Choosing the right automation for a metal lathe might seem tricky at first. Have you ever wondered how some workshops crank out perfect parts so quickly? Metal lathes can play a big part in this. With automation, they become even more powerful.

Imagine a machine that works all day, helping you create amazing things. Automation in metal lathes can save time and effort. But how do you know which one is right for you? What features should you look for?

In this article, we will explore how to choose metal lathe automation. You’ll discover tips to help you make the best choice. Get ready to unlock the potential of your metalworking projects!

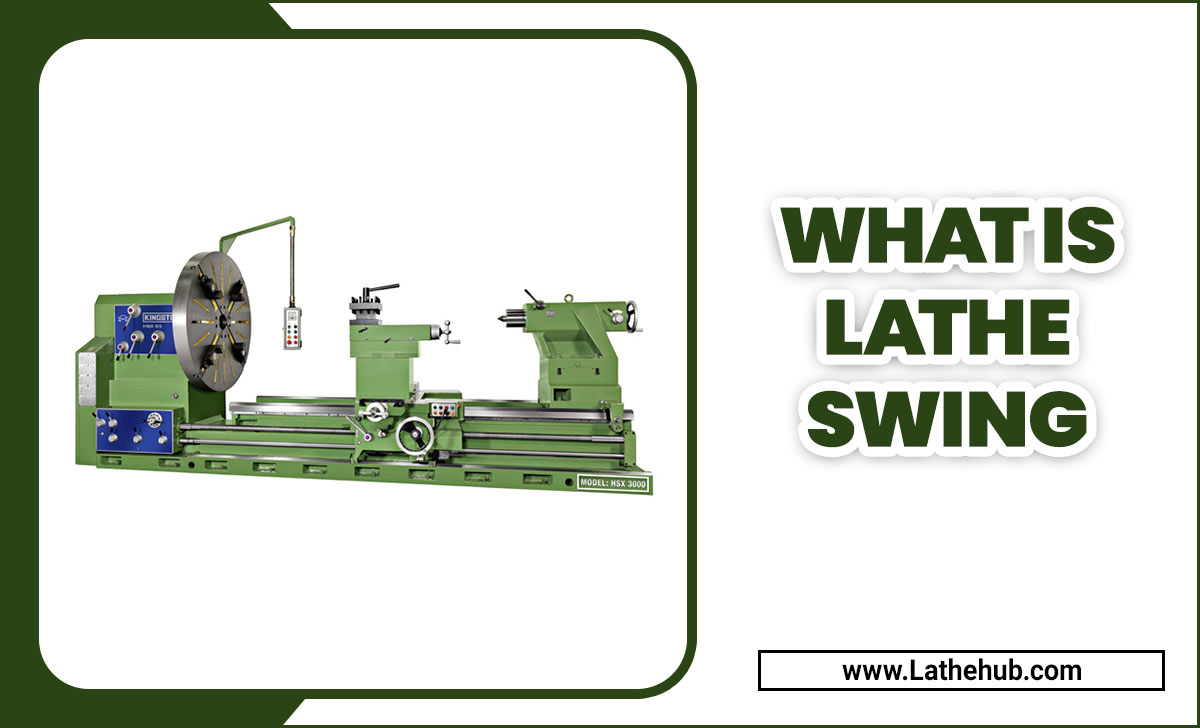

How To Choose Metal Lathe Automation: Essential Tips And Insights Choosing The Right Metal Lathe Automation For Your Projects Can Significantly Enhance Your Machining Efficiency And Precision. Whether You Are A Seasoned Machinist Or A Novice, Understanding The Key Factors Involved In Selecting The Appropriate Equipment Is Crucial. Below Are Some Essential Considerations To Guide You Through This Decision-Making Process. Understanding Your Needs Before Diving Into The Specifics Of Metal Lathe Automation, Consider Your Unique Requirements. What Types Of Projects Will You Be Undertaking? Do You Need High-Speed Production For Large Volumes, Or Will You Be Working On Smaller, Intricate Components? Identifying Your Operational Needs Will Help You Narrow Down Your Options. Assessing Automation Features Metal Lathe Automation Features Vary Greatly Between Models. Look For Lathes That Offer Advanced Capabilities Such As Cnc (Computer Numerical Control), Which Allow For Precision And Repeatability. Additionally, Consider The Availability Of Automatic Tool Changers, Part Loaders, And Other Features That Can Significantly Reduce Downtime And Increase Productivity. Exploring The Size And Capacity Size And Capacity Are Crucial Factors When Selecting A Metal Lathe. Ensure The Lathe You Choose Can Accommodate The Types Of Materials And Sizes You Plan To Work With. Consider The Swing Over The Bed, Distance Between Centers, And Maximum Spindle Speed. These Specifications Will Directly Impact Your Production Capabilities. Evaluating Brand Reputation And Support Not All Brands Are Created Equal. Research Various Manufacturers To Gauge Their Reputation In The Industry. Look For Customer Reviews And Testimonials That Speak To The Durability And Reliability Of The Equipment. Additionally, Consider The Availability Of Technical Support And Service Options, As This Can Be Vital When Issues Arise. Budget Considerations While It Might Be Tempting To Go For The Most Feature-Rich Metal Lathe Automation, Budget Constraints Are Often A Reality. Determine Your Budget Beforehand And Explore Options That Fit Within Your Range Without Sacrificing Quality Or Essential Functionalities. Remember, A Higher Initial Investment Might Pay Off In Terms Of Performance And Longevity. Conclusion Choosing The Right Metal Lathe Automation Requires Careful Consideration Of Various Factors, From Your Specific Machining Needs To Potential Budget Constraints. By Prioritizing Features That Align With Your Goals And Understanding The Market, You Can Make An Informed Decision That Enhances Your Productivity And Efficiency In The Workshop.

