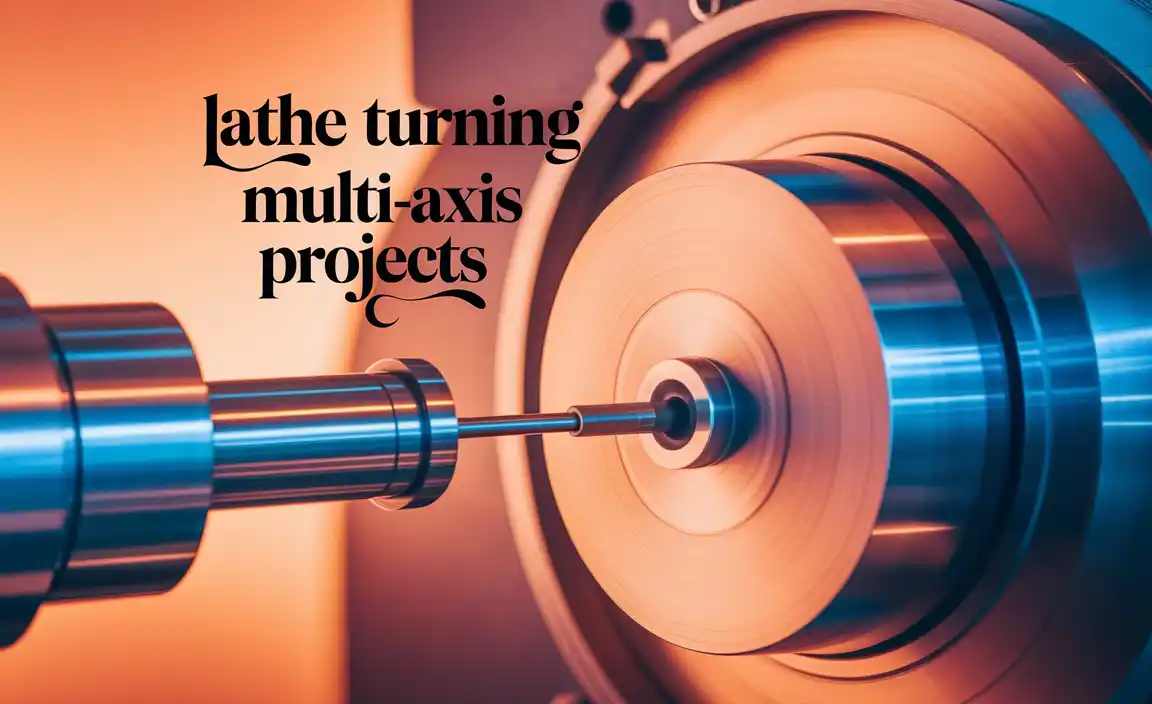

Have you ever wondered how metal parts are made? A lathe is a magical tool that shapes metal with precision. It spins the metal while cutting tools shape it into the desired form. But how do you pick the best metal lathe for your projects?

This article is your ultimate lathe application guide. We will help you understand what makes a metal lathe great. Do you know that even small lathes can create incredible work? With the right lathe, you can make everything from screws to car parts!

Let’s explore the key features to look for in a lathe. You’ll learn where to find the best options and how to make the most of your machine. Get ready to dive into the world of metal lathes. Adventure awaits in your workshop!

Lathe Application Guide: Best Metal Lathe For Precision Machining

Lathe Application Guide: Best Metal Lathe

Looking for the best metal lathe? You’ve come to the right place! This guide reveals important uses and tips for metal lathes. You’ll learn how to choose the right lathe for your projects. Do you want to create precise parts? Or maybe smooth out rough surfaces? Understanding different lathe applications can make your work easier and more enjoyable. Surprise yourself with how much a good lathe can change your crafting experience!Understanding the Basics of Metal Lathes

Definition and function of a metal lathe. Key components and their roles.A metal lathe is a machine used to shape metal into different forms. It spins the metal while tools cut it, like a barber giving a buzz cut. Key parts include the bed, where everything sits; the headstock, which holds the spindle; and the tailstock, which supports the other end of the metal. Each part works together like a band, making music in metal shaping!

| Component | Function |

|---|---|

| Bed | Supports the entire lathe and keeps it steady. |

| Headstock | Holds the spindle and powers the rotation. |

| Tailstock | Provides support and can hold tools or workpieces. |

With these parts, metal lathes can produce everything from simple rods to complex shapes. So, if you need a cool gadget, a lathe is your best friend!

