Have you ever wondered how metalworking professionals create precise parts with ease? A metal lathe is a powerful tool that plays a key role in this process.

In today’s article, we’ll explore a lathe application guide that highlights useful metal lathe accessories. These accessories can take your metalworking projects to the next level.

Did you know that the right accessory can significantly enhance your lathe’s performance? It’s true! Whether you are a hobbyist or a skilled machinist, having the right tools makes all the difference.

Imagine turning a simple piece of metal into an intricate design. With the right lathe accessories, you can achieve impressive results.

Get ready to dive in as we unlock the secrets to optimizing your metal lathe experience!

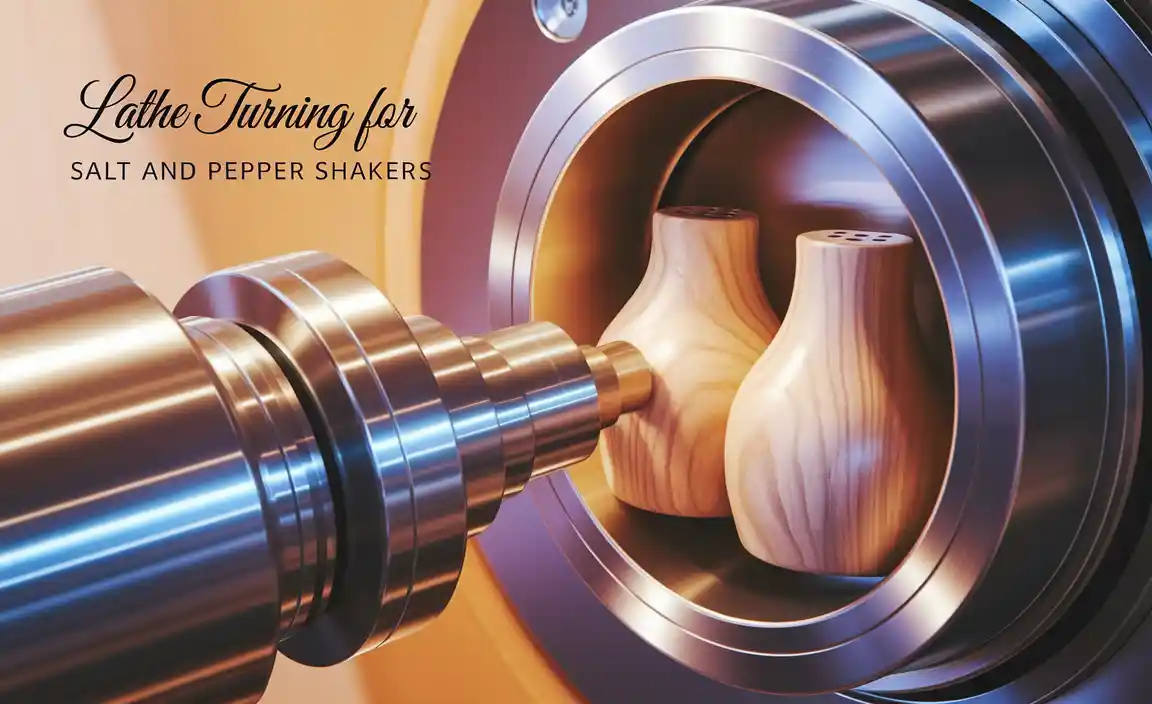

Comprehensive Lathe Application Guide: Metal Lathe Accessories

Lathe Application Guide for Metal Lathe Accessories

Understanding lathe applications opens up a world of creativity. Metal lathes can shape and cut materials into various forms. Accessories like tool holders, chucks, and tailstocks enhance the lathe’s capabilities. Have you ever wondered how a simple piece of metal transforms into a precise part? With the right accessories, your projects can become more accurate and efficient. Explore how these tools work together to bring ideas to life, making your metalworking journeys both fun and successful.Understanding Metal Lathes

Definition and purpose of metal lathes. Types of metal lathes and their functions.Metal lathes are machines that shape metal into many forms. They spin metal while cutting tools carve it into desired shapes—pretty cool, right? Imagine a big spinning candy cane, but made of metal! There are different types of metal lathes. Some are small and perfect for tiny projects, while others are large for serious tasks. Let’s check out a quick guide:

| Type of Lathe | Function |

|---|---|

| Bench Lathe | Great for small items and hobby projects. |

| Engine Lathe | Perfect for general-purpose machining. |

| CNC Lathe | Uses computer control for precision work. |

So, whether you’re turning metal into a tiny robot or a shiny spoon, these machines are super handy!

