Choosing the right wiring diagram for your metal lathe can feel overwhelming. Have you ever looked at a diagram and thought, “Where do I even start?” You’re not alone! Many people face this challenge when they delve into metal lathes.

The good news is that understanding how to choose the right metal lathe wiring diagram doesn’t have to be hard. It’s like figuring out a treasure map. You only need to know where to look!

Did you know that the wrong wiring can ruin your machine? A simple mistake can lead to costly repairs. That’s why picking the right diagram is so important. Think of it as ensuring your journey is safe and smooth.

In this article, we will help you navigate this maze. We will show you easy steps to pick the right wiring diagram for your metal lathe. So, let’s dive in and make this process exciting!

How To Choose Metal Lathe Wiring Diagram Effectively

How to Choose Metal Lathe Wiring Diagram

Choosing the right metal lathe wiring diagram is crucial for safe and efficient operation. Start by understanding your lathe’s specifications and power requirements. Consider wire gauge and circuit type, as these affect performance. Did you know a mistake in wiring can lead to serious accidents? Always refer to diagrams that match your lathe model for accuracy. With the right wiring, you’ll enjoy smooth operations and long-lasting results. Keep safety in mind!Understanding Metal Lathe Basics

Definition and purpose of a metal lathe. Key components of metal lathes that require wiring.A metal lathe is a machine that shapes metal. It spins the metal while a cutting tool removes material. This helps create items like parts for machines or tools. Key parts of a metal lathe that need wiring include:

- Motor: Drives the lathe and powers the spinning.

- Control Panel: Lets you manage speed and settings.

- Power Supply: Provides electricity to the lathe.

Understanding these basics helps you choose the right metal lathe wiring diagram.

What should I look for in a metal lathe?

Look for size, features, and price. Ensure it meets your project needs!

Importance of Wiring Diagrams

Role of wiring diagrams in metal lathe installation. Benefits of using a clear wiring diagram.Wiring diagrams are like maps for your metal lathe. They show how to connect wires and parts. This helps the user avoid mistakes. Clear wiring diagrams make setup easy. They save time and reduce confusion. Here are some benefits:

- Clarity: Easy to follow steps.

- Safety: Reduces risk of faulty connections.

- Efficiency: Speeds up the installation process.

With a good diagram, you can build your lathe correctly and start working faster!

Why are wiring diagrams important for metal lathe installation?

Wiring diagrams help you see where each wire goes. They keep things organized during setup. Without them, you might connect wires wrongly, causing problems.

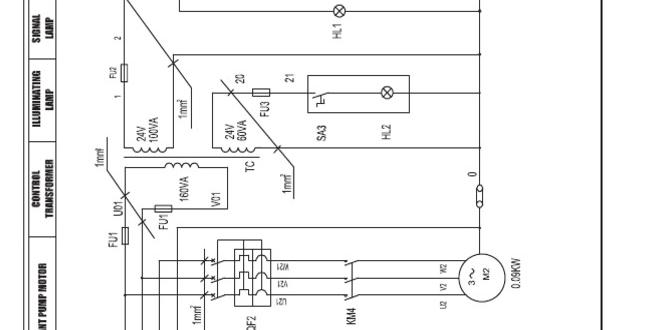

Essential Components of a Wiring Diagram

Common symbols used in wiring diagrams. Key components to include in your wiring diagram.Wiring diagrams are like treasure maps for electricians! They use common symbols to show connections. Wires are straight lines, while points where connections happen are often circles. It’s essential to include components like power sources, switches, and motors in your diagram to keep everything clear. Let’s add some humor to spice it up—imagine a wire trying to connect but getting tangled! Here’s a quick view of typical symbols:

| Component | Symbol |

|---|---|

| Wire | — |

| Connection Point | ● |

| Power Source | ⬆️ |

| Switch | 🔄 |

| Motor | ⚙️ |

Knowing these symbols and components makes your wiring diagram easier to read. You’ll be the wiring wizard in no time!

Choosing the Right Wiring Diagram for Your Lathe

Factors to consider (lathe model, power source, safety features). Resources for finding reliable wiring diagrams.Finding a wiring diagram for your lathe can feel like searching for a needle in a haystack. First, consider your lathe model. Not all lathes are created equal! Next, think about your power source. Is it compatible with your diagram? Lastly, check for safety features. You want to avoid zapping yourself! Reliable diagrams can often be found in user manuals or trusted websites. Don’t forget to double-check before you connect those wires! Remember, safety first—or you might end up with a shocking experience!

| Factor | Importance |

|---|---|

| Lathe Model | Ensures compatibility |

| Power Source | Prevents electrical mismatches |

| Safety Features | Protects you from electrical hazards |

Common Wiring Mistakes to Avoid

Typical errors in wiring a metal lathe. How to troubleshoot wiring issues effectively.Wiring a metal lathe can be tricky. Many people make mistakes that can lead to problems. Common errors include:

- Wrong wire connections. Always check the color codes.

