Choosing the right metal lathe drive system can feel overwhelming. Have you ever wondered how to make this important choice? When working with metal lathes, the drive system is crucial. It directly affects how well your lathe performs. Imagine if your machine could run smoothly and efficiently! That’s what a good drive system can do for you.

Many people don’t realize that not all drive systems are the same. Some are better for beginners, while others suit experts. Did you know that the right system can even save you money in the long run? It’s true! The choice you make can impact your projects, your time, and your budget.

Let’s explore how to choose the best metal lathe drive system for your needs. By the end of this article, you will have the knowledge to make an informed decision. So, are you ready to dive in?

How To Choose Metal Lathe Drive System Effectively

When selecting a metal lathe drive system, consider types like belt-driven, gear-driven, or direct drive. Each system has unique strengths and weaknesses. For example, belt-driven systems are quieter but may require more maintenance. Think about your projects’ demands. Do you need precision or speed? A surprising fact: proper drive choice can enhance your lathe’s lifespan. An informed decision leads to better work and satisfaction. So, what’s your next project? Choose wisely!

Key Factors to Consider

Importance of torque and RPM for machining needs. Evaluating power requirements based on material and project types.

Choosing the right drive system for a metal lathe is like picking the best superhero for a mission. Torque and RPM are the sidekicks that help your machine perform magic. Torque gives you the power to handle tough materials, while RPM helps you control the speed of your cuts. If you’re working with softer metals, lower torque might be enough, but harder materials need that extra oomph! Check out this quick guide:

| Material Type | Recommended Torque (Nm) | Recommended RPM |

|---|---|---|

| Aluminum | 5-10 | 1000-1500 |

| Steel | 20-30 | 300-800 |

| Cast Iron | 30-50 | 200-600 |

Always evaluate your project needs. Using too little torque can lead to slow cuts, while too much can ruin your materials. Remember, in the world of machining, balance is key. Happy turning!

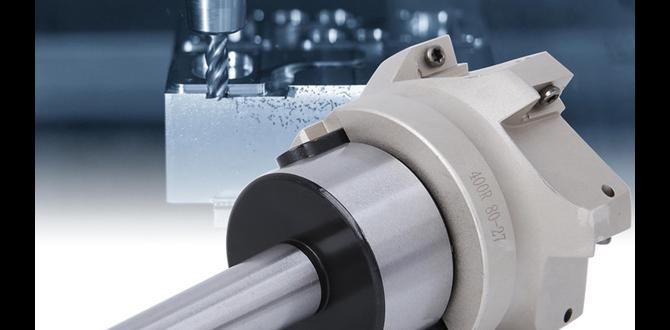

Types of Metal Lathe Drive Systems

Detailed comparison of belt drive systems. Analysis of direct drive systems and their advantages. Exploring geared drive systems and their unique features.

Metal lathes come with different drive systems that work like the engine of a car—each has its quirks! First, let’s look at belt drive systems. They are like a bicycle chain, offering smooth and quiet operation. However, they may wear over time. Next up are direct drive systems. Imagine a dog that won’t quit chasing its tail—this setup gives quick response and power, perfect for serious work. Lastly, there are geared drive systems, like a squirrel planning its next move. They provide unique gear ratios, allowing precise control and torque. Check out the table below for a quick comparison!

| Drive System | Advantages | Disadvantages |

|---|---|---|

| Belt Drive | Quiet and smooth operation | May wear out over time |

| Direct Drive | Quick response and high power | Can be more expensive |

| Geared Drive | Precise control and torque | Complex design |

Assessing Your Machining Needs

Determining your workload: hobbyist vs. professional use. Identifying materials you will be working with and their requirements.

Knowing what you need is key to picking a metal lathe drive system. Are you a hobbyist or a pro? That’s a big difference! Hobbyists might need light use, while professionals have higher demands. Consider your workload carefully. Also, think about the materials you will work with. Different materials like aluminum or steel require different tools and techniques. Pay attention to their specific needs.

What should I consider for my workload?

Decide if your work is light or heavy. This will help you choose the right system.

Factors to evaluate:

- Type of projects (small or large)

- Volume of work (occasional or daily)

- Materials used (soft or hard metals)

Budget Considerations

Evaluating cost vs. performance: what to expect at different price points. Understanding maintenance costs associated with different drive systems.

Finding the right balance between cost and performance is key. High-priced metal lathes often offer better features. However, you don’t always need the most expensive option. Look for what fits your needs and budget. Performance can vary widely. Also, remember maintenance costs can add up. Here are some things to think about:

- Low-End Models: Cheaper but may need frequent repairs.

