Large capacity wood lathe machines provide the power and space needed for bigger projects, allowing woodworkers to turn larger bowls, furniture legs, and spindles with confidence and precision. Choosing the right one unlocks greater creative potential for substantial woodworking tasks.

Turning wood on a lathe is a rewarding craft, opening up a world of possibilities for creating beautiful bowls, intricate spindles, and unique home décor. As your skills grow and your projects get bigger, you might find yourself bumping against the limits of a smaller lathe. That’s where a large capacity wood lathe machine comes in. These workhorses offer the power, stability, and swing (the diameter of wood it can handle) to tackle impressive pieces. Don’t let the idea of a bigger machine intimidate you; we’re going to break down exactly what makes these lathes essential and how to choose the right one for your workshop. Get ready to expand your turning horizons!

What Makes a Wood Lathe “Large Capacity”?

When we talk about a “large capacity wood lathe machine,” we’re referring to a few key features that set it apart from smaller, benchtop models. It’s not just about size; it’s about capability.

Swing and Bed Length: The Core of Capacity

The two most important measurements for lathe capacity are the swing and the bed length.

Swing: This is the maximum diameter of a workpiece that can be rotated without hitting the lathe bed. A larger swing means you can turn bigger bowls, platters, or decorative spheres. For example, a 12-inch swing can handle a roughly 10-inch diameter bowl if you account for the tool rest. A 20-inch swing opens up possibilities for much larger items.

Bed Length: This determines the maximum length of the workpiece the lathe can accommodate between the headstock and tailstock centers. For longer turnings like table legs, bedposts, or longer spindles, a considerable bed length is crucial.

Motor Power: The Muscle Behind the Turn

Large capacity wood lathes typically come with more powerful motors. Why is this important?

Handling Larger Wood: Bigger pieces of wood are heavier and can be out of balance, especially at the start of the turning process. A more powerful motor can more easily overcome the inertia and vibrations of these larger blanks.

Consistent Speed: More power often translates to better speed control under load. This means the lathe is less likely to bog down when you apply pressure with your chisels, leading to a smoother, more enjoyable turning experience and better finishes.

Tackling Hardwoods: If you plan to turn denser hardwoods, like oak, maple, or walnut, a more powerful motor is essential to cut through them effectively and without strain.

Tool Rest Support: Stability for Big Jobs

With larger workpieces, you need robust support for your turning tools. Large capacity lathes feature substantial tool rests and often have stronger banjo (the part that holds the tool rest and accommodates the tailstock) and tailstock assemblies capable of handling the torque and weight. This stability is vital for safety and for achieving clean cuts on massive projects.

Construction and Weight: The Foundation of Performance

A defining characteristic of many large capacity wood lathes is their sheer weight and robust construction. Cast iron beds and stands are common. This mass is essential for absorbing vibrations generated by turning larger, potentially unbalanced workpieces. Without this stability, your turns will suffer from chatter, and the experience will be less safe and far less enjoyable. A heavy, stable lathe is a key indicator of its ability to handle demanding tasks.

Why Upgrade to a Large Capacity Wood Lathe?

You might be wondering, “Can’t I just turn a big bowl on a smaller lathe?” While there are tricks to extend the reach of smaller machines, a true large capacity wood lathe offers distinct advantages that make a world of difference for specific projects.

1. Unleash Your Creative Ambition

The most significant reason to upgrade is to remove the limitations on your imagination.

Bigger Bowls and Platters: Turn those massive statement pieces for your dining table or decorative centerpieces that demand a larger scale.

Furniture Components: Create substantial table legs, chair spindles, lamp bases, and newel posts with a consistent diameter and length.

Architectural Elements: Rehabilitate or create new architectural trim and decorative elements for homes and businesses.

2. Improved Turning Experience and Results

Working with more wood demands more from your machine. A large capacity lathe elevates your experience:

Smoother Operation: Reduced vibration leads to cleaner cuts and smoother surfaces, meaning less sanding later.

