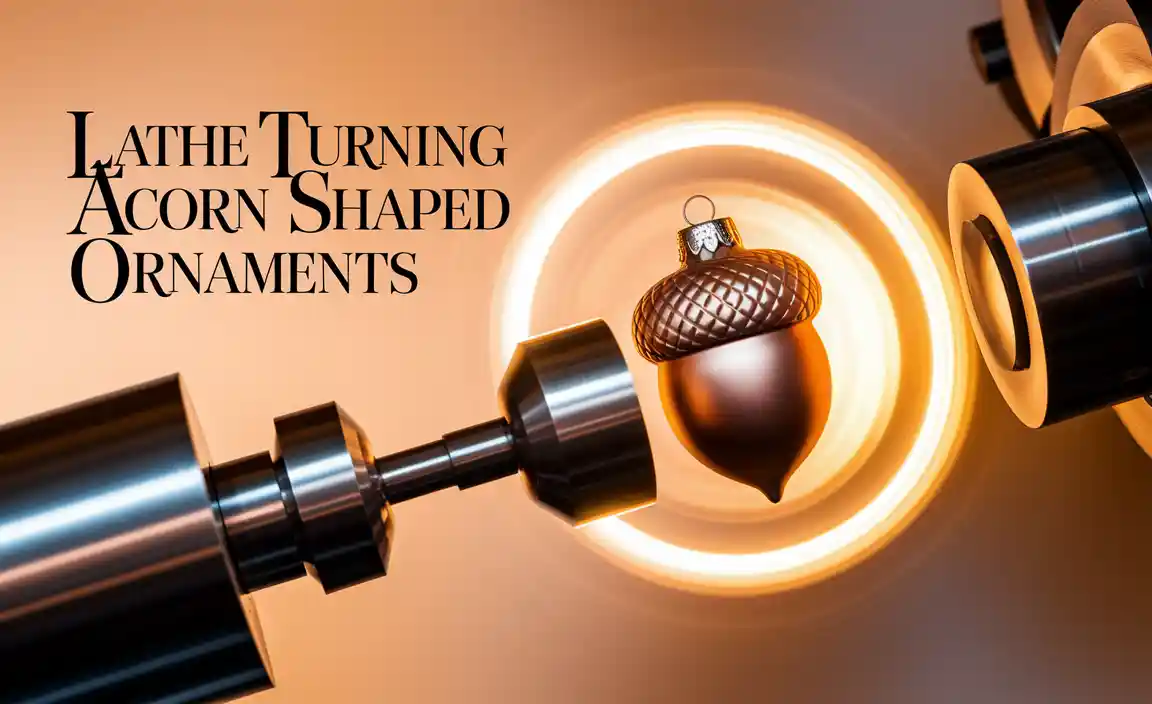

Have you ever wondered how a metal lathe works? These machines are tools that shape metal into amazing things, like parts for cars or tools for workshops. If you want to set up your very own metal lathe, a good starting point is the kit metal lathe wiring diagram. It can help you connect everything correctly.

Imagine you’re in your garage. You’ve got your metal lathe, and maybe some cool projects in mind. But then it hits you—how do you connect all those wires? This wiring diagram is like a treasure map. It guides you step-by-step in making the right connections.

Did you know that the right wiring can make your lathe run smoother and safer? Having a clear diagram can save you from mistakes. Plus, it helps you learn about your machine better. So, whether you’re a beginner or have some experience, understanding your kit metal lathe wiring diagram is key.

