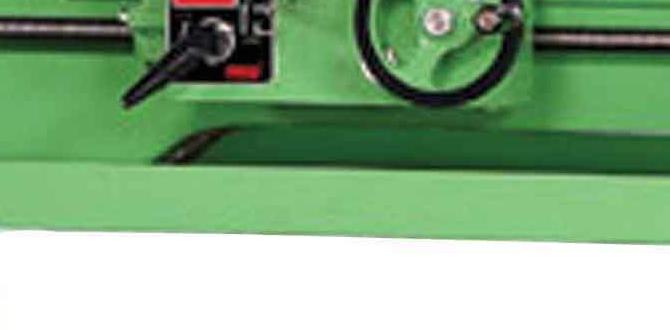

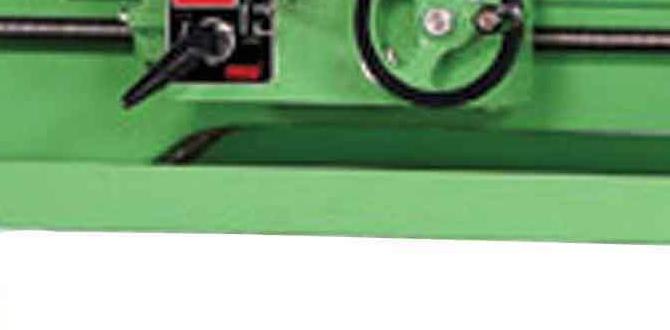

Have you ever watched a skilled craftsman shape metal? It’s mesmerizing, isn’t it? One tool that makes this magic happen is the metal lathe. But did you know that proper lathe adjustments can greatly impact the outcome of a project?

The quill on a lathe plays a crucial role in this process. It helps control the depth and accuracy of cuts. If the quill is not adjusted correctly, the result may be far from perfect. Imagine spending hours on a project, only to have a misaligned cut ruin it!

In this article, we will explore how to make lathe adjustments specifically for the metal lathe quill. We’ll share tips and tricks that can help you achieve better results every time. Whether you’re a beginner or an experienced machinist, getting these adjustments right can enhance your skills.

So, ready to dive into the world of lathes? Let’s discover how these small adjustments can lead to big improvements!

Essential Lathe Adjustments For Metal Lathe Quill Accuracy

Lathe Adjustments: Mastering Your Metal Lathe Quill

Adjusting the metal lathe quill is vital for precision. Proper adjustments help ensure smooth operation and accurate cuts. Did you know that a small mistake can lead to big errors in your work? With simple tweaks, you can improve your lathe’s performance. Learning how to align the quill correctly boosts your skills. This knowledge not only saves time but also enhances the quality of your projects. Why not become a pro at lathe adjustments today?Understanding the Metal Lathe Quill

Definition and function of the quill in a metal lathe. Importance of quill adjustments for precision machining.The quill in a metal lathe is like the little superhero of the machine. It helps hold and move the cutting tool. This motion is crucial for shaping metal into cool projects. Adjusting the quill is super important. Why? Because if it’s not right, your cuts can end up looking like a dog chewed them! Precision is key in machining to ensure everything fits perfectly. With the right adjustments, you can make clean cuts and avoid costly mistakes. Your lathe will thank you with shiny, smooth results!

| Function | Importance of Adjustments |

|---|---|

| Holds cutting tools | Ensures precise cuts |

| Moves for shaping | Avoids mistakes and waste |

Common Issues with Quill Alignment

Symptoms of misalignment and their effects on machining. Common causes of quill misalignment.Ever tried to bake a cake but forgot to measure the flour? Quill misalignment in machining is pretty similar—things can go wildly wrong! You might notice uneven edges or chattering noises, signs that something’s amiss. Common causes of misalignment can include wear and tear, improper adjustments, or even someone accidentally bumping into the machine (oops!).

| Symptoms | Possible Causes |

|---|---|

| Uneven cuts | Worn bearings |

| Chattering sounds | Incorrect setup |

| Poor surface finish | Bumps or impacts |

Keeping your quill aligned is key. It can save time, material, and maybe even sanity! And remember: aligning your quill is easier than getting your cat to take a bath!