Better Control: The increased stability and power give you finer control over your tools, allowing for more intricate work.

Efficient Material Removal: More power means you can remove material faster and more efficiently, saving time and effort, especially when roughing out large blanks.

3. Enhanced Safety

While any lathe requires respect and safety precautions, larger, heavier machines are inherently more stable. They are designed to manage the forces generated by substantial workpieces:

Reduced Wobble and Vibration: This minimizes unexpected movements of the workpiece that could lead to tool kickback or injury.

Robust Construction: The heavier build provides a more solid platform, making the machine less prone to tipping or instability.

4. Versatility for Various Projects

Beyond just large items, a capable large capacity lathe can often handle smaller projects with greater ease and precision than a small lathe can handle large ones. The broader range of speed control and the robust motor can make even small detail work more manageable.

Key Features to Look for in a Large Capacity Wood Lathe

When you’re ready to invest in a large capacity wood lathe machine, several features will significantly impact its performance and suitability for your needs.

Motor Size and Power Source

Horsepower (HP): For large capacity lathes, look for at least 1.5 HP. Many professional-grade machines offer 2 HP or even more. More horsepower means more torque and capability.

Power Requirements: Be mindful of whether the lathe requires a standard 120V outlet or a 240V outlet. A larger motor, especially over 1.5 HP, will likely need a 240V circuit. Check your workshop’s electrical setup.

Swing and Distance Between Centers

Swing: Decide on the maximum diameter you anticipate turning. Standard large capacity lathes often start at a 16-inch or 18-inch swing. Many offer swing-away tailstocks or bed extensions to increase this further.

Distance Between Centers (Bed Length): Measure the longest workpiece you might need to turn. Standard lengths can range from 30 inches to over 60 inches. Some lathes offer optional bed extensions for even greater length.

Variable Speed Control

This is non-negotiable for any modern wood lathe, especially a large capacity one.

Electronic Variable Speed (EVS): This allows you to adjust the RPMs on the fly without changing belts. It’s crucial for safety (slower speeds for roughing out unbalanced pieces) and for optimizing cutting speeds for different woods and tools.

Speed Range: Look for a wide RPM range. A lower low-speed setting (under 50 RPM) is excellent for working with very large, unbalanced blanks. A higher top speed (around 3000-4000 RPM) is useful for fine finishing.

Headstock and Tailstock Features

Headstock Swivel: A headstock that can swivel 90 degrees or more is a game-changer for turning large bowls and platters. It allows you to move the material outboard (beyond the lathe bed) and cut the face of the bowl with more comfortable access.

Spindle Thread: Standard is usually 1″ x 8 TPI, which is compatible with most chucks and faceplates.

Tailstock Quill Travel: A longer quill travel allows for more versatility when drilling or mortising with accessories.

Morse Taper: Most tailstocks use Morse Taper (MT) #2 or #3, which is standard for most accessories like drill chucks and live centers.

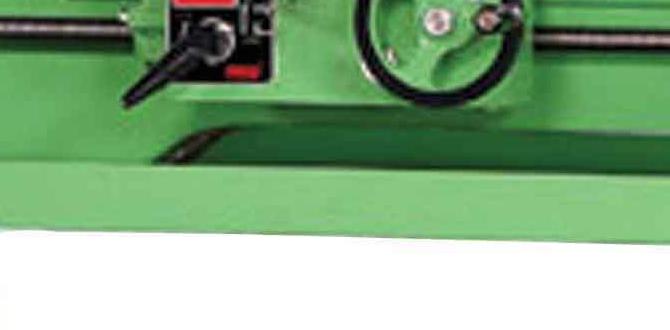

Bed Construction and Stability

Material: Heavy-duty cast iron is the gold standard for lathe beds. It provides the mass needed to dampen vibrations.

