Have you ever wondered how metal parts are made? A kit metal lathe drive system plays a big role in that process. It helps shape metal into the parts we see every day. Whether we’re talking about toys, tools, or even cars, metal lathes help create them.

Many people think metalworking is hard, but it can actually be fun! Using a metal lathe is like cooking. You start with raw ingredients and turn them into something amazing. Just like mixing flour and sugar to make a cake, a lathe turns metal into parts and designs.

Here’s a fun fact: did you know that the first lathes were made thousands of years ago? Ancient craftsmen used them to create tools, jewelry, and more. Today, with modern kit metal lathe drive systems, anyone can try their hand at metalworking.

So, how does it work? What makes these systems so special? Let’s dive in and explore the fascinating world of kit metal lathe drive systems together!

Kit Metal Lathe Drive System: Optimizing Performance Effectively

Understanding Kit Metal Lathe Drive Systems

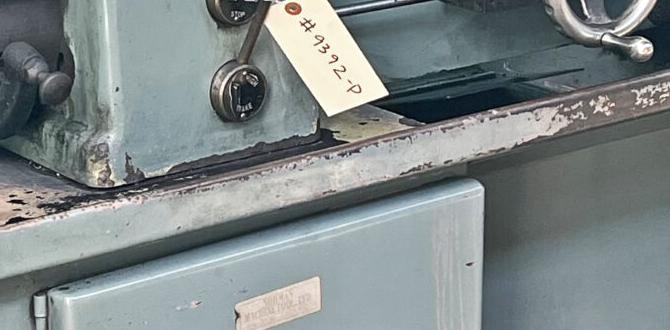

A kit metal lathe drive system is essential for smooth machining. It helps turn metal into precise shapes. Did you know that these systems use gears and belts to control speed? This allows hobbyists and professionals to customize their lathes easily. Understanding how these drive systems work can improve your projects. Imagine creating perfect parts that fit together just right. With the right kit, even beginners can achieve amazing results.What is a Kit Metal Lathe Drive System?

Definition and basic components of a drive system. Importance of drive systems in metal lathes.A drive system in a kit metal lathe is like the heartbeat of a robot dance party. It makes the lathe turn and helps shape metal into cool tools and designs. Key parts include the **motor**, which gives it power, the **belt** that moves the machine, and the **gears** that help control the speed. These pieces work together, showing why a good drive system is essential. Without it, the lathe would just sit there and look pretty—like a dancer who forgot the moves!

| Component | Function |

|---|---|

| Motor | Provides power to the lathe. |

| Belt | Transfers motion from motor to lathe. |

| Gears | Controls the speed and direction of the lathe. |

Benefits of Upgrading Your Drive System

Enhanced performance and efficiency. Impact on precision machining.Upgrading your drive system can make a big difference. It boosts performance and brings more efficiency to your work. This means machines run faster and smoother. Better drive systems help in precision machining. Issues like vibrations and tool wear are reduced. With precise movements, you can create better parts. Here’s a quick look at the benefits:

- Faster operations

- Less energy usage

- Improved accuracy

- Longer machine life

Why is an upgraded drive system important?

Upgrading means better speed and precision, which means you make high-quality pieces quickly.

How to Choose the Right Drive System for Your Lathe

Factors to consider (lathe size, type of work, budget). Key features to look for in a quality drive system.Choosing the right drive system for your lathe can feel like picking a favorite ice cream flavor—so many options! Start with the size of your lathe. A small lathe needs a different system than a big one. Next, think about the type of work you’ll do. Will you be turning tiny screws or hefty engine parts? Lastly, keep your budget in mind. Remember, just because it’s shiny doesn’t mean it’s the best fit! Look for features like smooth operation and reliability.

| Factors | Considerations |

|---|---|

| Lathe Size | Match the drive system to your lathe’s size |

| Type of Work | Consider if you’ll be working on small or large projects |

| Budget | Don’t break the bank for features you won’t use! |

In summary, pick a drive system that fits your needs—like shoes that don’t pinch your toes!

Installation Guide for Kit Metal Lathe Drive Systems

Stepbystep installation process. Common mistakes to avoid during installation.Installing a metal lathe drive system can sound tricky, but it’s easier than convincing your cat to take a bath! Start by laying out all your parts. Next, follow these steps:

| Step | Description |

|---|---|

| 1 | Attach the motor to the base. |

| 2 | Connect the drive belt. |

| 3 | Secure the control panel. |

| 4 | Test the system before final assembly. |

Common mistakes include missing screws and forgetting to check the tension on the drive belt. Trust us, a loose belt creates more noise than your uncle’s karaoke night! Pay attention, and your lathe will be as smooth as butter.

