Do you love making cool things with a metal lathe? If you do, then you know how important it is to have the right tools. One of those tools is the threading dial. But how do you choose the best one?

Imagine you are working on a project. You want to create a perfect thread, but your dial isn’t right. Frustrating, right? Picking the right threading dial can save you time and keep your project on track.

Learning how to choose a metal lathe threading dial can make a big difference. A good dial helps you measure threads easily. But with so many options out there, where do you start? Let’s dive into some simple tips!

Did you know that the right threading dial can improve accuracy? When you have the right tool, you can work faster and make fewer mistakes. This article will help guide you through the selection process. Ready to become a metal lathe pro?

How To Choose Metal Lathe Threading Dial For Precision Use

How to Choose Metal Lathe Threading Dial

Selecting the right metal lathe threading dial can greatly improve your projects. A good dial should be easy to read and accurate. Look for a dial that fits your lathe’s specifications. Did you know that a precise threading dial can save you time and prevent mistakes? Choose a sturdy material for durability. Consider your experience level as well. Whether you’re a beginner or an expert, the right dial can make all the difference in your work.Understanding Threading Dials

Definition and purpose of a threading dial in metal lathes. Importance of precision in threading operations.A threading dial is a small but mighty tool on a metal lathe. It helps you line up your cuts for threading. This means you can make screw-like shapes with great precision. Why does precision matter? Well, without it, your threads might not fit together. Imagine trying to screw in a bolt and it’s just a tad too big. Oops! That’s a faux pas in metalworking. Precision ensures a snug fit every time, and you’ll be turning out pieces that fit just right. And let’s be honest, who doesn’t want to look like a threading wizard?

| Purpose of Threading Dial | Importance of Precision |

|---|---|

| Aligns cuts | Fit ensures quality |

| Helps create threads | Reduces errors |

Key Features to Consider

Accuracy and calibration of the threading dial. Material and durability factors affecting performance.Choosing the perfect threading dial isn’t just a spin of the wheel! First, look for accuracy. A dial that calibrates well ensures your threads fit perfectly. Imagine trying to screw a lid on a jar that just won’t budge! Next, consider the material. Tough materials mean the dial can survive the test of time and the occasional accidental drop—because, let’s be honest, who hasn’t knocked something off their workbench? Finally, make sure it can withstand the wear and tear of daily use. After all, your projects deserve the best!

| Feature | Importance |

|---|---|

| Accuracy | Affects the precision of your threads |

| Durability | Ensures longevity and reliability |

Compatibility with Your Lathe

Factors to ensure compatibility with existing lathes. Common brands and models with threading dial options.Choosing a threading dial that fits your lathe is crucial. Compatibility is key to success. First, check your lathe model. Does it have a threading dial? Look for options that match common brands like Grizzly and Jet. They often offer threading dials as accessories. Also, consider size and mounting style to ensure a perfect fit. Remember, fitting parts and fun go hand in hand, but nobody wants a jigsaw puzzle instead of a lathe!

| Brand | Model | Threading Dial Options |

|---|---|---|

| Grizzly | G4003G | Yes |

| Jet | JWL-1442VSK | Yes |

| ModA | M300 | No |

Budget Considerations

Price range for different types of threading dials. Tips for balancing quality and cost.Buying a threading dial can feel like choosing a snack in a candy store! Prices vary widely. You can find basic models for around $50, while fancy ones may reach $300 or more. Remember, quality matters. A durable dial can save you money in the long run. Look for features that suit your needs without going overboard.

| Type of Dial | Price Range |

|---|---|

| Basic | $50 – $100 |

| Mid-range | $100 – $200 |

| High-end | $200 – $300+ |

Keep in mind, spending a little more can bring big benefits. So, don’t let a tight budget keep you from getting the right threading dial!

Installation and Maintenance

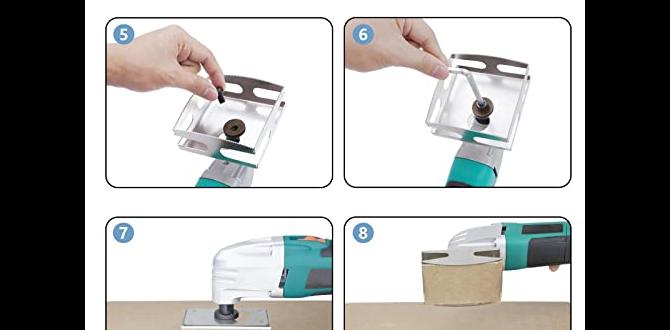

Stepbystep guide on installing a threading dial. Best practices for maintaining and calibrating for optimal performance.Setting up a threading dial is simple but important. Follow these steps for a smooth install:

- Check the manual for your lathe model.

- Clean the working area before starting.

- Align the dial with the threading tool.

- Secure the dial tightly to prevent movement.

To keep your threading dial in great shape:

- Regularly clean it to avoid dirt buildup.

- Check the calibration often to ensure accuracy.

- Replace worn parts to maintain performance.

Maintaining your tooling can help you work better and enjoy your projects!

How do I maintain my metal lathe threading dial?

For lasting performance, clean it regularly. Check its settings to ensure everything aligns perfectly. If something seems off, recalibrate. This keeps your work precise! Try setting a schedule to do maintenance.

