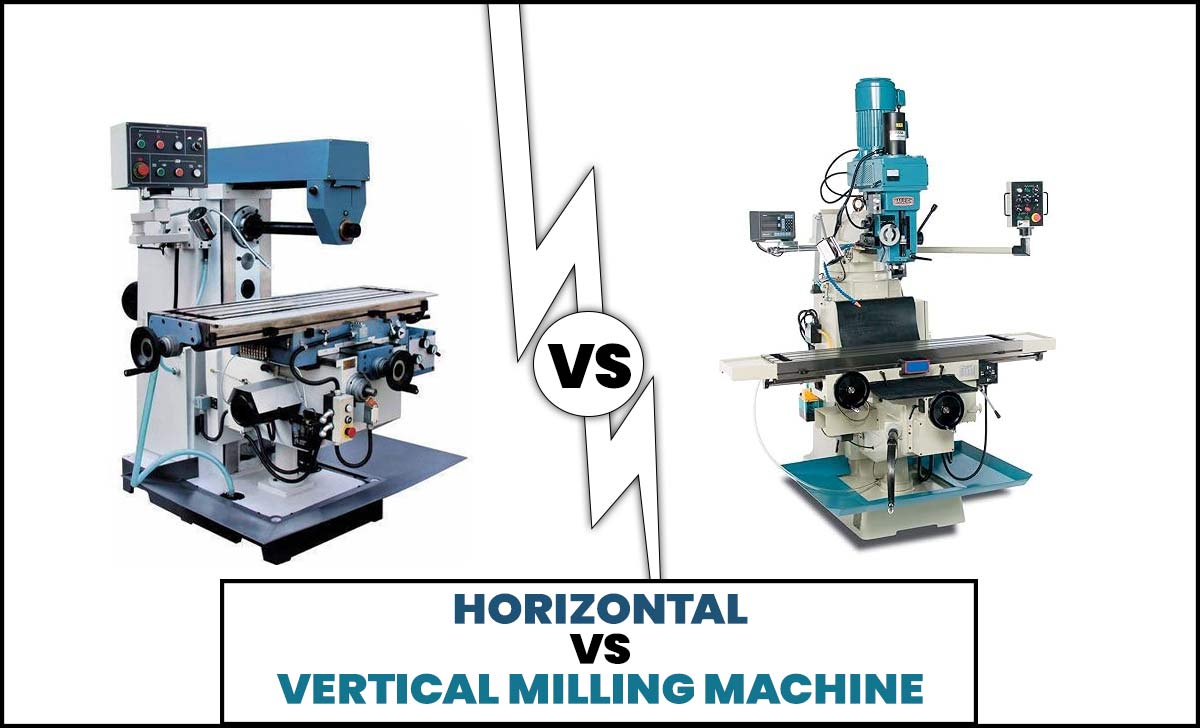

There are two main types of milling machines in the machining world: horizontal and vertical. These machines are crucial in creating precise and intricate designs on various materials. While both types of machines serve the same purpose, they have distinct differences that make each one suitable for different applications.

Understanding these differences is essential for any machinist or manufacturing professional looking to optimize their production processes. We will delve into the differences between horizontal vs vertical milling machines, including their functionality, advantages, and disadvantages.

We will also discuss the various applications where each type of machine excels, providing readers with a comprehensive understanding of their unique capabilities. So, let’s dive into the world of horizontal and vertical milling machines and explore their differences in detail.

