Have you ever wondered how metal parts are made? Imagine watching a small piece of metal turn into something useful. That’s what happens with a kit metal lathe. These machines shape metal into parts for cars, toys, and much more.

Now, picture making these parts without lifting a finger. That’s where automation comes in. Kit metal lathe automation can help manufacturers work faster and make fewer mistakes. Instead of spending hours on a single part, machines can create many parts in a short time.

Did you know that automation in metalworking is becoming more common? Factories today use robots and automated lathes. This helps people focus on designing and improving products instead of doing boring tasks. Wouldn’t you like to see a robot turning metal while you simply watch?

This new technology opens up exciting possibilities. It allows for creativity, saves time, and helps in making metal products more efficient. So, let’s dive into the wonderful world of kit metal lathe automation and discover what it can do!

Kit Metal Lathe Automation: Revolutionizing Precision Engineering

Summary of Kit Metal Lathe Automation

Kit metal lathe automation transforms how machines operate. Imagine a lathe that works without constant manual help! These automated systems reduce mistakes and speed up production. They make metalworking easier and more accurate. Did you know that automation can save time and money? Many businesses are adopting these kits to improve efficiency. As technology advances, more hobbyists and professionals enjoy the benefits of automated lathes. They can create more intricate designs with less effort.Understanding Kit Metal Lathes

Definition and components of kit metal lathes. Advantages of using kit metal lathes in machining.Kit metal lathes are cool machines that help shape metal into various parts. Think of them like giant spinning pencils, carving out shapes through cutting. They are made up of important parts like the spindle, tailstock, and tool post. These components work together to give precise cuts, just like a chef needing the right knife!

Using kit metal lathes comes with great perks. They enhance productivity and accuracy, which means your projects will look sharp. Plus, they save time and reduce waste, almost like putting your tools on a diet! So, whether you’re a hobbyist or a professional, kit metal lathes can help you create amazing things.

| Component | Function |

|---|---|

| Spindle | Holds and spins the metal workpiece |

| Tailstock | Supports the other end of the workpiece |

| Tool Post | Holds the cutting tool in place |

The Importance of Automation in Metalworking

Efficiency and precision benefits of automation. Impact of automation on labor costs and output quality.Automation in metalworking is very important. It makes machines work faster and with less errors. This means efficiency increases. Workers save time as machines do the hard tasks. Automation also helps cut down labor costs. Fewer mistakes mean better product quality. Companies can produce more with less effort. This leads to happy customers and higher profits.

Why is automation in metalworking important?

Automation boosts speed and reduces errors, making metalworking more efficient and cost-effective.

- Increased efficiency means lower costs.

- Higher precision leads to better quality products.

- Less manual work makes jobs safer.

Essential Features of Automated Kit Metal Lathes

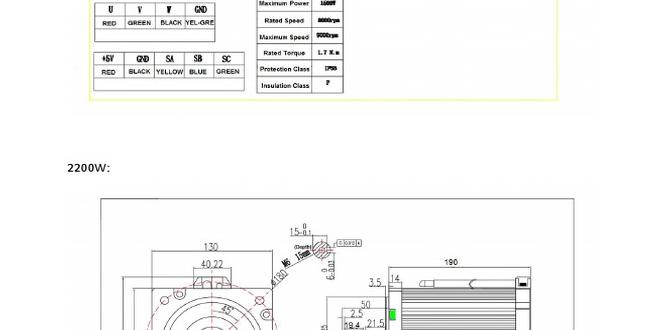

Key technical specifications to look for. Importance of software compatibility and ease of use.A good automated kit metal lathe should have some key features. First, look for strong technical specifications like motor horsepower and speed. These affect how well the lathe works. Software compatibility is also crucial. You want software that is easy to use; otherwise, you might need a dictionary to get started! Finally, user-friendliness is important. If it feels like rocket science, you might just be better off with a rubber chicken instead!

| Feature | Importance |

|---|---|

| Motor Power | Higher horsepower means better performance |

| Speed Control | Precise settings for different materials |

| Software Compatibility | Ease of use helps prevent headaches |

| Ease of Operation | A simple interface saves time |

Steps to Automate Your Kit Metal Lathe

Necessary equipment and software for automation. Stepbystep guide to implementing automation.Want to make your kit metal lathe do the heavy lifting? Start by gathering the right gear. You’ll need sensors, a controller, and some software. Think of them as your lathe’s new best friends! Next, follow these easy steps:

| Step | Action |

|---|---|

| 1 | Connect the sensors |

| 2 | Set up the controller |

| 3 | Install the software |

| 4 | Run a test |

| 5 | Adjust settings as needed |

With a bit of patience and a sprinkle of luck, you’ll soon have an automated metal lathe. Just remember, no one wants to be a lathe-tastrophe!