Tooling for Precision Work

Types of cutting tools used in metal lathes. Tips for selecting the right tooling for specific applications.Choosing the right cutting tools is key to making precise parts on a metal lathe. Common tools include carbide inserts, HSS tools, and drills. Each has its special job, like doing the twist at a dance party but with metal! Want to ensure you pick the right tool? Check the material you’re working with. For softer metals, HSS is great, while tougher metals like steel love carbide. Remember, the right tool means less chance of a metal disaster!

| Tool Type | Best For |

|---|---|

| Carbide Inserts | Tough materials |

| HSS Tools | Soft materials |

| Drills | Making holes |

Measuring and Alignment Tools

Importance of measurement and alignment in lathe operations. Common measuring tools used in conjunction with metal lathes.Accurate measurement and alignment are crucial in lathe operations. They ensure parts fit together well and work correctly. Using the right tools makes this easier and more reliable. Here are some common measuring tools:

- Calipers: Great for measuring small distances.

- Micrometers: Perfect for precise thickness.

- Dial Indicators: Help check alignment and movement.

- Tape Measures: Useful for larger dimensions.

With these tools, you can improve your work quality and avoid mistakes!

Why is measurement important in lathe work?

Measurement ensures the parts are made to the right size. This leads to better fitting and smoother operations.

Safety Accessories for Metal Lathe Operations

Essential safety equipment and gear for operating lathes. Best practices for maintaining a safe work environment.Using the right safety gear is important for anyone using a lathe. Essential items like safety goggles and gloves protect you from flying debris. A face shield adds extra protection for your face. Steel-toed boots keep your feet safe from heavy objects. Also, a first aid kit should be nearby. Always keep your workspace clean to prevent accidents. Following these tips can help create a safer work environment.

What safety gear do I need for metal lathe operations?

You need the following safety gear for metal lathe operations:

- Safety goggles: Protect your eyes from debris.

- Face shield: Extra protection for your face.

- Gloves: Keep your hands safe.

- Steel-toed boots: Protect your feet from heavy items.

- Ear protection: Safeguard your hearing from loud machines.

Maintenance Accessories for Longevity

Tools and products for regular maintenance of metal lathes. Tips for maintaining accessories to prolong their lifespan.Regular maintenance keeps your metal lathe running smoothly. Use basic tools like oil, brushes, and wrenches. These help clean and tighten parts. Here are some tips to extend the life of your accessories:

- Check for wear and tear often.

- Lubricate moving parts regularly.

- Store accessories in a dry place.

- Keep your work area clean.

Remember, small steps can make a big difference. A well-maintained lathe lasts longer and works better!

Why is regular maintenance important for metal lathe accessories?

Regular maintenance prevents wear, saves money, and keeps machines running efficiently.

Choosing the Right Accessories for Your Needs

Factors to consider when selecting lathe accessories. Common mistakes to avoid when purchasing accessories.Picking the right lathe accessories can feel like searching for a lost sock in the dryer. There are many things to think about. First, consider what projects you’ll work on. Different tasks need different tools. Next, avoid getting shiny new toys that don’t fit your lathe. This is a common mistake; size does matter! Lastly, check ratings or ask friends. A buddy’s advice might save you from a tool that’s more trouble than it’s worth!

| Factor | Tip |

|---|---|

| Project Type | Choose tools that match your project needs. |

| Compatibility | Make sure accessories fit your lathe size. |

| Research | Look up reviews or ask for recommendations. |

Conclusion

In summary, a lathe application guide helps you understand how to use metal lathe accessories effectively. These tools enhance your projects and improve your skills. You can create better workpieces with the right accessories. Take time to learn about each accessory and practice using them. Explore more resources to boost your metalworking knowledge and become a confident craftsman!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Accessories:Sure! Here are five related questions on metal lathe accessories: 1. What is a chuck and how does it work? 2. What are tool posts used for? 3. Why do we need a tailstock? 4. How do we use cutting tools? 5. What is a steady rest? These accessories help us work better on a metal lathe. They hold materials and tools securely. This makes it easier for you to shape metal. Each part has a special job to do!