Tools Required for Quill Adjustments

Essential tools for making adjustments. Safety equipment to consider during adjustments.Making quill adjustments requires a few important tools. You will need a wrench for loosening screws and a caliper for measuring distances accurately. A screwdriver is also essential; choose one that fits snugly. Don’t forget your safety equipment! Always wear safety goggles to protect your eyes. It’s wise to wear gloves, too, because we don’t want any unexpected “handshake” moments. Remember, a safe workshop is a happy workshop!

| Tool | Purpose |

|---|---|

| Wrench | Loosening screws |

| Caliper | Measuring distances |

| Screwdriver | Screwing and unscrewing |

| Safety Goggles | Eye protection |

| Gloves | Hand protection |

Step-by-Step Guide to Adjusting the Quill

Detailed instructions on checking quill alignment. Procedures for making precise adjustments.To check the quill alignment, follow these steps carefully. First, make sure your lathe is off and unplugged. Next, use a ruler to measure the distance from the quill to the bed of the lathe. Adjust the quill if it’s not even. Use the adjustment screw to make small changes. Tighten it gently to keep it in place. Always double-check after each adjustment to ensure it’s correct.

- Turn off the lathe.

- Measure quill distance.

- Use adjustment screw.

- Tighten and test.

How do you check a quill’s alignment?

Check a quill’s alignment by measuring its distance from the lathe bed and adjusting if needed.

Adjusting the quill helps improve precision. A well-aligned quill leads to better cuts. Remember, small changes make a big difference! Always keep practicing for the best results.

Tips for Maintaining Quill Accuracy

Routine checks to ensure continued accuracy. Best practices for routine maintenance.To keep your lathe quill accurate, regular checks are essential. Start by inspecting the quill’s alignment; it should be perfectly straight. A quick tip? Use a flashlight to spot any irregularities – shadows can reveal surprises! Next, clean any dust or chips. A tidy workspace is a happy workspace! Also, ensure all parts are lubricated properly. Lack of oil can lead to squeaks that would make a mouse jealous!

| Routine Check | Best Practice |

|---|---|

| Check alignment | Use a straight edge or laser tool |

| Clean regularly | Wipe down before and after use |

| Inspect lubrication | Apply oil to moving parts weekly |

Following these simple steps will help keep your quill in top shape. Remember: prevention is better than a costly repair!

Advanced Quill Adjustment Techniques

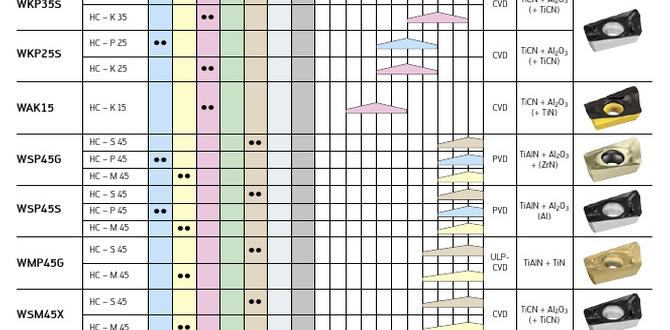

Techniques for specialized machining needs. Adjustments for different types of materials and projects.Mastering quill adjustments can greatly improve your machining skills. Different materials need different adjustments. For instance, soft metals like aluminum require less pressure than hard materials like steel. Here are some tips for specialized machining needs:

- Check the tool alignment before starting each project.

- Adjust the speed based on the material type.

- Use higher feed rates for plastic and lower for metal.

Each adjustment helps create a smoother finish.

What techniques help with advanced quill adjustments?

Specialized machining needs include adjusting speed and pressure for different materials. This ensures the best results and prevents tool wear. Try new settings based on past experience for effective outcomes.

Troubleshooting Common Quill Adjustment Problems

Identifying persistent issues despite adjustments. Solutions for overcoming recurring problems.Troubleshooting a quill adjustment can make you feel like you’re in an episode of a sitcom. You try to fix it, and it still acts up! First, check if your adjustments are consistent and precise. If not, it might be time to tighten those bolts or recalibrate. If problems keep popping up, don’t panic! Some solutions may involve cleaning the areas around the quill or replacing worn parts. Remember, even machines need a little TLC sometimes!

| Common Issues | Possible Solutions |

|---|---|

| Quill not moving smoothly | Clean and lubricate the mechanism |

| Inconsistent cuts | Check and adjust the alignment |

| Strange noises | Inspect for loose parts |

Conclusion

In summary, adjusting the quill on a metal lathe is essential for precision and smooth work. You can easily control cutting depth this way. Remember to check your settings regularly and make small adjustments as needed. For more tips, consider reading guides or watching tutorials. With practice, you’ll master these adjustments and improve your metalworking skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Adjustments For A Metal Lathe Quill:Sure! Here are five questions we can ask about adjusting a metal lathe quill: 1. What is a lathe quill? A lathe quill is a part that helps hold and move tools on the lathe. 2. Why do you need to adjust the quill? We adjust the quill to make sure the tools cut well and are smooth. 3. How do you know if the quill needs adjusting? You can tell if it cuts unevenly or makes unusual sounds. 4. What tools do you need to adjust the quill? You usually need a wrench and a measuring tool to make adjustments. 5. How often should you check the quill? It’s good to check the quill every time you use the lathe to keep it working well.

