Have you ever watched a metal lathe in action? It’s like a dance of precision and power. One fascinating part of many metal lathes is the quill. A **kit metal lathe quill** allows for more control and flexibility when shaping metal. Imagine transforming a dull piece of metal into a smooth, useful tool. Sounds interesting, doesn’t it?

Many people don’t know much about this essential part. The quill is often overlooked but plays a big role in how well the lathe works. Wouldn’t it be exciting to learn how to use a kit metal lathe quill to create your own projects? You can make everything from custom tools to intricate designs!

In the world of metalworking, understanding your equipment is key. Knowing how to use the quill effectively can elevate your skills fast. Join us as we dive into the important details of the kit metal lathe quill. You’ll discover tips, tricks, and stories that might surprise you!

Comprehensive Guide To Kit Metal Lathe Quill Setup

Understanding the Kit Metal Lathe Quill

The kit metal lathe quill is a vital part for precision work. But what does it really do? This component holds the cutting tool steady during operation. A well-functioning quill ensures smooth and accurate cuts. It’s interesting to think how much this small part impacts the final product! Proper maintenance can extend its life. Wouldn’t it be frustrating if your projects didn’t turn out right due to a faulty quill? Knowing how to care for it is essential for any metalworking enthusiast.What is a Kit Metal Lathe Quill?

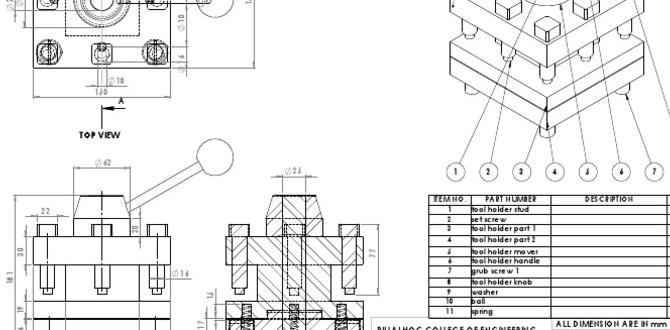

Definition and function of a quill in metal lathes. Key components and materials used in manufacturing quills.A quill is an important part of a metal lathe. It helps to hold and support the cutting tool. Think of it like a superhero sidekick—always ready to lend a hand! Key parts of a quill include the barrel, which holds the tool, and the clamp bolts, which keep everything tight. They are usually made from strong metals like steel, so they can handle tough jobs. Below is a simple table showing the key components:

| Component | Function | Material |

|---|---|---|

| Barrel | Holds the cutting tool | Steel |

| Clamp Bolts | Secure the tool in place | High-strength metal |

Next time you use a lathe, remember the quill’s superpower—making sure your tool stays exactly where you need it!

How to Choose the Right Kit Metal Lathe Quill

Factors to consider: size, compatibility, and intended use. Tips for assessing quality and durability.Picking the right kit metal lathe quill can be tricky, but keeping a few points in mind helps. First, consider the size. It should fit your lathe like a glove — a bad fit is like wearing shoes two sizes too small! Next, check compatibility. Your quill needs to work well with your lathe. Lastly, think about its intended use. Are you crafting tiny pieces, or making big projects? For quality, look for sturdy materials. A solid quill will last longer than a cheese sandwich at a picnic!

| Factor | What to Look For |

|---|---|

| Size | Fits snugly with your lathe |

| Compatibility | Works smoothly without fuss |

| Intended Use | Matches your project needs |

| Quality | Made from strong materials |

Installation and Setup of Metal Lathe Quills

Stepbystep guide to installing a quill in a metal lathe. Common mistakes to avoid during the installation process.Installing a metal lathe quill can seem tricky, but it’s easy with the right steps. First, gather all the tools you need. Second, read the manual carefully. Next, follow these simple steps:

- Clean the lathe and quill area.

- Align the quill with the lathe’s spindle.

- Secure it in place, ensuring it fits snugly.

- Double-check all connections before testing.

Common mistakes can lead to issues. Avoid these:

- Not tightening bolts enough.

- Forgetting to remove old parts.

- Misaligning the quill during setup.

Following these tips will help you succeed.

What should I check after installing the quill?

After installing, check for smooth movement. Ensure it operates without sticking and is firmly attached.

Maintenance Tips for Kit Metal Lathe Quills

Routine maintenance practices to ensure longevity and performance. Signs of wear and when to replace a quill.Maintaining your kit metal lathe quill is essential for it to work well. Regular care can help it last longer. Here are some useful tips:

- Clean after each use to remove dirt.

