Have you ever wondered how shiny some metal pieces look? It’s not just magic; it’s a process! If you want to learn how to polish metal on a lathe, you’ve come to the right place.

Picture this: a dull, rough metal part slowly transforming into a smooth, shiny masterpiece. It feels satisfying, doesn’t it? Polishing metal can breathe new life into old items. But how exactly does one achieve that sleek finish? Let’s dive into the world of lathes and polishing.

Imagine turning a simple block of metal on a lathe. As the machine spins, you can refine its shape. But there’s more! With the right technique, you can also polish it to perfection. Why settle for ordinary when you can create something extraordinary?

In this article, we will explore the steps to polish metal on a lathe. You will gain useful tips and tricks that make the process easier. So, get ready to shine as we journey through each step of this intriguing craft!

How To Polish Metal On A Lathe: Step-By-Step Guide

How to Polish Metal on a Lathe

Polishing metal on a lathe can transform dull pieces into shining treasures! Start by choosing the right polishing compound for your metal type. Secure your workpiece tightly on the lathe. As you spin the metal, apply the compound gently with a soft cloth or buffing wheel. Did you know that using the correct speed can prevent overheating? With patience and practice, you’ll learn to achieve a brilliant, smooth finish that makes your projects stand out.Understanding Metal Polishing

Definition and importance of metal polishing.. Different types of metals that can be polished on a lathe..Metal polishing makes metal shiny and smooth. It’s like giving your favorite spoon a sparkling bath! Polishing helps remove dirt, scratches, and rust. Different metals can be polished, each shining in its own way. For example, aluminum gleams nicely, while brass shines golden. Here’s a quick look:

| Type of Metal | Polishing Result |

|---|---|

| Aluminum | Bright and shiny |

| Brass | Golden glow |

| Stainless Steel | Mirror finish |

| Bronze | Warm luster |

Polishing on a lathe keeps your projects looking top-notch. Who doesn’t love a shiny metal masterpiece?

Essential Tools and Equipment

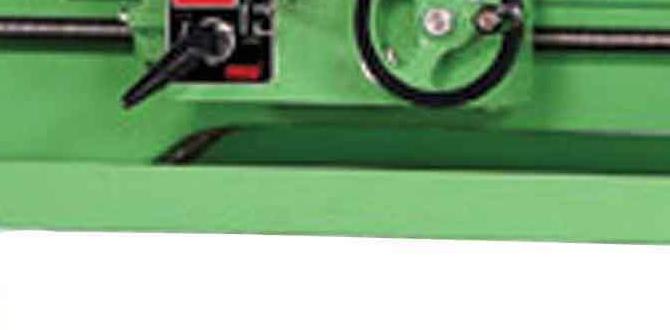

List of tools required for polishing on a lathe.. Recommended materials for polishing (e.g., polishing compounds, buffing wheels)..To polish metal like a pro, you need some handy tools. First up is a lathe, your trusty sidekick. Then grab some buffing wheels for that extra shine! Don’t forget the polishing compounds, which are like magic potions for metal. Your toolbox should look like a treasure chest, filled with goodies!

| Tool | Purpose |

|---|---|

| Lathe | Holds and spins the metal |

| Buffing Wheels | Polishes and smooths surfaces |

| Polishing Compounds | Adds shine and removes scratches |

With these tools, you’re ready to make metal sparkle! Remember, polishing is like giving your metal a spa day. Who wouldn’t want that?

Preparing the Metal Workpiece

Steps to clean and prepare the metal for polishing.. Safety measures to consider before starting the polishing process..Before diving into polishing, it’s important to prepare your metal workpiece. First, give it a good scrub! Use soap and water to wipe off dirt and grease. Dry it well to prevent rust. Next, check for sharp edges; we don’t want any surprise cuts! Safety glasses and gloves are your best pals here. They’ll keep you safe while you’re polishing. Remember, safety first or you might turn into a sad story!