Maintenance Tips for Longevity and Performance

Routine maintenance practices. Troubleshooting common issues.Keeping your lathe in shape is easier than it sounds! Start with a simple routine. Check the oil levels and make sure everything is clean. A dirty lathe is like a grumpy cat—it just won’t work right!

If something feels off, troubleshoot like a detective. Is a strange noise coming from the motor? Maybe it’s just asking for a snack! You can find common issues in the table below:

| Common Issue | Possible Fix |

|---|---|

| Unusual noises | Check for loose parts |

| Poor performance | Inspect the drive belt |

| Vibration | Balance the workpiece |

Remember, a little care can go a long way. With regular checks, your kit metal lathe drive system can keep spinning like a dancer at a party!

Comparative Analysis: Aftermarket vs. Original Drive Systems

Differences in quality and performance. Costeffectiveness and value.Choosing between aftermarket and original drive systems can feel like picking a favorite dessert: both are sweet but offer different flavors. Aftermarket systems often cost less, making them an appealing option. However, they might lack the shiny quality of original systems. Original systems generally offer better performance and longer life because they are made for your specific kit metal lathe. You can save money upfront with aftermarket systems, but you might have to spend more to fix issues down the road. Here’s a quick comparison:

| Criterion | Aftermarket Systems | Original Systems |

|---|---|---|

| Quality | Varies; sometimes good, sometimes not | High; made for specific models |

| Performance | May lag behind | Smooth and reliable |

| Cost | Usually cheaper | Higher upfront cost |

| Value | Potential hidden costs | Long-term savings |

So, which one suits your needs best? It might depend on your budget and how much you value long-term performance. Always choose wisely, because a happy lathe means a happy workshop!

Expert Insights: What Professionals Say About Drive Systems

Interviews or quotes from experienced machinists. Anecdotes highlighting the impact of drive system choices.Many experienced machinists agree on the importance of choosing the right drive system. According to one machinist, “A good drive system can change everything.” Their stories show how a reliable system boosts efficiency and reduces errors. Here are some insights:

- Better precision leads to higher quality work.

- Fewer breakdowns save time and money.

- Easy maintenance means less stress during projects.

These choices can impact creativity and success in machining. It’s clear that picking the right drive system matters a lot.

Why does a drive system matter?

A drive system affects the machine’s performance and the operator’s experience. Good systems can help machinists do their best work.

Future Trends in Metal Lathe Drive Systems

Innovations and technological advancements. Predictions for the upcoming years in the industry.New ideas are shaping the future of metal lathe drive systems. We can expect exciting changes coming soon. For starters, smart technology will make machines work better. Imagine machines that can think for themselves. Eco-friendly designs will also help save energy. They will cut costs and reduce waste. Here are some future trends to watch:

- Automation: More robots will take over routine tasks.

- Advanced Materials: Stronger, lighter materials will improve durability.

- AI Integration: Machines will learn and adapt to create better products.

These changes can make work faster and safer. The industry is ready for a bright future!

What advancements are on the horizon for drive systems?

Future advancements include smart technology, automation, and eco-friendly designs. These innovations will enhance efficiency and reduce the environmental impact of metal lathe drive systems.

Conclusion

In summary, a kit metal lathe drive system is essential for smooth machining. It helps control speed and torque effectively. You can improve your projects by choosing the right system. We encourage you to explore different kits and read user reviews. This will help you find the best fit for your metalworking needs. Happy machining!FAQs

Sure! Here Are Five Questions Related To The Drive System Of A Kit Metal Lathe:Sure! Here are five questions about the drive system of a kit metal lathe: 1. What does the drive system do? The drive system makes the lathe spin. It helps to cut and shape metal. 2. How do you start the lathe? You turn on the power switch. Then, you can adjust the speed. 3. What is a motor? A motor is a machine that moves things. In a lathe, it makes the spinning happen. 4. Why do we need different speeds? Different speeds let us cut metal better. Some metals need fast speeds, and some need slow speeds. 5. How do you stop the lathe? You press the stop button. This safely turns off the spinning.

Sure! Please provide the question you want me to answer.

