Have you ever wondered how to pick the right metal lathe for a CNC retrofit? The choices can be overwhelming. In today’s world of machinery, it’s easy to get lost among all the options.

Imagine standing in a workshop filled with shiny lathes, each promising the best performance. How do you know which one is perfect for you? Choosing the right metal lathe can feel like finding a needle in a haystack.

Did you know that the right CNC retrofit can elevate your work and boost creativity? Understanding some key points can make this choice simpler. You can enjoy crafting precise parts and turning your ideas into reality.

This article will guide you on how to choose metal lathe CNC retrofit with confidence. Let’s unravel the process together and make your decision easier!

How To Choose Metal Lathe Cnc Retrofit For Your Workshop

How to Choose Metal Lathe CNC Retrofit

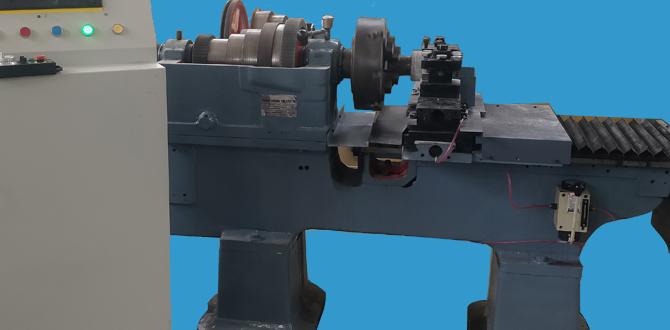

Choosing a metal lathe CNC retrofit can seem daunting. Start by assessing your current lathe’s size and capabilities. Research conversion kits tailored to your needs. Look for user reviews to ensure quality and reliability. Have you thought about your future projects? A good retrofit should expand your lathe’s functionality. For instance, it can help create parts faster. Remember, investing in the right retrofit can boost your workshop’s efficiency and creativity.Understanding CNC Retrofits

Definition and benefits of a CNC retrofit. Comparison with traditional machining methods.A CNC retrofit is like giving your old metal lathe a shiny upgrade. It turns a basic machine into a smart device. This can mean faster, more precise cuts without the guesswork. Instead of using gears and hand levers—think of it as turning a bike into a cool automatic scooter! With CNC, you can keep up with modern methods, making work easier and more fun.

| Aspect | CNC Retrofit | Traditional Machining |

|---|---|---|

| Precision | High | Moderate |

| Speed | Fast | Slow |

| Setup Time | Short | Long |

| Training Required | Less | More |

With CNC, you can enjoy quick updates without spending a fortune. You save time and can make complex parts easily. So, is it time to give your lathe a makeover? You bet! And who doesn’t like shiny new toys?

Assessing Your Current Metal Lathe

Key features to evaluate on your existing lathe. Age and condition considerations for retrofitting.Look closely at your current metal lathe before upgrading. Check its key features like turning capacity, feed rate, and tooling options. These will help you decide what upgrades you need. Also, think about its age and condition. Older lathes may need more work. Ask yourself: Is it worth retrofitting? Evaluating these aspects can save time and money.

What should I check for on my metal lathe?

Key features to look at include:

- Turning Capacity: How big can it handle?

- Feed Rate: Is it fast enough?

- Tooling Options: Can it use new tools?

Also, consider its age. An old lathe might need more upgrades. Always weigh costs and benefits.

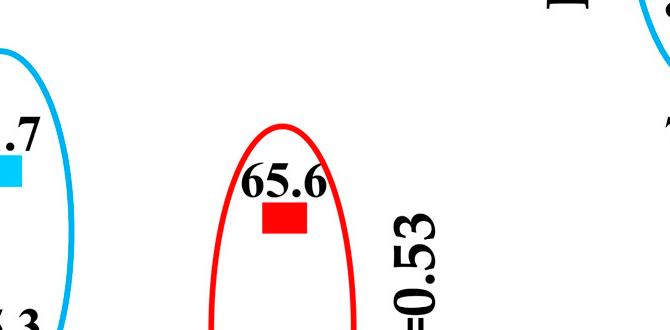

Identifying Specific Needs and Goals

Types of projects you plan to undertake. Desired accuracy and specifications in machining.Choosing the right lathe is like picking the perfect ice cream flavor—there are so many options! First, think about the types of projects you want to tackle. Are you making tiny gears or big sculptures? Each project needs different features. Next, consider the desired accuracy. How perfect do your pieces need to be? A slight wobble might work for a garden gnome but not for watch parts! Keep your list handy and make sure your lathe is ready to meet your goals.

| Project Type | Desired Accuracy |

|---|---|

| Small Parts | High Precision |

| Large Sculptures | Moderate Precision |

| Custom Designs | Varies |

Motor and Drive Options

Types of motors (servo vs. stepper). Importance of matching motor power with lathe capacity.Choosing the right motor for your CNC retrofit is crucial. You can go with a servo motor that offers precise control and speed or a stepper motor known for its simplicity and low cost. Each type has unique strengths. It’s important to match the motor’s power to your lathe’s capacity. If you don’t, it’s like trying to power a spaceship with a toy battery! Get it right to avoid a messy situation.

| Motor Type | Strengths | Best Use |

|---|---|---|

| Servo Motor | High precision, fast response | Complex projects |

| Stepper Motor | Cost-effective, simple control | Basic tasks |

Essential Components for a Successful Retrofit

List of musthave components (controllers, sensors, etc.). Optional upgrades that can enhance performance.To successfully retrofit a metal lathe, certain parts are essential. You need controllers, which act like the brain of your machine. Sensors help it understand its position. Don’t forget the power supply, which gives energy to everything. Optional upgrades can enhance performance. Here’s a quick list:

- Controllers

- Sensors

- Power Supply

- Stepper Motors for smooth movement

- Enhanced Cooling Systems

These upgrades can make your lathe work better and last longer.