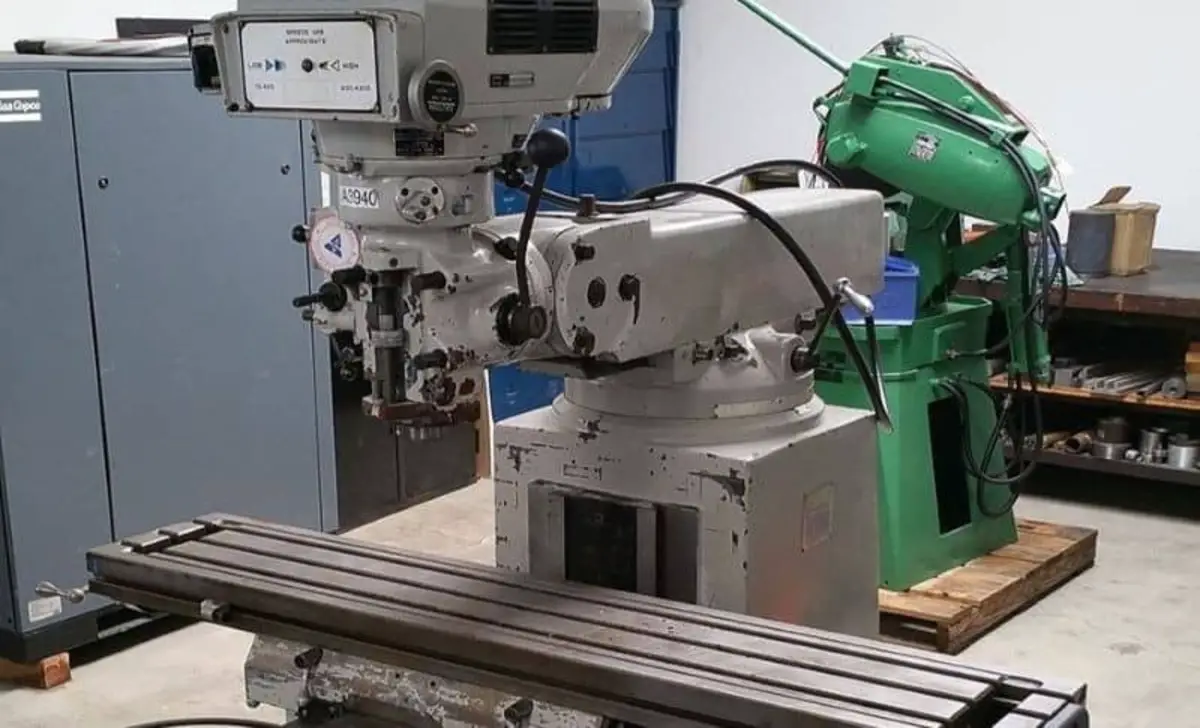

Overview Of Horizontal Milling Machine

A Horizontal Milling Machine is a versatile tool handy in machining processes. It has a horizontal spindle and a cutting tool that moves in multiple directions, allowing for precision and accuracy. This machine is ideal for various applications, such as face milling, slotting, and contouring.

With its ability to handle larger workpieces and perform different operations simultaneously, the Horizontal Milling Machine is a valuable asset in the manufacturing industry. Its features include a sturdy construction, an adjustable table, and a wide range of spindle speeds, making it suitable for small and large-scale production.

Specification

- Spindle Taper: ISO 40 or ISO 50

- Spindle Speed: Variable, typically 603000 RPM

- Table Size: Varies, commonly 1000×250 mm

- Table Travel:

- Longitudinal: 7001500 mm

- Cross: 200400 mm

- Vertical: 300500 mm

- Feed Rates:

- Longitudinal: 20800 mm/min

- Cross: 10500 mm/min

- Vertical: 5250 mm/min

- Power Feed: Yes

- Rapid Traverse: Yes

- Main Motor Power: 515 kW

- Weight: Varies, typically 20008000 kg

- Dimensions: Varies, depending on model

- Control System: Manual or CNC

Pros

- Versatile and can perform various milling operations

- Capable of handling larger and heavier workpieces

- Improved visibility and accessibility to the workpiece

- Enhanced productivity and efficiency with multiple cutting tools

Cons

- Horizontal milling machines require more floor space

- Less suitable for smaller workshops

Overview Of Vertical Milling Machine

A milling machine is a versatile tool used in machining operations to remove material from a workpiece. It comprises a rotating cutter along multiple axes, allowing for precise and complex cuts. The machine’s features include adjustable speed, table movement, and various cutting tools to accommodate different materials and shapes. With its versatility and precision, the milling machine is an essential tool in manufacturing, engineering, and metalworking industries.

Specification

- Machine Type: Vertical Milling Machine

- Number Of Axes: 3 (X, Y, Z)

- Table Size: Varies

- Spindle Speed Range: Variable

- Spindle Taper: R8 (standard), ISO 40 or ISO 50 (optional)