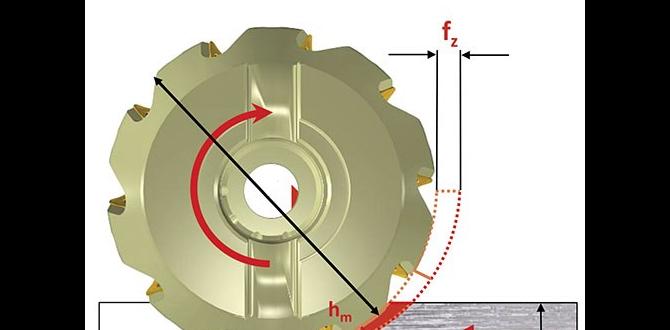

Key Features to Look for in a Metal Lathe

Importance of precision and accuracy in machining. Relevant specifications: swing, bed length, and spindle speed. Additional features: digital readouts, coolant systems, and tooling options.Choosing a metal lathe? Focus on accuracy first! Precision makes a big difference in machining. Consider these important specs:

- Swing: It’s the distance from the center of the spindle to the bed. A larger swing gives you more room for bigger projects.

- Bed Length: This affects how long the pieces you can work on. Longer beds mean longer items can be turned.

- Spindle Speed: This tells you how fast the spindle can spin. Higher speeds are great for different materials.

Look for cool add-ons too, like:

- Digital Readouts: They show exact measurements, making work easier.

- Coolant Systems: These keep the lathe cool and make cutting smoother.

- Tooling Options: More tools mean more projects you can create!

In short, all these features help you craft amazing things with your lathe!

What is the importance of precision in machining?

Precision is key in machining. It ensures correct dimensions and smooth finishes. Without it, parts may not fit together properly.

What specifications should I consider in a metal lathe?

Consider swing, bed length, and spindle speed when choosing a lathe. These specifications affect what you can make.

Applications of Metal Lathes in Different Industries

Automotive industry applications: engine parts, custom components. Aerospace manufacturing: precision parts and assemblies. Manufacturing and prototyping: small batches vs. mass production.Metal lathes are vital tools in many industries. They help create important parts for cars and airplanes. In the automotive world, lathes make engine parts and custom components. These are crucial for vehicle performance. In aerospace, they produce precision parts and complex assemblies. This ensures safety and reliability. Lathes also play a role in manufacturing. They are used for small batches as well as mass production. This flexibility makes them valuable in different sectors.

What are the key applications of metal lathes?

Metal lathes are essential in various fields. They help in the creation of:

- Automotive parts: Vital for engine performance.

- Aerospace parts: Ensuring precision and safety.

- Manufacturing: Supporting both small and large production runs.

These applications show how metal lathes shape our world. They enhance everything from cars to airplanes, making our lives easier and safer.

Choosing the Best Metal Lathe for Your Needs

Factors to consider based on usage: hobbyist vs. professional. Budget considerations and value for money.Picking the right metal lathe can make a big difference. Think about how you will use it. Hobbyists often need smaller lathes for home projects. Professionals might need bigger, more powerful machines for tough jobs. Next, consider your money. Set a budget. A good lathe can be an investment. Look for value over the cheapest option. You want a tool that will last and perform well. Compare features to find the best fit for you.

What should you consider when buying a metal lathe?

Consider size, power, and features that match your skill level.

Key points:

- Hobbyist: Smaller, affordable, and easy to use.

- Professional: Larger, robust, with advanced features.

- Budget: Determine what you can spend; quality matters.

- Value: Look for tools that will last longer.

Maintenance Tips for Longevity of Metal Lathes

Regular cleaning and lubrication practices. Identifying and addressing common issues.To keep your metal lathe running smoothly, regular cleaning is a must! Dust and grime can hide in sneaky spots, so grab a cloth and clean those areas often. Lubrication is also key. A drop of oil here and there can save the day! Keep an eye out for odd noises or excessive vibrations, as they may signal a problem. Addressing these issues early can save you from bigger headaches later!

| Common Issues | Quick Fixes |

|---|---|

| Unusual Noise | Check for loose parts. |

| Vibrations | Ensure it’s balanced properly. |

| Stiff Movements | Apply more lubricant. |

Taking these steps will help your lathe last longer than your favorite pair of socks! Remember, a little care goes a long way!

Sourcing Quality Metal Lathes

Recommended manufacturers and brands. Pros and cons of new vs. used lathes.Finding the right metal lathe can feel like looking for a needle in a haystack! Start by checking out brands like Jet and Grizzly; they’re known for quality machines. Don’t forget about used lathes—they can save you bucks! But be careful. A used lathe might come with charming quirks that could drive you batty! Here’s a quick comparison:

| Type | Pros | Cons |

|---|---|---|

| New Lathes | Latest technology, warranty included! | They can be pricey! |

| Used Lathes | More affordable, potentially great finds! | Risk of hidden issues! |

Remember, whether new or used, quality is key! So, happy lathe hunting!

User Reviews and Experiences

Analysis of user feedback on popular metal lathes. Case studies highlighting successful projects using specific models.User feedback is very important for metal lathes. Many users share their experiences with different models. For example, one user praised the XYZ Metal Lathe for its precision. They created beautiful parts for a hobby project. Other users noted how easy some lathes are to use. This helps beginners feel confident. Here are some key points from reviews:

- High precision is a common praise.

- Lightweight models are popular for small projects.

