Have you ever started a woodworking project only to find your pieces don’t fit together? It can be frustrating. One common reason for this trouble is wood lathe runout. You might wonder, what is runout? And how do you measure it?

Picture this: you’re spinning a piece of wood on your lathe, but it wobbles instead of turning smoothly. This wobbling can affect the quality of your work. Measuring wood lathe runout is key to keeping your projects at their best.

Did you know even a tiny amount of runout can lead to big problems? It might seem small, but it can ruin your design. Knowing how to measure wood lathe runout can save you time and effort. Plus, it ensures your work is precise and clean.

In this article, we’ll explore easy methods to measure runout. You’ll discover simple tools and techniques. By the end, you’ll feel confident checking your lathe. Ready to improve your woodworking skills? Let’s dive in!

How To Measure Wood Lathe Runout: A Comprehensive Guide

Understanding how to measure wood lathe runout is essential for woodturners. Runout refers to how much the workpiece wobbles as it spins. Learning to measure this helps ensure accurate cuts and smooth finishes. A simple method involves using a dial indicator, which measures slight movements. Noticing excessive runout could spark curiosity about your lathe’s setup. Proper alignment can improve your projects, making your woodworking journey even more enjoyable!

Understanding Lathe Runout

Definition of runout and its importance. Types of runout: axial vs. radial.

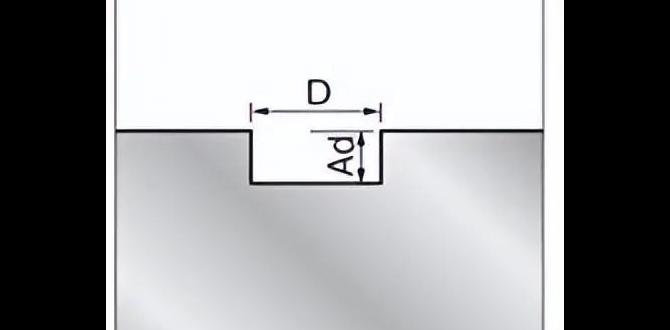

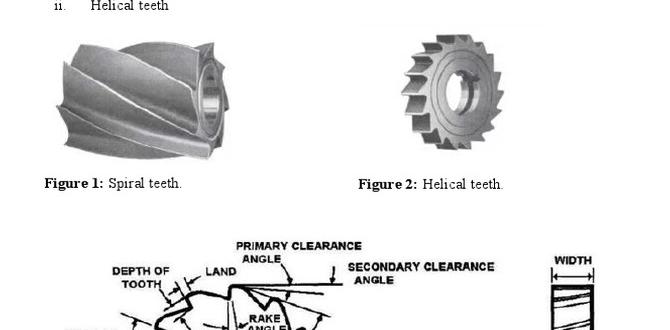

Runout is a measure of how much a spinning part wobbles. This is important because too much runout can cause uneven cuts and bad finishes. There are two types of runout: axial and radial. Axial runout happens along the length of the lathe. Radial runout is side-to-side. Both affect the quality of your work. Understanding these types helps you fix issues quickly.

What is the impact of lathe runout?

Lathe runout can create unsatisfactory work and waste materials. A good lathe setup reduces errors and improves results.

Types of Runout

- Axial Runout: Wobble along the length

- Radial Runout: Wobble side-to-side

Tools Needed for Measuring Runout

List of essential measuring tools. Recommendations for highquality tools.

To measure wood lathe runout, you’ll need specific tools. Here’s a list of essential items:

- Dial Indicator: This tool shows tiny changes in position.

- Magnetic Base: It holds the dial indicator in place firmly.

- Calipers: Use these for precise measurements.

- Straightedge: Great for finding flat spots on wood.

For quality, consider brands like Starrett or Mitutoyo. They are reliable and last long. With these tools, you can easily check runout.

What tools do I need to measure wood lathe runout?

You will need a dial indicator, magnetic base, calipers, and straightedge to measure wood lathe runout effectively.

Preparing Your Lathe for Measurement

Steps to ensure lathe stability and setup. Importance of clean work surfaces and tool maintenance.

Before diving into measurement, ensure your lathe is stable. Check its legs, as wobbly lathes can lead to wonky measurements. Give your work surface a nice clean sweep. Dust and debris can be sneak thieves, stealing accuracy from your work. Don’t forget tool maintenance—sharp tools are happy tools! Here’s a quick checklist:

| Task | Status |

|---|---|

| Check lathe stability | ✔️ Done! |

| Clean work surface | ✔️ Sparkling! |

| Inspect tools | ✔️ Sharper than a tack! |

Following these steps will set you up for success! Remember, a prepared lathe is a happy lathe, and happiness leads to precision.

Measuring Radial Runout

Stepbystep instructions for measuring radial runout. Tips for obtaining accurate readings.

Measuring radial runout helps to check how true a lathe spins. Follow these steps for accurate results:

- Start by turning on your lathe at a low speed.

- Place a dial indicator against the workpiece surface.

- Spin the workpiece and watch the indicator’s needle for movement.

- Record the highest and lowest readings.

For the best accuracy, make sure:

- The dial indicator is properly zeroed.

- The workpiece is securely mounted.

- The lathe is leveled before starting.

