Have you ever watched a metal lathe in action? It’s fascinating how it transforms a simple piece of metal into something useful. One key to this magic is the lathe adjustments that help control the machine’s movements.

Did you know that the gear train plays a vital role in these adjustments? A well-set gear train can make a big difference in precision. Imagine trying to create a perfect cut but struggling with the settings! It can be frustrating.

Understanding how to adjust your lathe and gear train can set you up for success. Whether you’re a hobbyist or a pro, these skills are important. With the right adjustments, you’re not just machining; you’re creating art.

In this article, we’ll explore how to master lathe adjustments and gear train setup. You’ll learn tips and tricks that can take your metalworking to the next level. Are you ready to dive in?

Lathe Adjustments: Mastering Metal Lathe Gear Train Techniques

Lathe Adjustments: Metal Lathe Gear Train

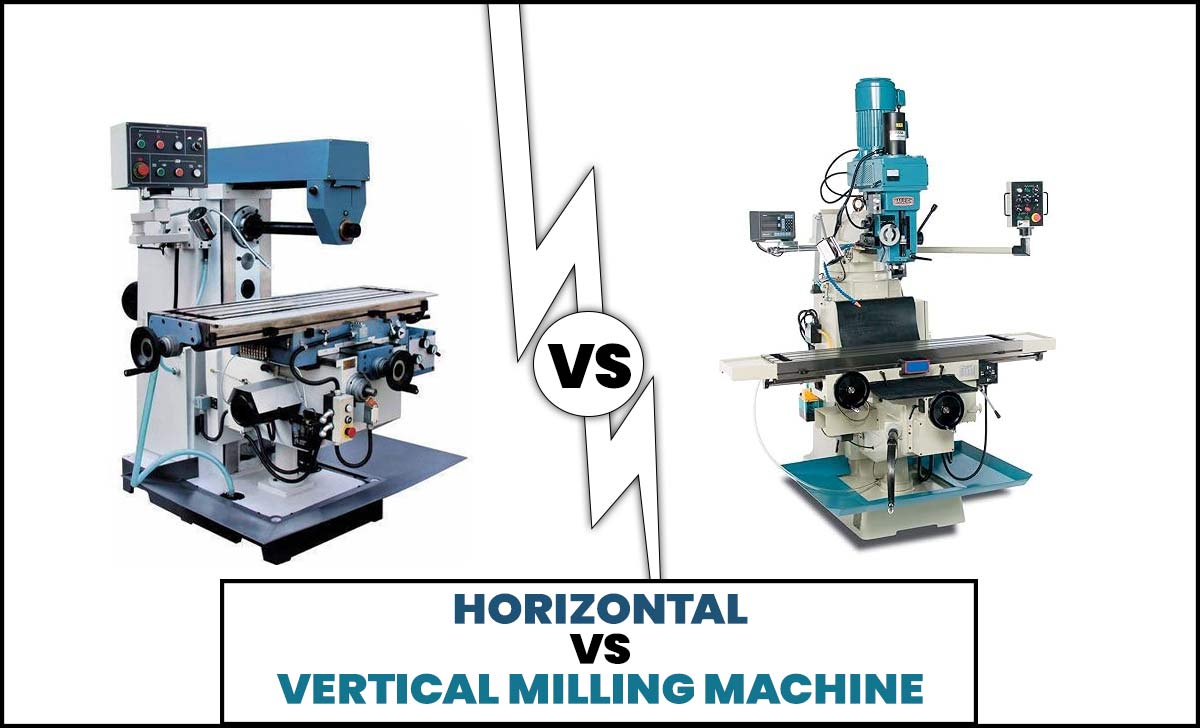

Adjusting a metal lathe’s gear train is key to smooth operation. Did you know small changes can greatly affect precision? Proper adjustments ensure your machine runs efficiently, creating accurate parts every time. You will learn how to check gear alignment and the benefits of routine maintenance. Also, understanding how gear ratios influence speed can help beginners. This knowledge makes lathe work easier and more enjoyable, whether for a hobby or a job!Understanding the Gear Train in Metal Lathes

Definition and role of the gear train in metal lathes. Types of gear trains commonly found in metal lathes.The gear train in a metal lathe is like the middleman that helps everything run smoothly. It connects the motor’s power to the tools that shape metal. Think of it as a train with different cars that work together to make sure you get the perfect cut. Common types include the simple gear train, which is easy to use, and the compound gear train, which offers more speed options.

| Type of Gear Train | Description |

|---|---|

| Simple Gear Train | Easy to set up, it’s great for basic tasks. |

| Compound Gear Train | More complex, but gives you faster speeds for tricky work. |

Smart adjustments to the gear train can make your lathe feel like a superhero! With the right setup, you can tackle any metal challenge, leaving your friends in awe of your skills.

