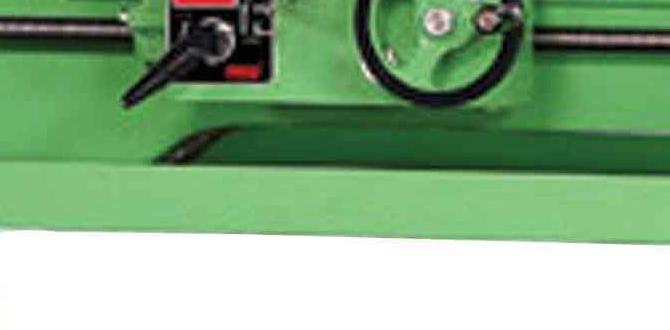

Are you interested in working with metal? Do you want to learn how to use a lathe? If so, you’re in for a treat! A lathe is a fantastic tool that can help you create precise metal parts. But did you know that a quick change tool post can make this process even better?

Imagine you’re in a workshop, surrounded by shiny machines. You pull out your metal lathe. With one quick motion, you switch tools. This is the magic of a quick change tool post! It boosts your efficiency and makes your work smoother.

In this article, we will explore the lathe application guide. From beginner tips to advanced techniques, we’ll cover everything you need. Whether you’re fixing old machinery or creating something new, this guide will help. Are you ready to discover the world of metal lathes? Let’s dive in!

Lathe Application Guide: Metal Lathe Quick Change Tool Post

Lathe Application Guide: Metal Lathe Quick Change Tool Post

A quick change tool post enhances the versatility of a metal lathe. This tool helps users switch between tools swiftly, saving time. Imagine finishing a project faster without fumbling. Readers will discover how to choose the right tool post for their lathe. They will learn about installation tips and maintenance tricks. Knowing these simple steps can significantly improve the quality of your work. It’s like having a magic wand in your workshop that boosts efficiency!What is a Quick Change Tool Post?

Definition and function of quick change tool posts. Advantages over traditional tool posts.A quick change tool post is a clever device for metal lathes. It helps you swap tools easily without wasting time. Imagine trying to change your clothes while juggling! That’s how traditional tool posts feel. Quick change posts let you switch tools in seconds, making your work faster and more fun. They save you from the headache of fiddling with screws every time. So, if you enjoy speed and convenience, a quick change tool post is your new best buddy!

| Feature | Quick Change Tool Post | Traditional Tool Post |

|---|---|---|

| Time to Change Tools | Seconds | Minutes |

| Ease of Use | Very Easy | Requires Tools |

| Setup Time | Minimal | Lengthy |

Selecting the Right Quick Change Tool Post

Key considerations for choosing a tool post. Compatibility with different lathe models.Choosing a quick change tool post requires careful thought. Here are some key things to consider:

- **Size**: Make sure the tool post fits your lathe’s size. An incorrect size can cause problems.

- **Material**: Look for durable materials like steel. They last longer and work better.

- **Ease of Use**: Choose one that is simple to install and adjust. Everyone loves quick changes!

- **Compatibility**: Check if it’s suitable for your lathe model. Some tool posts fit specific brands only.

By comparing these features, you can make the best choice for your lathe!

How do I know if the quick change tool post fits my lathe?

Check the size and model of your lathe. Different lathes require specific tool posts. It’s best to look at the manufacturer’s guidelines for compatibility.

Installation Process for Quick Change Tool Posts

Stepbystep guide to installation. Safety tips during installation.Installing a quick change tool post can be simple. Here’s a step-by-step guide to help you. First, clean the lathe bed where the tool post will sit. Next, remove the old tool post if there is one. Then, align the new tool post on the bed. Carefully tighten the screws to secure it. Finally, check the alignment before use.

Remember to follow safety tips. Always wear safety goggles to protect your eyes. Make sure your hair or loose clothing is tied back. Only work in a well-lit area. Following these steps will keep you safe and make your installation easier.

How do I safely install a quick change tool post?

Always wear safety gear like goggles. Check your tools each time you install. Never rush; take your time. Follow the instructions carefully, and you’ll do great!

