Have you ever wondered how to get your metal lathe working perfectly? Aligning it correctly is key. Imagine trying to create a smooth part, only to find it wobbles. It can be frustrating, right? But fear not! There are great lathe alignment tips that can help you master your machine.

Did you know that the way you wire your lathe can affect its performance? A good wiring diagram is essential for understanding how things connect. It’s like having a treasure map for your lathe! With the right information, you can make your metal lathe run like a dream. Let’s dive into some tips and tricks to make sure your lathe is aligned and wired the right way. Your projects will thank you!

Lathe Alignment Tips: Essential Metal Lathe Wiring Diagram

Lathe Alignment Tips & Metal Lathe Wiring Diagram

Alignment is key for smooth operation of a metal lathe. Did you know a misaligned lathe can lead to poor results? Using simple tips helps ensure precision. First, check the bed for straightness. Then, adjust the tailstock and headstock to align properly. A clear wiring diagram is vital too. It guides safe electrical connections. This prevents accidents and keeps the machine running efficiently. With proper alignment and wiring, your lathe work will shine!Understanding Lathe Alignment

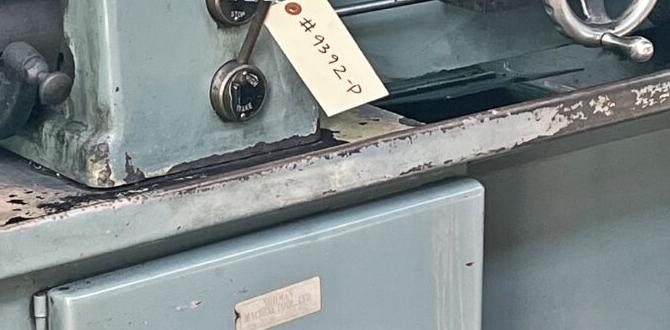

Importance of proper lathe alignment for machining accuracy. Common alignment issues faced in metal lathes.Having your lathe aligned correctly is like having a superhero sidekick. It saves you from making messy cuts and ensures your parts are accurate. Poor alignment can lead to wobbly pieces and those “oops” moments we all want to avoid. Common problems include the bed being off or the tailstock misaligned. Fixing these issues isn’t rocket science; a few tweaks can save the day!

| Common Alignment Issues | Solutions |

|---|---|

| Bed misalignment | Check the level with a ruler. |

| Tailstock offset | Adjust it until it’s lined up. |

| Chuck wobbling | Clean and tighten it properly. |

In the end, remember that a well-aligned lathe is your best friend in the workshop. So, treat it well, and it’ll help you craft perfectly shaped wonders!

Step-by-Step Lathe Alignment Process

Detailed steps for aligning a metal lathe accurately. Tips for various lathe types and configurations.To align a metal lathe accurately, follow these steps:

- First, check the level of your lathe. Use a bubble level for precision.

- Next, adjust the feet of the lathe until it’s perfectly level.

- Then, align the tailstock with the spindle. Use a dial indicator for accuracy.

- After that, double-check the adjustments and tighten all the bolts.

Each lathe type might need specific tweaks. Always read the user manual. Take your time. A well-aligned lathe gives better results and safety.

What are some quick lathe alignment tips?

Make sure to level your lathe and check the tailstock alignment. Using a dial indicator helps you find any gaps.

Common Mistakes in Lathe Alignment

Top errors to avoid when aligning a lathe. How to troubleshoot alignment issues effectively.Aligning a lathe can be tricky. Many people make common mistakes that lead to problems. Here are some errors to avoid:

- Skipping measurements: Always measure before adjusting.

- Ignoring the level: A level lathe works best.

- Not checking wear: Worn parts can change alignment.

- Forgetting to tighten: Loose screws can cause shifts.

To troubleshoot issues, regularly check your lathe. Look for loose parts and take time to adjust the settings. A well-aligned lathe leads to better performance and fewer mistakes in your work.

What are the top errors to avoid when aligning a lathe?

The biggest errors include skipping measurements, ignoring the level, not checking wear, and forgetting to tighten screws.