Importance of Proper Lathe Adjustments

How adjustments affect machining accuracy. Potential issues from improper adjustments.Proper lathe adjustments are key for high-quality machining. A well-set lathe can create precise parts. However, poor adjustments can lead to serious problems. For instance, parts may be cut incorrectly, resulting in waste. Here are some potential issues:

- Inaccurate measurements

- Poor surface finish

- Increased wear on tools

Precision matters in machining. A small mistake can lead to big problems. Always check your lathe settings to avoid headaches later on!

Why are lathe adjustments important?

Lathe adjustments are important because they ensure accuracy and quality in machining.

Key Components of Lathe Gear Trains

Detailed breakdown of main components of gear trains. Functionality and significance of each component.Lathe gear trains are like the superheroes of metalworking! Each component plays a special role. First, we have the gears, which mesh together to change speeds. Then, there are the drive belts that transfer power smoothly. We can’t forget the shafts, connecting parts and ensuring everything spins in harmony. Finally, the bearings reduce friction, keeping our lathe happy. Think of it this way: without these components, the lathe might just take a nap instead of working!

| Component | Function | Significance |

|---|---|---|

| Gears | Change speed | Essential for cutting accuracy |

| Drive Belts | Transfer power | Ensure smooth operation |

| Shafts | Connect parts | Maintain alignment |

| Bearings | Reduce friction | Prolong lifespan |

Step-by-Step Guide to Adjusting the Gear Train

Tools and materials needed for adjustments. Detailed procedure for making gear train adjustments.Gather your tools before diving into adjustments. You’ll need a wrench, screwdriver, and a trusty tape measure. With these, you’ll be a gear-train hero in no time!

First, inspect the gear alignment. Loosen the necessary screws, and shift the gears gently until they fit snugly. Tighten everything back up as if you’re putting a cap on your favorite soda—firm, but not too tight! Repeat this process for each gear until they all sing in harmony.

| Tools | Purpose |

|---|---|

| Wrench | To tighten or loosen screws. |

| Screwdriver | For making adjustments. |

| Tape Measure | To check distances between gears. |

Remember, adjusting a lathe’s gear train is like baking a cake: follow the steps, and you won’t end up with a flat pancake! Happy adjusting!

Troubleshooting Common Gear Train Issues

Identifying common symptoms of gear train problems. Solutions for typical issues and adjustments required.Gear train problems can really be a pain, like stepping on a Lego! Look out for signs like strange noises or uneven cuts. These are clues that your gear train might need some love. To fix it, check for loose screws or wear on the gears. Tightening parts can sometimes work wonders! Here’s a quick guide for common issues:

| Symptom | Possible Cause | Solution |

|---|---|---|

| Strange noises | Loose gears | Tighten screws |

| Uneven cuts | Worn gears | Replace gears |

| Slipping | Misalignment | Realign the train |

By paying attention to these signs and making quick adjustments, you can keep your lathe running smoothly. So, keep an eye (and ear) out for those gears!

Preventive Maintenance for Gear Trains

Best practices for maintaining gear trains in metal lathes. How regular maintenance can enhance longevity and performance.Keeping the gear train of a metal lathe in good shape is important for smooth operation. Regular checks and simple maintenance make a big difference. Here are some best practices:

- **Inspect the gears often.** Look for signs of wear or damage.

- **Lubricate regularly.** Proper lubrication reduces friction and wear.

- **Keep it clean.** Dust and debris can cause problems.

- **Adjust tightness.** Make sure gears are not too loose or too tight.

These actions can help your lathe last longer and work better. Did you know that proper maintenance can improve the lathe’s performance by up to 30%? Taking care of your gear train really pays off!

How can regular maintenance help gear trains?

Regular maintenance can **significantly enhance** the longevity and performance of gear trains. Simple actions, like checking and oiling the gears, ensure everything runs smoothly and cuts down on repairs.

