in the park! Online forums and support groups are buzzing with tips and tricks. Websites like Metalworking Fun and Lathe Lovers let users share ideas, ask questions, and show off projects. For those who want to dig deeper, check out recommended books like Lathe Operations and Metalworking for Beginners. Tutorials on YouTube can be gems too!

| Resource Type | Recommended Titles |

|---|---|

| Online Forum | Metalworking Fun, Lathe Lovers |

| Books | Lathe Operations, Metalworking for Beginners |

| Tutorials | YouTube Channels |

So join a group and let’s make shavings fly together!

Conclusion

In summary, a hobbyist metal lathe control panel is essential for safely running your lathe. It provides easy access to controls, enhancing your metalworking experience. Remember to familiarize yourself with each function to improve skills. You can explore tutorials online for a deeper understanding. Embrace your creativity and start making projects today!FAQs

What Are The Essential Components To Include In A Hobbyist Metal Lathe Control Panel For Optimal Functionality?To make a control panel for a metal lathe, you need a few important buttons and switches. First, include an on/off switch to start and stop the machine. Next, add a speed control knob to change how fast the lathe spins. It’s also good to have a feed control to adjust how the metal moves against the tool. Finally, make sure to include an emergency stop button that instantly shuts everything down if there’s a problem.

How Can I Design A Control Panel That Is User-Friendly For Beginners Using A Metal Lathe?To make a control panel easy for beginners, start with clear labels. Use big buttons that are easy to press. Include simple pictures to show what each button does. Place everything within reach and in a logical order. You want it to feel friendly and not too complicated!

What Safety Features Should Be Integrated Into A Metal Lathe Control Panel To Prevent Accidents During Operation?To keep you safe while using a metal lathe, the control panel should have a few important features. First, it should have an emergency stop button that you can reach easily. This way, if something goes wrong, you can stop the machine quickly. Next, add guards around moving parts to protect your hands. Finally, clear labels and warnings can help remind you to stay safe while you work.

Are There Recommended Microcontrollers Or Plcs For Building A Customizable Control Panel For A Hobbyist Metal Lathe?For a hobbyist metal lathe, you can use microcontrollers like Arduino or Raspberry Pi. They are easy to program and affordable. If you prefer using a PLC (Programmable Logic Controller), some simple ones are good for beginners. These choices let you customize your control panel easily!

How Can I Implement Digital Readouts And Feedback Systems In My Metal Lathe Control Panel For Improved Accuracy And Control?To add digital readouts to your metal lathe, you can start by buying a digital display unit. Next, connect it to the lathe’s movement parts, like the spindle or carriage, using cables. This helps you see exact measurements easily. You can also use sensors that send feedback to the display. This way, you know how much metal you are cutting and can make better adjustments.