Metal Lathe Wiring Diagrams Explained

Importance of understanding wiring diagrams for lathe operation. Components and symbols commonly found in wiring diagrams.Understanding wiring diagrams is super important for your lathe machine. They are like treasure maps! They show you how to connect everything properly. This helps your lathe work better and keeps you safe. Common symbols in these diagrams include circuits, switches, and power sources. Knowing what they mean turns you into a wiring wizard! If only reading diagrams came with magical spells, right? Here’s a quick look at some components:

| Component | Symbol |

|---|---|

| Power Supply | ☼ |

| Switch | ⚫ |

| Motor | ⏭ |

With this knowledge, you’ll be zipping around your metal lathe like a pro!

Creating a Custom Wiring Diagram for Your Lathe

Steps to tailor a wiring diagram to your specific lathe model. Safety precautions when working with electrical systems.Tailoring a wiring diagram for your lathe model can be fun and rewarding! First, gather the specifications for your machine. This helps you understand where each wire goes. Next, sketch a diagram, marking connections clearly. Remember to follow safety precautions: always unplug your lathe when working on electrical parts. No one wants a surprise zap during wiring! You can use the table below to keep track of key components:

| Component | Description |

|---|---|

| Power Supply | Feeds electricity to the lathe |

| Switch | Turns the lathe on and off |

| Motor | Powers the spindle for turning |

Lastly, double-check your diagram against your lathe’s manual. A little attention now can save you from big headaches later!

Troubleshooting Wiring Issues in Metal Lathes

Common electrical problems and their solutions. Best practices for maintaining wiring integrity.Troubleshooting can be tricky for metal lathe users. Electrical issues often pop up and can cause problems. Common issues include:

- Loose connections: Check wires for tightness.

- Frayed wires: Inspect cables for damage.

- Defective switches: Test switches to see if they work.

To keep your wiring in good shape, follow these tips:

- Regularly check wiring for signs of wear.

- Keep areas dry to prevent corrosion.

- Use cable ties to avoid tangled wires.

By being careful, you can solve problems quickly and keep your lathe running smooth!

What are common electrical problems in metal lathes?

Common electrical problems include loose connections, frayed wires, and defective switches. Regular checks help catch issues early.

How can I maintain my lathe’s wiring?

To maintain wiring, check for wear, keep it dry, and use ties to prevent tangling. Simple steps go a long way!

Resources for Further Learning

Recommended books, videos, and online courses on lathe alignment. Forums and communities for metalworking enthusiasts.If you’re keen to learn more about lathe alignment, plenty of resources are at your fingertips. Recommended books can be a goldmine of information, covering everything from basics to expert tips. Many videos on platforms like YouTube show step-by-step guides and even funny bloopers that lighten the learning mood. Don’t overlook online courses; they can be both informative and entertaining!

Joining forums and communities is another great way to connect with fellow metalworking enthusiasts. Everyone loves sharing tips, tricks, and even the occasional dad joke about lathe mishaps. So, grab your favorite book or surf some educational videos, and get ready to align with success!

| Resource Type | Suggestions |

|---|---|

| Books | “The Metalworking Handbook,” “Lathework: A Complete Guide” |

| Videos | YouTube channels like “Metalworking Wizard” |

| Online Courses | Platforms like Udemy and Skillshare |

| Forums | Reddit’s r/Metalworking and practicalmachinist.com |

Conclusion

In summary, understanding lathe alignment is crucial for quality work. Check your metal lathe’s wiring diagram to ensure everything is connected properly. Always keep tools and parts clean to increase accuracy. If you’re unsure, don’t hesitate to seek help or read more on lathe maintenance. By following these tips, you can improve your skills and create better projects.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Alignment Tips And Metal Lathe Wiring Diagrams:Sure! When we talk about lathe alignment tips, it means making sure the machine is straight and even. This helps us make better things. For metal lathe wiring diagrams, these are pictures that show how to connect the wires. They help you set up the machine safely. Always follow the diagrams carefully to avoid problems.

Of course! Please provide the question you’d like me to answer.

