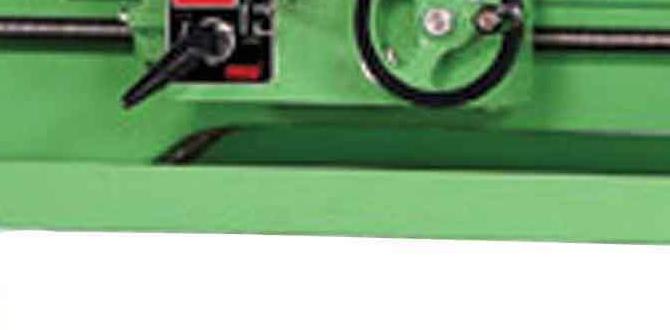

Have you ever wondered how machines shape metal with such precision? The metal lathe is a fascinating tool that turns blocks of metal into beautiful shapes. Just like a chef needs a clean kitchen to cook well, a lathe needs regular maintenance to function perfectly.

Think about it. Would you want to drive a car that hasn’t been serviced? Maintaining a metal lathe is similar. It is essential for accuracy and safety. In this lathe application guide, we will explore simple yet effective tips for metal lathe maintenance.

Did you know that a well-cared-for lathe can last for decades? Proper maintenance not only extends its life but also boosts its performance. Imagine the satisfaction of completing a project with a smoothly running lathe. Let’s dive into the world of metal lathe care!

Lathe Application Guide: Essential Metal Lathe Maintenance Tips

Lathe Application Guide: Metal Lathe Maintenance

Maintaining a metal lathe is essential for smooth operation and accurate results. Regular cleaning prevents build-up that can harm performance. Did you know that oiling moving parts can extend the lathe’s lifespan? This guide covers checking belts, adjusting tension, and inspecting tools. Understanding maintenance steps can save you time and money. Why let small issues become big problems? Keep your lathe in top shape and enjoy smoother machining experiences!Types of Metal Lathes

Description of various metal lathe models. Pros and cons of each type.Metal lathes come in different types, each with strengths and weaknesses. Understanding these can help you choose the right one for your needs. Here’s a quick overview:

- Engine Lathe: Great for general work. They are versatile and easy to use. However, they can be costly and may require frequent maintenance.

- CNC Lathe: This type uses a computer for precision. They create complex parts easily. But, setup can be complicated and costly.

- Bench Lathe: It is small and perfect for light work. They are affordable but may lack power for heavy tasks.

- Turret Lathe: Good for production work. They can switch tools quickly. Yet, they require a skilled operator, which can be a downside.

Choosing the right lathe depends on your needs and experience!

What should I know before choosing a metal lathe?

Before choosing, consider your budget, work type, and skill level. Think about how much space you have too!

Essential Lathe Components

Key parts of a metal lathe and their functions. Importance of each component in maintenance.Every metal lathe has key parts that are vital for its operation. These components work like a team, making sure everything runs smoothly. For example, the motor spins the lathe, while the chuck holds your metal piece tight, like a bear hug! The carriage moves the tool, shaping the metal just right. Regular checks on these parts make a difference; without them, your lathe may get grumpy! So, keeping everything in shape equals smooth sailing and lots of fun projects!

| Component | Function |

|---|---|

| Motor | Drives the lathe |

| Chuck | Holds the workpiece |

| Carriage | Maneuvers the cutting tool |

Routine Maintenance Practices

Daily maintenance tasks to improve longevity. Weekly and monthly maintenance checklist.Keeping your metal lathe in tip-top condition requires daily, weekly, and monthly maintenance tasks. For daily routines, check the oil levels and clean up any chips. Neglecting these chores can lead to squeaks that sound like a rusty old robot! Weekly, inspect the belts and tighten loose parts. Monthly, give your lathe a deep clean and check for wear. Here’s a handy checklist:

| Maintenance Task | Frequency |

|---|---|

| Check oil levels | Daily |

| Clean chips and debris | Daily |

| Inspect belts | Weekly |

| Tighten loose parts | Weekly |

| Deep clean and inspect wear | Monthly |

Remember, regular upkeep can help your lathe last longer—think of it as giving your machine a spa day! With proper care, you can avoid costly repairs and keep everything running smoothly.

Troubleshooting Common Lathe Issues

Identifying frequent mechanical problems. Stepbystep solutions for common issues.Lathe machines can have a few pesky problems that confuse even the best operators. Common issues include uneven cuts, strange noises, or the machine not starting at all. Don’t worry! Here’s a handy troubleshooting guide. If your lathe is cutting like a wobbly noodle, check the alignment. If it sounds like a rock concert, inspect the bearings. And if it’s playing hard to get, make sure it’s plugged in! Here’s a quick table for easy fixes:

| Issue | Solution |

|---|---|

| Uneven Cuts | Check alignment and tool sharpness. |

| Strange Noises | Inspect bearings and lubrication. |

| Machine Won’t Start | Ensure it’s plugged in and check circuit. |

With these simple steps, you’ll be back to spinning metal like a pro. Remember, even machines get moody sometimes!

