Have you ever watched a metal lathe spin? It’s amazing to see how it shapes metal. Many people wonder how these machines work. They might even think about using one in their projects. If you are curious about lathe applications, you’re in the right place.

In this article, we will explore the lathe application guide for metal lathe controllers. These tools help metalworkers achieve precise cuts and beautiful designs. Imagine creating a custom part for a project! With the right guide, anyone can learn how to use a metal lathe effectively.

Did you know that lathes have been around for thousands of years? They started as simple tools but now have advanced far beyond their origins. This evolution makes understanding their application even more exciting. Are you ready to dive into the world of metal lathes?

Join us as we navigate through the features and tips for using a lathe controller. You’ll discover how to turn your ideas into reality with these powerful machines.

Comprehensive Lathe Application Guide: Metal Lathe Controller

Lathe Application Guide for Metal Lathe Controllers

Do you ever wonder how metal lathes work? A lathe application guide helps you understand the various uses of metal lathes and how controllers enhance their functions. You’ll learn about different control systems that improve precision and efficiency for machining tasks. Did you know that lathes can create everything from simple parts to complex shapes? With the right controller, any project becomes easier. Explore how these tools shape our world!Understanding Metal Lathes

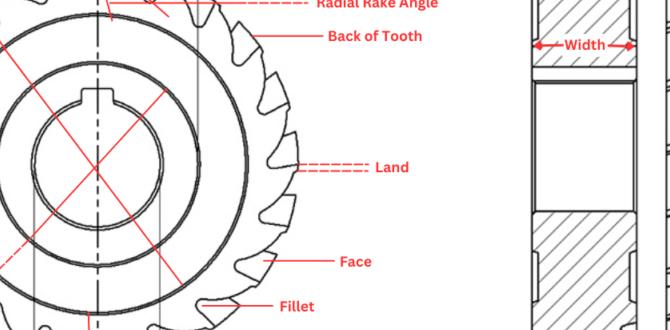

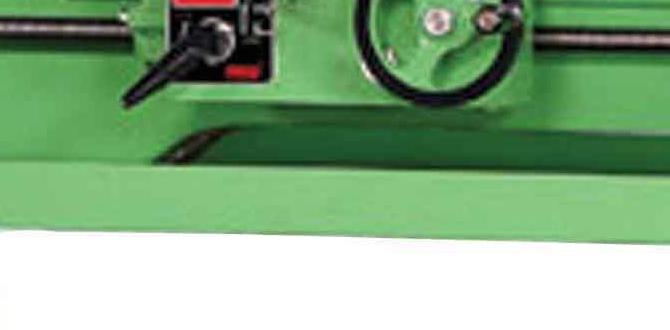

Definition and components of a metal lathe. Types of metal lathes commonly used in machining.A metal lathe is a machine that shapes metal into the desired form. Think of it as a giant pencil sharpener for metal! It has key parts, like the bed for support, a headstock to drive the workpiece, and a tailstock for stability. There are several types of metal lathes, such as the bench lathe, which is small and perfect for hobbies, and the engine lathe, used in big workshops. Each type makes turning metal easier and helps create amazing pieces.

| Type of Metal Lathe | Description |

|---|---|

| Bench Lathe | Great for small projects and hobbyists. |

| Engine Lathe | Common in workshops, versatile for various tasks. |

| CNC Lathe | Computer-controlled for precise work. |

Importance of a Metal Lathe Controller

Role of a controller in enhancing precision and efficiency. Differences between CNC and manual lathe controllers.A metal lathe controller is like a smart sidekick for your machining adventures. It boosts precision by guiding the tool for exact cuts. With a controller, you don’t just wing it; you get consistent results every time. Imagine trying to bake cookies without a recipe—chaos!

There are two main types: CNC and manual lathe controllers. CNC (Computer Numerical Control) automates the process like a robot chef, while manual controllers need your hands on the wheel, akin to riding a bike. Each has its perks, but if you want to race through projects, think CNC!

| Controller Type | Precision | Ease of Use |

|---|---|---|

| Manual | Moderate | Requires Skill |

| CNC | High | User-Friendly |

In the end, a metal lathe controller is not just a gadget; it’s your best buddy for turning metal into masterpieces!

