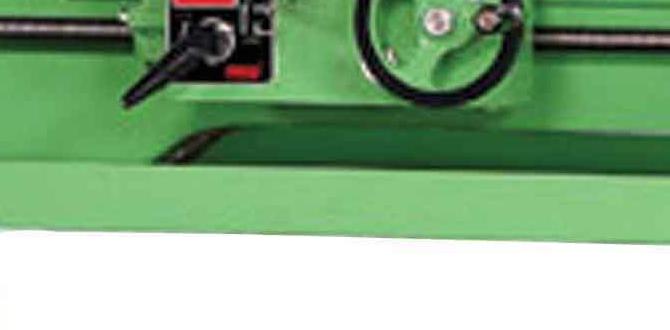

Have you ever wondered how metal lathes make precise cuts? These machines use something called a controller board to help them work. Fine-tuning or lathe adjustments can make a big difference in how well a lathe performs.

Imagine you’re building a model car, and every tiny piece needs to fit perfectly. A metal lathe helps create those pieces accurately. But what happens when things don’t go as planned?

That’s where understanding the lathe adjustments and how to use the controller board becomes important. Did you know that even a small change can lead to much better results?

In this article, we will explore how lathe adjustments can improve your projects. Let’s dive into the exciting world of metal lathes and learn how their controllers make magic happen!

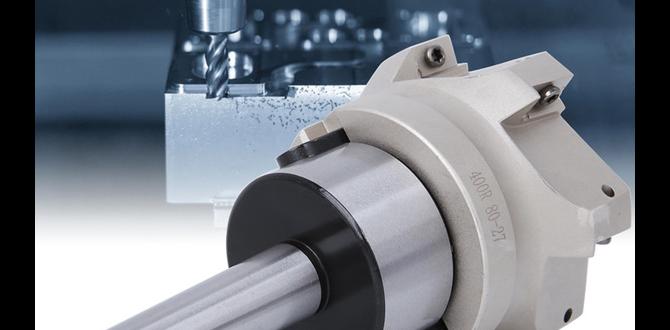

Essential Lathe Adjustments For Your Metal Lathe Controller Board

Lathe Adjustments and Metal Lathe Controller Boards

Lathe adjustments can greatly affect how well your machine operates. For example, a correctly calibrated metal lathe controller board ensures accuracy in your projects. It allows you to adjust speed and direction easily. Did you know improper settings can lead to damage? Understanding how to tweak these adjustments is crucial for beginners and experts alike. Discovering the right settings can make your lathe experiences more enjoyable and productive! Don’t overlook the importance of these adjustments.Types of Metal Lathe Controller Boards

Different types of controller boards available for metal lathes. Key features to look for in a controller board.Controller boards are key parts of metal lathes. They control the machine’s movements. Different types suit different needs. Here are a few popular types:

- Basic Controller Boards: Simple and cost-effective, great for beginners.

- Advanced Controller Boards: Offer better precision and features for experienced users.

- Programmable Boards: Allow custom settings for special projects.

When choosing a controller board, consider these features:

- Compatibility: Make sure it fits your lathe.

- Ease of Use: Look for clear instructions.

- Support and Updates: Check for help and software updates.

What features should a metal lathe controller board have?

A good controller board should offer easy setup, reliable performance, and good support.

Key Adjustments for Metal Lathes

Adjusting the tailstock for alignment. Finetuning the carriage and crossslide.Getting your metal lathe just right can feel like trying to stack pancakes without a plate! First, make sure the tailstock is perfectly aligned. This ensures your workpiece spins without wobbling. Next, finetune the carriage and crossslide for smooth movement. If they’re off, you might end up with uneven cuts, and nobody wants a lopsided cupcake!

| Adjustment | Description |

|---|---|

| Tailstock Alignment | Ensures the workpiece spins evenly. |

| Carriage Adjustments | Allows smooth motion for precise cuts. |

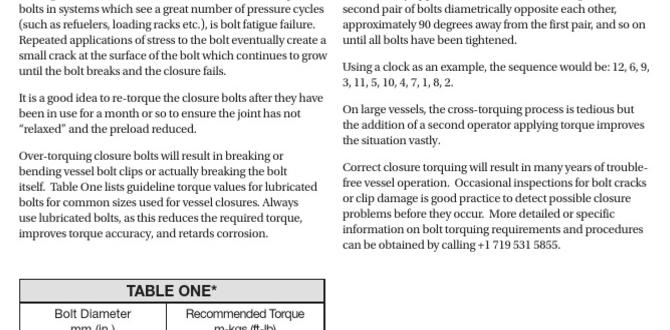

Calibrating Your Metal Lathe Controller Board

Stepbystep guide on calibration procedures. Common issues encountered during calibration.Getting your metal lathe controller board right is like setting up a date; you want everything to be perfect! Start by checking alignment; it can save you from future heartache. Use a caliper to measure the distance between your tool and the workpiece. Next, adjust the motor speed and torque settings. A too-fast spindle can ruin your project and send metal flying! If you’re having trouble, common issues include misalignments or incorrect settings. Don’t stress; you can fix it!

| Common Calibration Issues | Solutions |

|---|---|

| Misaligned Tool Rest | Re-adjust and check measurements. |

| Inaccurate Speed Settings | Consult the manual for proper values. |

Follow these simple steps, and your lathe will be ready to roll—or should I say, spin? Happy calibrating!