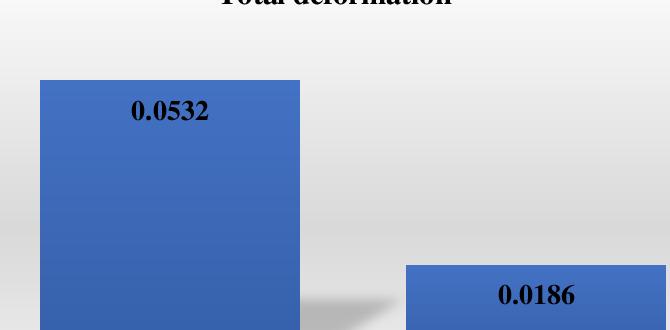

Upgrading and Modifying Your Lathe

Popular upgrades that enhance metal lathe performance. Safety considerations when modifying lathe equipment.Making your lathe even better is like giving it a new set of superhero powers! Popular upgrades include adding a new digital readout. This makes measuring much easier and more accurate. You can also think about improving the motor for extra speed. But wait! Safety first! Always check your new parts and follow all safety rules. Make sure there are no loose screws, or you might end up with a dance party of flying tools!

| Upgrade | Benefit |

|---|---|

| Digital Readout | Improved accuracy |

| Jet Motor | Faster performance |

| Tool Rests | Better stability |

Remember, a happier lathe means a happier maker!

Best Practices for Operating a Metal Lathe

Tips for maximizing precision and efficiency. Safety protocols to follow while operating.To run a metal lathe well, follow some smart practices. This helps with precision and saves time. Here are important tips:

- Always check your tools before starting.

- Keep your workspace clean and organized.

- Adjust the speed based on the material.

- Use proper cutting techniques for better results.

Safety matters too! Here are safety protocols:

- Wear protective goggles at all times.

- Keep hair and loose clothes away from the machine.

- Never bypass safety guards.

- Always disconnect power when changing tools.

By using these tips, you can operate a lathe more efficiently and safely!

How can I improve my lathe skills?

Practice regularly and learn from experienced users. Watching tutorials can also help you pick up new techniques easily.

Resources for Continued Learning

Recommended books and online courses for lathe maintenance. Communities and forums for metalworking enthusiasts.Learning about lathe maintenance can be exciting. Many resources are out there to help you improve. Books like “Machining Fundamentals” provide clear instructions. Online courses allow hands-on practice. Consider joining metalworking communities to share tips. You’ll get support and learn from others too. Here are some popular resources:

- Machining Fundamentals by Michael Fitzpatrick

- Online platforms like Udemy offer great courses.

- Forums like Practical Machinist provide helpful advice.

What are good books for learning lathe maintenance?

Books such as “Machining Fundamentals” and “The Essential Guide to Metalworking” are fantastic for beginners. They cover key topics with simple explanations. You can learn about tools, techniques, and safety.

Where can I find online courses for lathe skills?

Websites like Coursera and Udemy offer great courses on lathe maintenance. These courses often include videos and quizzes.

Engaging with others online can turn learning into fun. Join communities to ask questions and share your work. It’s a great way to meet like-minded people.

Tools and Supplies for Lathe Maintenance

Essential tools for routine upkeep. Recommended brands and suppliers for quality components.For keeping your lathe in great shape, you’ll need some essential tools. Here are a few that are important:

- Wrenches for adjustments

- File sets to smooth edges

- Oil and grease for lubrication

- Measuring tools, like calipers

- Brushes to clean parts

Now, for quality supplies, look for trusted brands. Companies like Starrett and Mitutoyo offer great measuring tools. Choose Mobil for lubrication products. Reliable supplies help ensure your lathe runs smoothly and lasts longer.

What are the best tools for lathe maintenance?

Some of the best tools are wrenches, files, oil, calipers, and brushes. Using these tools correctly keeps your lathe in top shape.

Conclusion

In summary, metal lathe maintenance is essential for quality projects. You should regularly clean and lubricate your lathe. Check for wear and tear often. Follow a maintenance schedule to keep everything running smoothly. For more detailed tips, consider reading our maintenance guide. Taking these steps will help you work more safely and efficiently. Happy turning!FAQs

Sure! Here Are Five Questions Related To Metal Lathe Maintenance:Sure! Here are some answers to the questions about metal lathe maintenance: 1. How often should I clean my lathe? You should clean your lathe after each use. This helps keep it in good shape. 2. What oil should I use? Use a light machine oil. It helps the parts move smoothly and prevents rust. 3. How do I check for wear? Look at the parts for scratches or dents. If you find any, it might be time to replace them. 4. Why is it important to check the belts? Belts help the lathe work. If they are loose or worn, the machine might not run well. 5. How can I keep my lathe’s parts from rusting? Keep your lathe dry and apply oil regularly. This stops rust from forming.