| Preparation Steps | Safety Measures |

|---|---|

| Clean the metal | Wear safety glasses |

| Dry it completely | Use gloves |

| Check for sharp edges | Keep a first-aid kit nearby |

Setting Up the Lathe for Polishing

Adjusting the lathe speed for optimal polishing results.. Importance of proper lathe setup to avoid damage to the workpiece..Before you start polishing, make sure to adjust the lathe speed just right. Too fast, and your metal might fly off like a superhero! Too slow, and you’ll be there forever, daydreaming. Proper speed helps achieve a smooth finish without damaging your workpiece. Think of it as Goldilocks: not too fast, not too slow, but *just right*. Here’s a handy table to guide you:

| Speed (RPM) | Material Type | Result |

|---|---|---|

| 1000 | Aluminum | Shiny and bright |

| 500 | Steel | Smooth and sleek |

| 300 | Brass | Like new! |

Getting this setup right is key. A proper lathe setup helps avoid any damage, saving you from a very expensive metal frisbee! Always double-check your settings and protect your project. Happy polishing!

Polishing Techniques on a Lathe

Detailed explanation of effective polishing techniques.. Common mistakes to avoid during the polishing process..Polishing on a lathe can turn dull metal into shiny treasures. First, use the right polishing compound for each type of metal. Rubbing too hard can lead to scratches, so it’s important to glide smoothly! A soft cloth or buffing wheel will help bring out the shine. Common mistakes? Forgetting to check the speed of your lathe can ruin your work. Always start slow and gradually increase speed. Too fast? You might just turn your masterpiece into confetti!

| Common Mistakes | How to Avoid Them |

|---|---|

| Using the wrong compound | Match the compound with the metal type |

| Polishing too aggressively | Apply light pressure and use smooth motions |

| Ignoring lathe speed | Start slow and adjust speed gradually |

Post-Polishing Care and Maintenance

How to clean the workpiece after polishing.. Tips for maintaining the polished finish over time..After polishing, it’s important to keep your workpiece shining like a star! First, clean it gently to remove any polishing compound. A soft cloth works wonders. To keep that polished finish sparkling, try using a spray wax. It’s like sunscreen for metal – protects it from rust and dirt. And remember, store your metal in a dry place to avoid embarrassing rust spots. No one wants their nice shine to turn into a sad brown!

| Cleaning Steps | Tips for Maintenance |

|---|---|

| 1. Wipe with a soft cloth. | Use spray wax regularly. |

| 2. Rinse gently if needed. | Store in a dry environment. |

| 3. Avoid harsh chemicals. | Keep away from humidity. |

Troubleshooting Common Issues

Identifying and resolving issues encountered while polishing on a lathe.. How to diagnose and fix problems with the polishing tool or technique..Sometimes, you might notice your metal polish isn’t looking shiny, but don’t panic! First, check if your lathe speed is too slow; it might need a little *zoom* to shine. If the polishing tool leaves scratches, it might need a clean. Dust can be sneaky, like a ninja! Adjust your pressure too; too much can ruin the smooth look. And if you hear funny noises, find out what that is before your lathe starts a rock band. Below is a handy table to help you spot issues and their fixes:

| Issue | Solution |

|---|---|

| Scratches on metal | Clean the tool and adjust pressure. |

| Dim shine | Increase lathe speed. |

| Strange noises | Check for loose parts or debris. |

Remember, polishing on a lathe is all about practice. Like baking cookies, a little trial and error can lead to a delicious glow!

Application of Polished Metals

Various industries and applications that utilize polished metals.. Benefits of using polished metals in manufacturing and craftsmanship..Polished metals shine bright in many industries. They are used in everything from car parts to kitchen appliances. The smooth surface makes them look good and easy to clean. Plus, polished metals are strong and resist rust, so they last longer. This saves money in the long run. Think about shiny bathroom fixtures or that glimmering trophy you want to win! Everyone loves a little bling!

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Engine components | Improved performance and durability |

| Manufacturing | Parts and tools | Reduced friction and wear |

| Aerospace | Aircraft components | Lightweight yet strong |

| Consumer Products | Appliances | Attractive and easy to maintain |

Conclusion

In conclusion, polishing metal on a lathe can make your projects shine. Start by cleaning the metal surface and using the right polishing compound. Remember to adjust the speed for better results. Practice makes perfect! Now, grab your lathe and try polishing some scrap metal. For more tips, check out tutorials online or ask experienced friends for advice. Happy polishing!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Polishing Metal On A Lathe:Sure! Polishing metal on a lathe makes it shiny and smooth. A lathe is a machine that spins metal pieces. You can use special tools and polish to get a nice finish. It’s like making a metal surface look like a mirror! We can practice safely by following all the steps.

