Have you ever wondered how machines can shape metal into beautiful designs? A kit metal lathe gear train plays a huge role in this process. It helps turn raw metal into precise parts. Imagine a tiny superhero making things from scratch! That’s what a lathe does.

In the world of metalworking, these machines are like magic. They spin metal while cutting it into desired shapes. But have you thought about how they do this so smoothly? The secret lies in the gear train! It connects different parts, helping them work together.

Do you know that some lathes can create intricate patterns and shapes? With the right gear train, a simple piece of metal can transform into something amazing. By learning how these gears work, you can make your own cool projects. So, let’s explore the kit metal lathe gear train and unlock the wonders of metalworking!

Understanding Kit Metal Lathe Gear Train Components A Kit Metal Lathe Gear Train Is An Essential Assembly In Metalworking, Providing The Necessary Mechanical Advantage And Control For Effective Machining. This Gear Train Plays A Crucial Role In The Functionality Of A Lathe By Enabling The Conversion Of Motor Power Into Rotational Movement, Which Is Vital For Shaping And Cutting Metal. What Is A Kit Metal Lathe Gear Train? A Kit Metal Lathe Gear Train Consists Of Several Interconnected Gears Designed To Transmit Rotational Force From The Motor To The Spindle Of The Lathe. This System Allows For Different Speeds And Torque Settings, Enhancing The Lathe’S Versatility. Understanding The Components And How They Interact Is Essential For Any Enthusiast Looking To Optimize Their Metalworking Projects. Key Components Of A Gear Train 1. **Gears:** The Primary Components That Transmit Motion And Power. Each Gear Varies In Size And Tooth Count, Affecting The Gear Ratio And Output Speed. 2. **Spindle:** Acts As The Central Axis That Rotates And Holds The Workpiece. 3. **Levers And Switches:** Allow Operators To Adjust Settings Quickly For Speed And Torque Changes. 4. **Bearings:** Ensure Smooth Rotation Of The Gears, Minimizing Friction And Wear Over Time. Benefits Of A Gear Train In Metal Lathes – **Versatility:** Offers The Ability To Tailor Speeds And Feeds Based On The Material And Task. – **Precision:** Enhances Accuracy In Cuts And Finishes, Crucial For Professional-Quality Work. – **Power Efficiency:** Increases The Efficiency Of Motor Use, Ensuring Proper Transmission Of Energy. Maintenance Tips To Keep Your Kit Metal Lathe Gear Train Functioning Smoothly, Consider The Following Tips: – **Regular Lubrication:** Apply Quality Lubricant To Reduce Friction Between Gears. – **Inspect For Wear:** Check Gears Regularly For Signs Of Wear Or Damage That May Affect Performance. – **Alignment Checks:** Ensure All Components Are Properly Aligned To Prevent Unnecessary Strain On The Motor. Conclusion Incorporating A Kit Metal Lathe Gear Train Into Your Lathe Setup Is A Significant Step Towards Enhancing Your Metalworking Capabilities. Understanding Its Components And Maintenance Can Lead To Improved Efficiency And Precision In Your Projects. Whether You Are A Seasoned Professional Or A Hobbyist, Mastering The Gear Train Will Elevate Your Machining Skills To New Heights.

Exploring the Kit Metal Lathe Gear Train

A kit metal lathe gear train is vital for metalworking projects. It helps change speeds and torque for different tasks. With a gear train, you can make precise cuts and shapes in metal. Imagine building a robot or a model vehicle! Understanding this gear system opens up exciting possibilities for creativity and innovation. Plus, did you know that different gear ratios affect how fast you work? This simple yet powerful tool can reshape your metalworking experience!What is a Gear Train in Metal Lathes?

Definition and purpose of a gear train. Importance in metal lathe functionality.A gear train is a system of gears that work together to transfer power. This setup helps machines, like metal lathes, run smoothly. Gear trains adjust the speed and torque needed for various tasks. Their importance lies in making metal lathes precise and efficient. Without them, lathes wouldn’t function well, leading to poor results.