- Quill Travel: Varies

- Motor Power: Varies

- Maximum Weight Capacity: Varies

- Control System: Manual or CNC

- Overall Dimensions: Varies

- Weight: Varies

- Applications: Milling, drilling, boring, reaming, and other machining tasks

Pros

- Vertical Milling Machine: precise and accurate cutting and shaping

- Versatile: drilling, slotting, boring

- Suitable For Large-Scale Production: heavy-duty tasks, multiple pieces at once

- Easy visibility and accessibility of workpiece

Cons

- Large size and vertical design

- Higher cost compared to other milling machines

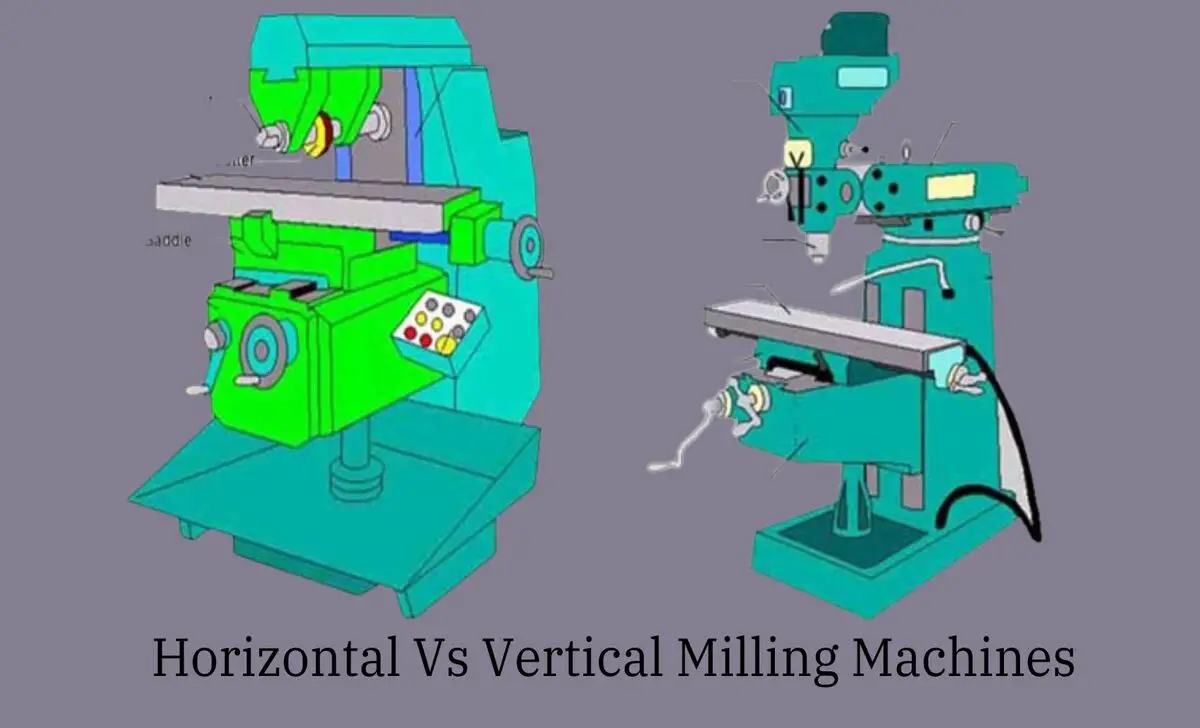

Comparison Of Horizontal Vs Vertical Milling Machines

Two commonly used types of milling machines in various industries are horizontal milling machines and vertical milling machines. Both machines have unique features and advantages, making them suitable for different applications. Both horizontal and vertical milling machines have advantages and are suitable for different applications.

The choice between the two depends on factors such as the workpiece’s size, the job’s complexity, and the desired level of precision. By understanding each machine’s unique features and capabilities, businesses can make informed decisions to maximize productivity and achieve the desired results. Here, we discuss horizontal vs vertical milling machines.

Spindle Orientation

There is a distinguishable variation in spindle orientation between horizontal and vertical milling machines. Vertical mills, also known as vertical machines, have a vertical spindle, allowing for easy up-and-down movement of the cutting tool. On the other hand, horizontal milling machines have the spindle positioned horizontally, enabling the cutting tool to move from side to side. Additionally, bed milling machines, commonly called bed mills, offer a sturdy and stable platform for precise machining operations. Whether using vertical or horizontal machines, bed mills provide excellent versatility and accuracy for various milling applications.

Differences In Design, Operation, And Functionality

Horizontal and vertical milling machines differ in various aspects, including design, operation, and functionality. The horizontal mill features a horizontal spindle orientation, positioning the cutting tool horizontally. It is well-suited for heavy-duty milling tasks and is commonly used for horizontal milling operations.

On the other hand, the vertical mill has a vertical spindle orientation, enabling the cutting tool to be positioned vertically. This mill type is ideal for precision work, such as drilling and tapping operations. Despite their differences, both machines offer unique advantages and are essential tools in machining.

Workpiece Size And Shape Compatibility

Significant differences exist in workpiece size and shape compatibility between horizontal and vertical milling machines. Horizontal machines are typically more suitable for larger and heavier workpieces, offering a greater range of movement and flexibility.

On the other hand, vertical machines excel in handling smaller and more intricate pieces, providing precise and accurate results. It is important to consider the specific requirements of the workpiece to determine the most appropriate machine for the job.

Material Removal Rate

The material removal rate is crucial when comparing horizontal and vertical milling machines. Horizontal milling machines excel in high-volume production, as they can remove material rapidly due to their multi-axis capabilities.

