Have you ever wondered how metal pieces are shaped into perfect forms? The answer often lies in a lathe. This powerful machine can create smooth parts with great precision. But there’s more to it than just spinning metal. Let’s talk about the lathe application guide for the metal lathe bed.

Picture this: you’re crafting a metal masterpiece. You want it to be accurate and beautiful. But how do you get there? Understanding the metal lathe bed’s role is essential. It’s the sturdy base that keeps everything aligned as you work.

Did you know that lathes have been around for thousands of years? Early craftsmen used them to make pottery and wooden items. Today, they shape metal for all sorts of products. From tiny screws to large engine parts, lathes play a key part.

This guide will help you explore the different applications of metal lathe beds. You’ll learn tips and tricks to maximize your lathe’s potential. Ready to dive in and discover the world of metalworking? Let’s get started!

Comprehensive Lathe Application Guide: Metal Lathe Bed Insights

Lathe Application Guide for Metal Lathe Bed

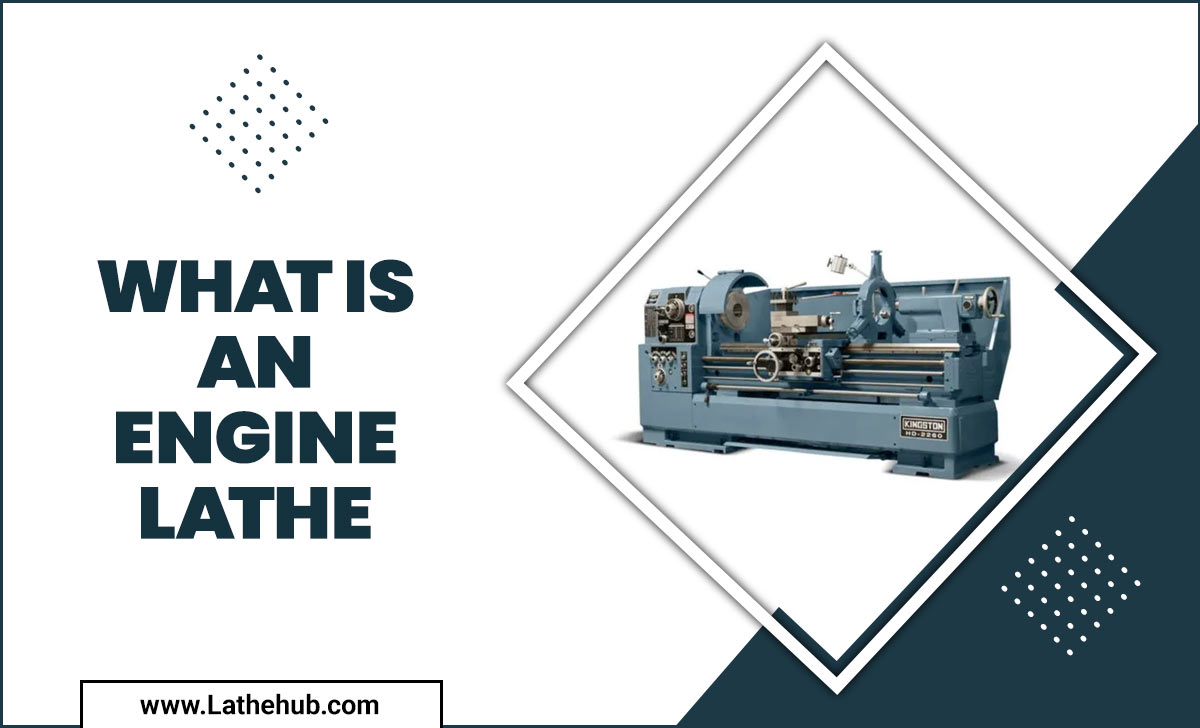

Metal lathes are essential tools in machine shops and hobbies alike. A well-built lathe bed keeps the machine stable and precise. Did you know the bed’s material affects the lathe’s performance? Using cast iron helps absorb vibrations, leading to cleaner cuts. Proper maintenance, like regular cleaning, can extend its lifespan. Choosing the right lathe bed will improve your metalworking experience. Remember, a sturdy foundation makes all the difference in crafting quality pieces!Key Components of a Metal Lathe Bed

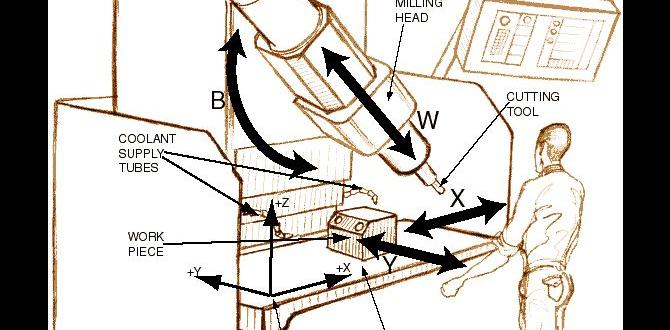

Detailed breakdown of the components: headstock, tailstock, carriage, and bed.. Discussion on the materials and design considerations for durability and accuracy..A metal lathe bed has important parts that help it work well. Here are the main components:

- Headstock: This part holds the motor and controls.