Why are gear trains important in metal lathes?

Gear trains provide support for accurate cuts and adjustments. They allow you to control the speed and strength of the lathe. This ensures your projects turn out just right!

- Boosts efficiency

- Improves precision

- Controls speed and torque

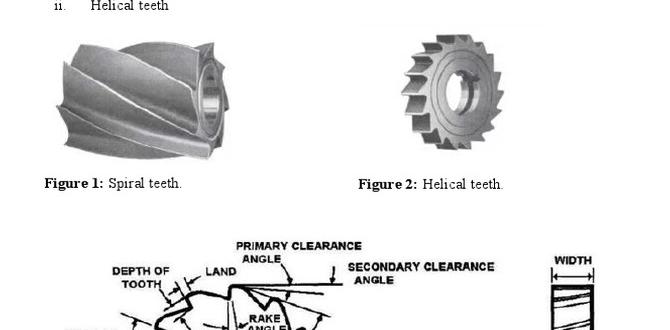

Types of Gear Trains Used in Metal Lathes

Differentiation between simple and compound gear trains. Advantages and disadvantages of each type.Metal lathes use two main types of gear trains: simple and compound. A simple gear train has a single set of gears, making it easier to set up. However, it might not provide enough speed options. On the other hand, a compound gear train combines multiple gears, offering more speed settings but can be trickier to manage. Think of it like making pancakes: one pan is simple, but a multi-pan setup gives you a pancake fiesta! Here’s a handy table to break it down:

| Type | Advantages | Disadvantages |

|---|---|---|

| Simple | Easier to use | Limited speed options |

| Compound | More speed choices | More complex setup |

How to Choose the Right Gear Train for Your Metal Lathe

Factors to consider based on lathe specifications. Common gear train configurations and their applications.Choosing the right gear train for your metal lathe can feel like picking toppings for pizza—everyone has their favorites! Start by checking your lathe’s specs. Powerful machines need strong gear trains. Next, look at common configurations. For example, a direct drive is like a speedy racecar. It’s fast but may lack torque. Meanwhile, sergeant gear trains can deliver more force, perfect for harder materials.

| Configuration | Speed | Torque | Application |

|---|---|---|---|

| Direct Drive | High | Low | Fine Cuts |

| Sergeant Gear | Moderate | High | Heavy Work |

Know what your projects need, and you’ll find the perfect match—like peanut butter and jelly! Remember, the best choice depends on what you plan to create.

Installation and Adjustment of Gear Trains

Stepbystep guide on setting up your gear train. Tips for troubleshooting common installation issues.Setting up your gear train can feel like solving a fun puzzle. First, gather your tools and parts. Line them up like little soldiers ready for duty. Begin by placing the gears onto the spindle. Make sure they fit snugly. Remember, too tight could mean trouble, and too loose is just asking for chaos! If you run into trouble, check if the gears are aligned right. They should mesh together like cookies and milk!

| Issue | Solution |

|---|---|

| Gears won’t turn | Realign and check for obstructions. |

| Noise during operation | Lubricate the gears; they love a good oil bath! |

| Gear slipping | Tighten the screws and check connections. |

Follow these steps, and your gear train will be running smoothly in no time! Who knew mechanics could be this much fun?

Maintaining Your Gear Train for Longevity

Best practices for regular maintenance. Signs of wear and when to replace components.To keep your gear train running smoothly, regular maintenance is key. Always check for any strange noises or unusual vibrations; these are signs that something might be off. Cleaning your gear train helps it stay efficient and can prevent problems. If you notice worn-out components, it’s time to replace them. Waiting too long might lead to bigger issues—and nobody wants a gear train drama! Here’s a quick guide to make it easy:

| Maintenance Task | Frequency | Signs to Replace |

|---|---|---|

| Clean gears | Monthly | Visible wear or scratches |

| Check lubrication | Every 3 months | Dry gears or squeaking sounds |

| Inspect for damage | Biannually | Cracks or loose parts |

Keeping an eye on these things will help your gear train live a long and happy life!

