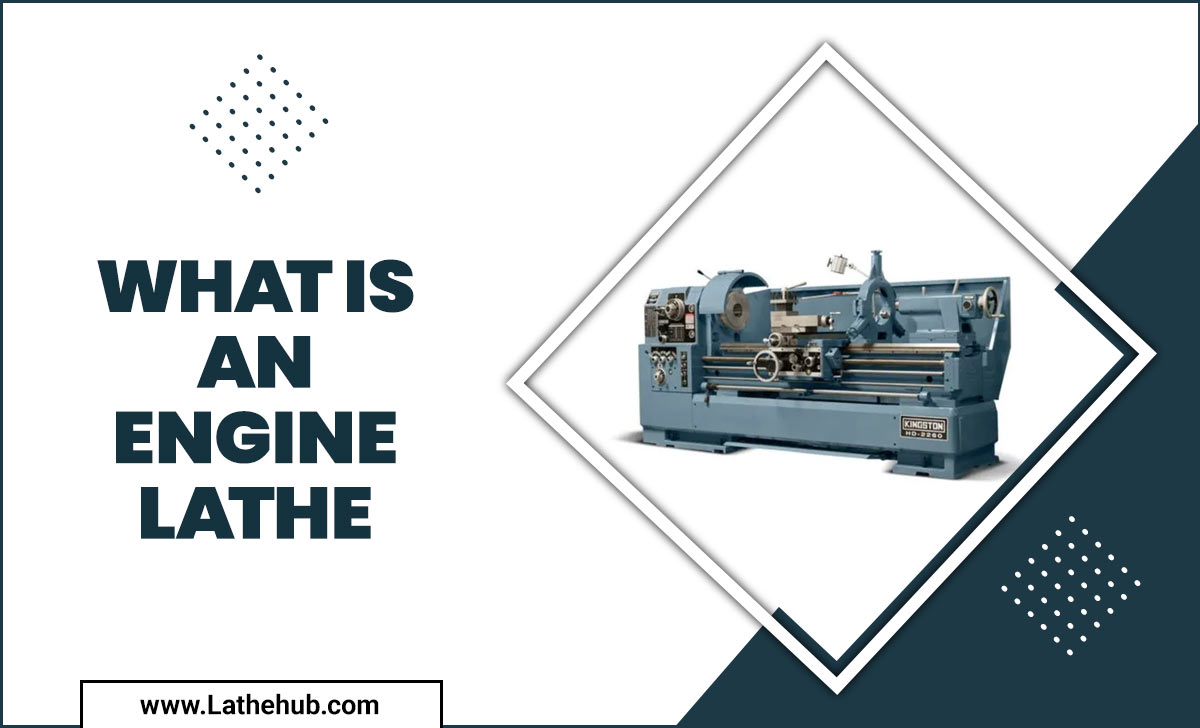

Have you ever wondered how machines create such precise shapes from metal? It’s like magic, but it’s really about something called lathe applications.

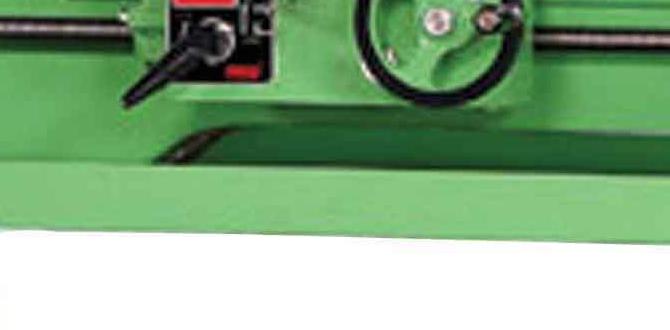

In a metalworking shop, a lathe is a powerful tool. It spins metal pieces while cutting tools shape them. But, to get the best results, the lathe must be aligned correctly. Without proper alignment, even the best machine can create mistakes.

Think about a bike wheel. If it’s out of alignment, it wobbles and makes riding hard. The same idea applies to metal lathes. Proper alignment helps the machine work smoothly and produce top-quality products.

Did you know that some of the most famous engineering feats depend on perfect lathe alignment? From car parts to intricate jewelry, everything starts with a well-aligned lathe.

This guide will walk you through the basics of lathe alignment. Whether you’re a beginner or an expert, understanding this process can boost your metalworking skills.

