Have you ever thought about how machines shape the world around us? One important machine is the industrial metal lathe. It works by spinning metals to create shapes and parts. But do you know how much power it takes to do this? That’s where torque comes into play.

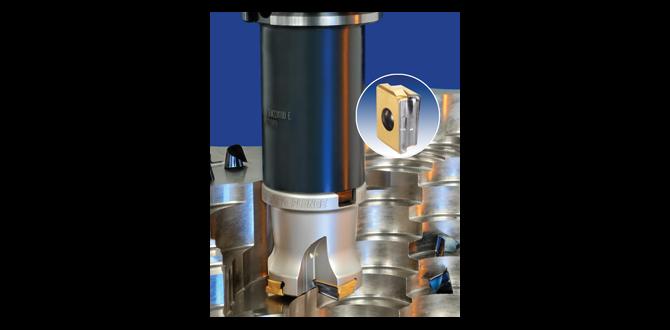

Torque is like the strength behind the spinning motion. The more torque a lathe has, the easier it cuts through tough metals. Imagine trying to open a tight jar lid. The harder you twist, the more torque you use. This simple idea helps us understand the strength needed for metalworking.

In this article, we will explore industrial metal lathe torque in depth. We’ll look at why it matters and how it affects the tools we use. Whether you’re a curious learner or a budding machinist, there’s something here for you. Get ready to dive into the world of metal lathes and discover what makes them so powerful!

Understanding Industrial Metal Lathe Torque And Its Importance

Understanding Industrial Metal Lathe Torque

Industrial metal lathe torque is vital for shaping metal. Did you know that torque affects how smoothly the lathe operates? When the torque is just right, it makes cutting easier and safer. Users find that high torque helps in working with tougher materials. Imagine if you had to carve a block of wood with a dull knife; it would be hard! Proper torque helps machines work efficiently, making the job quicker and better.What is Industrial Metal Lathe Torque?

Definition of torque in the context of metal lathes. Importance of torque in machining operations.Torque is a measure of how much force a metal lathe can apply to turn or cut metal. It’s like the oomph behind your favorite superhero! In machining, having the right torque is crucial. If a lathe has too little torque, it might struggle to cut through tough materials. But too much torque? Well, that can lead to disaster, like a cake that collapses under its own weight! Finding the sweet spot ensures smooth and effective operations. Here’s a quick look at torque levels and their importance:

| Torque Level | Significance |

|---|---|

| Low Torque | May lead to poor cutting performance. |

| Moderate Torque | Optimal for most machining tasks. |

| High Torque | Can result in damage if not controlled. |

Factors Affecting Torque in Industrial Metal Lathes

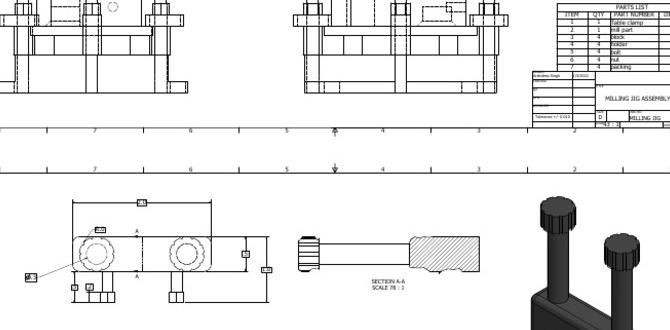

Role of machine design and motor power. Influence of workpiece material and size on torque requirements.Several factors influence torque in industrial metal lathes. One major factor is design. A strong machine design helps manage torque effectively. Motor power is another critical element. More power means the motor can handle tougher tasks. The material of the workpiece also matters. Harder materials need higher torque. Lastly, the size of the workpiece changes torque needs. Larger pieces demand more strength to turn.

What factors affect torque in industrial metal lathes?

Design, motor power, workpiece material, and size all affect torque requirements.

Key Factors:

- Machine design quality

- Motor power capacity

- Workpiece material hardness

- Size of the workpiece

Calculating Torque for Metal Lathes

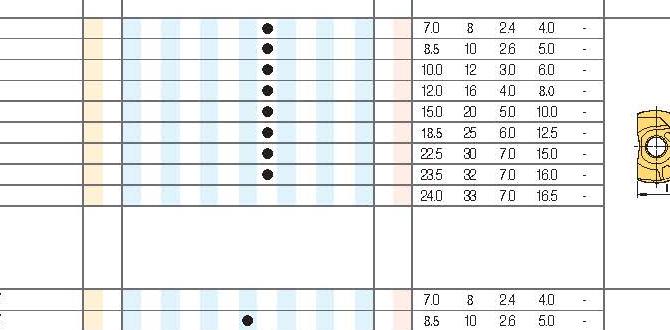

Key formulas for torque calculation. Examples of calculating torque for different materials.Calculating torque for metal lathes is like figuring out how much juice you need to squeeze from a lemon; it’s all about the right formula! The basic formula is: Torque = Force x Distance. So, if you know how much force you’re using and the distance from the center, you can find your torque. For example, if you’re working with aluminum, you might calculate a torque of 150 Nm, while steel could require around 200 Nm. Here’s a quick peek at a helpful table:

| Material | Torque (Nm) |

|---|---|

| Aluminum | 150 |

| Steel | 200 |

| Brass | 180 |

Remember, more torque can mean more power, but too much can lead to a lot of “oops” moments. Keep it balanced, and you’ll be the torque master in no time!

