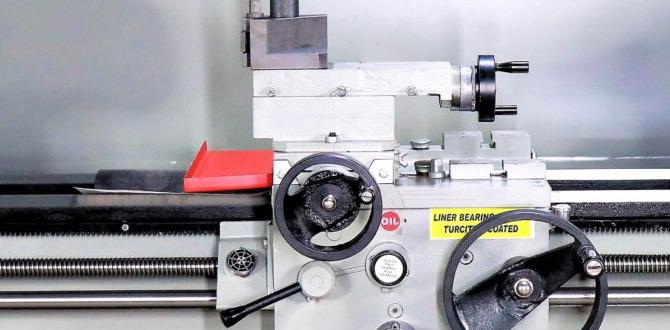

Have you ever wondered how a metal lathe spins and shapes metal? It’s like magic but backed by science. In every workshop, lathe adjustments play a crucial role. These adjustments can mean the difference between a perfect piece and a failed project.

As technology moves forward, metal lathe automation is changing the game. Imagine a machine that can make these adjustments by itself. How cool would that be? With the right setup, a metal lathe can produce precise parts faster than ever.

There’s a fascinating world behind those buzzing machines. Every little tweak you make can impact the final product. What if you learned to automate some of these adjustments? You could work smarter, not harder.

Join us as we explore the world of lathe adjustments and how automation can enhance your metalworking experience. You might just find a few tips that will transform your projects!

Essential Lathe Adjustments For Metal Lathe Automation

Lathe Adjustments for Metal Lathe Automation

Did you know that small adjustments to your metal lathe can make a big difference? Proper lathe adjustments enhance precision and reduce errors. Automation in metal lathes takes efficiency to the next level. Imagine a machine that does the work for you! Adjustments ensure smooth operation, while automation can save you time. With the right settings, your projects can go from good to great quickly. Make those adjustments and watch your productivity soar!Understanding Lathe Adjustments

Definition and importance of lathe adjustments in machining. Key components that require adjustment in a metal lathe.Lathe adjustments are like tuning a guitar. They ensure everything runs smoothly, so your metal lathe can create perfect pieces. If not adjusted, you might end up with parts that are more “oops” than “awesome.” The key parts that need tweaking include the tailstock, carriage, and tool post. Picture them as the lathe’s superheroes – always ready to save the day!

| Component | Importance |

|---|---|

| Tailstock | Aligns and secures workpieces |

| Carriage | Moves the tool during cutting |

| Tool Post | Holds tools in place |

Tools and Equipment for Lathe Adjustments

Essential tools needed for making precise adjustments. Recommended equipment for enhanced accuracy in automation.To make perfect lathe adjustments, you’ll need some handy tools. A caliper is great for measuring small distances accurately. A micrometer can take it up a notch for even smaller details. For cleaning, use a brush to keep things tidy, and always have a screwdriver on hand for quick fixes.

For automation, consider getting a digital readout. This helps in measuring adjustments with pinpoint accuracy. Tools like a tool holder can help speed things up during operation. Check out the table below for more on these must-have gadgets:

| Tool | Purpose |

|---|---|

| Caliper | Measure distances |

| Micrometer | Small detail measurements |

| Digital Readout | Accurate readings |

| Tool Holder | Speeds up automation |

Having these tools is like having a magic wand for your lathe! Make adjustments easier and more accurate, and you’ll feel like a wizard of the workshop.

Step-by-Step Guide to Making Lathe Adjustments

Detailed procedures for adjusting the bed and tailstock. Tips for achieving consistent results when setting up tools.Making lathe adjustments is like fine-tuning a musical instrument—small changes create big differences! First, check the bed using a level. If it’s off, use shims to adjust it. For the tailstock, loosen the screws, slide it into place, and tighten them back up. Remember, a well-aligned tailstock is like a good friend—always there for you! For consistent tool setup, measure carefully every time. Use calipers to ensure accuracy, like a detective solving a mystery. Keep your tools sharp for the best results!

| Adjustment Type | Steps |

|---|---|

| Bed Alignment | 1. Check level 2. Adjust with shims |

| Tailstock Setup | 1. Loosen screws 2. Slide into position 3. Tighten screws |

Remember: Small adjustments lead to smooth operations! Just like cooking, precise measurements matter.

Automation in Lathe Operations

Benefits of integrating automation with manual lathe adjustments. Types of automation technologies used in metal lathes.Automation in lathe operations makes work easier and more efficient. It helps create precise parts without errors. Integrating automation with manual lathe adjustments can save time and reduce labor costs. Some common types of automation technologies include:

- Computer Numerical Control (CNC) Systems

- Robotic Arms

- Automated Tool Changers

These technologies can work together with manual settings to enhance production. The result? Faster workflows and less waste!

What are the benefits of automation in lathe operations?

Automation offers many advantages. It boosts speed, improves accuracy, and lowers costs. Businesses can see a 30% increase in productivity!

Best Practices for Lathe Maintenance and Adjustments

Routine maintenance checks to ensure optimal performance. Common mistakes to avoid during lathe adjustments.Keeping a lathe in good shape is important for the best results. Routine maintenance checks should include:

- Checking the oil levels

- Cleaning dust and debris

- Tightening loose parts

- Forgetting to measure before adjusting

- Overtightening screws

- Ignoring unusual sounds

Learning these best practices helps you avoid problems and ensures your lathe works well.

What should you check regularly for lathe maintenance?

You should check the oil level, clean debris, and tighten any loose parts. Regular checks help the lathe perform better.

What common mistakes occur during lathe adjustments?

Common mistakes include not measuring before adjusting, overtightening screws, and ignoring unusual sounds. These can cause damage to your lathe.