Advanced Techniques for Experienced Users

Specialized adjustments for enhanced performance. Customizations based on specific machining needs.Fine-tuning your lathe can be like giving it a spa day. Specialized adjustments can boost performance, making your machine sing with joy. Want to mix it up? Tailor your setup according to your machining needs. It’s like dressing your lathe in its Sunday best! Here’s how:

| Adjustment Type | Benefit |

|---|---|

| Speed Settings | Enhances precision |

| Gear Train Modifications | Increases torque |

| Tooling Options | Improves surface finish |

Customizing your lathe doesn’t need a degree in rocket science. A few tweaks here and there can take your projects from “meh” to “wow”! Remember, the right adjustments can make all the difference.

Resources and Further Reading

Recommended books and manuals for lathe users. Online communities and forums for support and advice.Reading more about metal lathes helps users get better at their craft. Here are some top resources:

- Books: “The New Metalworker’s Workbook” and “Metalworking for Beginners” offer great tips and tricks.

- Manuals: Check the manufacturer’s manual for your lathe for specific guidance.

Joining online communities can also provide help. Websites like Reddit and specific lathe forums allow users to ask questions and share advice. This way, you never have to work alone!

What are the best resources for lathe users?

Recommended resources for lathe users include informative books, detailed manuals, and supportive online communities. These resources boost confidence and skills in metal lathe tasks.

Conclusion

In conclusion, understanding lathe adjustments and the metal lathe gear train is essential for smooth operation. You can improve accuracy by regularly checking and adjusting your gear train. Remember, small changes can make a big difference in your projects. Keep reading about lathe maintenance to enhance your skills and enjoy better results in your machining work!FAQs

Sure! Here Are Five Questions Related To Lathe Adjustments, Specifically Focusing On The Gear Train Of A Metal Lathe:Sure! Here are five questions about adjusting the gear train on a metal lathe. 1. What is a gear train? A gear train is a system of gears that helps control how fast the lathe turns. 2. Why do we adjust the gear train? We adjust it to change the speed or power of the machine for different jobs. 3. How do you know if the gear train needs adjustment? If the lathe makes strange noises or the speed is off, it might need adjusting. 4. What tools do we need to adjust the gear train? You will need wrenches and maybe a screwdriver to make the changes. 5. Can you adjust the gear train while the lathe is on? No, you should always turn off the lathe before making adjustments for safety.

Sure! Please share the question you want me to answer, and I’ll help you with it.

What Are The Key Components Of A Metal Lathe’S Gear Train, And How Do They Contribute To The Machining Process?A metal lathe’s gear train has important parts like gears and belts. These help change how fast or slow the machine turns. When you adjust the gears, you can make different shapes in the metal. This helps you control your cuts better and create smoother finishes. Using the gear train properly makes your work easier and more accurate.

How Do You Properly Adjust The Gear Train On A Metal Lathe To Achieve Accurate Thread Cutting?To adjust the gear train on a metal lathe for precision thread cutting, first find the right gears for your project. Change the gears to match the thread size you want to cut. Make sure each gear slides smoothly and is tight. Then, test it on some scrap metal to check if the threads are correct. Adjust again if needed until everything looks perfect!

What Signs Indicate That The Gear Train On A Metal Lathe May Need Adjustment Or Maintenance?If the metal lathe makes strange noises, that’s a sign to check it. You might notice that it shakes or vibrates too much when running. Sometimes, it doesn’t cut evenly or smoothly anymore. If you see broken or worn parts, it’s time for maintenance. Always keep an eye on how it works!

How Does Changing The Gear Ratio Within The Gear Train Affect Spindle Speed And Torque During Machining Operations?Changing the gear ratio in a machine affects how fast the spindle spins and how much force it has. If you use a higher gear ratio, the spindle spins faster but has less force. If you lower the gear ratio, the spindle spins slower but can apply more force. This helps us choose the right speed and power for different jobs.

What Are The Steps To Troubleshoot And Correct Issues With The Gear Train Of A Metal Lathe That Lead To Inconsistent Surface Finishes?To fix problems with the gear train of a metal lathe, first, check for loose parts. Make sure everything is tight and secure. Next, examine the gears for any damage or wear. If you see any broken teeth, you need to replace them. Finally, clean the gears and add some oil to keep them running smoothly.