Struggling with dull lathe tools? A sharpening jig is your secret weapon! This guide shows you how to choose, set up, and use a jig to get razor-sharp tools safely and easily. Master the art of sharpening and make your lathe projects a joy.

Hey there, fellow makers! Daniel Bates, your guide from Lathe Hub, here. Ever feel like your lathe tools are fighting you, leaving rough cuts and frustrating your carefully planned projects? It’s a common problem, but the solution is simpler than you might think. Keeping your lathe tools sharp is crucial for good results, safety, and making your time in the workshop enjoyable. A dull tool doesn’t cut cleanly, it heats up more, and it’s more likely to catch and cause a dangerous situation. But don’t worry! Today, we’re diving deep into the world of jigs for sharpening lathe tools. These simple devices are your best friend for achieving that perfect, reliable edge every time. We’ll walk through everything you need to know, from picking the right jig to using it like a pro, so get ready to transform your tool kit!

Why Sharpening Jigs Are A Game Changer

Sharpening lathe tools by hand can be a bit of a mystery, especially when you’re starting out. Getting the right angle consistently, holding the tool steady, and avoiding over-grinding are all challenges. This is where a sharpening jig steps in, acting like a helpful assistant to ensure precision and repeatability. It takes the guesswork out of angling your tools against the grinding wheel or sharpening stone, giving you confidence in your results. Instead of a wobbly, inconsistent edge, you’ll achieve a clean, reliable bevel that will make your turning so much smoother and safer.

What is a Lathe Tool Sharpening Jig?

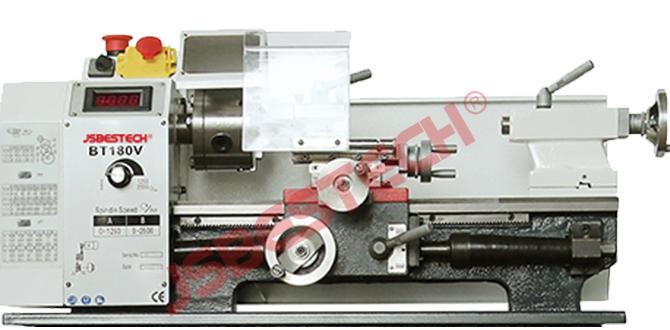

At its heart, a jig for sharpening lathe tools is a device designed to hold your cutting tool at a specific, repeatable angle while you sharpen it. Think of it as a fixture that guides your tool against an abrasive surface, like a grinding wheel or a whetstone. These jigs typically have a base that rests on the grinding rest or bench, and an arm or slot that securely holds the tool. Some are simple blocks with angled slots, while others are more complex, adjustable mechanisms. The goal is always the same: to ensure the bevel you’re creating on the cutting edge is consistent and at the optimal angle for the type of tool and material you’re working with.

Types of Sharpening Jigs

When you start looking for jigs, you’ll notice a few different styles. Each has its own strengths, and what works best often depends on the type of lathe tools you use most and your preferred sharpening method. Let’s break down the common types:

Fixed-Angle Jigs

These are generally the simplest and most affordable jigs. They feature a pre-set angle, usually around 30 degrees, which is suitable for many common lathe tools like scrapers or gouges. You simply slide your tool into the designated slot, and the jig ensures it contacts the grinding wheel at that specific angle. They are great for beginners because they eliminate the need to “find” the angle yourself while grinding.

Adjustable-Angle Jigs

For those who want more versatility, adjustable-angle jigs are the way to go. These allow you to fine-tune the angle of your tool before and during sharpening. This is invaluable if you work with a wide variety of tools, each requiring a slightly different bevel. For instance, a roughing gouge might benefit from a wider bevel than a detailer. Adjustable jigs often have a pivoting arm or a sliding mechanism that lets you set and lock in your desired angle. This level of control gives you great precision over your tool’s cutting geometry.

Brand-Specific Jigs

Many tool manufacturers offer jigs designed to work with their specific line of lathe tools. These are often tailored to the geometry of their tools, ensuring a perfect fit and optimal sharpening angle. If you’ve invested in a particular brand of turning tools, their proprietary jig might be a worthwhile accessory.