Troubleshooting Lathe Adjustment Issues

Identifying signs of misalignment or incorrect adjustments. Effective solutions for common adjustmentrelated problems.Have you noticed your lathe acting like it’s had one too many drinks? Signs of misalignment include uneven cuts or strange noises. Don’t panic! Most issues are easy to fix. First, check for loose bolts or worn-out parts. A few tweaks can get your lathe back in shape. Always remember: a happy lathe makes a happy crafter!

| Issue | Solution |

|---|---|

| Uneven cuts | Check alignment and adjust the tool rest. |

| Strange noises | Lubricate moving parts and tighten loose screws. |

| Vibrations | Ensure the lathe is placed on a stable surface. |

With these tips, your machine will hum like a happy bee! And remember, if all else fails, it’s okay to ask for help. After all, even lathes need a buddy sometimes!

Maintaining Your Lathe for Precision Adjustments

Routine maintenance tips to ensure consistent performance. Tools and resources required for maintaining lathe adjustments.Keeping your lathe in tip-top shape is essential for smooth operations. Regular checks and maintenance can help avoid big problems later. Be sure to clean it often—grime is like glitter; it gets everywhere! Having the right tools makes a difference, too. We recommend essential items like wrenches, lubricant, and a trusty ruler for those precise adjustments.

| Tool | Purpose |

|---|---|

| Wrench | Tightens loose parts |

| Lubricant | Reduces friction |

| Ruler | Ensures right measurements |

Remember, a well-maintained lathe is a happy lathe! Regular maintenance can prevent problems that may lead to awkward surprises. Why risk it? Stay ahead and keep your lathe humming along!

Upgrading Your Metal Lathe Controller Board

Signs that indicate an upgrade is necessary. How to choose the right upgrade for your lathe model.If your metal lathe starts making strange noises, it might be time for an upgrade. Some signs include slow speeds or incorrect cuts. These issues can turn crafting into a real headache! Choosing the right upgrade is key. Check your lathe model, and find a controller board that fits. Ask yourself, “Is my lathe ready for this upgrade, or should I be looking for a new friend instead?”

| Sign of Upgrade | Possible Cause |

|---|---|

| Strange Noises | Worn Components |

| Inaccurate Cuts | Weak Controller |

| Slow Speeds | Outdated Tech |

The right controller board will improve your lathe’s performance. Upgrade smartly, and you’ll turn metal into a masterpiece instead of a rusty paperweight!

Advanced Techniques for Fine-Tuning Lathe Operations

Techniques for enhancing precision and reducing vibrations. Best practices for integrating technology with manual adjustments.Fine-tuning your lathe operations can feel like trying to teach a cat to fetch. It’s tricky but totally doable! To enhance precision, you can use laser guides and insert tools for extra accuracy. Reducing vibrations can be as simple as using a sturdy workbench or adding a dampening mat. Mix tech with manual adjustments for the best results. Think of technology as your helpful sidekick, not the boss! Here’s a quick table with some tips:

| Technique | Benefit |

|---|---|

| Laser Guides | Adds precision to cuts |

| Dampening Mats | Reduces vibrations |

| Manual Adjustments | Customizes operations |

Remember, a smooth lathe is happy lathe! So keep tweaking and you’ll make perfect pieces every time.

Conclusion

In summary, lathe adjustments are crucial for precise work on a metal lathe. Understanding how the controller board works helps improve your skills. Always check and adjust settings for better accuracy. Try experimenting with different adjustments to see how they affect your projects. For more tips, consider reading guides or watching tutorials online. You’ll become a pro in no time!FAQs

What Are The Common Adjustments Needed For A Metal Lathe Controller Board To Ensure Accurate Machining Operations?To make sure a metal lathe works well, you need to adjust a few things. First, check the speed settings. You want it to turn at the right speed for your metal. Next, adjust the tool height and position. This helps the tool cut properly. Finally, make sure the power supply is stable. This keeps everything running smoothly!

How Can One Troubleshoot Issues Related To The Lathe Controller Board Affecting Spindle Speed And Feed Rate?To troubleshoot your lathe controller board, start by checking the power connection. Make sure it’s plugged in and working. Next, look for loose wires or broken parts. If everything seems fine, reset the controller. Finally, test the speed and feed rate again to see if it’s better.

What Guidelines Should Be Followed For Calibrating The Metal Lathe’S Digital Readout In Relation To The Controller Board?To calibrate the metal lathe’s digital readout, first, you should check the manual for instructions. Then, measure a known length with a ruler. Adjust the digital readout until it matches the measured length exactly. Repeat this check a few times to be sure it’s correct. Finally, save the settings on the controller board to keep them safe.

Can Modern Metal Lathe Controller Boards Be Retrofitted To Older Lathe Models, And What Adjustments Would Be Necessary?Yes, you can fit new controller boards to older lathes. First, check if the size matches. You might need to change some wires and connections. Also, make sure the power supply is right. With some tweaks, you can make it work.

What Safety Precautions Should Be Taken When Making Adjustments To The Metal Lathe Controller Board?When adjusting the metal lathe controller board, always turn off the machine first. Make sure to unplug it to avoid any shocks. Wear safety glasses to protect your eyes from small flying pieces. Keep your hands clear of moving parts and be careful with tools. Lastly, work in a tidy area to prevent accidents.