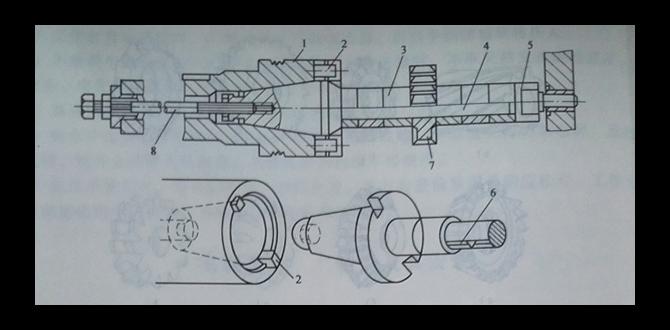

Complete Kit Metal Lathe Wiring Diagram Guide For Beginners — When It Comes To Setting Up A Kit Metal Lathe, Having A Clear Wiring Diagram Is Essential For Ensuring Your Machine Operates Safely And Efficiently. In This Article, We Will Explore What A Kit Metal Lathe Wiring Diagram Entails, Its Importance, And Some Key Components To Consider While Making Connections. Understanding The Basics Of Kit Metal Lathe Wiring A Kit Metal Lathe Typically Includes Various Electrical Components That Need To Be Correctly Wired To Function Properly. The Wiring Diagram Serves As A Blueprint, Showing How Each Part Connects To Power Sources, Motors, And Control Switches. Familiarity With The Diagram Is Crucial For Both Beginners And Experienced Users. Key Components Of A Kit Metal Lathe Wiring Diagram 1. **Power Supply**: The Source Of Electricity That Powers The Lathe’S Motor And Other Components. 2. **Motor**: The Heart Of The Lathe, Converting Electrical Energy Into Mechanical Energy To Drive The Spindle. 3. **Control Switches**: These Allow Users To Start, Stop, And Regulate The Speed Of The Lathe. 4. **Fuses And Circuit Breakers**: Important For Safety, These Components Protect The Wiring From Overloads And Short Circuits. 5. **Wires And Connectors**: Ensure That You Use The Appropriate Gauge Of Wire And Connectors To Handle The Operational Currents. Importance Of Following The Wiring Diagram Following The Wiring Diagram Closely Is Vital For Several Reasons: – **Safety**: Proper Wiring Minimizes The Risk Of Electric Shock Or Equipment Damage. – **Efficiency**: Correct Connections Ensure Optimal Performance And Prolong The Lifespan Of Your Lathe. – **Troubleshooting**: A Good Wiring Diagram Helps Pinpoint Issues When Problems Arise, Making Repairs Easier. Conclusion Successfully Wiring A Kit Metal Lathe Is A Crucial Task That Shouldn’T Be Taken Lightly. With A Solid Wiring Diagram, Understanding The Components, And Following Safety Precautions, You’Ll Be Well On Your Way To A Fully Operational Metal Lathe. Always Refer To The Manufacturer’S Guidelines And Consult Professionals If You’Re Uncertain About Any Aspect Of The Wiring Process. Remember, A Well-Wired Lathe Is Not Just About Functionality—It’S About Safety And Longevity As Well.

Understanding Kit Metal Lathe Wiring Diagrams

A kit metal lathe wiring diagram helps users connect electrical components safely. These diagrams show how to link motors, switches, and power sources correctly. Proper wiring ensures the lathe operates smoothly and prevents accidents. Imagine powering up your lathe for the first time, knowing everything is wired correctly! Familiarizing yourself with these diagrams can enhance your confidence in DIY projects. An engaging diagram can make learning about lathe wiring easy and enjoyable.Importance of Wiring Diagrams for Metal Lathes

Explanation of how wiring diagrams facilitate proper assembly and troubleshooting.. Discussion on safety considerations when working with wiring..Wiring diagrams play a key role in building and fixing metal lathes. They show the correct connections of wires, making assembly simple. This prevents mistakes that could cause trouble later. Diagrams also help troubleshoot issues. A quick glance can reveal where things might be wrong.

Safety is crucial when dealing with wiring. Follow these guidelines:

- Always turn off power before working.

- Use insulated tools.

- Wear safety glasses.

Being careful can prevent accidents and keep you safe. Remember, a clear wiring diagram is your best friend!

Why are wiring diagrams essential for metal lathes?

Wiring diagrams ensure correct assembly and easy troubleshooting for metal lathes. They also help identify safety risks when working with electrical components.