- Check for rust and treat it quickly.

- Oil moving parts to keep them smooth.

- Look for cracks or bends that shouldn’t be there.

Watch for signs of wear. If you notice strange noises or trouble moving parts, it might be time to replace the quill. Keeping an eye on these details will help you avoid problems later.

What should you look for when checking your quill?

Look for rust, cracks, or stiffness in the movement to know if your quill needs attention. Regular checks can prevent larger issues and keep your lathe running smoothly.

Comparing Kit Metal Lathe Quills to Alternative Options

Differences between quills and other lathe attachment options. Situations where a quill is preferable over alternatives.Kit metal lathe quills differ from other attachments in several ways. Quills offer precise depth control. They allow for easy adjustment, helping users create accurate designs. Other options might lack this flexibility. Here are times when a quill shines:

- Fine detail work: Quills excel during intricate projects.

- Easy adjustments: They make quick changes simple.

- Consistent results: Quills help maintain precision.

For many tasks, a quill is the best choice to achieve high-quality results quickly.

Why choose quills over other options?

Quills provide better control and accuracy for detailed work compared to some alternatives. They are great when constant adjustments matter.

Real-world Applications of Kit Metal Lathe Quills

Industry use cases showcasing the benefits of quills. Examples of specific projects utilizing quills effectively.Quills have become the unsung heroes in the metalworking industry. They make precision tasks easier and help create amazing projects. For instance, a quill can assist in drilling holes in metal parts, which is key in building fancy machines. Imagine a robot needing a perfectly aligned hole! With a quill, that’s possible. In fact, companies report boosting their productivity by over 30% just by using these handy tools. That’s more time for coffee breaks!

| Project | Benefit |

|---|---|

| Automotive Parts | Precision holes for better fit. |

| Machine Tools | Improved accuracy enhances safety. |

| Artistic Metalwork | Creates precise designs. |

Conclusion

In summary, a kit metal lathe quill is an important tool for precision work. It helps you create accurate parts and shapes. By learning how to use it, you can improve your skills. Explore different kits and read guides to find the best one for your projects. Start practicing, and soon you’ll gain confidence in your metalworking abilities!FAQs

Sure! Here Are Five Related Questions On The Topic Of A Kit Metal Lathe Quill:Sure! A kit metal lathe quill is a part of a machine that helps shape and cut metal. You use it to hold tools in place while they spin. This makes it easier to make accurate cuts. Quills can be adjusted or moved up and down for different jobs. Keeping it clean and well-oiled helps it work better!

Sure! Please provide me with the question you want answered.

What Are The Key Components Of A Quill In A Metal Lathe, And How Do They Function Together During Operation?A quill in a metal lathe has a few important parts. First, there is the body, which holds everything together. Then, there is a tool holder, where we place cutting tools to shape the metal. The quill moves up and down, letting us change how deep the tool cuts into the metal. All these parts work together to shape metal pieces smoothly and accurately.

How Do You Properly Install And Align A Quill On A Kit Metal Lathe To Ensure Accurate Machining?To install a quill on a kit metal lathe, first, check the quill for any dirt or damage. Next, attach the quill to the machine according to the instructions. Make sure it fits snugly and isn’t loose. To align it, you can use a ruler or gauge to check that it’s straight. Adjust it until it lines up perfectly for precise machining.

What Are The Common Materials Used For Manufacturing Quills In Metal Lathes, And How Do They Affect Durability And Performance?Quills in metal lathes are often made from steel or aluminum. Steel is strong and lasts a long time. Aluminum is lighter, making it easier to move. Strong materials help the quill work better and last longer. Choosing the right material helps you do your work without problems.

How Do You Troubleshoot Common Issues With A Metal Lathe Quill, Such As Unwanted Play Or Misalignment?To fix problems with a metal lathe quill, we start by checking for loose parts. First, make sure all screws are tight. Next, look for any dirt or dust that might cause issues and clean it out. If you notice play or misalignment, we might need to adjust or replace the bearings. Finally, test the lathe to see if it works better.

What Are The Advantages And Disadvantages Of Using A Quill In A Kit Metal Lathe Compared To A Fixed Tailstock Design?Using a quill in a metal lathe lets you move it up and down easily. This helps with different tasks. If you need to change how deep or far you cut, a quill makes it simple. However, a fixed tailstock is more stable. It stays in one place, which helps with accuracy but can be harder to adjust.