Weight: A heavier machine is generally a more stable machine. Look at the overall weight specification, especially for benchtop models versus floor-standing ones.

Stand: A sturdy, stable stand is essential. Some come with legs, others with wheeled bases for mobility.

Tool Rest and Banjo

Tool Rest Diameter: Ensure the tool rest is robust enough for larger work and has a good range of motion.

Banjo Lock-up: The mechanism that locks the banjo to the bed needs to be strong and secure to prevent shifting during operation.

Ease of Maintenance and Accessories

Belt Access: How easy is it to change belts if needed?

Accessory Compatibility: Can you easily add a bed extension, tool caddy, or other useful accessories?

Table: Comparing Lathe Capacities

To better illustrate what “large capacity” means in practical terms, let’s look at a comparative table.

| Feature | Compact Lathe | Mid-Size Lathe | Large Capacity Lathe | Extra Large Capacity Lathe |

|---|---|---|---|---|

| Swing Diameter | 10″-12″ | 12″-16″ | 16″-20″ | 20″+ |

| Distance Between Centers | 16″-20″ | 20″-30″ | 30″-45″ | 45″+ |

| Motor HP | 0.5 – 1 HP | 1 – 1.5 HP | 1.5 – 2 HP | 2 HP+ |

| Ideal for Bowls | Small to Medium (up to ~8″ finished) | Medium (up to ~12″ finished) | Large (up to ~16″ finished) | Very Large/Platters (up to ~20″+ finished) |

| Ideal for Spindles | Short, less intricate | Medium length, some detail | Longer, more substantial furniture legs | Very long decorative turned elements |

Note: Finished workpiece diameter is approximate due to tool rest interference and centering offset.

Essential Accessories for Your Large Capacity Wood Lathe

Once you have your large capacity wood lathe machine, a few key accessories will help you make the most of its capabilities.

1. Lathe Chuck

A good chuck is arguably the most important accessory for a woodturner.

Functionality: It securely grips your workpiece to the headstock spindle, allowing for safe rotation.

Types: Scroll chucks are the most common, with jaws that expand internally into a chucking spigot (tenon) or contract externally onto a jam chuck. Cole Jaws, Jumbo Jaws, and Faceplate Jaws offer specialized gripping options for unique shapes.

Size: Ensure the chuck is appropriately sized for your lathe’s spindle thread (e.g., 1″ x 8 TPI) and can handle the size of workpieces you intend to turn. Look for chucks designed for larger bowl turning.

2. Faceplate

A simple, robust disk that threads onto your lathe spindle.

Functionality: You can attach large workpieces directly to a faceplate using screws, making it ideal for turning large face-on bowls or platters where you need to access the entire front surface without the tool rest getting in the way.

When to Use: This is where a headstock that swivels becomes invaluable.

3. Tool Rest System

While your lathe comes with a basic tool rest, consider upgrades.

Ergonomics: Different lengths and curves can improve comfort and access for various projects.

Swing-away Tailstock: For very large bowls, a swing-away tailstock can be a lifesaver, allowing the headstock to pivot and the tailstock to swing out of the way.

4. Turning Tools

You’ll need a good set of chisels. For larger work, consider:

Gouge Sizes: Larger gouges (e.g., 1/2″ or 5/8″ spindle gouges, 3/4″ or 1″ bowl gouges) are efficient for removing material from substantial blanks.

Scrapers: A few well-sharpened scrapers can be useful for fine-tuning shapes and surfaces on large pieces.

5. Safety Gear (Non-Negotiable!)

Safety Glasses or Face Shield: Essential for protecting your eyes from flying debris. A full face shield is recommended for larger work.

Dust Mask or Respirator: Wood dust can be harmful. A good respirator is crucial, especially when sanding.

Hearing Protection: Lathes can be noisy, and prolonged exposure can damage your hearing.

Apron: A sturdy apron made of denim or leather can protect your clothing and skin from dust and minor scrapes.