Common Issues and Solutions

Typical problems encountered with threading dials. Troubleshooting tips and maintenance advice.Using a threading dial can sometimes feel like a comedy show, with its share of mishaps! You might face issues like misalignment, affecting your cuts. To tackle this, always check if the dial is properly calibrated. Another common problem is wear and tear. Regular cleaning can help, and remember, grease isn’t just for old machines—it keeps your threading dial smooth! If things still go wacky, consult the manual or ask a buddy. After all, teamwork makes the dream work!

| Issue | Solution |

|---|---|

| Misalignment | Check calibration and adjust as needed. |

| Wear and Tear | Regular cleaning and lubrication are key. |

| Dial Sticking | Inspect and replace springs if necessary. |

User Reviews and Recommendations

Summary of toprated threading dials based on user feedback. Expert recommendations for different user needs and applications.User feedback often guides choices for threading dials. Many users praise certain brands for their accuracy and ease of use. Reviews address different needs, like hobbyists or professionals. Top-rated options include:

- Brand A: Known for precision.

- Brand B: Best for beginners.

- Brand C: Offers advanced features.

Experts recommend selecting based on your work type. Some suggest Brand A for detailed projects, while Brand B suits light tasks. Choose wisely for your needs!

What do users say about threading dials?

Users often mention ease of setup and accuracy in reviews. Many enjoy how smooth the dials turn. Happy users say that a good threading dial makes their work easier.

Conclusion

In summary, choosing a metal lathe threading dial involves understanding its features and how it fits your projects. Look for accuracy, durability, and ease of use. Consider your specific needs and budget. To learn more, explore guides or ask experienced users. With the right threading dial, you can create amazing projects and improve your skills. Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Choosing A Metal Lathe Threading Dial:Sure! When you choose a metal lathe threading dial, look for one that is easy to read and use. Check if it fits your lathe model. You want it to help you make good threads on the metal. Good quality will last a long time. Always ask for advice from someone who knows about lathes.

Sure! Please provide the question you’d like me to answer.

What Features Should I Look For In A High-Quality Metal Lathe Threading Dial?When looking for a good metal lathe threading dial, you should check if the numbers are clear and easy to read. A smooth turning dial is important, so it should move easily. Make sure it fits well on your lathe. You also want it to be strong and last a long time. Finally, reviews from other users can help you decide if it’s worth buying.

How Does The Design Of A Threading Dial Affect Threading Accuracy And Ease Of Use?The threading dial is a tool that helps you make threads on a machine. A good design means you can see the numbers easily. This helps you get the right spot more accurately. When it’s easy to use, you can make threads faster without mistakes. So, the design makes threading better and simpler!

Are There Specific Brands Or Models Of Threading Dials That Are Recommended For Beginners?Yes, there are good brands of threading dials for beginners. You might like the “Brother” or “Janome” brands. They make easy-to-use machines. Look for models that have clear instructions and good reviews. This will help you learn faster and enjoy sewing!

How Do I Determine The Compatibility Of A Threading Dial With My Existing Metal Lathe?To see if a threading dial works with your lathe, check the brand and model numbers. You can look in your lathe manual or online for the right match. Next, measure the size of your lathe’s threading area and compare it with the threading dial. Finally, ask a store expert or look for reviews online to make sure it fits well.

What Materials Are The Best For A Threading Dial To Ensure Durability And Precision?For a threading dial, good materials are important for it to last long and work well. Metal like steel is strong and precise. Plastic can also be used, but it should be tough so it doesn’t break easily. Using these materials helps the dial stay accurate while you work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Choosing A Metal Lathe Threading Dial:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you choose a metal lathe threading dial, look for one that is easy to read and use. Check if it fits your lathe model. You want it to help you make good threads on the metal. Good quality will last a long time. Always ask for advice from someone who knows about lathes.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Features Should I Look For In A High-Quality Metal Lathe Threading Dial?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When looking for a good metal lathe threading dial, you should check if the numbers are clear and easy to read. A smooth turning dial is important, so it should move easily. Make sure it fits well on your lathe. You also want it to be strong and last a long time. Finally, reviews from other users can help you decide if it’s worth buying.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Threading Dial Affect Threading Accuracy And Ease Of Use?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial is a tool that helps you make threads on a machine. A good design means you can see the numbers easily. This helps you get the right spot more accurately. When it’s easy to use, you can make threads faster without mistakes. So, the design makes threading better and simpler!”}},{“@type”: “Question”,”name”: “Are There Specific Brands Or Models Of Threading Dials That Are Recommended For Beginners?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are good brands of threading dials for beginners. You might like the Brother or Janome brands. They make easy-to-use machines. Look for models that have clear instructions and good reviews. This will help you learn faster and enjoy sewing!”}},{“@type”: “Question”,”name”: “How Do I Determine The Compatibility Of A Threading Dial With My Existing Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To see if a threading dial works with your lathe, check the brand and model numbers. You can look in your lathe manual or online for the right match. Next, measure the size of your lathe’s threading area and compare it with the threading dial. Finally, ask a store expert or look for reviews online to make sure it fits well.”}},{“@type”: “Question”,”name”: “What Materials Are The Best For A Threading Dial To Ensure Durability And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a threading dial, good materials are important for it to last long and work well. Metal like steel is strong and precise. Plastic can also be used, but it should be tough so it doesn’t break easily. Using these materials helps the dial stay accurate while you work.”}}]}