What Are The Essential Steps For Aligning A Metal Lathe To Ensure Precision In Machining?To align a metal lathe, first, make sure it’s level on the floor. You can use a bubble level to check this. Next, adjust the tailstock so it’s straight with the main part, called the bed. Then, check the tool holder to ensure it’s also lined up correctly. Finally, test the machine by running it to see if everything is working well.

How Can One Identify Common Alignment Issues In A Metal Lathe And What Are The Recommended Solutions?You can spot alignment issues in a metal lathe by looking for uneven cuts or weird shapes on the metal. If your metal piece wobbles or doesn’t spin straight, something is off. To fix this, we can check if everything is level and adjust the legs of the lathe. Sometimes, we may need to realign the cutting tool or replace worn-out parts. Adjusting these things can help our lathe work better again.

What Tools Are Necessary For Checking And Adjusting The Alignment Of A Metal Lathe?To check and adjust the alignment of a metal lathe, you need a few important tools. First, you will want a level to see if the lathe is straight. A dial indicator helps you measure how far off the parts are. You might also need a straightedge, which is a long, flat piece to check flat surfaces. Finally, some wrenches will help tighten or loosen bolts to make adjustments.

Where Can I Find Detailed Wiring Diagrams For Different Types Of Metal Lathes, And How Can I Safely Follow Them During Electrical Repairs?You can find wiring diagrams in the user manuals for your metal lathe. Check the manufacturer’s website or online forums. You can also find books that have these diagrams. When following the diagrams, make sure to turn off the power first. Always use tools safely and wear gloves if needed.

How Does Proper Lathe Alignment Affect The Overall Performance And Longevity Of The Machine?Proper lathe alignment helps the machine work smoothly. When it’s aligned well, it cuts accurately, so we get better shapes. If it’s not aligned, it can wear out faster and break down. This means we have to repair it more often, which costs time and money. Taking care of alignment helps our lathe last longer and work better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Alignment Tips And Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When we talk about lathe alignment tips, it means making sure the machine is straight and even. This helps us make better things. For metal lathe wiring diagrams, these are pictures that show how to connect the wires. They help you set up the machine safely. Always follow the diagrams carefully to avoid problems.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Steps For Aligning A Metal Lathe To Ensure Precision In Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align a metal lathe, first, make sure it’s level on the floor. You can use a bubble level to check this. Next, adjust the tailstock so it’s straight with the main part, called the bed. Then, check the tool holder to ensure it’s also lined up correctly. Finally, test the machine by running it to see if everything is working well.”}},{“@type”: “Question”,”name”: “How Can One Identify Common Alignment Issues In A Metal Lathe And What Are The Recommended Solutions?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can spot alignment issues in a metal lathe by looking for uneven cuts or weird shapes on the metal. If your metal piece wobbles or doesn’t spin straight, something is off. To fix this, we can check if everything is level and adjust the legs of the lathe. Sometimes, we may need to realign the cutting tool or replace worn-out parts. Adjusting these things can help our lathe work better again.”}},{“@type”: “Question”,”name”: “What Tools Are Necessary For Checking And Adjusting The Alignment Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check and adjust the alignment of a metal lathe, you need a few important tools. First, you will want a level to see if the lathe is straight. A dial indicator helps you measure how far off the parts are. You might also need a straightedge, which is a long, flat piece to check flat surfaces. Finally, some wrenches will help tighten or loosen bolts to make adjustments.”}},{“@type”: “Question”,”name”: “Where Can I Find Detailed Wiring Diagrams For Different Types Of Metal Lathes, And How Can I Safely Follow Them During Electrical Repairs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find wiring diagrams in the user manuals for your metal lathe. Check the manufacturer’s website or online forums. You can also find books that have these diagrams. When following the diagrams, make sure to turn off the power first. Always use tools safely and wear gloves if needed.”}},{“@type”: “Question”,”name”: “How Does Proper Lathe Alignment Affect The Overall Performance And Longevity Of The Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Proper lathe alignment helps the machine work smoothly. When it’s aligned well, it cuts accurately, so we get better shapes. If it’s not aligned, it can wear out faster and break down. This means we have to repair it more often, which costs time and money. Taking care of alignment helps our lathe last longer and work better!”}}]}