What are the key components for a metal lathe retrofit?

Key components include controllers, sensors, and a reliable power supply. Optional items, like stepper motors and cooling systems, can improve overall performance.

Budgeting for Your CNC Retrofit Project

Cost considerations for both parts and labor. Tips for maximizing value within your budget.Starting a CNC retrofit project? First, you need to make a budget. Parts can be pricey, especially for a metal lathe. Don’t forget to include costs for labor too— it’s like hiring a wizard to turn your dreams into metal reality! To get the best bang for your buck, consider buying second-hand parts or looking for sales. You can also learn some DIY skills; after all, who doesn’t want to feel like a master craftsman?

| Cost Factors | Estimated Price |

|---|---|

| New Parts | $1,000 – $5,000 |

| Labor | $500 – $2,000 |

| DIY Savings | Up to 30% |

Keep track of your costs, and don’t let your dreams break the bank. Remember, budgeting is key to making your CNC retrofit a success!

Installation and Calibration Processes

Stepbystep guide to installing your retrofit components. Importance of calibration for precision machining.Getting your retrofit components up and running is easier than you think! First, gather your tools and parts like a kid ready for a treasure hunt. Follow the instructions step by step, and don’t be shy about asking for help if you get lost—sometimes it takes a village (or a user manual) to install a new machine.

Calibration is key for precise machining. Think of it like adjusting your favorite video game settings; getting it right might make the difference between smooth sailing and a total disaster. A well-calibrated machine can save time and materials.

| Step | Action |

|---|---|

| 1 | Prepare the area and gather tools. |

| 2 | Install the retrofit components carefully. |

| 3 | Double-check all connections. |

| 4 | Power up and perform initial tests. |

| 5 | Calibrate the machine for precision. |

Remember, a little patience goes a long way! Happy machining!

Post-Retrofit Maintenance and Support

Recommended maintenance practices to ensure longevity. Finding reliable support and resources for troubleshooting.After giving your metal lathe a shiny retrofit, keeping it in top shape is key. Regular maintenance helps it last longer. Remember to clean all parts weekly and check for wear and tear. Think of it as brushing your teeth; skip it, and things start to stink!

For any hiccups, look for reliable support. An online community can be your best friend. Check forums or manufacturers for resources. You wouldn’t call a cat to fix your fish tank, right? Here’s a quick table of tips:

| Maintenance Tips | Frequency |

|---|---|

| Clean machine parts | Weekly |

| Lubricate moving parts | Monthly |

| Inspect for damage | Every 3 months |

| Update software | As needed |

Your machine will love the attention, and you’ll enjoy smooth operations! A well-maintained lathe can boost productivity by up to 50%—that’s a win-win!

Conclusion

In conclusion, choosing a metal lathe CNC retrofit involves understanding your needs, budget, and skill level. Research different options and read reviews. Ask for advice from experienced users. Once you’re ready, plan your retrofit carefully to ensure it meets your goals. For more tips and detailed guides, keep exploring online resources or visit local workshops. Happy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Choosing A Metal Lathe Cnc Retrofit:Sure! When you want to choose a metal lathe CNC retrofit, think about what you need. First, look at the size of your lathe to make sure the retrofit fits. Next, check how easy it is to install and use. You also want to know how much it costs and if you can get help if you need it. Lastly, read reviews from other people who used the same retrofit to see what they think.

Sure! Just give me the question you want me to answer, and I’ll help you out!

What Are The Key Features To Consider When Selecting A Cnc Retrofit Kit For A Metal Lathe?When picking a CNC retrofit kit for a metal lathe, you should consider a few important features. First, check if the kit fits your lathe’s size and shape. Then, look for easy instructions so you can install it yourself. Next, see if it works with the software you want to use. Finally, read reviews to learn how well it works for others.

How Do Different Types Of Cnc Control Systems Impact The Performance Of A Retrofitted Metal Lathe?Different types of CNC control systems can change how well a retrofitted metal lathe works. Some systems are very simple, making it easier for you to use. Others are more advanced, which can let you create more complex shapes. A better control system can help you make things faster and more accurately. Overall, the right control system makes your lathe better at cutting metal.

What Is The Estimated Cost Range For Retrofitting A Metal Lathe With Cnc Capabilities?Retrofitting a metal lathe means adding Computer Numerical Control (CNC) features to it. This can cost between $2,000 and $20,000. The price depends on the parts you need and how much work is involved. It’s like upgrading a toy; some toys need more new pieces than others. This change can help you make better and more precise designs!

How Can I Determine If My Existing Metal Lathe Is Compatible With A Cnc Retrofit?To check if your metal lathe can become a CNC (Computer Numerical Control) machine, look at a few things. First, check the size and shape of your lathe. Then, see if it has enough space for the new parts. You can also search online for retrofit kits that fit your lathe model. Finally, ask experts or visit forums for advice from other users.

What Are The Advantages And Disadvantages Of Common Retrofit Options, Such As Open-Loop Vs. Closed-Loop Systems?Open-loop systems pull water from a nearby source, like a lake or river. They’re often cheaper to set up. However, they can harm the environment if too much water is taken. Closed-loop systems, on the other hand, use pipes buried underground. They save more energy but can cost a lot to install.