- Tailstock: It provides support at the end of the lathe.

- Carriage: This moves the cutting tool along the metal.

- Bed: The flat base supports all other parts.

For durability, the bed is often made of cast iron or steel. These materials help to keep the lathe steady and accurate. A sturdy design is essential for smooth operation and better results.

What is the main purpose of each lathe component?

The headstock spins the workpiece. The tailstock offers support. The carriage guides the cutting tool. The bed gives stability.

Choosing the Right Metal Lathe Bed for Your Needs

Factors to consider: size, rigidity, and intended applications.. Comparison of various metal lathe bed types available in the market..Picking the perfect metal lathe bed can feel like a treasure hunt! First, think about size: make sure you have enough space for your projects. Second, consider rigidity: a strong bed prevents wiggles and wobbles, like trying to write on a bumpy road! Lastly, what do you plan to make? Different beds suit different jobs.

| Type of Metal Lathe Bed | Size | Rigidity | Best for |

|---|---|---|---|

| Cast Iron | Large | Very Rigid | Heavy Work |

| Steel | Medium | Moderately Rigid | General Purpose |

| Aluminum | Small | Lightweight | Small Projects |

Remember, it’s like picking the right shoes for a dance party. You want them to fit well, be sturdy, and help you shine on the dance floor—or in this case, your workshop!

Maintenance Tips for Longevity of Metal Lathe Beds

Best practices for cleaning and lubricating lathe beds.. Signs of wear and when to replace or repair components..Taking care of your metal lathe bed helps it last longer. Clean it regularly with a soft cloth. Use oil to keep parts running smoothly. Watch for these signs of wear: it feels rough or makes strange noises. If you notice these, it’s time to check if you need repairs or replacements.

How do I clean and lubricate my lathe bed?

Clean with a soft cloth and use appropriate oil for lubrication.Best Practices:

- Wipe debris after each use.

- Lubricate moving parts monthly.

- Inspect for rust and damage regularly.

Keeping an eye on these details will help your lathe stay in good shape for many years. Take care of your tools, and they will serve you well!

Common Applications of Metal Lathes

Industries that utilize metal lathes: automotive, aerospace, and manufacturing.. Specific tasks performed using metal lathes (turning, threading, etc.)..Many industries use metal lathes to create important parts. The three main ones are automotive, aerospace, and manufacturing. Each industry benefits from a metal lathe’s precision and speed.

- Automotive: Lathes shape car parts and engine components.

- Aerospace: They help make aircraft parts that need to be very strong and light.

- Manufacturing: Metal lathes assist in producing various tools and machinery parts.

This equipment can perform tasks like turning and threading. With turning, pieces are rotated against tools to shape them. Threading creates spirals on the surface for screws and bolts. Without metal lathes, making these items would be much harder.

Why are metal lathes important?

Metal lathes allow industries to create accurate, high-quality parts quickly. They save time and reduce waste. In fact, metalworking tools like lathes are essential for daily operations in many factories.

Upgrades and Modifications for Enhanced Performance

Popular upgrades for metal lathe beds: adding steadies, digital readouts, etc.. Customization options based on specific project needs..Making your metal lathe work better is a fun project. Some popular upgrades include adding steadies to keep your workpiece stable and installing digital readouts for precise measurements. You can tailor your lathe with different features that fit your needs. Here are some ideas:

- Add steadies for support.

- Use a digital readout for accuracy.

- Customize the speed settings for different tasks.

- Change the tool holder for better versatility.

These improvements help you achieve better results and enjoy your projects more. Are you ready to upgrade your lathe?

What are the benefits of upgrading a metal lathe bed?

Upgrading your lathe bed can improve accuracy, stability, and overall performance. This leads to smoother cuts and better-quality workpieces.

Safety Practices When Using Metal Lathes

Essential safety gear and protocols in a machining environment.. Common hazards and how to mitigate risks while working with lathes..Using metal lathes can be fun, but safety is very important. Wear essential gear like goggles, gloves, and earplugs. This gear helps protect you from flying chips and loud noises. Always follow these safety tips:

- Keep your work area clean.

- Secure loose clothing and long hair.

- Don’t distract others while they work.

Common hazards include sharp tools and spinning parts. To stay safe, always pay attention and think before you act. Following these simple practices can help you avoid accidents.

What safety gear do I need for using a lathe?

You need proper protection to stay safe. Always wear goggles to shield your eyes from debris, gloves to protect your hands, and earplugs to block loud noises.

Frequently Asked Questions about Metal Lathe Beds

Answers to common queries regarding usage, maintenance, and troubleshooting.. Expert tips from experienced machinists on optimizing lathe performance..Many newcomers to metal lathes have questions. Understanding the lathe bed is key. Here are some common queries:

How do I maintain my metal lathe bed?

To keep your lathe bed in good shape, clean it regularly. Use a soft cloth and non-abrasive cleaner. Make sure to oil the sliding parts, too.