Optimal Torque Settings for Various Applications

Recommended torque settings for common materials (steel, aluminum, etc.). Adjusting torque for different machining tasks (turning, facing, etc.).Selecting the right torque setting is important for different materials. Here are some recommendations:

- For steel: Aim for 50-70 Nm.

- For aluminum: Use 30-50 Nm.

- For brass: Target around 20-40 Nm.

Adjust torque based on the task:

- Turning: Generally, use lower torque for better control.

- Facing: Slightly higher torque helps achieve a smooth finish.

This way, you optimize how you work with different materials and tasks.

What are the optimal torque settings for machining?

The best torque settings help improve performance and make your work easier. Always remember to choose the right one for the material you’re using. Use lower torque for precision and higher torque for speed.

Common Torque-Related Issues and Solutions

Analysis of problems related to insufficient or excessive torque. Troubleshooting tips for maintaining optimal performance.Sometimes, metal lathes can feel like an angry cat—too much torque and they might hiss, or too little, and they just sit there, pouting. Insufficient torque can cause poor cuts, while excessive torque can damage your workpiece. It’s like Goldilocks; you need it to be “just right.” Regular checks on the torque settings can save your tools from tantrums. Here’s a quick troubleshooting table to help:

| Torque Issue | Cause | Solution |

|---|---|---|

| Insufficient Torque | Loose settings | Tighten the torque settings. |

| Excessive Torque | Incorrect adjustments | Reduce the torque settings immediately. |

By keeping an eye on your torque settings, you can ensure your industrial metal lathe runs smoothly and stays happy. Remember, a happy tool makes for a happy crafter!

Advancements in Torque Control Technology

Innovations in torque measurement and control systems. Future trends in torque management for industrial metal lathes.New gadgets in torque control are changing how we use metal lathes. Imagine a tool that can measure torque like a superhero! These advancements help keep machinery safe and efficient. Precise torque management means fewer breakdowns and happier workers. Future trends show even smarter systems ahead. They’ll make machines easier to use and more reliable. Who wouldn’t want a robot buddy that helps with the tough stuff?

| Innovation | Impact |

|---|---|

| Advanced Sensors | Better accuracy |

| Smart Feedback Loops | Fewer errors |

| Predictive Maintenance | Less downtime |

Conclusion

In summary, understanding industrial metal lathe torque is crucial for effective machining. Torque affects performance, shaping accuracy, and tool lifespan. By grasping these concepts, you can enhance your projects. Consider exploring more about torque settings and lathe operations. We encourage you to practice using a lathe safely and efficiently. Your skills will improve with hands-on experience!FAQs

What Factors Influence The Torque Output Of An Industrial Metal Lathe During Different Machining Operations?The torque output of a metal lathe depends on a few key factors. First, the material we are cutting can change how much power is needed. Softer materials need less torque, while harder ones need more. Next, the speed of the lathe matters; higher speeds can also require more torque. Lastly, the cutting tool’s shape and sharpness can affect how easily it cuts, influencing torque as well.

How Does The Torque Capacity Of A Metal Lathe Affect Its Performance When Working With Various Materials?The torque capacity of a metal lathe is how much twisting force it can handle. If you work with hard materials like steel, you need more torque. If the torque is low, the lathe might struggle or stall. This can make it harder for you to shape the material right. So, a lathe with good torque helps you work better and faster!

What Are The Common Torque Ratings For Industrial Metal Lathes, And How Do They Vary Based On Size And Application?Industrial metal lathes usually have torque ratings from 20 to 3,000 inch-pounds. Smaller lathes for light work have lower torque. Bigger lathes can handle higher torque for tough jobs. The type of work you do affects the torque you need. So, if you’re working with heavy metal, you need more torque!

How Can Understanding The Torque Characteristics Of A Metal Lathe Improve The Quality And Precision Of Finished Parts?Understanding how much force a metal lathe can handle helps us make better parts. When we know the torque, we can set the machine correctly. This means the cuts will be smoother and more accurate. If the lathe has enough power, it won’t make mistakes. So, knowing torque helps us create really good, precise pieces.

What Are The Potential Consequences Of Exceeding The Recommended Torque Limits On A Metal Lathe During Operation?If you use too much force on a metal lathe, it can break. This might damage both the lathe and the piece you are working on. You could also get hurt if the machine breaks. Plus, it makes your work less accurate and can waste your time. Always follow the rules to stay safe!