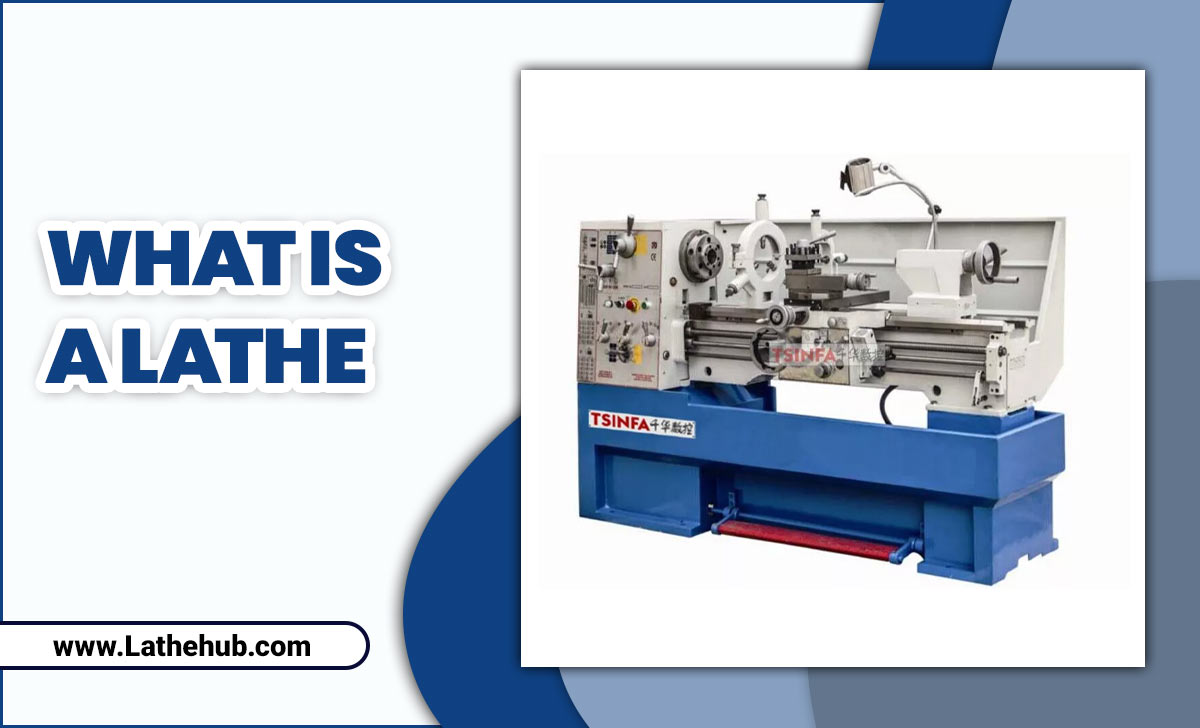

Have you ever wondered why some metal lathes work better than others? A lot of it comes down to the tailstock alignment. You might think it’s just a small part, but a misaligned tailstock can ruin your projects. What if your tool doesn’t cut straight? That could lead to mistakes and wasted materials.

Choosing the right tailstock alignment is more important than you might think. It can be the difference between a perfect piece and a complete failure. Imagine spinning a beautiful piece of wood only to see it wobble. Frustrating, isn’t it?

In this article, we’ll dive into how to choose the best metal lathe tailstock alignment. We’ll share tips that anyone can use. Whether you’re a beginner or a seasoned pro, knowing how to set up your lathe can help you create better works of art.

Did you know that even professional machinists check their alignment regularly? They know that a few small adjustments can make a big difference. Let’s explore some simple techniques to achieve perfect alignment and true your projects.

How To Choose Metal Lathe Tailstock Alignment For Precision

Choosing Metal Lathe Tailstock Alignment

Picking the right alignment for your metal lathe tailstock is crucial. It helps ensure accurate cuts and improves the quality of your work. Check for gaps by using a straightedge. Adjustments may be necessary to keep everything straight. Did you know even a small misalignment can lead to big errors? Regular checks will save you time and materials. So, take a moment to align your tailstock properly—it can make a world of difference!Types of Metal Lathes

Description of different types of metal lathes and their tailstock features.. Advantages and disadvantages of each type concerning alignment..Metal lathes come in several types. Each type has special features for the tailstock. For example, the **bench lathe** is small and perfect for light jobs. It’s easy to align but not strong enough for big projects. The **engine lathe** is more robust, great for heavy-duty tasks. But, it can be tricky to align the tailstock accurately. Last, the **CNC lathe** does the work automatically. However, it may cost more and needs tech-savvy users. Here’s a quick comparison:

| Type | Advantages | Disadvantages |

|---|---|---|

| Bench Lathe | Easy alignment | Not for heavy work |

| Engine Lathe | Strong for heavy tasks | Aligning can be tricky |

| CNC Lathe | Automatic work | Higher cost and tech skills needed |

Choosing the right lathe is like picking a pizza topping. It’s all about your taste and what you need! Remember, aligning the tailstock correctly helps make better pieces without those wobbly surprises.