6. Bandsaw and Dust Collection

Bandsaw: A bandsaw is invaluable for cutting out large, potentially irregular blanks for bowls and platters. This is often the first step when using a large capacity lathe.

Dust Collection System: A good dust collector is vital for workshop health and safety, especially when turning large pieces that generate significantly more dust.

Safety First: Operating Your Large Capacity Wood Lathe

Operating any woodworking machinery requires a mindful approach to safety, and large capacity machines are no exception. In fact, the increased power and capacity demand even greater vigilance.

1. Read Your Lathe’s Manual

This might sound obvious, but every lathe is slightly different. Familiarize yourself with its specific features, safety recommendations, and limitations.

2. Wear Appropriate Safety Gear

As mentioned above, this is non-negotiable. Always wear safety glasses or a face shield, a dust mask or respirator, and hearing protection. Avoid loose clothing, jewelry, or gloves that can get caught in the rotating workpiece. Tie back long hair.

3. Secure Your Workpiece Properly

Chuck and Faceplate: Ensure your chuck jaws are tight and properly seated, or that your faceplate is securely threaded onto the spindle. For faceplates, use appropriate screws and ensure they are not overtightened, which can split the wood.

Centers: If using between-centers turning, ensure the tailstock is firmly locked and the quill is engaged sufficiently. The drive spur (on the headstock) must properly engage the wood.

4. Start Slow and Increase Speed Gradually

When turning a new or unbalanced piece of wood, always start at the lowest RPM.

Check Balance: As the speed increases, feel for wobble or vibration. If there’s significant imbalance, slow down and consider making the blank more round on a bandsaw or by using a gouge at a very low speed. This is critical for preventing dangerous kickback.

Listen to Your Machine: Pay attention to any unusual noises or excessive vibration.

5. Use the Tool Rest Correctly

Positioning: The tool rest should be as close as safely possible to the workpiece without touching it during rotation. A common rule of thumb is about 1/8 inch away.

Angle: For spindle turning, the rest is typically parallel to the bed. For bowl turning, it’s angled to allow comfortable access for your gouges.

Lock It Down: Ensure the tool rest and banjo are securely locked. A shifting tool rest is a major safety hazard.

6. Maintain Sharp Tools

Dull tools require more force, leading to fatigue and increased risk of slips or kickback. Keep your chisels and gouges sharp.

7. Be Aware of Your Surroundings

Ensure your workspace is clear of clutter. Have a plan for where you’ll place tools and workpiece blanks. Keep children and pets away from the immediate work area.

8. Practice “Outboard Turning” Safely

When turning very large diameter bowls (where the workpiece extends beyond the ways of the lathe), the forces become significantly greater. Always:

Use the lowest possible speed setting.

Ensure the headstock is securely locked in its swivel position.

Use long-handled gouges with good leverage and technique.

Consult resources specifically on outboard turning techniques if you are new to it. According to the American Association of Woodturners (AAW), proper technique and awareness are paramount for safe turning.

Choosing Between Different Types of Large Capacity Lathes

Not all large capacity wood lathes are created equal. They often fall into a few categories, each with its own pros and cons.

1. Full-Size Floor Standing Lathes

These are the titans of the woodturning world.

Pros: Incredible stability due to their sheer weight, typically have the largest swing and distance between centers, often have powerful motors and robust headstock/tailstock designs, can accommodate substantial accessories.

Cons: Take up a lot of floor space, can be very expensive, often require dedicated higher-voltage power (220V).

Best For: Dedicated woodturning workshops, professional woodturners, those frequently tackling massive projects.

2. Larger Benchtop/Console Lathes

These machines offer increased capacity over smaller benchtop models but can sometimes be housed on a sturdy workbench or come with their own console base.

Pros: Offer a good compromise between capacity and workshop footprint, generally more affordable than full-size floor models, can often be moved with a shop helper or