How to Choose Metal Lathe Automation

Selecting metal lathe automation can be tricky. You need to think about your specific needs first. What projects will you typically handle? Consider the lathe’s size and capabilities. Ask yourself, is speed important to you? Look for automation that enhances productivity. A fun fact: automated lathes can work while you relax! Choosing wisely means better results. So, invest time in research to find the perfect fit for your workshop. Happy turning!Understanding Metal Lathe Automation

Definition and purpose of metal lathe automation.. Benefits of automating metal lathe processes..Metal lathe automation is like giving your lathe a superpower! It helps machines run without constant human help. This means they can work longer and faster. Think of it as hiring a robot buddy that never gets tired or needs coffee breaks.

Automating metal lathe processes brings several shiny benefits:

| Benefit | Description |

|---|---|

| Increased Efficiency | Machines can work non-stop, cranking out parts like a chocolate factory runs on sweets! |

| Improved Precision | Robots don’t shake due to caffeine or talk about their weekend plans, so they cut accurately! |

| Cost Savings | Fewer mistakes mean less waste, saving coins for the ice cream truck. |

So, if you want to boost your metal working game, consider automation. You may not end up with a superhero, but you will have a much happier lathe!

Assessing Your Production Needs

Identifying production volume and complexity of tasks.. Determining the level of precision required for projects..Knowing your production needs is the first step to choosing a metal lathe. Start by figuring out how much you will produce and how complex the tasks are. For example, will you make many pieces quickly, or just a few with special details? Also, think about how precise your work should be. Some projects need perfect measurements, while others don’t.

- Think about your production volume.

- Consider the complexity of tasks.

- Decide the precision needed for each project.

What factors should I consider for production needs?

Look at volume, task complexity, and precision requirements. These factors help you choose the right lathe for your work style and needs.

Key Features to Consider

Importance of spindle speed and torque specifications.. Evaluation of control systems and user interfaces..Picking the right metal lathe automation is exciting. You must look closely at some key features. First, check the spindle speed and torque specifications. These tell you how quickly and powerfully the machine can work. Next, evaluate the control systems and user interface. A simple, easy-to-use interface makes work smoother and more fun. Better control helps you make awesome projects with accuracy!

What are important factors for choosing metal lathe automation?

Focus on these factors:

- Spindle Speed: This shows how fast the lathe can spin.

- Torque: This indicates how strong the machine is when cutting materials.

- User Interface: An easy interface helps you use the machine better.

- Control Systems: Better controls give you more precision while working.

Budgeting for Automation

Factors influencing the cost of metal lathe automation.. Longterm savings vs. initial investment..Choosing automation for a metal lathe can feel like picking a favorite candy. There are many factors that influence the cost, like the type of automation you need and the parts required. You might think, “Wow, that sounds expensive!” But consider this: what seems like a lot today might save you time and money tomorrow. Over time, these machines can lower production costs and boost efficiency. In the end, it’s all about balancing initial investments against long-term savings.

| Factor | Impact on Cost |

|---|---|

| Type of Automation | Higher tech means higher prices! |

| Quality | Good quality lasts longer, but it costs more. |

| Maintenance | Regular care can prevent pricey fixes. |

Supplier Reputation and Support

Researching manufacturer credibility and customer reviews.. Importance of aftersales support and service options..Choosing the right metal lathe supplier is important. First, check their reputation. Look for reviews from other customers. Positive feedback shows trustworthiness. Consider also their aftersales support. This means help when problems arise. Find out if they offer service options. Good suppliers help you even after the sale.