Key Features to Look for in a Metal Lathe Controller

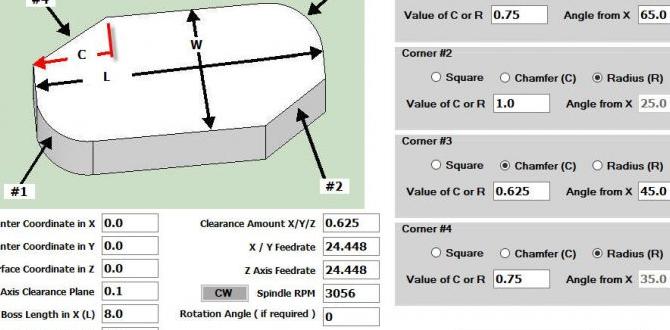

User interface and ease of operation. Compatibility with various lathe models.Think about how easy it is to use a metal lathe controller. A good controller should have a simple user interface. You don’t want to struggle with complicated buttons. Look for clear screens and easy-to-read menus. Also, make sure it works with many lathe models. If it’s compatible, it opens more options for your projects.

- Simple and clear buttons

- Easy-to-read display

- Works with different lathe types

Why is user interface important?

A simple user interface helps you focus on your work. You spend less time learning how to use the controller.

How do I know if a controller is compatible?

Check the manufacturer’s description. It usually lists which lathe models are supported.

Setting Up Your Metal Lathe Controller

Stepbystep installation process. Calibration tips for optimal performance.Before you start using your lathe controller, proper setup is key. Follow these steps carefully:

- Unpack the lathe components. Make sure all parts are included.

- Follow the included manual for installation. Each step is important.

- Connect the power supply securely. Safety first!

- Check all wiring connections. Ensure they are tight and correct.

To calibrate for the best performance:

- Adjust the speed settings slowly. Test each speed.

- Use a gauge to check precision. Accuracy matters!

- Make minor tweaks as needed. Small changes can make a big difference.

Setting up correctly can help your lathe run smoothly. Enjoy creating with your machine!

How do I install a metal lathe controller?

Installation involves following the manual closely, connecting all parts securely, and ensuring proper alignment. Make sure to test it after.

What are calibration tips for a metal lathe?

Use accurate gauges, test different speeds, and make incremental adjustments. This ensures optimal performance.

Common Applications of Metal Lathes

Types of projects and industries that benefit from metal lathes. Examples of products made with metal lathes.Metal lathes play a huge role in various projects and industries. They shape metal into useful products. Think of car parts, tools, and even jewelry! In fact, without lathes, most machinery would be a jumbled mess of metal. Here’s a fun fact: they help make everything round, from nuts to bolts! Types of projects include:

| Industry | Typical Products |

|---|---|

| Automotive | Engine components |

| Aerospace | Aircraft parts |

| Jewelry | Rings and bracelets |

These machines make our lives easier without us even knowing it! So, next time you see a shiny new tool or a fancy car, remember the magic of metal lathes!

Troubleshooting Common Issues with Metal Lathe Controllers

Identifying and solving common malfunctions. Maintenance tips to ensure longevity of the controller.Many users face problems with metal lathe controllers. Common issues include unresponsive buttons, display errors, and sudden shutdowns. To fix these, check connections, software settings, and power supply. Regular maintenance can prevent issues. Here are a few tips:

- Keep the controller clean and free of dust.

- Check wires and cables regularly for damage.

- Update software to the latest version.

With good care, your controller can last longer and work better.

What are the main signs of a failing metal lathe controller?

Look for frequent errors, strange noises, or power issues. These often mean it needs attention.

Future Trends in Metal Lathe Technology

Innovations in metal lathe controllers. The impact of automation and AI on metal machining.The future of metal lathes looks bright and full of cool gadgets! Innovations in metal lathe controllers are making machines smarter. These new controllers can learn from their mistakes, making machining more precise. Picture a lathe that almost reads your mind! With these advancements, manual setup is becoming a thing of the past.

Automation and AI are shaking things up too. Machines are getting so clever, they can handle tasks all on their own. Thanks to AI, metal machining is faster and safer. Imagine a robot lathe that never gets tired, unlike us after gym class!

| Trend | Impact |

|---|---|

| Smart Controllers | Increased Precision |

| Automation | Faster Production |

| AI Integration | Reduced Errors |

With these innovations, the manufacturing world is on a wild ride. Hold on to your hard hats!