Sure! Just ask your question, and I’ll give you a simple, clear answer.

What Are The Essential Routine Maintenance Tasks That Should Be Performed On A Metal Lathe To Ensure Optimal Performance?To keep a metal lathe working well, you should do a few important tasks. First, clean the machine often to remove dust and chips. Second, check and change the oil to keep everything moving smoothly. Third, make sure all parts are tight and not loose. Lastly, sharpen the cutting tools regularly so they cut better.

How Often Should Lubrication Be Applied To The Moving Parts Of A Metal Lathe, And What Type Of Lubricants Are Recommended?You should lubricate a metal lathe quite often, maybe every few hours of use. For the best results, use a light oil for the moving parts. Grease can be used for parts that don’t move too much. Remember to check the oil levels regularly to keep everything running smoothly.

What Are The Common Signs Of Wear Or Malfunction In A Metal Lathe, And How Can Operators Address These Issues?Common signs of wear in a metal lathe include strange noises, uneven cuts, and loose parts. If you notice these problems, check the tools and tighten any loose screws. You might also need to clean the lathe to remove dirt. If something is broken, you should ask a grown-up to help fix it. Regular checks can help keep your lathe working well.

What Safety Precautions Should Be Taken During The Maintenance Of A Metal Lathe To Protect Both The Operator And The Machine?To keep yourself safe while working on a metal lathe, always wear safety glasses to protect your eyes. Make sure to turn off the machine and unplug it before you start fixing anything. Keep your hands and tools away from moving parts. Finally, keep the area clean and free from any clutter to avoid accidents.

How Can One Effectively Clean The Work Area And Components Of A Metal Lathe To Extend The Machine’S Lifespan And Maintain Accuracy?To clean your metal lathe, first turn it off and unplug it. Use a brush or cloth to remove dust and chips. Wipe down the surface with a damp cloth to get rid of grease. Check for any oil spots and clean them too. Keeping everything tidy helps the lathe work better and last longer!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Metal Lathe Maintenance:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some answers to the questions about metal lathe maintenance: 1. How often should I clean my lathe? You should clean your lathe after each use. This helps keep it in good shape. 2. What oil should I use? Use a light machine oil. It helps the parts move smoothly and prevents rust. 3. How do I check for wear? Look at the parts for scratches or dents. If you find any, it might be time to replace them. 4. Why is it important to check the belts? Belts help the lathe work. If they are loose or worn, the machine might not run well. 5. How can I keep my lathe’s parts from rusting? Keep your lathe dry and apply oil regularly. This stops rust from forming.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll give you a simple, clear answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Routine Maintenance Tasks That Should Be Performed On A Metal Lathe To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, you should do a few important tasks. First, clean the machine often to remove dust and chips. Second, check and change the oil to keep everything moving smoothly. Third, make sure all parts are tight and not loose. Lastly, sharpen the cutting tools regularly so they cut better.”}},{“@type”: “Question”,”name”: “How Often Should Lubrication Be Applied To The Moving Parts Of A Metal Lathe, And What Type Of Lubricants Are Recommended?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should lubricate a metal lathe quite often, maybe every few hours of use. For the best results, use a light oil for the moving parts. Grease can be used for parts that don’t move too much. Remember to check the oil levels regularly to keep everything running smoothly.”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Or Malfunction In A Metal Lathe, And How Can Operators Address These Issues?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common signs of wear in a metal lathe include strange noises, uneven cuts, and loose parts. If you notice these problems, check the tools and tighten any loose screws. You might also need to clean the lathe to remove dirt. If something is broken, you should ask a grown-up to help fix it. Regular checks can help keep your lathe working well.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken During The Maintenance Of A Metal Lathe To Protect Both The Operator And The Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep yourself safe while working on a metal lathe, always wear safety glasses to protect your eyes. Make sure to turn off the machine and unplug it before you start fixing anything. Keep your hands and tools away from moving parts. Finally, keep the area clean and free from any clutter to avoid accidents.”}},{“@type”: “Question”,”name”: “How Can One Effectively Clean The Work Area And Components Of A Metal Lathe To Extend The Machine’S Lifespan And Maintain Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean your metal lathe, first turn it off and unplug it. Use a brush or cloth to remove dust and chips. Wipe down the surface with a damp cloth to get rid of grease. Check for any oil spots and clean them too. Keeping everything tidy helps the lathe work better and last longer!”}}]}