- Loose connections. Tighten screws firmly to avoid sparks.

- Neglecting to follow the diagram. Keep it nearby for reference.

If you face issues, troubleshoot by:

- Testing the power supply.

- Checking each connection.

- Using a multimeter to find errors.

Small mistakes can cause big problems. Take your time and follow the wiring diagram carefully.

What are typical wiring mistakes in a metal lathe?

Typical wiring mistakes include incorrect connections, loose wires, and ignoring the wiring diagram.

How can I troubleshoot wiring issues effectively?

To troubleshoot, check the power source, inspect connections, and use a multimeter for testing.

Safety Considerations When Wiring a Metal Lathe

Important safety practices to follow. Protective equipment and tools recommended.Wiring a metal lathe can be fun but also risky. Always put safety first. Here are some important safety practices:

- Wear safety glasses to protect your eyes.

- Use gloves to avoid cuts and scrapes.

- Keep tools organized and within reach.

- Ensure the lathe is unplugged before wiring.

Use these protective items to stay safe:

- Hard hat for head protection.

- Steel-toed boots to shield your feet.

- Dust mask to avoid breathing in debris.

Stay safe and enjoy the work!

What should I wear while wiring a metal lathe?

You should wear safety glasses and gloves for protection. Soft clothes can get caught, so wear fitted gear. Steel-toed boots can protect your feet too.

Expert Tips for DIY Metal Lathe Wiring

Stepbystep approach for wiring a metal lathe from scratch. Best practices and tools needed for a successful wiring project.Wiring a metal lathe can be simple with the right steps. Begin with a clear plan using a wiring diagram. Gather essential tools like wire strippers, a multimeter, and electrical tape. Follow these best practices:

- Read the manual for safety instructions.

- Organize wires to avoid confusion.

- Double-check connections to prevent shorts.

This approach helps ensure a smooth wiring process. Patience and attention to detail lead to a successful project.

What tools do you need for wiring a metal lathe?

You need wire strippers, a multimeter, electrical tape, and a screwdriver.Conclusion

In conclusion, choosing a metal lathe wiring diagram requires understanding your lathe model and power requirements. Make sure to gather all necessary tools and materials. Always prioritize safety by following proper procedures. For deeper insights, we recommend reading specialized guides or watching instructional videos. Taking these steps will help you wire your metal lathe confidently and effectively.FAQs

Certainly! Here Are Five Related Questions On The Topic Of Choosing A Wiring Diagram For A Metal Lathe:Sure! When choosing a wiring diagram for a metal lathe, first think about your machine’s power needs. You need to know how much electricity it takes to run. Next, find a diagram that matches your lathe’s model. This helps ensure everything is connected correctly. Finally, always double-check your work before you turn it on for safety!

Sure! Please provide the question you’d like me to answer.

What Are The Essential Electrical Specifications To Consider When Selecting A Wiring Diagram For A Metal Lathe?When choosing a wiring diagram for a metal lathe, you need to check a few key things. First, look for the voltage, which is how strong the electricity is. Most lathes use 120V or 240V. Next, check the amperage, which shows how much electricity the lathe uses. Lastly, make sure the wiring can handle the load safely. This keeps everything running smoothly and safely!

How Can I Determine The Voltage Requirements Of My Metal Lathe To Find The Appropriate Wiring Diagram?To find out the voltage needs of your metal lathe, check the label on the motor. It usually says what voltage you need. If there’s no label, look in the user manual. You can also ask the manufacturer for help. This way, you’ll know the right wiring diagram to use.

What Safety Features Should Be Included In A Wiring Diagram For A Metal Lathe?A wiring diagram for a metal lathe should include a few important safety features. First, it should show an emergency stop button. This button lets you turn off the machine quickly if something goes wrong. Second, there should be circuit breakers to prevent overloads. These help protect you and the machine from electrical problems. Lastly, it should clearly show proper grounding to prevent shocks.

Are There Standard Wiring Diagrams Available For Popular Metal Lathe Models, And Where Can I Find Them?Yes, there are standard wiring diagrams for many popular metal lathes. You can usually find them in the owner’s manual that comes with the lathe. If you don’t have the manual, search online. Websites for the manufacturers or user groups often share these diagrams. Remember to look for the specific model of your lathe!

How Can I Modify An Existing Wiring Diagram To Accommodate Aftermarket Components Or Upgrades On My Metal Lathe?To modify a wiring diagram for your metal lathe, start by identifying the new parts you’re adding. Check their instructions for how they connect. Next, draw lines on your diagram to show how the wires will connect to these parts. You may need to remove old parts and add the new ones in the right places. Remember to be careful and double-check everything before you connect the power!