Being organized and safe makes installation smooth. With these steps, you’ll enjoy using your lathe much more!

Setting Up and Adjusting the Tool Post

Techniques for proper alignment. Common adjustments for optimal performance.Aligning the tool post is key for smooth cutting. Here are some tips to help:

- Check the level: Use a level to ensure it sits flat.

- Adjust the height: The cutting tool should sit right above the workpiece.

- Angle check: Make sure the tool is straight with the workpiece.

- Secure all screws: Tighten everything before starting to work.

For best performance, common adjustments include:

- Keeping the cutting edge sharp.

- Avoiding too much pressure while cutting.

- Regularly checking for wear and tear.

How do I align a quick change tool post?

Align the tool post by checking if it is level and securely fastened. Ensure the cutting tool is positioned just above the workpiece for best results.

Application Techniques Using Quick Change Tool Posts

Different machining processes and their requirements. How to switch tools efficiently.Using a quick change tool post can make your lathe work a lot easier! Different machining processes, like turning and drilling, have special needs. Each tool does its job best, like a superhero with a unique power. You can switch tools quickly, saving time like it’s flying away! Just loosen the knob, swap the tool, and tighten it back. It’s almost like magic! Here’s a handy table summarizing some processes and their tool requirements:

| Machining Process | Required Tool | Key Feature |

|---|---|---|

| Turning | Lathe Cutter | Shapes materials |

| Drilling | Drill Bit | Makes holes |

| Facing | Facing Tool | Flattens surfaces |

With practice, you’ll be a tool-switching whiz! Remember, every second counts in your machining adventure!

Maintenance Tips for Longevity

Routine care for quick change tool posts. Troubleshooting common issues.Keeping your quick change tool post happy and healthy is key. Regular cleaning and lubrication extend its life, kind of like giving it a spa day! Tighten loose screws and check for wear. If something feels off, don’t panic. Check this handy table for some quick fixes:

| Issue | Solution |

|---|---|

| Tool not staying secure | Tighten the locking knob. |

| Tool post stuck | Clean and lubricate the post. |

| Uneven cuts | Adjust the height of the tool. |

With proper care, your tool post can last longer than your last video game marathon—now, that’s saying something!

Exploring Advanced Features and Accessories

Additional attachments that enhance tool post functionality. Upgrades to consider for more complex tasks.Upgrading your metal lathe opens doors to more exciting projects! Want to make your tool post super cool? Check out accessories like quick-change tool holders. They let you switch tools in a snap, speeding up your work like a superhero! For more complex tasks, consider adding a steady rest or a follow rest. These help keep your pieces stable and precise. They’re like extra hands—who wouldn’t want that?

| Accessory | Functionality |

|---|---|

| Quick-Change Tool Post | Speeds up tool changes |

| Steady Rest | Improves stability |

| Follow Rest | Enhances precision |

Common Mistakes to Avoid

Pitfalls in tool post setup and usage. How to prevent wear and tear on tools.Setting up a tool post seems easy, but many get it wrong. A common mistake is not aligning the tool properly. This can lead to bad cuts and tools wearing out quickly. Always check the alignment before starting. Another pitfall is using the wrong tool for the job. This can cause unnecessary wear and tear. Remember, using the right tool is like choosing a good pair of shoes. Don’t wear flip-flops for a run!

| Common Mistakes | How to Avoid |

|---|---|

| Improper alignment | Always double-check before cutting. |

| Using wrong tools | Pick the right tool for each job. |

| Over-tightening | Snug the bolts, don’t crank them! |

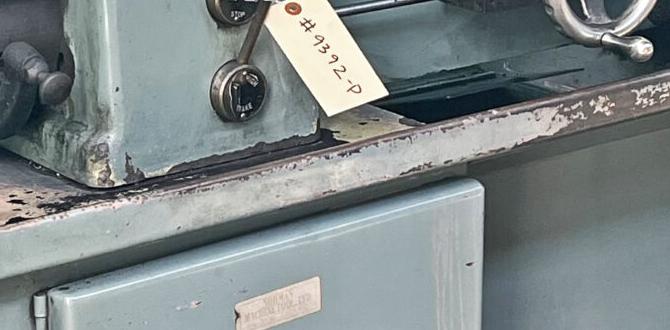

Real-World Applications and Case Studies

Industry use cases highlighting tool post effectiveness. Testimonials from experienced machinists.Machinists around the world love quick change tool posts. These tools help them work faster and better. Many industries benefit from their use. For example:

- Automotive: Tool posts improve speed in car part production.