Step-by-Step Guide to Reading a Metal Lathe Wiring Diagram

Instruction on how to interpret symbols and connections.. Tips for following circuit paths and understanding flow..Reading a wiring diagram is like playing a treasure hunt. First, look for the symbols; they are the clues! Common symbols include circles for connections and lines for wires. Understanding these icons helps you follow the flow of electricity. Now, when tracing the circuit paths, remember: always start from the power source before sailing through the maze of wires. Think of it like a roller coaster ride; you need to know the starting point before enjoying the twists and turns!

| Symbol | Meaning |

|---|---|

| 🔌 | Power Source |

| ⚡ | Electric Flow |

| 🔗 | Connection |

Common Wiring Issues and Solutions

Identification of frequent wiring problems in metal lathes.. Suggested troubleshooting steps for resolving these issues..Wiring problems in metal lathes can feel like a bad plot twist. Common issues include loose connections, frayed wires, and blown fuses. These can turn your metal masterpiece into a quiet, sad machine. First, check for broken or loose connections—think of it like a friendship: if it’s loose, it won’t work! If you spot a frayed wire, it might need a quick “band-aid” repair. Lastly, if your lathe is totally unresponsive, try replacing the fuse as a first step.

| Problem | Solution |

|---|---|

| Loose connections | Check and tighten connections. |

| Frayed wires | Replace or repair wiring. |

| Unresponsive machine | Replace the fuse. |

Remember, troubleshooting is a bit like detective work—you’re looking for clues to solve the case of the silent lathe! Happy wiring!

DIY Wiring Tips for Kit Metal Lathes

Essential tools and materials needed for wiring.. Safety best practices during wiring installation..Before diving into wiring your kit metal lathe, gather some essential tools. You’ll need wire strippers, a screwdriver, and a multimeter. These buddies will help you make safe connections. Don’t forget materials like wires and connectors! Remember, safety first! Always wear gloves and goggles to protect yourself. Electricity can be a tricky friend, and a little sparkle on your finger isn’t a good look! Follow these tips for a smooth wiring adventure, and you won’t end up sending your lathe on a wild electric ride.

| Tools | Purpose |

|---|---|

| Wire Strippers | Strip insulation off wires |

| Screwdriver | Fasten and connect terminals |

| Multimeter | Measure voltage and continuity |

By using these tools and following safety practices, you’ll become a wiring wizard in no time!

Comparative Analysis of Wiring Diagrams from Different Metal Lathe Kits

Comparison of wiring diagrams from popular metal lathe brands.. Discussion on variances in complexity and common features..Wiring diagrams can look as different as a cat in a dog show! Each popular metal lathe brand has its own style. Some are simple, while others may resemble a maze. Most diagrams share common features, like power connections and motor wiring. However, a few brands throw in extra components that can confuse even the best of us.

| Brand | Complexity Level | Common Features |

|---|---|---|

| Brand A | Low | Clear labels |

| Brand B | Medium | Extra connectors |

| Brand C | High | Multiple circuits |

While those added features can be useful, they can also leave you scratching your head. Remember, whether simple or complex, always double-check the details to keep your lathe running smooth!

Resources for Further Learning About Metal Lathe Wiring

Recommended books, websites, and forums for additional information.. Suggestions for online tutorials and videos for visual learners..Learning about metal lathe wiring can be exciting! Here are some resources to help you dive deeper:

- Books: Check out titles like “The Metal Lathe” by Tom Wiley for hands-on guidance.

- Websites: Explore sites like Instructables and Practical Machinist for helpful articles and tips.

- Forums: Join discussions on The Home Machinist to ask questions and share experiences.

- Videos: Search for tutorials on YouTube. Channels like “This Old Tony” offer step-by-step lessons.

These resources can help you master your kit metal lathe wiring diagram. Happy learning!

What are the best online resources for metal lathe wiring?

For beginners, YouTube and Instructables are fantastic for visual learners. They provide clear tutorials and hands-on projects. For written guides, visit Practical Machinist and The Home Machinist forums. They have great tips from experienced users.