Common Challenges and Solutions in Metal Lathe Automation

Technical difficulties and how to overcome them. Maintenance considerations for automated systems.Working with metal lathe automation can feel like juggling cats. There are technical bumps along the way, such as software glitches. To tackle these, keep your software updated and provide training for your team. Maintenance is key too; think of it as giving your machine a spa day. Regular check-ups can prevent major issues. Pull up a seat—here’s a simple table to guide your maintenance schedule:

| Task | Frequency | Notes |

|---|---|---|

| Clean machine | Daily | Dust bunnies are not your friends! |

| Check oil levels | Weekly | Oil keeps things running smoothly. |

| Inspect belts | Monthly | Like checking shoelaces before a race. |

Stay ahead of challenges, and your automated lathe will work like a charm—at least until it gets bored looking at metal all day!

Case Studies: Successful Implementations of Kit Metal Lathe Automation

Examples of industries benefiting from automation. Analysis of productivity improvements and ROI.Various industries have embraced automation with kit metal lathes, showing amazing results. For example, the automotive sector has boosted production speed by 30%, leaving competitors in the dust. A gourmet cupcake factory even automated its process and increased output by 50%, meaning more cupcakes and fewer crumbs on the floor! The Return on Investment (ROI) often outweighs initial costs, making it a sweet deal.

| Industry | Productivity Improvement | ROI |

|---|---|---|

| Automotive | +30% | Quick |

| Food Production | +50% | Delicious |

| Electronics | +25% | Promising |

In today’s fast world, having the right tools can make a big difference. Just imagine sipping coffee while machines do the hard work! Easily, kit metal lathe automation is reshaping industries, ensuring they churn out products faster than ever.

Future Trends in Kit Metal Lathe Automation

Emerging technologies in metalworking automation. Predictions for the next decade in kit metal lathe automation practices.New tools and software are changing how metalworking is done. Robotics and artificial intelligence are leading the way. They help make tasks faster and safer. In the next ten years, we can expect:

- More machines working together without help from humans.

- Smarter lathes that can adjust settings on their own.

- Better training programs using virtual reality.

These changes will make kit metal lathe automation easier and more efficient.

How will kit metal lathe automation change?

Many experts believe automation will boost productivity by up to 30%. This means factories can make more parts quicker. Also, workers can focus on more creative tasks, leaving the hard work to machines.

Resources and Tools for Further Learning

Recommended books, online courses, and forums. Key manufacturers and software providers for automation solutions.For those wanting to dive deeper into kit metal lathe automation, various resources are available. Reading books, taking online courses, and joining forums can enhance your knowledge. Here are some good options:

- Books: “The Practical Guide to CNC Programming.”

- Online Courses: Websites like Udemy and Coursera offer classes on CNC machining.

- Forums: Check out Machinist Forums for discussions and help.

Also, explore key manufacturers and software providers. They can offer valuable tools and tech solutions for your projects.

What are some recommended resources for learning about kit metal lathe automation?

Books, online courses, and forums are excellent resources. They help you understand and improve your skills in metal lathe automation.

Conclusion

In conclusion, kit metal lathe automation makes metalworking easier and faster. You can create accurate parts with less effort. This technology saves time and boosts productivity. If you’re interested in metalworking, consider exploring kits that automate lathes. We encourage you to read more about this topic to enhance your skills and discover new possibilities. Happy machining!FAQs

What Are The Key Components Required For Automating A Kit Metal Lathe, And How Do They Integrate With The Existing Machine Setup?To automate a kit metal lathe, you need a few key parts. First, you need a motor to turn the lathe. Next, you require sensors to help it know where to cut. You will also need a computer or control panel to tell it what to do. These parts connect to the lathe, making it easier to use without much help.

How Can Sensors And Cnc Controls Enhance The Precision And Efficiency Of Automated Operations On A Kit Metal Lathe?Sensors and CNC controls help kit metal lathes work better. Sensors check things like speed and position. When they find a mistake, the CNC (Computer Numerical Control) can quickly fix it. This means the machine can make parts more accurately and faster. You get better products and less wasted time!

What Common Challenges Do Hobbyists Face When Implementing Automation In Kit Metal Lathes, And How Can They Be Overcome?Hobbyists often face problems like wiring issues, software bugs, and wrong settings when using automation in kit metal lathes. To solve these, you should carefully follow instructions and double-check your work. You can also join online groups to ask for help. Practice makes perfect, so take your time and keep trying!

What Are The Advantages Of Using Open-Source Software For Controlling Automated Kit Metal Lathes Compared To Proprietary Systems?Using open-source software for metal lathes is great because it’s usually free. You can change it if you need to. This means you can make it work just the way you want. Also, many people help each other online, so you can find answers easily. Finally, it helps you learn more about how the machines work.

How Can User Safety Be Ensured During The Automation Of Kit Metal Lathes, Especially In A Home Workshop Environment?To keep you safe while using automatic kit metal lathes, always wear safety gear like goggles and gloves. We should keep the area tidy and free from clutter to avoid accidents. Make sure to read all safety instructions before starting. Use emergency stops to quickly turn off the machine if something goes wrong. Finally, never work alone; always have someone else around to help you.