Future Trends in Metal Lathe Gear Train Technology

Innovations and advancements in gear train design. Impact of technology on efficiency and precision.The future of metal lathe gear train technology is bright. New designs are making gear trains more efficient and precise. Innovations can help machines run smoother and longer. This means better products and less waste. Exciting changes are happening! Some key advancements include:

- Smart sensors that monitor performance.

- Lightweight materials for less energy use.

- Advanced software for quick adjustments.

With these improvements, manufacturers can produce items faster and with high quality. Imagine machines that think for themselves! It’s like having a robot assistant, making work easier and better.

What are some innovations in gear train design?

Innovations include smart sensors, lightweight materials, and advanced software. These help machines work more efficiently and precisely.

FAQs About Kit Metal Lathe Gear Trains

Common questions regarding functionality and compatibility. Expert answers to enhance user understanding.Many people have questions about the kit metal lathe gear train. Understanding how it works can help users make better choices. Here are some common queries:

Is the gear train compatible with all lathes?

It depends! Not all gear trains fit every lathe. Check the specifications before buying.

How does the gear train impact functionality?

A gear train can improve cutting precision. More gears often lead to smoother operation.

Common FAQs:

- Does it require special tools for installation? Yes, basic tools are usually needed.

- Can I upgrade my existing lathe? Yes, many users find upgrades are helpful.

Asking questions helps you learn. Enjoy your crafting!

Conclusion

In conclusion, a kit metal lathe gear train is essential for smooth machining. It helps control speed and torque. Understanding its parts will improve your projects. You can enhance your skills by exploring more about lathe gears. Practical experience will make you confident. So, dive into hands-on projects and enjoy creating with your metal lathe!FAQs

What Is The Function Of A Gear Train In A Metal Lathe, And How Does It Affect The Lathe’S Performance?A gear train in a metal lathe helps control how fast the lathe spins. It connects different gears to change speeds and force. This means you can work on materials more easily. A good gear train helps you make better cuts and shapes. Overall, it makes the lathe work better for your projects.

How Do Different Gear Ratios In A Lathe’S Gear Train Impact The Cutting Speed And Torque?Different gear ratios in a lathe change how fast the cutting tool spins. A higher gear ratio means the tool spins faster but has less power. This is good for cutting smooth surfaces. A lower gear ratio gives more power but makes the tool spin slower, which is better for cutting tougher materials. So, we can adjust the gears to get the right speed and strength for what we are working on.

What Are The Common Materials Used For Gears In A Kit Metal Lathe, And How Do They Affect Durability And Performance?Gears in a kit metal lathe are often made from steel, aluminum, or plastic. Steel is strong and lasts a long time, but it can be heavy. Aluminum is lighter and still pretty strong, making machines easier to use. Plastic gears are lighter and cheaper, but they might wear out faster. The material you choose affects how long the gears last and how well they work.

How Can A User Adjust Or Replace Gears In The Gear Train Of A Metal Lathe To Achieve Specific Machining Results?To adjust or replace gears in a metal lathe, first, turn off the machine and unplug it for safety. Then, find the gear train, which is a set of gears inside the lathe. You can remove the old gears by unscrewing them. After that, choose new gears that fit and help you make the cuts you want. Finally, put everything back together and test the lathe to see if it works like you need!

What Are The Benefits And Drawbacks Of Using A Gear Train Versus A Direct Drive System In A Commercial Metal Lathe?Using a gear train in a metal lathe helps us change speeds easily. It lets us work with different materials better. However, gear trains can be noisy and need more maintenance. A direct drive system is quieter and easier to use, but it doesn’t allow for as many speed changes. So, each system has its good and bad sides!