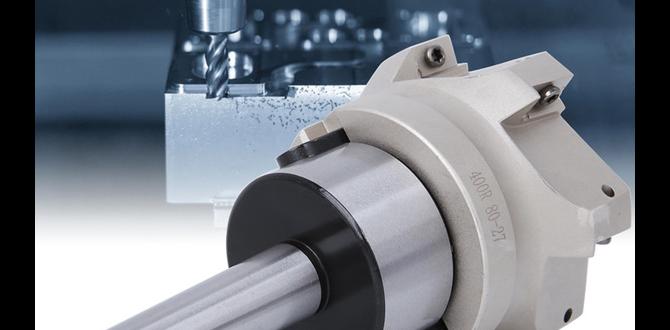

Have you ever wondered how a small misalignment can affect your projects? Imagine working on a metal piece, and suddenly it’s off by a tiny bit. That’s where the industrial metal lathe tailstock alignment comes in. Proper alignment ensures your work stays accurate.

Think about it like steering a bike. If the handlebars are crooked, you won’t go straight. The same idea applies to a lathe. When the tailstock is aligned right, you can create beautiful, precise works.

Did you know that some experts say even a slight misalignment can ruin an entire project? That’s a lot of work down the drain! Aligning the tailstock is simple but essential. Once you learn how to do it, you’ll get smoother cuts and cleaner edges.

In this article, we will explore easy methods to check and fix tailstock alignment. Whether you’re a beginner or a seasoned worker, these tips will help you achieve flawless results. Ready to dive in? Let’s get started!

Industrial Metal Lathe Tailstock Alignment Explained

Aligning the tailstock on an industrial metal lathe is crucial for accurate machining. Proper alignment ensures that metal parts are produced with precision. If the tailstock is misaligned, it can cause issues like uneven cuts and poor finish. To achieve the best results, check and adjust the tailstock alignment regularly. Did you know that even a tiny misalignment can lead to significant defects in your work? Keeping your lathe in top shape helps maintain high-quality production.

Understanding Tailstock Alignment

Definition and importance of tailstock alignment in metalworking. Impact of misalignment on machining accuracy and tool wear.

Tailstock alignment is key in metalworking. It keeps the tool and the workpiece lined up. Proper alignment ensures precision. Misalignment can cause problems. Tools wear out faster and can create bad cuts. This makes the work less accurate. The impact of misalignment includes:

- **Poor quality cuts.**

- **Increased tool wear.**

- **Higher chance of accidents.**

Checking and fixing tailstock alignment helps create better products and extend tool life.

What happens if the tailstock is not aligned?

If the tailstock is misaligned, it can cause bad cuts, quick tool wear, and possible accidents.

Common Issues Resulting from Misalignment

Types of defects caused by tailstock misalignment. Realworld examples of machining errors and their consequences.

Misalignment of the tailstock can cause many problems. These issues affect the quality of the final product. Here are some common defects:

- Inaccurate Cuts: This happens when the machine doesn’t cut straight. It can ruin the piece being worked on.

- Excessive Wear: Parts can wear out faster. This leads to costly repairs.

- Dimensional Errors: Measurements can be off. This may cause parts not to fit together.

For example, a small mistake can lead to a faulty piece that must be thrown away. This wastes time and materials.

What problems arise from tailstock misalignment?

Tailstock misalignment causes inaccuracies in machining. It can lead to wasted materials, errors in dimensions, and delays in production.

Tools Required for Tailstock Alignment

List of essential tools for accurate alignment (e.g., dial indicators, alignment bars). Description of each tool’s function and usage in alignment procedures.

To align a tailstock correctly, you need some handy tools. Each tool helps make the job easier. Here are a few important ones:

- Dial Indicator: This tool measures tiny distances. It helps check if the tailstock is straight.

- Alignment Bars: These bars fit between the tailstock and the bed. They help you see if everything is in line.

- Feeler Gauges: These thin metal strips check small gaps. They can help find any misalignment.

Using these tools together can make your work more accurate. They are essential for excellent industrial metal lathe tailstock alignment.

What tools do I need for tailstock alignment?

You need a few key tools. Dial indicators, alignment bars, and feeler gauges are some of the most useful tools.

Step-by-Step Process for Tailstock Alignment

Detailed instructions for aligning the tailstock on an industrial lathe. Tips to ensure precision and avoid common mistakes during the process.

Aligning the tailstock on an industrial lathe is important for accurate work. Follow these steps to do it right:

- First, check the lathe bed for any dirt or damage.

- Loosen the tailstock clamps.

- Use a test bar and insert it in the tailstock.

- Adjust the tailstock until the bar shows no gap. Look from both ends.