Sure! Please provide the question you’d like me to answer.

What Is The Purpose Of The Quill On A Metal Lathe, And How Does It Contribute To Machining Accuracy?The quill on a metal lathe helps move the tool in and out easily. This means you can adjust how deep the tool cuts into the metal. When you use the quill correctly, your work comes out more precise and neat. It helps us make sure everything fits together well. So, the quill is very important for making accurate shapes!

How Can You Determine If The Quill On Your Metal Lathe Is Properly Aligned And Functioning Correctly?To check if your quill is aligned, first, make sure it’s clean and free of dirt. Next, lower the quill and look at how it moves. If it slides easily and straight, it’s good. You can also use a ruler to see if it’s the same distance from the tool to the workpiece all along. If something feels off, you may need to adjust it.

What Are The Common Signs Of Wear Or Misalignment In The Quill Mechanism Of A Metal Lathe, And How Can These Issues Be Addressed?You might notice some signs of wear or misalignment in the quill of a metal lathe. If the quill shakes or makes strange noises, that’s a problem. It can also be hard to move or feel loose. To fix these issues, you can check the parts for damage and clean them. Sometimes, tightening screws or replacing worn parts helps, too.

What Adjustment Procedures Should Be Followed To Ensure The Quill Remains Stable During Operation And Prevents Chatter Or Vibration?To keep the quill steady and stop shaking, first, check that it is tight and secure. You can also adjust the speed to a lower setting if you notice any vibrations. Make sure the machine is on a strong surface and isn’t wobbling. Lastly, always use sharp tools, as dull ones can cause more chatter. Taking these steps helps keep everything running smoothly!

How Do Feed Rate And Spindle Speed Settings Interact With Quill Adjustments To Affect The Overall Machining Process On A Metal Lathe?Feed rate and spindle speed work together to control how fast we cut metal. The feed rate is how quickly the tool moves across the metal. Spindle speed is how fast the metal spins. When we adjust the quill, which holds the cutting tool, it changes how deep we cut. If everything is set right, we get a smooth, clean cut on the metal.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Adjustments For A Metal Lathe Quill:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions we can ask about adjusting a metal lathe quill: 1. What is a lathe quill? A lathe quill is a part that helps hold and move tools on the lathe. 2. Why do you need to adjust the quill? We adjust the quill to make sure the tools cut well and are smooth. 3. How do you know if the quill needs adjusting? You can tell if it cuts unevenly or makes unusual sounds. 4. What tools do you need to adjust the quill? You usually need a wrench and a measuring tool to make adjustments. 5. How often should you check the quill? It’s good to check the quill every time you use the lathe to keep it working well.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of The Quill On A Metal Lathe, And How Does It Contribute To Machining Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The quill on a metal lathe helps move the tool in and out easily. This means you can adjust how deep the tool cuts into the metal. When you use the quill correctly, your work comes out more precise and neat. It helps us make sure everything fits together well. So, the quill is very important for making accurate shapes!”}},{“@type”: “Question”,”name”: “How Can You Determine If The Quill On Your Metal Lathe Is Properly Aligned And Functioning Correctly?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if your quill is aligned, first, make sure it’s clean and free of dirt. Next, lower the quill and look at how it moves. If it slides easily and straight, it’s good. You can also use a ruler to see if it’s the same distance from the tool to the workpiece all along. If something feels off, you may need to adjust it.”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Or Misalignment In The Quill Mechanism Of A Metal Lathe, And How Can These Issues Be Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice some signs of wear or misalignment in the quill of a metal lathe. If the quill shakes or makes strange noises, that’s a problem. It can also be hard to move or feel loose. To fix these issues, you can check the parts for damage and clean them. Sometimes, tightening screws or replacing worn parts helps, too.”}},{“@type”: “Question”,”name”: “What Adjustment Procedures Should Be Followed To Ensure The Quill Remains Stable During Operation And Prevents Chatter Or Vibration?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the quill steady and stop shaking, first, check that it is tight and secure. You can also adjust the speed to a lower setting if you notice any vibrations. Make sure the machine is on a strong surface and isn’t wobbling. Lastly, always use sharp tools, as dull ones can cause more chatter. Taking these steps helps keep everything running smoothly!”}},{“@type”: “Question”,”name”: “How Do Feed Rate And Spindle Speed Settings Interact With Quill Adjustments To Affect The Overall Machining Process On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Feed rate and spindle speed work together to control how fast we cut metal. The feed rate is how quickly the tool moves across the metal. Spindle speed is how fast the metal spins. When we adjust the quill, which holds the cutting tool, it changes how deep we cut. If everything is set right, we get a smooth, clean cut on the metal.”}}]}