Factors to Consider When Choosing a Tailstock

Key factors such as construction, material, and design that affect alignment.. Discussion on tailstock movement and its impact on precision..Choosing the right tailstock isn’t as easy as picking a favorite ice cream flavor, but it can be fun! First, look at the construction—a solid build means better alignment. Next, notice the material. Steel is sturdy, while aluminum is lighter but less tough. Then, consider the design. A good design allows easy movement, impacting precision. After all, if your tailstock goes on an unexpected adventure, your project might end up looking like modern art!

| Factor | Importance |

|---|---|

| Construction | Sturdiness for accurate alignment |

| Material | Durability vs. weight |

| Design | Facilitates smooth movement |

Tools and Techniques for Aligning the Tailstock

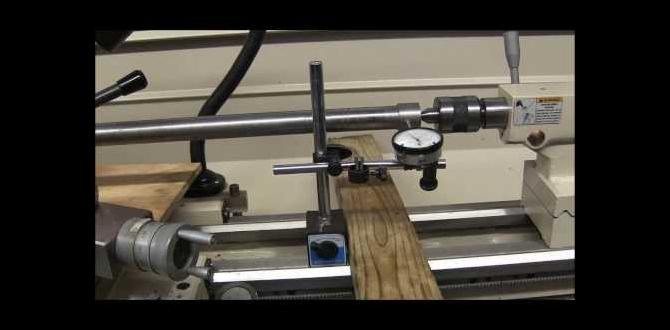

Essential tools needed for proper alignment (e.g., alignment bars, indicators).. Stepbystep techniques for achieving optimal tailstock alignment..Getting your tailstock aligned is not rocket science—more like a fun puzzle! First, grab some essential tools: alignment bars and dial indicators are your best friends here. You’ll also need a ruler for some quick measuring. Why not place a few cookies near you? That way, you can reward yourself with a treat after each step!

Now, here’s a step-by-step technique to get that tailstock just right:

| Step | Description |

|---|---|

| 1 | Secure the alignment bars in place and check their position. |

| 2 | Use the dial indicator to see if adjustments are needed. |

| 3 | Adjust the tailstock until it aligns perfectly with the bars. |

| 4 | Double-check your work for accuracy! |

And voilà, your tailstock is ready to rock! If only aligning my socks was this easy!

Common Tailstock Alignment Issues

Identification of typical issues related to tailstock misalignment.. Troubleshooting tips to rectify alignment problems effectively..Many people face issues with tailstock alignment. Common signs include uneven cuts and strange noises during operation. These problems can lead to frustration and poor results. To fix these alignment issues, remember these tips:

- Check for loose screws or bolts.

- Look for wear and tear on parts.

- Ensure the tailstock is clean and free of debris.

- Adjust the tailstock until it lines up correctly.

By identifying these typical issues and following these steps, you can improve your metal lathe’s performance.

What are common signs of tailstock misalignment?

Signs include uneven cuts, difficulties while tightening, and unusual noises.

Maintenance and Fine-tuning of the Tailstock

Routine maintenance practices for tailstock longevity.. Tips for finetuning alignment as part of regular upkeep..Taking care of your tailstock is like giving a hug to your metal lathe. Regular maintenance keeps it happy and working well. Check for loose screws and clean it often. A clean tailstock is a happy tailstock! Finetuning its alignment is important for smooth operation. Use a dial gauge to check the setup and make slight adjustments. A perfectly aligned tailstock can save you from misaligned projects. Remember, a happy tailstock makes precision easier!

| Tip | Action |

|---|---|

| Check Screws | Ensure they’re tight |

| Clean Regularly | Remove dust and chips |

| Use a Dial Gauge | Check alignment often! |

Choosing the Right Metal Lathe for Tailstock Alignment

Factors influencing the selection of a metal lathe based on alignment capabilities.. Recommendations for brands and models known for superior tailstock alignment..Choosing a metal lathe involves understanding its tailstock alignment features. The right lathe helps create accurate projects. Here are key factors to consider:

- Stability: A sturdy machine prevents wobbling during use.

- Adjustability: Look for lathes with easy alignment settings.

- Brand Reputation: Trusted brands are likely to offer quality.

Popular models known for excellent alignment include:

- Grizzly G0765: Known for its accuracy and durability.

- Jet JWL-1442: Offers great features for alignment.

- South Bend SB1002: Reliable and respected in the industry.

What factors influence metal lathe selection?

Key factors are stability, adjustability, and brand reputation. These help ensure better alignment and quality work.

Expert Recommendations and User Experiences

Insights from industry professionals regarding tailstock alignment.. User testimonials on their experiences with various tailstock alignments..Many professionals share that tailstock alignment is tricky but essential. They recommend checking the alignment regularly. A smart tip? Use a dial indicator for accuracy. Users often talk about the differences they see. One user said that better alignment made their finish smoother. Another joked, “It was like turning butter into cheese!” It’s clear that taking time to align can pay off. Here’s a quick look at some experiences:

| User | Experience |

|---|---|

| Alex | Found smoother cuts after adjusting. |

| Jamie | Alignment errors caused wasted time. |

| Chris | Happy with a simple DIY tailstock mod. |

Learning from others helps us do better, and some laughs along the way never hurt!