- Check online reviews.

- Ask for referrals from other users.

- Look at the supplier’s history.

- Ensure they offer quick support.

Why is supplier reputation important?

A strong reputation means quality products. It shows they are reliable and care about their customers. A good supplier also values your concerns.

What should I look for in aftersales service?

- Response time to issues.

- Availability of parts.

- Technical support offerings.

Integration with Existing Equipment

Assessing compatibility with current workshop technology.. Considerations for space and infrastructure requirements..Before adding a metal lathe, confirm it fits with your current tools. Think about how they work together. Is the new machine compatible with your existing setup? Check the space you have. The lathe should fit well without crowding the area. Also, consider any needed changes to your workshop’s layout. Proper planning helps to avoid tight spots.

What should I check for equipment compatibility?

Always look for:

- Electrical supply needs.

- Space available for the new machine.

- Connection types between machines.

Training and Skill Requirements

Understanding the skill level needed for operation and maintenance.. Options for training and skill development for staff..Understanding the skill level needed for operating and maintaining a metal lathe is like picking the right tool for a job. Not all lathes are created equal! Some need experts, while others welcome newbies. Good training helps bridge this gap. You can choose from hands-on workshops or online courses. Both can turn a curious beginner into a pro. Remember, practice makes perfect, but keep it safe—no one wants a flying wrench!

| Training Option | Skill Level Target |

|---|---|

| Hands-on Workshop | Beginner to Intermediate |

| Online Courses | All Levels |

| Mentorship | Expert Guidance |

This approach helps staff feel confident and skilled. After all, happy workers create happy machines!

Future Trends in Metal Lathe Automation

Exploration of emerging technologies in machining.. Predictions on the evolution of automation in manufacturing industries..New technologies are changing how machines work. 3D printing is one exciting development. It helps create parts faster and cheaper. Another trend is Artificial Intelligence. AI can improve how machines run, making them smarter. Experts predict automation will keep growing. This means fewer mistakes and more efficiency in factories.

- More robotic helpers in workshops.

- Advanced sensors for better accuracy.

- Reports that show machine performance instantly.

What are some emerging technologies in metal lathe automation?

Emerging technologies include 3D printing, AI, and smart sensors. These tools make machines more efficient and accurate.

Future Predictions

Experts believe automation will change the manufacturing world. Factories will become faster and smarter. More jobs will focus on tech rather than manual work. This change aims for cleaner and safer workplaces.

Conclusion

In summary, choosing metal lathe automation involves understanding your needs, assessing your budget, and considering features like precision and speed. Think about the types of projects you’ll do. Take your time to research options and read reviews. Next, visit local shops or websites to see machines in action. This will help you make a confident choice!FAQs

What Are The Key Factors To Consider When Selecting A Metal Lathe For Automation In A Production Environment?When choosing a metal lathe for automated production, you should look at a few key things. First, think about its size and power. It needs to fit your space and handle the materials you use. Next, check how easy it is to use and program. We want machines that can be quickly set up. Lastly, consider the cost and how long it lasts. Good lathes can save money in the long run.

How Do Different Types Of Automation (Cnc Vs. Manual) Impact The Choice Of A Metal Lathe?When choosing a metal lathe, you need to think about how you want to work. A CNC lathe uses a computer to control the machine. This makes it easier to create precise shapes quickly. If you choose a manual lathe, you will use your hands and skills to shape the metal. Manual lathes can be fun and help you learn, but they often take more time.

What Are The Advantages And Disadvantages Of Integrating Robotic Automation With Metal Lathes?Integrating robotic automation with metal lathes has some great benefits and a few downsides. First, robots can work really fast and don’t get tired, so they can make more parts. This saves time and money. However, robots can be expensive to set up and may need special care. Also, they can’t always think or solve problems like a person can.

How Can The Materials And Workpieces Being Machined Influence The Decision On Metal Lathe Automation?The materials we use can change how we automate a metal lathe. If the materials are hard, we might need special tools to help. Softer materials might not need as much help, so we can keep it simple. Different shapes of workpieces also matter. Sometimes, they need more careful work, which might need more automation.

What Is The Role Of Software And Control Systems In Maximizing The Efficiency Of Automated Metal Lathes?Software and control systems help metal lathes work better and faster. They tell the machine what to do and when to do it. This way, the lathes can make precise shapes without wasting time or materials. By using these systems, we can produce more items in less time, making everything run smoothly.