What should I do if my lathe bed shows wear?

If you notice wear, check the alignment first. Misaligned parts can cause problems. Adjust them carefully.

What are some tips for better lathe performance?

- Use sharp tools to get clean cuts.

- Adjust your speed based on the material you’re working with.

- Keep everything lubricated for smooth operation.

With these tips, you can enjoy a better metal lathe experience!

Conclusion

In summary, a lathe application guide for metal lathe beds helps you understand their use and importance. You can create precise shapes from metal and wood. Remember to choose the right lathe for your projects. Explore more resources and practice regularly to improve your skills. By learning these techniques, you’ll gain confidence in your metalworking journey!FAQs

Certainly! Here Are Five Related Questions On The Topic Of A Metal Lathe Bed Application Guide:Sure! A metal lathe bed is a part of a machine that helps shape metal. It holds the metal piece steady while it spins. This way, you can cut or smooth it into the right shape. You use the lathe for making things like parts for toys or tools. It helps you make your projects look neat and professional!

Sure! Please provide the question you want me to answer.

What Are The Key Factors To Consider When Selecting A Metal Lathe Bed For Precision Machining?When picking a metal lathe bed for precision machining, think about size and weight. You want a sturdy bed that won’t move while you work. Also, check the material. A strong metal like cast iron is good because it lasts longer. Lastly, look at the design; a flat and smooth surface helps make better cuts.

How Does The Construction Material Of A Lathe Bed Impact The Overall Stability And Performance Of The Lathe?The lathe bed is the base where everything sits. If it’s made from heavy materials like cast iron, it won’t move easily. This stability helps you make better, smoother cuts. If it’s made from lighter materials, the lathe can shake, making it harder to work. So, strong materials make the lathe more reliable!

What Maintenance Practices Are Essential To Ensure The Longevity Of A Metal Lathe Bed?To keep a metal lathe bed lasting a long time, you should clean it regularly. Wipe off dust and metal chips after each use. Make sure to oil the bed to keep it smooth and working well. Always check for any scratches or dents that could cause problems. Finally, keep it covered when you’re not using it to protect it from dust and damage.

How Do Different Bed Types (E.G., Flat Bed Vs. Slant Bed) Affect The Machining Capabilities Of A Metal Lathe?The bed of a metal lathe is the part that holds everything in place. A flat bed is level and stable, which helps with precision cutting. A slant bed is tilted, making it easier to see and reach the workpiece. This can make it simpler to handle bigger pieces. Both types work well, but each has its own benefits based on what you want to do.

What Are Common Signs Of Wear And Tear On A Lathe Bed, And How Can They Be Effectively Addressed?Common signs of wear and tear on a lathe bed include scratches, dents, and uneven surfaces. You might notice that parts don’t move smoothly. To fix these problems, we can clean the bed and use a special oil to help it move better. If it’s really bad, replacing the bed might be necessary. Always check your lathe regularly to keep it in good shape!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of A Metal Lathe Bed Application Guide:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe bed is a part of a machine that helps shape metal. It holds the metal piece steady while it spins. This way, you can cut or smooth it into the right shape. You use the lathe for making things like parts for toys or tools. It helps you make your projects look neat and professional!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting A Metal Lathe Bed For Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a metal lathe bed for precision machining, think about size and weight. You want a sturdy bed that won’t move while you work. Also, check the material. A strong metal like cast iron is good because it lasts longer. Lastly, look at the design; a flat and smooth surface helps make better cuts.”}},{“@type”: “Question”,”name”: “How Does The Construction Material Of A Lathe Bed Impact The Overall Stability And Performance Of The Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lathe bed is the base where everything sits. If it’s made from heavy materials like cast iron, it won’t move easily. This stability helps you make better, smoother cuts. If it’s made from lighter materials, the lathe can shake, making it harder to work. So, strong materials make the lathe more reliable!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential To Ensure The Longevity Of A Metal Lathe Bed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe bed lasting a long time, you should clean it regularly. Wipe off dust and metal chips after each use. Make sure to oil the bed to keep it smooth and working well. Always check for any scratches or dents that could cause problems. Finally, keep it covered when you’re not using it to protect it from dust and damage.”}},{“@type”: “Question”,”name”: “How Do Different Bed Types (E.G., Flat Bed Vs. Slant Bed) Affect The Machining Capabilities Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The bed of a metal lathe is the part that holds everything in place. A flat bed is level and stable, which helps with precision cutting. A slant bed is tilted, making it easier to see and reach the workpiece. This can make it simpler to handle bigger pieces. Both types work well, but each has its own benefits based on what you want to do.”}},{“@type”: “Question”,”name”: “What Are Common Signs Of Wear And Tear On A Lathe Bed, And How Can They Be Effectively Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common signs of wear and tear on a lathe bed include scratches, dents, and uneven surfaces. You might notice that parts don’t move smoothly. To fix these problems, we can clean the bed and use a special oil to help it move better. If it’s really bad, replacing the bed might be necessary. Always check your lathe regularly to keep it in good shape!”}}]}