Lathe Application Guide: Metal Lathe Alignment Techniques

Lathe Application Guide: Metal Lathe Alignment

Understanding metal lathe alignment is key to crafting precise parts. A well-aligned lathe produces better quality and accuracy in your projects. Did you know that even a tiny misalignment can ruin your work? This guide teaches you how to align your metal lathe properly. It covers techniques to check and adjust alignment. By mastering this skill, you can enhance your machining results and enjoy your hobby even more. Are you ready to create flawless pieces?Understanding Metal Lathe Alignment

Definition and importance of alignment in metal lathes. Common alignment issues and their impact on machining accuracy.Alignment in metal lathes is key for precise machining. It means making sure all parts work together. Good alignment helps create accurate and smooth cuts. Without it, you can face common problems like uneven surfaces and poor fits. These issues can cause wasted time and materials. It’s crucial to check alignment often to keep everything working well.

What are common alignment issues?

Common issues include:

- Bed twist: Causes uneven cutting.

- Tailstock misalignment: Leads to boring errors.

- Chuck wobble: Results in inaccurate diameters.

Fixing these problems can significantly improve machining accuracy. Remember, a well-aligned lathe is your best friend in metalworking!

Essential Tools for Lathe Alignment

List of tools required for precise alignment (e.g., levels, indicators). Explanation of how each tool is used in the alignment process.For precise lathe alignment, you need a few essential tools. These tools help ensure everything works perfectly. Here’s a quick list:

- Levels: They check if the lathe is flat and steady.

- Indicators: These measure tiny changes. They help align parts carefully.

- Dial Gauges: They help to find any wobbles in the lathe.

- Alignment Bars: These check if the center line is correct.

Using these tools correctly means you can adjust your lathe for better performance. This makes your work safer and more precise!

What tools do I need for lathe alignment?

You need tools like levels, indicators, and dial gauges. These tools help to make sure everything is straight and true.

Step-by-Step Guide to Lathe Alignment

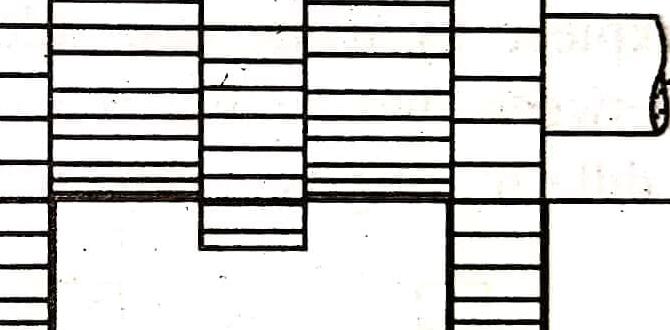

Detailed procedures for aligning the tailstock and headstock. Methods to ensure alignment of other critical components (e.g., bed, carriage).To align a lathe for accurate work, follow these steps carefully. Start with the headstock. Use a level to check its position. Adjust as needed until it sits perfectly straight. Next, focus on the tailstock. Keep it aligned with the headstock. Use a dial indicator to check the distance. Ensure both parts match closely. Finally, check the bed and carriage. Look for any uneven spots. Here are the key methods:

- Use a straight edge to spot any discrepancies.

- Regularly measure distances between components.

- Tighten all bolts firmly but don’t overdo it.

How do you check a lathe for alignment?

To check alignment, use a dial indicator to measure distances between parts. Ensure each component, like the headstock and tailstock, is straight. Regular checks can help keep your lathe in great shape!

Checking and Maintaining Alignment

Importance of regular checks and maintenance routines. Tips for troubleshooting misalignments and ensuring longevity.Regular checks and proper care are key to keeping your lathe in top shape. Misalignments can cause problems, like uneven cuts or machine wear. By regularly checking the alignment, you ensure smooth performance and lasting quality. Here are some tips:

- Check the bed and tailstock for level.

- Inspect the spindle for any wobble.

- Clean the machine regularly to avoid debris build-up.

- Adjust parts slowly, making small changes.

Taking these steps can help you catch issues early and extend your lathe’s life.

Why is alignment important for lathe performance?

Proper alignment guarantees accurate cuts and smooth operation. It also helps prevent damage, making your lathe last longer.

Real-World Applications of Proper Lathe Alignment

Case studies showcasing the benefits of correct alignment in precision machining. Examples of industries that rely heavily on metal lathe alignment.Correct lathe alignment is crucial in many industries. One example is the automotive industry. Here, precise machining improves car part quality. In the aerospace sector, aligning lathes leads to safer and lighter aircraft parts. These benefits highlight why industries prioritize lathe alignment.