Measure around the piece at different spots. This ensures no hidden issues.

How can I get the best readings?

To get the most accurate readings, check your setup. Ensure good lighting and keep your hands steady.

Tips include:

- Use a magnetic base for the dial indicator.

- Measure at several points around the workpiece.

- Maintain a slow and steady speed while spinning.

Measuring Axial Runout

Detailed process for checking axial runout. Methods to confirm measurements’ reliability.

To check axial runout, start by placing a dial indicator on the lathe’s spindle. Gently spin the spindle and watch the indicator’s readings. If the needle jumps around like it’s doing a happy dance, there’s runout! Measure at different points for accuracy. To confirm your findings, repeat the process. Doing it multiple times ensures you’re not just imagining things or talking to your wood chips.

| Method | Description |

|---|---|

| Dials Up! | Use a dial indicator to check the spindle. |

| Spin It! | Gently rotate the spindle for steady readings. |

| Repeat, Repeat! | Measure several times for reliability. |

Keep it light and fun, just like your wood shavings!

Interpreting Runout Results

Understanding acceptable runout limits. What the results mean for your projects.

Runout shows how off-center a wood lathe might be. Understanding the numbers is important. Acceptable limits are usually very low, often less than 0.002 inches. If you see higher numbers, think about how it affects your project. A high runout can lead to uneven cuts, ruining your woodwork. Here’s what different results mean:

- **0.001 – 0.002 inches**: Great for fine work.

- **0.003 – 0.005 inches**: Acceptable for general projects.

- **0.006 inches or more**: Needs adjustment; may cause problems.

What does runout mean for your projects?

High runout affects the quality of your work. It can cause vibration and rough surfaces. Lower runout offers smoother results. Always check your lathe before starting a new project.

Adjusting Your Lathe to Reduce Runout

Common adjustments to improve accuracy. Troubleshooting tips for persistent runout issues.

To make your lathe more accurate, try these common adjustments:

- Check the tailstock and headstock alignment.

- Ensure the spindle is securely tightened.

- Inspect the drive belt for wear or looseness.

If runout issues persist, follow these troubleshooting tips:

- Clean the spindle and chuck to remove debris.

- Check for worn bearings or parts needing replacement.

Regular checks can help your lathe perform better and create great projects!

How do I reduce wood lathe runout?

You can reduce wood lathe runout by checking the alignment of all parts. Make sure everything is tight and clean. Regular maintenance helps keep your lathe in top shape.

Preventive Measures to Maintain Runout Standards

Regular maintenance practices for your lathe. Best practices for storage and handling of tools.

Keeping your wood lathe in tip-top shape is essential for smooth turning. Regular maintenance is key. Always clean your lathe after each use. Dust and wood shavings can create problems. Check the belt tension and replace it if it’s worn. Store your tools in a dry place, away from moisture. This prevents rust. Remember, a happy lathe makes happy wood! Below are some easy tips:

| Practice | Description |

|---|---|

| Regular cleaning | Wipe down after use to avoid buildup. |

| Inspect belts | Change them if they show wear and tear. |

| Proper storage | Keep tools dry to stop rust. |

These simple steps can help you maintain runout standards with ease. And hey, even a lathe deserves a little TLC!

Conclusion

In summary, measuring wood lathe runout helps us ensure accuracy and precision. You can use a dial indicator or feeler gauge for this task. Remember to check both ends of the spindle for the best results. By understanding how to reduce runout, you can improve your woodworking projects. Keep experimenting and consider reading more about lathe maintenance!

FAQs

What Tools Are Needed To Measure Runout On A Wood Lathe?

To measure runout on a wood lathe, you need a few simple tools. First, you can use a dial indicator. This tool helps you see if the wood is perfectly round. You may also need a mounting bracket to hold the dial indicator in place. Finally, remember to have a ruler or caliper for extra measurements.

How Do You Determine If The Runout Is Within Acceptable Limits For Your Turning Project?

To check if the runout is okay, you first measure it using a special tool called a dial indicator. Place the tool against the spinning part. Then, watch the needle move. If it doesn’t move too much, the runout is good. If it shakes a lot, you might need to fix it.

What Steps Should Be Followed To Accurately Measure The Runout On The Spindle Of A Wood Lathe?

To measure the runout on the spindle of a wood lathe, first, gather a dial indicator. This tool helps us see tiny movements. Next, attach the dial indicator to the lathe. Then, spin the spindle and watch the dial. If the needle moves, there is some runout, which means the spindle isn’t perfectly straight.

How Can I Reduce Or Eliminate Runout On My Wood Lathe?

To reduce or eliminate runout on your wood lathe, you should first check the spindle. Make sure it’s straight and not damaged. Next, tighten the chuck and ensure it holds your wood firmly. You can also use a good alignment tool to help position your workpiece correctly. Finally, balance your wood by making sure it’s even all around. This will help it spin better!

What Are Some Common Causes Of Runout In Wood Lathes, And How Can They Be Diagnosed?

Runout in wood lathes can happen for a few reasons. One common cause is if the wood piece isn’t put in straight. Another reason is if the machine isn’t aligned properly. You can check for runout by using a dial gauge, which shows if the wood wobbles. If you notice any wobbling, adjust your setup to fix it.