Resources and Tools for Further Learning

Recommended books and online courses on metal lathing. Community forums and groups for lathe enthusiasts.Learning about metal lathing can be exciting and fun! There are plenty of books and online courses that will help you grasp the basics and advanced techniques. Books like “The Metal Lathe” are full of tips. Online platforms, such as Udemy and Coursera, offer courses that can turn you into a lathe master from the comfort of your home. Joining community forums is a great way to connect with other lathe lovers. You can share experiences, ask questions, and maybe even swap funny lathe stories!

| Resource Type | Recommended Links |

|---|---|

| Books | The Metal Lathe |

| Online Courses | Udemy Metalworking |

| Forums | Practical Machinist |

So, grab a book, sign up for a course, or join a forum. You might just meet your new best friend—your lathe!

Conclusion

In conclusion, a lathe application guide helps you understand how to use a metal lathe controller effectively. You learn about key features and best practices. By exploring these insights, you can improve your skills and make better projects. Dive deeper into this topic for more knowledge, and don’t hesitate to try out what you’ve learned!FAQs

What Are The Key Features To Look For In A Metal Lathe Controller For Optimal Machining Performance?When choosing a metal lathe controller, look for a clear display screen. This helps you see your settings easily. You want buttons that are easy to press, too. Good controllers allow fast changes and have safety features to keep you safe while working. Lastly, choose one that can work with different machines for more options.

How Does A Cnc Lathe Controller Differ From A Manual Lathe Controller In Terms Of Usability And Precision?A CNC lathe controller uses a computer to control the machine. This makes it very precise and good for complicated shapes. You just input the design, and the machine does the work. With a manual lathe, you need to use your hands to guide everything, which can be less accurate. So, CNC lathes are easier to use and can create better results.

What Programming Languages Or Software Are Commonly Used With Metal Lathe Controllers To Automate Machining Processes?We often use software like G-code to control metal lathe machines. G-code tells the machine what to do, like where to cut. Other programming languages, like Python, can help with more complex tasks. You might also see CAD (Computer-Aided Design) software to design parts before making them. These tools make it easier for us to automate and improve our machining processes.

How Can A Metal Lathe Controller Improve The Efficiency And Accuracy Of Metalworking Operations?A metal lathe controller helps you work faster and more accurately. It tells the machine exactly how to cut the metal. This means less waste and mistakes. You can make the same part many times, and they will all be very similar. Overall, it makes your metalworking tasks easier and better!

What Safety Considerations Should Be Kept In Mind When Operating A Metal Lathe With An Automated Controller?When using a metal lathe with an automated controller, you should wear safety goggles to protect your eyes. Keep your hands and loose clothing away from moving parts so you don’t get hurt. Always make sure the machine is turned off before you change tools or clean it. It’s also important to follow the instructions and never rush while using the machine. This will help keep you safe while you work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Metal Lathe Controller For Optimal Machining Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a metal lathe controller, look for a clear display screen. This helps you see your settings easily. You want buttons that are easy to press, too. Good controllers allow fast changes and have safety features to keep you safe while working. Lastly, choose one that can work with different machines for more options.”}},{“@type”: “Question”,”name”: “How Does A Cnc Lathe Controller Differ From A Manual Lathe Controller In Terms Of Usability And Precision? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A CNC lathe controller uses a computer to control the machine. This makes it very precise and good for complicated shapes. You just input the design, and the machine does the work. With a manual lathe, you need to use your hands to guide everything, which can be less accurate. So, CNC lathes are easier to use and can create better results.”}},{“@type”: “Question”,”name”: “What Programming Languages Or Software Are Commonly Used With Metal Lathe Controllers To Automate Machining Processes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We often use software like G-code to control metal lathe machines. G-code tells the machine what to do, like where to cut. Other programming languages, like Python, can help with more complex tasks. You might also see CAD (Computer-Aided Design) software to design parts before making them. These tools make it easier for us to automate and improve our machining processes.”}},{“@type”: “Question”,”name”: “How Can A Metal Lathe Controller Improve The Efficiency And Accuracy Of Metalworking Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe controller helps you work faster and more accurately. It tells the machine exactly how to cut the metal. This means less waste and mistakes. You can make the same part many times, and they will all be very similar. Overall, it makes your metalworking tasks easier and better!”}},{“@type”: “Question”,”name”: “What Safety Considerations Should Be Kept In Mind When Operating A Metal Lathe With An Automated Controller? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe with an automated controller, you should wear safety goggles to protect your eyes. Keep your hands and loose clothing away from moving parts so you don’t get hurt. Always make sure the machine is turned off before you change tools or clean it. It’s also important to follow the instructions and never rush while using the machine. This will help keep you safe while you work.”}}]}