- Automotive: Enhances part quality.

- Aerospace: Ensures safety and reduces weight.

- Manufacturing: Increases production efficiency.

Why is lathe alignment important?

Lathe alignment ensures accuracy and efficiency. Misalignment can cause waste and unsafe products.

Conclusion

In summary, aligning your metal lathe is essential for precise work. You should regularly check and adjust the alignment to ensure accuracy. Remember to follow your lathe application guide closely for the best results. Keep practicing, and don’t hesitate to explore more resources to improve your skills. Happy machining!FAQs

What Are The Key Steps For Aligning A Metal Lathe To Ensure Accurate Machining Results?To align a metal lathe, first, make sure it’s on a flat surface. Next, check the bed for twists or bends. You should then adjust the tailstock and headstock to be perfectly straight. Finally, test it with a piece of metal to see if it works well. This way, you can make accurate cuts!

How Can You Determine If Your Metal Lathe Is Misaligned, And What Symptoms Should You Look For?To check if your metal lathe is misaligned, you can look for a few signs. First, pay attention to how your tool cuts the metal. If it makes uneven or rough edges, something might be wrong. Also, check for unusual vibrations or noises while it runs. Lastly, measure the distance from the tool to the workpiece at both ends; if it’s different, your lathe may be misaligned.

What Tools And Instruments Are Recommended For Properly Aligning A Metal Lathe?To align a metal lathe, you need a few simple tools. A leveling tool helps you check if the lathe is straight. You might also use a dial indicator, which shows how level the parts are. A straight edge helps you see if everything lines up right. Finally, a wrench is handy for tightening bolts as needed.

How Often Should Routine Alignment Checks Be Performed On A Metal Lathe To Maintain Precision?You should check the alignment of a metal lathe often, like once a week. If you use it a lot, check it even more. Regular checks help keep the machine working well and making good parts. If you notice anything off, check it right away. This way, you can fix problems before they become big.

What Are Common Mistakes To Avoid When Aligning A Metal Lathe, And How Can They Affect Machining Quality?When aligning a metal lathe, you should avoid not checking the level of the machine. If it’s not level, pieces can come out crooked. Also, don’t forget to check the tailstock and headstock positions. If they’re off, it can make your cuts uneven. Finally, make sure all parts are tight; loose parts can cause wobbling and bad cuts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Steps For Aligning A Metal Lathe To Ensure Accurate Machining Results? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align a metal lathe, first, make sure it’s on a flat surface. Next, check the bed for twists or bends. You should then adjust the tailstock and headstock to be perfectly straight. Finally, test it with a piece of metal to see if it works well. This way, you can make accurate cuts!”}},{“@type”: “Question”,”name”: “How Can You Determine If Your Metal Lathe Is Misaligned, And What Symptoms Should You Look For? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if your metal lathe is misaligned, you can look for a few signs. First, pay attention to how your tool cuts the metal. If it makes uneven or rough edges, something might be wrong. Also, check for unusual vibrations or noises while it runs. Lastly, measure the distance from the tool to the workpiece at both ends; if it’s different, your lathe may be misaligned.”}},{“@type”: “Question”,”name”: “What Tools And Instruments Are Recommended For Properly Aligning A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align a metal lathe, you need a few simple tools. A leveling tool helps you check if the lathe is straight. You might also use a dial indicator, which shows how level the parts are. A straight edge helps you see if everything lines up right. Finally, a wrench is handy for tightening bolts as needed.”}},{“@type”: “Question”,”name”: “How Often Should Routine Alignment Checks Be Performed On A Metal Lathe To Maintain Precision? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the alignment of a metal lathe often, like once a week. If you use it a lot, check it even more. Regular checks help keep the machine working well and making good parts. If you notice anything off, check it right away. This way, you can fix problems before they become big.”}},{“@type”: “Question”,”name”: “What Are Common Mistakes To Avoid When Aligning A Metal Lathe, And How Can They Affect Machining Quality? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When aligning a metal lathe, you should avoid not checking the level of the machine. If it’s not level, pieces can come out crooked. Also, don’t forget to check the tailstock and headstock positions. If they’re off, it can make your cuts uneven. Finally, make sure all parts are tight; loose parts can cause wobbling and bad cuts.”}}]}