On the other hand, vertical milling machines offer greater versatility and precision, making them ideal for intricate and complex machining operations. Ultimately, the choice between the two depends on the project’s specific requirements, considering factors such as production volume, complexity, and accuracy.

Flexibility In Operations

Several factors come into play when comparing the flexibility in operations of horizontal and vertical milling machines. Horizontal milling machines offer versatility in workpiece size and shape, allowing larger and heavier components to be machined.

On the other hand, vertical milling machines excel in their ability to perform intricate and precise operations, making them ideal for tasks requiring high accuracy levels. Ultimately, the choice between the two depends on the project’s specific requirements, considering factors such as the complexity of the part, desired precision, and available workspace.

Ease Of Setup And Operation

Several factors come into play when comparing the ease of setup and operation between horizontal and vertical milling machines. Horizontal milling machines typically offer simpler setup processes due to their straightforward workpiece placement. However, vertical milling machines provide greater cutting angles and spindle movement flexibility.

Vertical mills are often equipped with digital controls, making them easier to operate and program. Ultimately, the choice depends on the specific requirements and preferences of the user, as both types have advantages and suitability for different applications.

Cost Considerations

The average price of a horizontal and vertical milling machine can vary depending on various factors such as brand, size, and features. Generally, horizontal milling machines are more expensive than vertical milling machines due to their versatility and capability to handle larger workpieces.

Prices for a new horizontal milling machine can range from $15,000 to $1 million, while vertical milling machines can range from $5,000 to $100,000. It is recommended to check with industrial machinery suppliers, online marketplaces, and local dealerships to understand the specific prices and options better.

Applications And Industries

Horizontal milling machines, also known as horizontal mills, are commonly used in automotive, aerospace, and manufacturing industries. These machines are ideal for heavy-duty, high-volume production work. On the other hand, vertical milling machines, also known as vertical mills, are commonly used in industries such as mould-making, prototyping, and small-scale production. They are known for their versatility and ability to perform intricate tasks with their vertical orientation.

Turret milling machines, a type of vertical milling machine, are especially popular due to their ability to rotate the spindle and perform various operations. In summary, horizontal milling machines are preferred for large-scale production, while vertical milling machines, including turret mills, excel in precision and versatility for specific applications.

How To Maintain Horizontal Vs Vertical Milling Machine

Maintenance for horizontal and vertical milling machines is crucial to ensure optimal performance and longevity. Inspecting all components, such as the spindle, motor, and cutting tools, is necessary to detect any wear or damage. Lubrication should be done according to manufacturer guidelines to prevent friction and ensure smooth operation. Additionally, cleaning and removing debris or chips from the machine’s surfaces is essential to maintain accuracy and prevent potential issues.

- Inspect and clean the machine regularly.

- Lubricate the appropriate parts according to the manufacturer’s guidelines

- Check for wear and tear, replace or repair damaged parts

- Calibrate and align machine components as needed

- Check and replace filters for coolant or hydraulic systems

- Regularly inspect electrical connections

Conclusion:

The choice between a horizontal or vertical milling machine ultimately depends on the specific needs and goals of the user. Both have unique advantages and can be suitable for different projects. These machines can cut and shape a wide range of materials with extreme precision, making them essential tools for manufacturing, construction, and engineering professionals.

It is important for professionals to carefully consider the features and capabilities of each machine and their intended use to make the best decision for their work. Whichever machine is chosen, one thing is for sure: horizontal and vertical milling machines are powerful tools that can greatly enhance the efficiency and precision of any project.

FAQ:

1.What Are The Limitations Of Vertical Milling Machines?

Ans: Some limitations of vertical milling machines include limited size and weight capacity, difficulty milling irregular shapes, and the need for specialized tooling for certain operations.

2.What Are The Hazards Of Vertical Milling?

Ans: The hazards of vertical milling include the risk of injury from the rotating cutter, flying debris, and accidental contact with the machine’s moving parts.

3.What Is The Purpose Of A Horizontal Mill?

Ans: The purpose of a horizontal mill is to accurately and efficiently remove material from a workpiece by using a rotating horizontal spindle and a cutting tool.

4.What Is The Name Of A Vertical Milling Machine?

Ans: A vertical milling machine is typically called a “vertical mill” or a “vertical machining centre”. A vertical milling machine, also known as a vertical mill or a vertical machining centre, is a versatile and essential tool in the manufacturing industry.

5.What Is The Unit Of Feed?

Ans: The feed unit is typically measured in pounds or kilograms, depending on the country or region. In the world of agriculture and animal husbandry, the feed unit is a crucial aspect in ensuring the health and productivity of livestock.