- Mid-Range Models: Good balance of cost and reliability.

- High-End Models: Best performance but expensive to maintain.

What are maintenance costs for metal lathes?

Maintenance costs vary by type. Typically, low-end lathes require more repairs, while high-end models are made from better materials, so they last longer. Choose wisely to save money!

Installation and Maintenance Tips

Guidelines for properly installing a metal lathe drive system. Routine maintenance practices to extend the life of the drive system.

Installing your metal lathe drive system correctly is key for smooth operation. First, ensure the base is level. This helps prevent vibration during use. Then, follow the manufacturer’s instructions closely. Regular maintenance keeps your machine running well. Here are some tips:

- Check oil levels monthly.

- Clean dust and chips from parts.

- Inspect belts for wear and tear.

Doing these tasks will help extend the life of your drive system.

What are some maintenance tips for a metal lathe drive system?

Routine checks on oil, cleanliness, and belt condition are important to keep your metal lathe running smoothly.

User Experiences and Reviews

Gathering insights from experienced machinists. Key takeaways from user reviews on various drive systems.

Experienced machinists share valuable insights about different drive systems. They often highlight performance, durability, and ease of use. One user shared, “The smoother the drive, the happier I am!” Reviews commonly mention quick change capabilities and power efficiency as game-changers. Here’s what users love the most:

| Drive System | User Rating | Key Feature |

|---|---|---|

| AC Drive | ⭐⭐⭐⭐⭐ | Smooth operation |

| DC Drive | ⭐⭐⭐⭐ | Cost-effective |

| Stepper Motor | ⭐⭐⭐⭐⭐ | Precision control |

With these insights, you can make a smart choice! Remember, a great drive can turn a metal lathe into a magician’s tool. Who knew machining could be this much fun?

Frequently Asked Questions

Addressing common queries related to choosing drive systems. Myths and misconceptions about metal lathe drive systems.

Many people have questions about metal lathe drive systems. Here are some common ones:

What is a metal lathe drive system?

A metal lathe drive system helps turn metal pieces. It uses a motor to drive the lathe. This lets you shape metal into tools or parts.

Are all drive systems the same?

No, they are not. Different systems offer various speeds and power options. Choosing the right one is important for your projects.

Can I use any motor for my lathe?

No, using the right motor is vital. Incorrect motors can cause damage or safety issues.

Common Myths:

- Myth: All lathes require gears.

- Myth: Drive systems are too complex to understand.

Don’t be fooled by these myths! The right knowledge will help you select the best drive system for your metal lathe.

Conclusion

In conclusion, choosing the right metal lathe drive system involves understanding your needs and options. Consider factors like power, speed, and budget. We recommend researching different systems and reading reviews. Hands-on experience can also help. Take your time to compare choices and ask for advice if needed. Happy lathe shopping! For more, check out guides or talk to experts.

FAQs

What Are The Key Differences Between Geared Drive And Belt Drive Systems In Metal Lathes?

Geared drive systems use gears to transfer power, while belt drive systems use belts. Gears are usually stronger and can handle more power. Belts can be quieter and easier to replace when they wear out. Gears often give you more precise control, while belts can allow for faster speeds. Each type has its own pros and cons for different jobs.

How Does The Horsepower And Torque Of A Drive System Impact The Performance Of A Metal Lathe?

Horsepower is how much power the machine has. Torque is how much force it uses to turn things. A metal lathe with more horsepower can cut through tough materials better. More torque helps it spin heavier pieces smoothly. Together, they make the lathe work faster and easier.

What Maintenance Considerations Should Be Taken Into Account When Selecting A Drive System For A Metal Lathe?

When choosing a drive system for a metal lathe, think about how easy it is to take care of. You want parts that are simple to reach for cleaning and fixing. Check if the system needs special tools or skills for repairs. It’s also good to pick one that doesn’t break down often, so you can keep working without stopping.

What Are The Advantages Of Using A Variable Speed Drive System Over A Fixed Speed System In Metal Lathes?

Using a variable speed drive system lets you change the speed of the metal lathe easily. This means you can work faster or slower, depending on what you need. It helps you make smoother cuts, which can be more accurate. You also use less energy, which is better for the environment. Overall, it gives you more control while working.

How Do Different Drive Systems Affect The Precision And Finishing Quality Of Machined Parts On A Lathe?

Different drive systems power the lathe in various ways. Some systems give smooth and steady movement. This helps us create precise parts. If the drive system isn’t good, the parts might be wobbly or rough. So, a better drive system means better quality in our work!