Sure! Please provide me with the question you would like me to answer.

What Types Of Polishing Compounds Are Best Suited For Use On A Lathe When Polishing Metal?When you polish metal on a lathe, use compounds like Tripoli or rouge. Tripoli is great for rough polishing, while rouge makes things shiny. You can also try polishing wax for a smooth finish. Always remember to use the right kind for the job to get the best results!

How Do You Properly Set Up A Lathe For Polishing Metal Workpieces?To set up a lathe for polishing metal pieces, first, make sure the machine is clean and safe. Next, choose the right polishing pad that matches your metal. Then, attach the pad to the lathe’s chuck tightly. Finally, turn on the lathe at a slow speed and carefully hold your metal piece against the pad. Always wear safety gear like goggles to protect your eyes.

What Safety Precautions Should Be Taken When Polishing Metal On A Lathe?When polishing metal on a lathe, you should wear safety goggles to protect your eyes. Use gloves to keep your hands safe from sharp edges. Make sure to tie back long hair and remove loose clothing to avoid getting caught in the machine. Keep your workspace clean and organized so you won’t trip or bump into anything. Always follow the machine’s safety rules to stay safe while working.

What Are The Differences Between Polishing And Sanding Metal, And When Should Each Technique Be Used On A Lathe?Sanding and polishing metal are different steps. Sanding uses rough paper to make the surface smoother and shape the metal. You should sand first to remove scratches and bumps. Polishing makes the metal shiny and smooth after sanding. Use polishing at the end to give your metal a nice shine!

How Can You Achieve A Mirror Finish On Metal Using A Lathe And Polishing Techniques?To get a mirror finish on metal, you first need to use a lathe. The lathe spins the metal to shape it smoothly. After that, use fine sandpaper to make the surface even smoother. Finally, polish the metal with a soft cloth and polishing compound. Keep working until it shines like a mirror!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Polishing Metal On A Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Polishing metal on a lathe makes it shiny and smooth. A lathe is a machine that spins metal pieces. You can use special tools and polish to get a nice finish. It’s like making a metal surface look like a mirror! We can practice safely by following all the steps.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Types Of Polishing Compounds Are Best Suited For Use On A Lathe When Polishing Metal?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you polish metal on a lathe, use compounds like Tripoli or rouge. Tripoli is great for rough polishing, while rouge makes things shiny. You can also try polishing wax for a smooth finish. Always remember to use the right kind for the job to get the best results!”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up A Lathe For Polishing Metal Workpieces?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a lathe for polishing metal pieces, first, make sure the machine is clean and safe. Next, choose the right polishing pad that matches your metal. Then, attach the pad to the lathe’s chuck tightly. Finally, turn on the lathe at a slow speed and carefully hold your metal piece against the pad. Always wear safety gear like goggles to protect your eyes.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Polishing Metal On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When polishing metal on a lathe, you should wear safety goggles to protect your eyes. Use gloves to keep your hands safe from sharp edges. Make sure to tie back long hair and remove loose clothing to avoid getting caught in the machine. Keep your workspace clean and organized so you won’t trip or bump into anything. Always follow the machine’s safety rules to stay safe while working.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Polishing And Sanding Metal, And When Should Each Technique Be Used On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sanding and polishing metal are different steps. Sanding uses rough paper to make the surface smoother and shape the metal. You should sand first to remove scratches and bumps. Polishing makes the metal shiny and smooth after sanding. Use polishing at the end to give your metal a nice shine!”}},{“@type”: “Question”,”name”: “How Can You Achieve A Mirror Finish On Metal Using A Lathe And Polishing Techniques?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get a mirror finish on metal, you first need to use a lathe. The lathe spins the metal to shape it smoothly. After that, use fine sandpaper to make the surface even smoother. Finally, polish the metal with a soft cloth and polishing compound. Keep working until it shines like a mirror!”}}]}