- Durability is frequently mentioned, especially in tough jobs.

These positive reviews show how specific lathes can lead to successful projects. Users love their machines and the work they create!

What do users say about metal lathes?

Users say metal lathes are essential tools. They value features like ease of use and precision for projects.Future Trends in Metal Lathe Technology

Innovations in CNC technology and automation. The impact of 3D printing and hybrid manufacturing on traditional lathing.Exciting changes are coming to the world of metal lathes! CNC technology is evolving rapidly. New machines now use smart automation to make lathing tasks smoother and faster. This means less time waiting and more time creating. Plus, 3D printing is shaking things up! It allows makers to produce complex shapes that lathes can’t. Hybrid manufacturing combines the best of both worlds. Traditional lathes and modern techniques can work together. The future of metal lathing looks bright—and maybe even a little wacky!

| Innovation | Description |

|---|---|

| CNC Technology | Smart machines that automate tasks for quicker results. |

| 3D Printing | Creating shapes that lathes alone can’t make. |

| Hybrid Manufacturing | Combining traditional and modern methods for better outputs. |

Conclusion

In summary, choosing the best metal lathe means considering size, features, and price. A good lathe enhances your projects and skills. Explore different models to find the right fit for your needs. Don’t forget to check user reviews and guides for more tips. Start your journey with metal lathes today, and see what amazing things you can create!FAQs

What Factors Should Be Considered When Selecting The Best Metal Lathe For A Specific Application?When picking a metal lathe, think about its size and how much space you have. You should also check how heavy the pieces you will work with are. Remember to look at the type of work you want to do. Lastly, consider your budget and how much you want to spend. These choices will help you find the best lathe for your needs.

How Do Different Lathe Configurations (E.G., Cnc Vs. Manual) Impact Performance And Usability In Metalworking?Different lathe setups can change how we work with metal. A CNC lathe, which stands for Computer Numerical Control, uses a computer to help you make precise cuts. This makes it faster and easier to create complex shapes. A manual lathe requires you to do everything by hand, which can take more time and skill. So, CNC lathes are great for quick, exact work, while manual lathes give you more control but need more practice.

What Are The Most Common Applications Of Metal Lathes In Various Industries?Metal lathes are machines that help us shape metal into different parts. You can find them in car factories making engine parts. They work in tool shops, creating tools and gadgets we use every day. They also help in making pipes for water and gas. In short, metal lathes are used everywhere we need shaped metal pieces!

How Can Operators Optimize The Setup And Tooling Of A Metal Lathe For Improved Accuracy And Efficiency?To make a metal lathe work better, you can start by checking that all parts are clean and tight. Use sharp tools because they cut more easily and make better shapes. You should also set the right speed for the material you’re using. Finally, double-check your measurements to avoid mistakes. This all helps the lathe work faster and cleaner!

What Safety Measures Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Ensure Safe Machining Practices?When using a metal lathe, always wear safety goggles to protect your eyes. Keep long hair tied back and wear tight-fitting clothes. Make sure your workspace is clean and free of distractions. Always keep your hands away from moving parts. Finally, pay attention and follow all instructions carefully.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting The Best Metal Lathe For A Specific Application? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a metal lathe, think about its size and how much space you have. You should also check how heavy the pieces you will work with are. Remember to look at the type of work you want to do. Lastly, consider your budget and how much you want to spend. These choices will help you find the best lathe for your needs.”}},{“@type”: “Question”,”name”: “How Do Different Lathe Configurations (E.G., Cnc Vs. Manual) Impact Performance And Usability In Metalworking? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different lathe setups can change how we work with metal. A CNC lathe, which stands for Computer Numerical Control, uses a computer to help you make precise cuts. This makes it faster and easier to create complex shapes. A manual lathe requires you to do everything by hand, which can take more time and skill. So, CNC lathes are great for quick, exact work, while manual lathes give you more control but need more practice.”}},{“@type”: “Question”,”name”: “What Are The Most Common Applications Of Metal Lathes In Various Industries? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes are machines that help us shape metal into different parts. You can find them in car factories making engine parts. They work in tool shops, creating tools and gadgets we use every day. They also help in making pipes for water and gas. In short, metal lathes are used everywhere we need shaped metal pieces!”}},{“@type”: “Question”,”name”: “How Can Operators Optimize The Setup And Tooling Of A Metal Lathe For Improved Accuracy And Efficiency? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal lathe work better, you can start by checking that all parts are clean and tight. Use sharp tools because they cut more easily and make better shapes. You should also set the right speed for the material you’re using. Finally, double-check your measurements to avoid mistakes. This all helps the lathe work faster and cleaner!”}},{“@type”: “Question”,”name”: “What Safety Measures Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Ensure Safe Machining Practices? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Keep long hair tied back and wear tight-fitting clothes. Make sure your workspace is clean and free of distractions. Always keep your hands away from moving parts. Finally, pay attention and follow all instructions carefully.”}}]}