Sure! Please provide the question you would like me to answer.

What Are The Essential Accessories That Every Metal Lathe Should Have For Optimal Performance?To make your metal lathe work better, you need some important accessories. First, a chuck holds the metal tightly so it doesn’t move. Next, you’ll want cutting tools to shape the metal just right. A tailstock helps support long pieces of metal while you work. Finally, a coolant system keeps everything cool and makes cutting easier.

How Do Different Types Of Cutting Tools And Tool Holders Enhance The Functionality Of A Metal Lathe?Different cutting tools and tool holders help a metal lathe work better. Cutting tools shape the metal into different forms, like smooth or pointed edges. Tool holders keep the cutting tools steady while they spin. This makes it easier for you to create the parts you need. With the right tools, we can make more precise and nicer-looking metal pieces!

What Safety Accessories Should Be Considered When Working With A Metal Lathe To Ensure A Safe Working Environment?When using a metal lathe, you should wear safety goggles to protect your eyes. Use earmuffs or earplugs to keep your ears safe from loud noise. Gloves can protect your hands from sharp metal, but make sure they fit well. A sturdy apron keeps your clothes and body safe from flying metal pieces. Finally, keep the area clean and free of clutter to prevent accidents.

How Can Work-Holding Devices, Such As Chucks And Collets, Impact The Accuracy And Quality Of Machining On A Metal Lathe?Work-holding devices like chucks and collets help hold the metal tightly. When they grip the metal well, it stays in place while we cut it. This makes our cuts more precise and clean. If the metal wobbles, our work can be uneven and messy. So, good devices mean better accuracy and quality in our projects.

What Advanced Accessories Can Be Used For Cnc Conversion In A Traditional Metal Lathe, And How Do They Improve Machining Capabilities?You can add accessories like a CNC controller, stepper motors, and a spindle drive. A CNC controller helps you program the lathe to run automatically. Stepper motors move the parts very precisely. A spindle drive makes the lathe go faster and smoother. Together, these tools help you make more detailed and complex shapes easily.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Accessories:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions on metal lathe accessories: 1. What is a chuck and how does it work? 2. What are tool posts used for? 3. Why do we need a tailstock? 4. How do we use cutting tools? 5. What is a steady rest? These accessories help us work better on a metal lathe. They hold materials and tools securely. This makes it easier for you to shape metal. Each part has a special job to do!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Accessories That Every Metal Lathe Should Have For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your metal lathe work better, you need some important accessories. First, a chuck holds the metal tightly so it doesn’t move. Next, you’ll want cutting tools to shape the metal just right. A tailstock helps support long pieces of metal while you work. Finally, a coolant system keeps everything cool and makes cutting easier.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Cutting Tools And Tool Holders Enhance The Functionality Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tools and tool holders help a metal lathe work better. Cutting tools shape the metal into different forms, like smooth or pointed edges. Tool holders keep the cutting tools steady while they spin. This makes it easier for you to create the parts you need. With the right tools, we can make more precise and nicer-looking metal pieces!”}},{“@type”: “Question”,”name”: “What Safety Accessories Should Be Considered When Working With A Metal Lathe To Ensure A Safe Working Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, you should wear safety goggles to protect your eyes. Use earmuffs or earplugs to keep your ears safe from loud noise. Gloves can protect your hands from sharp metal, but make sure they fit well. A sturdy apron keeps your clothes and body safe from flying metal pieces. Finally, keep the area clean and free of clutter to prevent accidents.”}},{“@type”: “Question”,”name”: “How Can Work-Holding Devices, Such As Chucks And Collets, Impact The Accuracy And Quality Of Machining On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Work-holding devices like chucks and collets help hold the metal tightly. When they grip the metal well, it stays in place while we cut it. This makes our cuts more precise and clean. If the metal wobbles, our work can be uneven and messy. So, good devices mean better accuracy and quality in our projects.”}},{“@type”: “Question”,”name”: “What Advanced Accessories Can Be Used For Cnc Conversion In A Traditional Metal Lathe, And How Do They Improve Machining Capabilities?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can add accessories like a CNC controller, stepper motors, and a spindle drive. A CNC controller helps you program the lathe to run automatically. Stepper motors move the parts very precisely. A spindle drive makes the lathe go faster and smoother. Together, these tools help you make more detailed and complex shapes easily.”}}]}