Conclusion

In conclusion, aligning your metal lathe tailstock is crucial for accurate work. First, check your tailstock for any damage. Next, use a dial indicator to ensure it’s straight. Adjust as needed for precision. Remember, practice makes perfect! For deeper understanding, explore more resources or guides on lathe maintenance. With these tips, you’re ready to improve your skills. Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Choosing Metal Lathe Tailstock Alignment:Sure! When you set up a metal lathe, making sure the tailstock is aligned is very important. An aligned tailstock helps you make straight cuts and keeps your work safe. To check it, you can use a piece of wood or metal as a guide. If it doesn’t match up, you can adjust it until it does! Proper alignment will make your projects look great.

Sure! I’m ready to answer your question. Please ask me what you want to know!

What Are The Key Factors To Consider When Aligning The Tailstock Of A Metal Lathe?When aligning the tailstock of a metal lathe, we need to check a few important things. First, make sure the tailstock is level with the lathe bed. Next, you should line it up with the spindle for good accuracy. Also, check that the tailstock opens and closes smoothly. Lastly, make sure it locks in place securely after adjustment.

How Can You Determine If Your Tailstock Is Properly Aligned With The Spindle?To check if your tailstock lines up with the spindle, you can use a simple method. First, put a piece of round wood (called a dowel) in the spindle and the tailstock. Then, use a pencil to trace around the dowel where it meets the wood. If the lines match up on both sides, your tailstock is aligned correctly. If not, you may need to adjust it until the lines meet perfectly.

What Tools Or Gauges Are Recommended For Checking Tailstock Alignment On A Metal Lathe?To check tailstock alignment on a metal lathe, you can use a few simple tools. A dial indicator is helpful because it shows tiny changes. You can also use a test rod, which is a straight bar that fits in the tailstock. Some people like to use a combination square for measuring angles. All these tools help make sure everything is straight and works well!

How Does Misalignment Of The Tailstock Affect Machining Accuracy And The Quality Of The Finished Part?When the tailstock is misaligned, it can cause problems while we work. The part may wobble or not fit correctly. This means the pieces we make might not be the right size or shape. So, our finished parts won’t look good or work well. We need everything lined up properly for the best results.

What Are Common Signs That Indicate Your Metal Lathe’S Tailstock Needs To Be Realigned?If your metal lathe’s tailstock needs realignment, you might notice a few signs. First, your cuts might be uneven. Second, your workpiece could wobble or shake. Third, you may find that your drills don’t go straight. Lastly, check for unusual wear on your tools. These all mean it’s time to fix the tailstock!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Choosing Metal Lathe Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you set up a metal lathe, making sure the tailstock is aligned is very important. An aligned tailstock helps you make straight cuts and keeps your work safe. To check it, you can use a piece of wood or metal as a guide. If it doesn’t match up, you can adjust it until it does! Proper alignment will make your projects look great.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! I’m ready to answer your question. Please ask me what you want to know!”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Aligning The Tailstock Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When aligning the tailstock of a metal lathe, we need to check a few important things. First, make sure the tailstock is level with the lathe bed. Next, you should line it up with the spindle for good accuracy. Also, check that the tailstock opens and closes smoothly. Lastly, make sure it locks in place securely after adjustment.”}},{“@type”: “Question”,”name”: “How Can You Determine If Your Tailstock Is Properly Aligned With The Spindle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if your tailstock lines up with the spindle, you can use a simple method. First, put a piece of round wood (called a dowel) in the spindle and the tailstock. Then, use a pencil to trace around the dowel where it meets the wood. If the lines match up on both sides, your tailstock is aligned correctly. If not, you may need to adjust it until the lines meet perfectly.”}},{“@type”: “Question”,”name”: “What Tools Or Gauges Are Recommended For Checking Tailstock Alignment On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check tailstock alignment on a metal lathe, you can use a few simple tools. A dial indicator is helpful because it shows tiny changes. You can also use a test rod, which is a straight bar that fits in the tailstock. Some people like to use a combination square for measuring angles. All these tools help make sure everything is straight and works well!”}},{“@type”: “Question”,”name”: “How Does Misalignment Of The Tailstock Affect Machining Accuracy And The Quality Of The Finished Part?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the tailstock is misaligned, it can cause problems while we work. The part may wobble or not fit correctly. This means the pieces we make might not be the right size or shape. So, our finished parts won’t look good or work well. We need everything lined up properly for the best results.”}},{“@type”: “Question”,”name”: “What Are Common Signs That Indicate Your Metal Lathe’S Tailstock Needs To Be Realigned?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe’s tailstock needs realignment, you might notice a few signs. First, your cuts might be uneven. Second, your workpiece could wobble or shake. Third, you may find that your drills don’t go straight. Lastly, check for unusual wear on your tools. These all mean it’s time to fix the tailstock!”}}]}