DIY Jigs

Don’t underestimate the power of a well-made homemade jig! Many machinists and woodturners create their own sharpening jigs from scrap wood, metal, or even 3D printed parts. This can be a cost-effective solution and allows you to customize a jig precisely to your needs and workspace. There are many designs available online, often shared by experienced makers. For example, a simple “V-block” style jig can be made with two pieces of wood screwed together at an angle, providing a channel to hold your tool.

Essential Tools and Materials

To get started with your jig, you’ll need a few key items:

- Lathe Tool Sharpening Jig: The centerpiece of your setup. Choose one that suits your tools and budget.

- Grinding Wheel or Sharpening Stone: This is what does the actual sharpening. A grinder with different grit wheels (e.g., 60-grit for aggressive shaping/repair and 80-120 grit for general sharpening) is ideal. For woodworking tools, diamond stones or water stones are excellent choices.

- Tool Rest: This is the adjustable bar on your grinder or lathe where the jig will sit. Ensure it’s sturdy and at the correct height.

- Lathe Tools: Your dull tools that are waiting to be brought back to life!

- Safety Glasses: Non-negotiable! Always protect your eyes when grinding or sharpening.

- Dust Mask/Respirator: If you’re using a dry grinder, especially for metal tools, fine dust is produced. A mask is essential for your respiratory health.

- Gloves (Optional but Recommended): To protect your hands from sharp edges and hot metal.

- Marking Tool (e.g., Sharpie): Useful for marking the bevel angle on your tool before you start.

- Magnifying Glass (Optional): For inspecting the edge to see if it’s truly sharp and free of burrs.

Setting Up Your Sharpening Jig

Correct setup is key to using your jig effectively. Here’s how to get it ready:

- Mount the Jig: Place your sharpening jig on the tool rest of your grinder or lathe. Ensure it sits securely and doesn’t wobble. For most jigs, the bottom surface will rest flat on the rest.

- Adjust the Tool Rest Height: The height of your tool rest is critical. It should be positioned so that when your tool is held in the jig, it contacts the grinding wheel at the correct point. You want the wheel to contact the bevel area, not the heel or the tip of the tool. A common starting point is to have the center of the grinding wheel at about the same height as the desired edge. For jigs, follow the manufacturer’s instructions or experiment carefully.

- Set the Angle (if adjustable): If you have an adjustable jig, set your desired sharpening angle. For many standard woodworking chisels and lathe tools, an angle between 20-30 degrees is common. For metalworking tools, you might aim for slightly different angles depending on the specific tool and application. Consult your tool’s manual or a reliable machining guide for recommended angles. A good resource for machining angles can be found on Purdue University’s Engineering Technology section.

- Check for Stability: Ensure the jig is firmly seated on the tool rest and that the tool itself can be held within the jig without excessive play. If there’s looseness, it will lead to inconsistent results.

How to Use Your Jig: Step-by-Step

Now, let’s get to the satisfying part – sharpening your tools! This process is similar whether you’re using a grinder or oil/water stones, though the abrasive surface will differ.

Step 1: Prepare Your Tool and Jig

Ensure your tool is clean and free from old grinding dust or debris. Place it into the jig, making sure it’s square and held firmly. If your jig has a clamp, tighten it securely. If it’s a slot, ensure the tool sits snugly.

Step 2: Position the Tool Against the Abrasive

Turn on your grinder (if using one) and let it reach full speed. Carefully bring the jig with the tool into contact with the grinding wheel. You want the wheel to grind the intended bevel area. For many jigs, this means the tool’s cutting edge will meet the wheel at the pre-set angle. Let the jig do the work of maintaining the angle. Crucially, move the tool back and forth slightly to ensure you’re grinding evenly along the entire cutting edge. Avoid dwelling on one spot, as this can create a divot.

Step 3: Grind One Side of the Bevel

Apply light pressure and move the tool across the abrasive. You’re aiming to create a consistent bevel. A few passes are usually enough to establish or refine the edge. If you’re repairing a damaged tool, you may need more substantial grinding. Listen to the sound – a smooth whir is good, a squeal might mean too much pressure. For woodworking tools, especially, it’s easy to overheat them. Be careful not to overheat your tools as this can ruin their temper and make them softer. A good tip is to dip the tool in water frequently during grinding to cool it down. For metalworking tools, heat is less of a concern in the initial grinding, but sharp edges are still paramount.

