Have you ever wondered how to choose the right gear train for a metal lathe? Making that choice can feel tricky. There are so many options! Using a metal lathe can help you create amazing projects. But the right gear train is the key to getting the best results.

Imagine crafting a perfect wooden toy or a shiny metal part for a robot. The gear train makes all the difference in how smoothly your machine works. Did you know that different gear setups can change the speed and power of your lathe? It’s true!

In this article, we will explore how to choose metal lathe gear trains. You’ll find tips and tricks to simplify your decision. Let’s dive in and unlock the secrets to making your metal lathe experience enjoyable and successful!

How To Choose Metal Lathe Gear Train For Optimal Performance

How to Choose Metal Lathe Gear Train

Selecting a metal lathe gear train can seem daunting. Start by considering the types of projects you’ll tackle. Different materials and designs require specific gear ratios. Did you know that even small changes in gear setup can drastically affect production? Ease of operation and durability are also key factors. Make sure the gear train fits your lathe model well. Finally, always read reviews to help you make the best choice for your metalworking tasks!Understanding Gear Train Basics

Definition of gear trains in metal lathes. Importance of gear train selection for performance.Imagine a gear train as a team of tiny superheroes in your metal lathe. These gears work together to control speed and power, much like a well-practiced football team. Choosing the right gear train is crucial for performance. If you pick wisely, your lathe will cut like butter, but a poor choice can make it feel more like slicing through a brick wall! Understanding how gear trains work will help you make the best choice for your projects.

| Why Gear Train Matters | Performance Boost | Common Mistakes |

|---|---|---|

| Controls machining speed | Better accuracy in cuts | Ignoring compatibility |

| Adjusts power delivery | Extends tool life | Choosing the wrong ratios |

| Affects vibration | Improves finish quality | Lack of research |

Factors to Consider When Choosing a Gear Train

Required torque and speed considerations. Material compatibility and machine specifications.Choosing the right gear train involves a few key points. First, consider the required torque and speed. Your machine needs enough power to work smoothly. If it’s too weak, it’s like an elephant trying to dance! Next, think about material compatibility. Not all gears get along. Metal gears need metal machines. Lastly, check your machine specifications to ensure everything fits. Remember, the right gear train can turn your project from “uh-oh” to “wow!”

| Factor | Importance |

|---|---|

| Torque & Speed | Ensures proper functioning |

| Material Compatibility | Prevents damage and breakdowns |

| Machine Specifications | Guarantees the right fit |

Assessing Workpiece Requirements

Influence of workpiece material on gear train choice. Size and complexity of projects as a determining factor.The type of material you use for your workpiece can change your gear train choice. For example, softer metals need less force, while harder materials require more power. Consider these points:

- Softer metals like aluminum can use a lighter gear train.

- Harder metals like steel need stronger gears.

Also, the size and complexity of your projects matter. Simple tasks need basic setups. Complex parts may need advanced arrangements. Assess these factors carefully for the best results.

How Does Material Affect Gear Train Selection?

The workpiece material influences gear selection. Softer materials often require simpler gears, while harder metals need robust gear systems. Always match the gear train with the project material for success.

Evaluating Gear Train Components

Key components of a gear train and their roles. How to assess the quality and durability of components.Understanding the key parts of a gear train is like knowing the ingredients of a great pizza. You need the right toppings for the best flavor! Gear wheels, shafts, and bearings play important roles. Wheels transfer motion, shafts connect parts, and bearings help everything spin smoothly. To check their quality, look for sturdy materials and solid craftsmanship. A strong gear train should last long, just like your favorite superhero. So, choose wisely!

| Component | Role | Quality Tips |

|---|---|---|

| Gear Wheels | Transfer motion | Check for wear and tear |

| Shafts | Connect components | Look for strong materials |

| Bearings | Reduce friction | Ensure they spin smoothly |

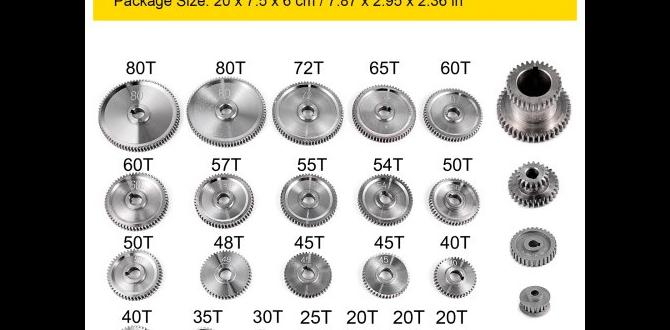

Optimal Gear Ratios for Lathe Operations

Understanding gear ratios and their effect on machining. Recommended gear ratios for specific tasks.Understanding gear ratios is like knowing how to bake a perfect cake; it can make or break your machining project! The gear ratio affects cutting speed and torque. Too high a ratio, and you might end up with a slow, lumbering lathe. Too low? You risk a high-speed fiasco! For tasks like threading, a ratio of 20:1 works wonders, while 10:1 is great for general use. Here’s a quick look:

| Task | Recommended Gear Ratio |

|---|---|

| Threading | 20:1 |

| Turning | 10:1 |

| Facing | 5:1 |

Now, you’re ready to tackle the metal lathe with confidence. It’s less about the gear and more about the gear ratio, my friend!

Common Mistakes to Avoid

Frequent pitfalls in gear train selection. Tips for ensuring compatibility with existing equipment.Choosing the right metal lathe gear train can feel tricky, but dodging common mistakes helps. First up, don’t forget to check compatibility with your existing equipment. Mixing incompatible parts is like trying to fit a square peg in a round hole—frustrating! Also, avoid rushing your decision. Take your time to evaluate options.

Here’s a quick checklist to guide you:

| Mistake | Tip |

|---|---|

| Ignoring specifications | Read manuals closely! |

| Overlooking part sizes | Measure twice, order once! |

| Skipping user reviews | Learn from others’ experiences! |

By avoiding these pitfalls, you’ll make a wise choice and save yourself some headaches!

Resources for Further Learning

Recommended literature and online resources. Communities and forums for sharing experiences and advice.To enhance your knowledge, explore various resources. Books and websites can provide helpful insights. Check out tools like online videos and guides. You might also join forums to connect with others.

- Books: Look for titles about metal lathe gear trains.

- Websites: Visit forums like Reddit and specialized machine forums.

- Videos: Search for tutorials on YouTube.

Engaging with a community allows for sharing tips and experiences. Ask questions and learn from skilled users. These resources make learning fun and effective!

What are some helpful communities for metal lathe enthusiasts?

Online forums like Reddit and dedicated machining websites offer great ways to connect with others. These platforms provide advice and share experiences.

Conclusion

In conclusion, choosing a metal lathe gear train involves understanding your project needs and gear ratios. Start by identifying your machining tasks and required precision. Consider the lathe’s size and motor power too. Research different gear options before making a decision. Now, dive deeper into tutorials or guides to gain confidence in your choices. Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Choosing A Metal Lathe Gear Train:Sure! When choosing a gear train for a metal lathe, think about how fast you want to turn the metal. You need the right gears to get the best speed and power. Check that the gears fit your lathe well. You also want to use strong materials. This way, your lathe works smoothly and lasts a long time.

Sure! Please provide the question you’d like me to answer.

What Are The Key Factors To Consider When Selecting A Gear Train For A Metal Lathe?When picking a gear train for a metal lathe, you should think about a few important things. First, look at the size of the lathe and make sure the gears fit. Next, consider the type of work you will do. Some projects need more power or speed. Also, check if the gears are strong enough to handle the metal you will use. Finally, it’s good to choose gears that are easy to find and replace.

How Do Different Gear Ratios Impact The Performance And Functionality Of A Metal Lathe?Different gear ratios help a metal lathe turn at different speeds. If you use a high gear ratio, the lathe spins faster, making it good for light tasks. A low gear ratio makes it turn slower, which is better for heavy cutting. So, changing these ratios helps us do different jobs easier and better.

What Types Of Gear Configurations Are Commonly Used In Metal Lathes, And What Are Their Advantages And Disadvantages?Metal lathes use several gear setups. The most common ones are belt drives and gear trains. Belt drives are quieter and easier to change speeds. However, they can wear out faster. Gear trains are strong and good for heavy work, but they can be noisy and tough to adjust. Each type has its own uses based on what you need to do.

How Does The Choice Of Materials For Gears Affect The Durability And Efficiency Of A Metal Lathe Gear Train?The materials we choose for gears can make a big difference. Strong materials, like steel, last longer and don’t break easily. If we pick lighter materials, the gears might wear out faster. Good materials help the lathe work better and smoother. This means your projects can be done quicker and with less trouble!

What Maintenance Practices Are Essential For Ensuring Optimal Performance Of A Metal Lathe’S Gear Train?To keep your metal lathe’s gear train working well, you should do a few simple things. First, always clean it regularly to remove dirt and grime. Next, check the gears for wear and tear to catch problems early. You should also oil the gears to keep them moving smoothly. Finally, make sure all bolts and parts are tight and not loose.