What Are The Main Components Of A Drive System In A Kit Metal Lathe, And How Do They Function Together?The main parts of a drive system in a kit metal lathe are the motor, belts, and gears. The motor gives power to the lathe. The belts connect the motor to the gears, helping them turn. Gears change the speed and direction of the spinning. Together, these parts help you shape metal into different forms.

How Does The Choice Of Motor (Ac Vs. Dc) Impact The Performance And Capabilities Of A Kit Metal Lathe?Choosing between an AC (Alternating Current) motor and a DC (Direct Current) motor for a metal lathe really matters. AC motors are good for steady power, making them great for long jobs, but they can be harder to control. DC motors are easier to control, so you can speed up or slow down quickly. This helps with detailed work. Overall, the motor type can change how the lathe works and what you can build with it.

What Are The Advantages And Disadvantages Of Using Belt-Driven Versus Direct-Drive Systems In Metal Lathe Applications?Belt-driven systems use a long belt to connect the motor to the lathe. They are usually cheaper and easier to fix. However, they can wear out over time and cause noise. Direct-drive systems connect the motor right to the lathe. They are quieter, more powerful, and require less maintenance, but they can be more expensive.

How Can Users Effectively Maintain And Troubleshoot The Drive System Of A Kit Metal Lathe To Ensure Optimal Performance?To keep the drive system of your kit metal lathe working well, you should check it often. First, make sure everything is clean and free from dust. You can also look for loose parts and tighten them if needed. If it makes strange noises, turn it off immediately and check for problems. Finally, always follow the instructions in the manual for help.

What Modifications Or Upgrades Can Be Made To The Drive System Of A Kit Metal Lathe To Improve Torque And Speed Control?You can make your metal lathe work better by changing a few things. First, you can add a better motor for more power. You can also use a speed controller to change how fast it goes. Changing the drive belt to a stronger one helps with torque, too. These upgrades will let you make smoother and easier cuts!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Drive System Of A Kit Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about the drive system of a kit metal lathe: 1. What does the drive system do? The drive system makes the lathe spin. It helps to cut and shape metal. 2. How do you start the lathe? You turn on the power switch. Then, you can adjust the speed. 3. What is a motor? A motor is a machine that moves things. In a lathe, it makes the spinning happen. 4. Why do we need different speeds? Different speeds let us cut metal better. Some metals need fast speeds, and some need slow speeds. 5. How do you stop the lathe? You press the stop button. This safely turns off the spinning.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Main Components Of A Drive System In A Kit Metal Lathe, And How Do They Function Together?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The main parts of a drive system in a kit metal lathe are the motor, belts, and gears. The motor gives power to the lathe. The belts connect the motor to the gears, helping them turn. Gears change the speed and direction of the spinning. Together, these parts help you shape metal into different forms.”}},{“@type”: “Question”,”name”: “How Does The Choice Of Motor (Ac Vs. Dc) Impact The Performance And Capabilities Of A Kit Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing between an AC (Alternating Current) motor and a DC (Direct Current) motor for a metal lathe really matters. AC motors are good for steady power, making them great for long jobs, but they can be harder to control. DC motors are easier to control, so you can speed up or slow down quickly. This helps with detailed work. Overall, the motor type can change how the lathe works and what you can build with it.”}},{“@type”: “Question”,”name”: “What Are The Advantages And Disadvantages Of Using Belt-Driven Versus Direct-Drive Systems In Metal Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Belt-driven systems use a long belt to connect the motor to the lathe. They are usually cheaper and easier to fix. However, they can wear out over time and cause noise. Direct-drive systems connect the motor right to the lathe. They are quieter, more powerful, and require less maintenance, but they can be more expensive.”}},{“@type”: “Question”,”name”: “How Can Users Effectively Maintain And Troubleshoot The Drive System Of A Kit Metal Lathe To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the drive system of your kit metal lathe working well, you should check it often. First, make sure everything is clean and free from dust. You can also look for loose parts and tighten them if needed. If it makes strange noises, turn it off immediately and check for problems. Finally, always follow the instructions in the manual for help.”}},{“@type”: “Question”,”name”: “What Modifications Or Upgrades Can Be Made To The Drive System Of A Kit Metal Lathe To Improve Torque And Speed Control?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can make your metal lathe work better by changing a few things. First, you can add a better motor for more power. You can also use a speed controller to change how fast it goes. Changing the drive belt to a stronger one helps with torque, too. These upgrades will let you make smoother and easier cuts!”}}]}