Conclusion

In summary, a kit metal lathe wiring diagram helps you understand how to connect parts safely. Knowing this diagram is essential for setting up your lathe correctly. Don’t hesitate to explore more resources or ask for help if you feel confused. By using the right wiring, you can improve your metalworking skills and create amazing projects. Happy turning!FAQs

What Are The Key Components To Understand In A Kit Metal Lathe Wiring Diagram?To understand a kit metal lathe wiring diagram, you need to know a few key parts. First, identify the power source, which gives electricity to the lathe. Next, find the switches that control the lathe, turning it on and off. You should also look for the motor wires, as they connect to the lathe’s spinning parts. Finally, check the safety features, like fuses, which protect the lathe from too much electricity.

How Do I Identify The Power Supply Connections In A Metal Lathe Wiring Diagram?To identify power supply connections in a metal lathe wiring diagram, look for wires labeled “power” or “supply.” These wires usually connect to a switch or a plug. You might see symbols like a battery or a plug for power sources. Follow the lines to see where they go. Remember to be careful and ask an adult for help if you’re unsure!

What Safety Precautions Should I Take When Wiring A Kit Metal Lathe?When wiring a metal lathe, always unplug it first. This way, you won’t get shocked. Use insulated tools to protect yourself. Keep your workspace dry and tidy to avoid accidents. Finally, wear safety goggles to protect your eyes.

How Can I Troubleshoot Common Wiring Issues In A Metal Lathe?To troubleshoot wiring issues in a metal lathe, first, check the power source. Make sure it’s plugged in and turned on. Next, look for any loose wires or damaged connections. You can also use a multimeter to test for electricity in the wires. If something looks broken, it may need to be replaced. Always remember to turn off the power before touching any wires!

Are There Specific Wiring Diagrams For Different Models Of Kit Metal Lathes, And Where Can I Find Them?Yes, there are different wiring diagrams for each model of kit metal lathes. You can usually find them in the manual that comes with the lathe. If you don’t have the manual, you can check the manufacturer’s website. Some online forums and groups for metalworking also share these diagrams. Just ask other people who use kit metal lathes for help!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Components To Understand In A Kit Metal Lathe Wiring Diagram? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To understand a kit metal lathe wiring diagram, you need to know a few key parts. First, identify the power source, which gives electricity to the lathe. Next, find the switches that control the lathe, turning it on and off. You should also look for the motor wires, as they connect to the lathe’s spinning parts. Finally, check the safety features, like fuses, which protect the lathe from too much electricity.”}},{“@type”: “Question”,”name”: “How Do I Identify The Power Supply Connections In A Metal Lathe Wiring Diagram? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To identify power supply connections in a metal lathe wiring diagram, look for wires labeled “power” or “supply.” These wires usually connect to a switch or a plug. You might see symbols like a battery or a plug for power sources. Follow the lines to see where they go. Remember to be careful and ask an adult for help if you’re unsure!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should I Take When Wiring A Kit Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a metal lathe, always unplug it first. This way, you won’t get shocked. Use insulated tools to protect yourself. Keep your workspace dry and tidy to avoid accidents. Finally, wear safety goggles to protect your eyes.”}},{“@type”: “Question”,”name”: “How Can I Troubleshoot Common Wiring Issues In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot wiring issues in a metal lathe, first, check the power source. Make sure it’s plugged in and turned on. Next, look for any loose wires or damaged connections. You can also use a multimeter to test for electricity in the wires. If something looks broken, it may need to be replaced. Always remember to turn off the power before touching any wires!”}},{“@type”: “Question”,”name”: “Are There Specific Wiring Diagrams For Different Models Of Kit Metal Lathes, And Where Can I Find Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are different wiring diagrams for each model of kit metal lathes. You can usually find them in the manual that comes with the lathe. If you don’t have the manual, you can check the manufacturer’s website. Some online forums and groups for metalworking also share these diagrams. Just ask other people who use kit metal lathes for help!”}}]}