Have you ever wondered how metal pieces come together in machines? One of the secrets lies in a metal lathe. This powerful tool helps shape and cut metal into precise forms.

But what makes it work so smoothly? The answer is the lathe pulley. This small yet mighty component plays a vital role in the lathe’s performance. It connects the motor to the spindle, allowing the lathe to spin. Without it, shaping metal would be much harder.

Imagine trying to ride a bike without gears. It would be tough, right? Similarly, without the right lathe application guide, understanding how a metal lathe pulley functions can feel confusing.

In this article, we’ll dive into the world of lathe applications. You will learn how to choose the best pulley for your needs. With this guide, you’ll soon be ready to tackle your metalworking projects!

A Comprehensive Lathe Application Guide: Metal Lathe Pulley

Lathe Application Guide: Metal Lathe Pulley

Understanding **lathe applications** is essential for anyone working with metalworking tools. A **metal lathe pulley** helps in controlling the speed and power of the lathe. Did you know that using the right pulley can make your projects smoother? It can also extend the lifespan of your machine. Moreover, different pulley sizes can change the cutting speed. This guide provides tips on choosing and using lathe pulleys effectively, ensuring precise and safe operations.Understanding Lathe Systems

Definition and purpose of a lathe. Key components of a metal lathe.A lathe is a machine that shapes materials like metal or wood. It spins the material while a tool cuts away parts. Think of it as a chef slicing a cake into perfect pieces! The main goal is to make shapes, like cylinders or disks, easily and precisely.

Key parts of a metal lathe include:

| Component | Purpose |

|---|---|

| Headstock | Holds the spindle and drives the material |

| Tailstock | Supports the other end of the material |

| Carriage | Moves the cutting tool |

Each part plays a role in creating amazing forms. So, next time you see a lathe, remember it’s more than metal; it’s a shaping machine that loves to spin!

Benefits of Using Pulley Systems

Advantages of pulley systems in lathe operations. Impact on efficiency and precision.Pulley systems in lathe operations are like the friendly sidekick of a superhero. They make everything easier! With pulleys, machines run smoother and faster. This leads to better efficiency, as operators can complete tasks without struggling with heavy loads. Precision also shines. The right pulley setup helps maintain accurate movements, which is vital for quality work. Fun fact: using a pulley can reduce the workload by up to 50%! Talk about a great buddy!

| Benefits | Details |

|---|---|

| Efficiency | Reduces effort needed, making tasks quicker. |

| Precision | Ensures accurate movements for high-quality results. |

| Versatility | Adaptable for various tasks and setups. |

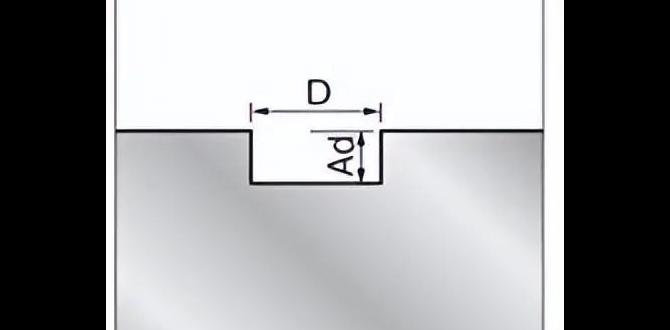

Choosing the Right Pulley for Your Metal Lathe

Factors to consider when selecting pulleys. Compatibility with different lathe models.Choosing the right pulley for your metal lathe is important for smooth operation. First, think about the size. A pulley too big or too small can mess things up. Next, check compatibility with your lathe model. Not all pulleys fit every lathe, like trying to squeeze into your little brother’s shoes! Thickness and material matter too; you want something durable. A little research can save you big headaches later!

| Factor | Details |

|---|---|

| Size | Must match the lathe spindle. |

| Compatibility | Check if it fits your lathe model. |

| Material | Durability is key for long-term use. |

Pulley Maintenance and Troubleshooting

Common issues with lathe pulleys. Maintenance tips for longevity and performance.Lathe pulleys can face some common problems. These include wear and tear, misalignment, and strange noises during operation. Regular maintenance helps keep your lathe running smoothly. Here are some simple tips:

- Check for wear on belts and pulleys regularly.

- Lubricate moving parts to reduce friction.

- Tighten loose connections to prevent vibration.

- Inspect for misalignments to avoid extra wear.

Taking care of your lathe pulley can improve its performance and lifespan. Keeping an eye on it makes your work easier.

What are common issues with lathe pulleys?

Common issues include wear and tear, misalignment, and unexpected noises. Regular checks can prevent these problems.

How to maintain lathe pulleys for better performance?

To maintain lathe pulleys, regularly lubricate parts and inspect for damage. Keeping everything tight and aligned can help avoid issues.

Advanced Techniques Using Pulley Systems

Innovative applications of pulleys in lathe work. Tips for maximizing performance with advanced setups.Pulleys can transform lathe work into a smooth dance. Use them to change the speed and torque, giving your projects new life and pizzazz. Want to make your lathe sing? Try a double pulley system for extra power yet with less effort on your part—like having a super assistant! But remember, too much excitement can lead to chaos. Keep things balanced. Here are some tips:

| Technique | Description |

|---|---|

| Maximize Speed | Use lighter materials to reduce resistance. |

| Optimize Torque | Experiment with different pulley sizes. |

| Easy Maintenance | Keep your pulleys clean and lubricated. |

With these nifty tricks, your lathe will be the star of the show, spinning its way to glory!