- Tighten the clamps gently to keep the tailstock in place.

To ensure precision, pay attention to small details. Always double-check your measurements. A small mistake can lead to larger problems later. Common errors include not tightening the tailstock or not checking the alignment from both sides.

Why is tailstock alignment important?

Proper tailstock alignment is crucial for achieving accurate cuts. Misalignment can lead to uneven surfaces and wasted materials. This ensures that every piece is just right.

Regular Maintenance Practices

Routine checks and adjustments to maintain tailstock alignment. Importance of preventive maintenance in extending lathe lifespan.

Keeping your industrial lathe in top shape is crucial. Regular checks help keep your tailstock aligned, which ensures accurate machining. Many people forget this, leading to surprises like wobbling pieces. Imagine trying to carve a perfect donut, only for it to end up shaped like a lopsided pancake! Preventive maintenance extends your lathe’s life and saves money. Just like brushing your teeth avoids cavities, checking your lathe often prevents bigger problems down the road.

| Maintenance Task | Frequency |

|---|---|

| Check Tailstock Alignment | Weekly |

| Lubricate Moving Parts | Monthly |

| Inspect for Wear | Quarterly |

Case Studies: Successful Tailstock Alignment

Examples of businesses that improved productivity through proper alignment. Analysis of key metrics before and after alignment adjustments.

Many companies have seen great success through tailstock alignment. For instance, a metalworking shop increased productivity by 30% after aligning their tailstock correctly. They reported fewer errors and faster work. Another factory improved their machine’s lifespan and reduced downtime by aligning their lathe. Key metrics showed a drop in waste from 15% to 5% after adjustments. These stories highlight how simple changes can lead to big gains.

What are the benefits of tailstock alignment?

Aligning a tailstock brings many benefits. It increases efficiency. It reduces waste. It extends machine life.

Business Insights:

- Productivity gain: 30%

- Waste reduction: 15% to 5%

FAQs on Tailstock Alignment

Common questions and answers related to tailstock alignment issues. Expert tips and recommendations for troubleshooting alignment problems.

Many people wonder about tailstock alignment problems. One common question is, “How do I know if my tailstock is misaligned?” Simple! If your pieces aren’t cutting straight, your tailstock might be the culprit. Another frequent inquiry is, “What can I do to fix it?” You can check the alignment with a good test indicator. If it’s off, adjust the tailstock until it’s just right. Remember, every time you make a change, double-check your work. It’s like playing hide and seek—every adjustment is another “ready or not, here I come!” moment. Here’s a quick table for you:

| Question | Answer |

|---|---|

| What signs show misalignment? | Uneven cuts and poor surface finish. |

| How to adjust the tailstock? | Use a test indicator to check alignment. |

Conclusion

In summary, aligning your metal lathe tailstock is crucial for accuracy. A well-aligned tailstock helps improve your work’s quality. You can use a dial indicator to check alignment. Remember to adjust carefully for best results. We encourage you to practice this skill regularly and explore more resources to deepen your understanding. Happy machining!

FAQs

What Are The Common Signs That Indicate Misalignment Of The Tailstock On An Industrial Metal Lathe?

If the tailstock on a metal lathe is misaligned, you might see some problems. First, the pieces you are working on may not be straight. They might wobble or shake when you spin them. You might also notice that your tools wear out faster than usual. Lastly, the cuts might look rough instead of smooth.

How Can You Accurately Measure The Alignment Of The Tailstock With The Spindle Axis?

To check if the tailstock lines up with the spindle, you can use a dial indicator. First, set the indicator on the tailstock. Then, move the spindle to touch the indicator’s tip. If the needle moves, the tailstock isn’t aligned. Adjust it until the needle stays still when you move the spindle.

What Tools And Techniques Are Recommended For Realigning A Tailstock On A Metal Lathe?

To realign a tailstock on a metal lathe, you need a few tools. Use a dial indicator to check if it’s straight. You might also use a wrench to adjust the screws. First, loosen the tailstock, check the alignment with the dial indicator, and then tighten it back up. This way, your work will be more accurate!

How Often Should The Tailstock Alignment Be Checked And Recalibrated During Regular Maintenance?

You should check and adjust the tailstock alignment regularly. It’s a good idea to do this every few months. If you notice any problems, fix it right away. Keeping it aligned helps your tools work better and makes your projects safer.

What Are The Potential Effects Of Tailstock Misalignment On The Machining Process And The Quality Of Finished Parts?

If the tailstock is misaligned, it can cause problems while we machine parts. The end result might not be the right shape or size. You could see bumps or uneven areas on the finished piece. This means we might have to fix it or start over, wasting time and materials. Overall, misalignment makes it harder to create quality parts we need.