Step 4: Check for a Burr

After grinding one side, carefully feel for a slight “burr” or “wire edge” on the opposite side of the cutting edge. This is a tiny curl of metal that indicates you’ve ground all the way to the edge. A magnifying glass can help you see this. Exercise extreme caution when feeling for a burr – the edge can be very sharp! A safer method is to use a piece of hard wood to drag across the edge; if it snags, you have a burr.

Step 5: Grind the Other Side or Hone

If your jig is designed to grind both sides of a bevel (like for some gouges or chisels), carefully reposition the tool in the jig and repeat the grinding process on the other side until a matching burr is formed.

If your jig is for a single-bevel tool or you’ve established the primary bevel, you’ll often move to a finer sharpening medium like a whetstone or honing steel to refine the edge and remove the burr. For woodworking tools, this is often done on fine grit water stones or diamond plates. For metalworking tools, you might use a fine-grit stone or a honing compound on leather.

Step 6: Hone and Strop for a Razor Edge

After the grinding, the edge might feel sharp but can have microscopic teeth. Honing on a finer stone to remove the burr and then stropping on leather (ideally with honing paste) will create a polished, incredibly sharp edge. For woodworking tools, a well-honed edge is crucial for fine finishes. For metalworking, a deburred and polished edge reduces friction and wear.

Here’s a quick comparison of how different tool types typically finish:

| Tool Type | Typical Sharpening Method | Finishing Steps |

|---|---|---|

| Woodworking Gouges & Chisels (e.g., spindle gouge, skew chisel) | Grinder (e.g., 80-120 grit wheel) to establish bevel, then water stones or diamond plates (e.g., 1000-8000 grit) | Honing on fine stones, stropping on leather with honing compound. |

| Metalworking Lathe Tools (e.g., HSS turning tools, parting tools) | Grinder (e.g., 60-80 grit wheel for repair, 120-240 grit for sharpening) or diamond files | Honing on fine grit stones (e.g., 400-1000 grit, sometimes higher), deburring, optional leather strop. |

| Scrapers (Woodworking) | Grinder to establish initial bevel/hook, then filing or sharpening stones | Creating a “hook” or burr by filing or scraping the edge at a slight angle. |

Safety First, Always!

Working with spinning wheels and sharp tools demands respect. Here are the golden rules:

- Eye Protection: Always wear safety glasses. Grinding can send sparks and small metal or abrasive particles flying.

- Respiratory Protection: Use a dust mask or respirator when grinding, especially dry grinding, to avoid inhaling fine particles.

- Keep Hands Clear: Ensure your hands and fingers are never in the path of the grinding wheel or the tool being sharpened.

- Secure the Jig: Make sure your jig is stable. A jig that shifts during grinding is dangerous.

- Don’t Force It: Let the abrasive do the work. Forcing the tool can lead to overheating, loss of temper, or a broken tool.

- Cool Metals: If grinding metal tools, take breaks to cool the tool in water. Overheating can soften the steel.

- Be Aware of Rotation: Always know which way your grinder wheel is spinning and position yourself and the tool accordingly. For most bench grinders, you want to approach the wheel so the grinding action pulls the tool edge into the wheel, not pushes it away.

- Turn Off the Grinder: Never attempt to adjust the jig or tool rest while the grinder is running.

Tips for Better Sharpening Results

Here are some pro tips to elevate your sharpening game:

- Use the Right Grit: For aggressive shaping or repairing damaged tools, use a coarser grit. For general sharpening and touch-ups, a medium to fine grit is better. Always finish with a finer grit for a smoother, keener edge. For woodworking, higher grits on stones are essential for that glass-smooth finish.

- Maintain Your Abrasives: Grinding wheels can get glazed or loaded with metal. Keep them clean and “dressed” (flattened and sharpened) using a dressing tool to ensure efficient grinding. For stones, ensure they are flat; you may need to use a flattening stone periodically.