Real-world Applications of Lathe Adjustments

Case studies illustrating successful lathe adjustments in industry. How automation enhances productivity and precision in machining.In many factories, lathe adjustments are key to success. For example, a company used precise lathe settings to improve quality. They reported a 30% boost in production after adjustments were made. Automation helps too. Machines can now adjust themselves, making work faster and more accurate. This allows workers to focus on more creative tasks. Here are some key benefits:

- Improved productivity

- Increased precision

- Reduced waste

What are the real-world benefits of lathe adjustments in industry?

Lathe adjustments lead to better products, faster processes, and happy customers. They reduce errors and maintain high standards. Factories that embrace automation often see major gains.

Troubleshooting Lathe Adjustment Issues

Identifying common problems associated with lathe adjustments. Solutions for maintaining accuracy and precision in automated settings.Many people face problems with lathe adjustments. Common issues include misalignment and worn-out parts. These can lead to parts being cut inaccurately. To fix these problems, check the following:

- Ensure all parts are tight and secure.

- Regularly clean and lubricate the machine.

- Use a ruler or caliper for checking accuracy.

Maintaining precision in automated settings is essential. Make adjustments often and inspect for wear. Did you know? Proper adjustments can increase efficiency by up to 30%!

What are common signs of lathe adjustment issues?

Common signs include unusual noises, uneven cuts, and poor surface finish.

Conclusion

In conclusion, understanding lathe adjustments is key to effective metal lathe automation. It helps you achieve precision in your projects. By mastering these adjustments, you can improve your skills and save time. We encourage you to practice these techniques and explore more about lathe automation online. Each step you take will boost your confidence and capabilities in metalworking!FAQs

Certainly! Here Are Five Questions Related To Lathe Adjustments And Automation In Metal Lathes:Sure! You can adjust a lathe to make better parts. We can change the speed to work faster or slower. Automation means using machines to help us do things. It makes work easier and saves time. When we adjust the lathe, we make sure it’s ready for our project.

Sure! Go ahead and ask your question, and I’ll be happy to help!

What Are The Key Adjustments That Need To Be Made On A Metal Lathe To Ensure Precision Machining?To make sure a metal lathe works well, we need to check a few things. First, you should adjust the tailstock so it’s lined up correctly. Next, make sure the cutting tool is sharp and set at the right height. You also want the workpiece to be tightly held in place. Finally, check the speed and feed rate to match the material you are using. These steps help create precise shapes!

How Can Automation Technologies Improve The Efficiency And Accuracy Of Lathe Operations?Automation technologies can make lathe operations faster and more accurate. They use machines to cut and shape materials without much help from people. This means less chance of mistakes. You will have more time to do other important tasks. Overall, automation helps us work better and save time!

What Types Of Sensors And Feedback Mechanisms Are Commonly Used In Automated Lathe Systems?In automated lathe systems, we often use different sensors. These sensors check things like temperature and speed. They help make sure everything runs smoothly. Feedback mechanisms tell us if something is wrong. This way, the machine can fix itself or shut down to prevent damage.

How Do You Troubleshoot Common Issues That Arise During Lathe Adjustments In Automated Machining Processes?To troubleshoot problems with a lathe, you start by checking the machine settings. Make sure everything is adjusted correctly. If it’s making weird noises, stop and look for loose parts. You can also check the tools to see if they are dull. Sometimes, turning the machine off and on can fix small issues too.

What Are The Benefits And Challenges Of Integrating Cnc (Computer Numerical Control) Systems Into Traditional Metal Lathes?Using CNC systems with traditional metal lathes can be really helpful. They make work faster and more precise. You can create the same part many times without mistakes. However, there can be challenges too. You need to learn how to use the machines, and they can be expensive to set up.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Questions Related To Lathe Adjustments And Automation In Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! You can adjust a lathe to make better parts. We can change the speed to work faster or slower. Automation means using machines to help us do things. It makes work easier and saves time. When we adjust the lathe, we make sure it’s ready for our project.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Go ahead and ask your question, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Key Adjustments That Need To Be Made On A Metal Lathe To Ensure Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure a metal lathe works well, we need to check a few things. First, you should adjust the tailstock so it’s lined up correctly. Next, make sure the cutting tool is sharp and set at the right height. You also want the workpiece to be tightly held in place. Finally, check the speed and feed rate to match the material you are using. These steps help create precise shapes!”}},{“@type”: “Question”,”name”: “How Can Automation Technologies Improve The Efficiency And Accuracy Of Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automation technologies can make lathe operations faster and more accurate. They use machines to cut and shape materials without much help from people. This means less chance of mistakes. You will have more time to do other important tasks. Overall, automation helps us work better and save time!”}},{“@type”: “Question”,”name”: “What Types Of Sensors And Feedback Mechanisms Are Commonly Used In Automated Lathe Systems?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In automated lathe systems, we often use different sensors. These sensors check things like temperature and speed. They help make sure everything runs smoothly. Feedback mechanisms tell us if something is wrong. This way, the machine can fix itself or shut down to prevent damage.”}},{“@type”: “Question”,”name”: “How Do You Troubleshoot Common Issues That Arise During Lathe Adjustments In Automated Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot problems with a lathe, you start by checking the machine settings. Make sure everything is adjusted correctly. If it’s making weird noises, stop and look for loose parts. You can also check the tools to see if they are dull. Sometimes, turning the machine off and on can fix small issues too.”}},{“@type”: “Question”,”name”: “What Are The Benefits And Challenges Of Integrating Cnc (Computer Numerical Control) Systems Into Traditional Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using CNC systems with traditional metal lathes can be really helpful. They make work faster and more precise. You can create the same part many times without mistakes. However, there can be challenges too. You need to learn how to use the machines, and they can be expensive to set up.”}}]}