Safety Considerations When Working with Lathes and Pulleys

Safety equipment and practices. Recognizing potential hazards and preventing accidents.Working with lathes and pulleys can be exciting, but safety is key. Always wear safety gear like goggles, gloves, and ear protection. This will help keep you safe from injuries. It’s important to recognize hazards, like moving parts and sharp tools. Always keep your workspace clean. This reduces the chance of accidents. Remember these safety tips:

- Check tools before use.

- Keep your hands away from moving parts.

- Do not wear loose clothing.

- Be alert and focused while working.

Did you know that many accidents come from distractions? Stay focused to avoid injuries! Safe practices make working with lathes enjoyable and secure.

What should I wear for safety when using a lathe?

Wear goggles, gloves, and ear protection to keep yourself safe while using a lathe. Always make sure your clothing is snug to avoid getting caught in the machine.

Conclusion

In summary, a lathe application guide helps you understand how to use a metal lathe with a pulley. This setup improves precision and efficiency in your projects. We recommend exploring different pulley options and settings to find what works best for you. You can practice these techniques to enhance your skills further. Happy turning!FAQs

Certainly! Here Are Five Related Questions On The Topic Of A Metal Lathe And Its Pulley System:Sure! A metal lathe is a machine that spins metal to make it smooth and shaped. The pulley system helps control how fast the lathe turns. When you pull a lever, it can change the speed and help us make better shapes. This way, we can create many useful metal items. It’s really cool to see how it all works together!

Sure! Please provide the question you’d like me to answer.

What Is The Function Of The Pulley System In A Metal Lathe, And How Does It Affect The Lathe’S Performance?The pulley system in a metal lathe helps turn the machine’s parts. It helps us change speeds easily. This makes cutting metal faster or slower, depending on what we need. A good pulley system means better performance and smoother work. It helps you make better shapes and designs while using the lathe.

How Do You Select The Appropriate Pulley Size For A Specific Metal Lathe Application?To choose the right pulley size for a metal lathe, you need to know the lathe’s speed. First, check the lathe’s manual for the speed requirements. Next, measure the size of the original pulley or use a pulley chart. Finally, pick a pulley that fits those needs. This way, your lathe will work well!

What Are The Common Materials Used For Lathe Pulleys, And How Do They Impact Durability And Precision?Common materials for lathe pulleys include steel, aluminum, and plastic. Steel is strong and lasts a long time. Aluminum is lighter and can move fast. Plastic is cheap but may wear out quicker. The material you choose affects how long the pulley lasts and how accurately it works.

How Can Improper Pulley Alignment On A Metal Lathe Lead To Operational Issues Or Inaccurate Machining?Improper pulley alignment on a metal lathe can cause big problems. If the pulleys are not lined up, the machine can shake or wobble. This makes it hard for you to cut metal accurately. You might end up with parts that are the wrong size or shape. Always make sure the pulleys are aligned for smooth and precise work!

What Maintenance Practices Should Be Followed To Ensure The Longevity And Efficiency Of A Metal Lathe Pulley System?To keep a metal lathe pulley system working well, you should check it regularly. Clean the pulleys to remove dust and grease. Make sure the belts are tight and not worn out. Lubricate the moving parts with oil to help them move smoothly. Finally, look for any signs of damage and fix them right away.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of A Metal Lathe And Its Pulley System:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe is a machine that spins metal to make it smooth and shaped. The pulley system helps control how fast the lathe turns. When you pull a lever, it can change the speed and help us make better shapes. This way, we can create many useful metal items. It’s really cool to see how it all works together!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Function Of The Pulley System In A Metal Lathe, And How Does It Affect The Lathe’S Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The pulley system in a metal lathe helps turn the machine’s parts. It helps us change speeds easily. This makes cutting metal faster or slower, depending on what we need. A good pulley system means better performance and smoother work. It helps you make better shapes and designs while using the lathe.”}},{“@type”: “Question”,”name”: “How Do You Select The Appropriate Pulley Size For A Specific Metal Lathe Application?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right pulley size for a metal lathe, you need to know the lathe’s speed. First, check the lathe’s manual for the speed requirements. Next, measure the size of the original pulley or use a pulley chart. Finally, pick a pulley that fits those needs. This way, your lathe will work well!”}},{“@type”: “Question”,”name”: “What Are The Common Materials Used For Lathe Pulleys, And How Do They Impact Durability And Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common materials for lathe pulleys include steel, aluminum, and plastic. Steel is strong and lasts a long time. Aluminum is lighter and can move fast. Plastic is cheap but may wear out quicker. The material you choose affects how long the pulley lasts and how accurately it works.”}},{“@type”: “Question”,”name”: “How Can Improper Pulley Alignment On A Metal Lathe Lead To Operational Issues Or Inaccurate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Improper pulley alignment on a metal lathe can cause big problems. If the pulleys are not lined up, the machine can shake or wobble. This makes it hard for you to cut metal accurately. You might end up with parts that are the wrong size or shape. Always make sure the pulleys are aligned for smooth and precise work!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity And Efficiency Of A Metal Lathe Pulley System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe pulley system working well, you should check it regularly. Clean the pulleys to remove dust and grease. Make sure the belts are tight and not worn out. Lubricate the moving parts with oil to help them move smoothly. Finally, look for any signs of damage and fix them right away.”}}]}