- Aerospace: They ensure accuracy for high-stakes components.

- Manufacturing: Workers finish jobs more efficiently with less effort.

Experienced machinists emphasize the tool’s ease of use. One machinist said, “It saves me time and makes my work cleaner.” Another shared, “Switching tools is quick, which boosts my output.” These real-world examples show the effectiveness of quick change tool posts.

What industries use quick change tool posts?

Many industries, including automotive, aerospace, and general manufacturing, use quick change tool posts to enhance efficiency and accuracy.

Conclusion

In conclusion, a lathe application guide for metal lathes helps you understand how to use quick change tool posts effectively. These tool posts save time and improve your work quality. Experiment with different setups to find what works best for you. For more tips and techniques, check out additional resources and keep practicing your lathe skills. Happy machining!FAQs

What Are The Key Advantages Of Using A Quick Change Tool Post On A Metal Lathe Compared To Traditional Tool Holders?Using a quick change tool post makes changing tools on a metal lathe fast and easy. You can switch tools in seconds, which saves you time. With traditional tool holders, it takes longer to change tools. A quick change tool post helps us work more efficiently and keeps us focused on our project. It also makes our work smoother and simpler.

How Can Operators Ensure Proper Alignment And Setup Of The Quick Change Tool Post For Optimal Performance?To set up the quick change tool post correctly, you should first clean the tool post and the lathe. Then, make sure the tool post sits flat and centered on the lathe. You can check this with a level. After that, tighten all the screws firmly. Finally, test the tools to see if they cut smoothly.

What Types Of Cutting Tools Are Compatible With Quick Change Tool Posts, And How Do They Differ From Standard Tools?Quick change tool posts work with different cutting tools, like turning tools and boring bars. These tools are made to be easily swapped out. Unlike standard tools, which need extra time for changing, quick change tools can switch fast. This helps you work quicker and keeps your projects moving smoothly. You can try many tools without wasting time!

What Maintenance Steps Are Necessary To Keep A Quick Change Tool Post Functioning Smoothly Over Time?To keep a quick change tool post working well, we should clean it regularly. You should wipe off dust and dirt after using it. Oil the moving parts so they can move easily. Check the screws and tighten them if they feel loose. This will help it last a long time!

How Can A Quick Change Tool Post Increase Production Efficiency In A Metalworking Environment?A quick change tool post helps you switch tools faster when you’re working with metal. That means you spend less time looking for tools and more time making parts. When you save time, you can create more items in a day. This makes your work easier and helps everyone be more productive.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Advantages Of Using A Quick Change Tool Post On A Metal Lathe Compared To Traditional Tool Holders? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a quick change tool post makes changing tools on a metal lathe fast and easy. You can switch tools in seconds, which saves you time. With traditional tool holders, it takes longer to change tools. A quick change tool post helps us work more efficiently and keeps us focused on our project. It also makes our work smoother and simpler.”}},{“@type”: “Question”,”name”: “How Can Operators Ensure Proper Alignment And Setup Of The Quick Change Tool Post For Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up the quick change tool post correctly, you should first clean the tool post and the lathe. Then, make sure the tool post sits flat and centered on the lathe. You can check this with a level. After that, tighten all the screws firmly. Finally, test the tools to see if they cut smoothly.”}},{“@type”: “Question”,”name”: “What Types Of Cutting Tools Are Compatible With Quick Change Tool Posts, And How Do They Differ From Standard Tools? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Quick change tool posts work with different cutting tools, like turning tools and boring bars. These tools are made to be easily swapped out. Unlike standard tools, which need extra time for changing, quick change tools can switch fast. This helps you work quicker and keeps your projects moving smoothly. You can try many tools without wasting time!”}},{“@type”: “Question”,”name”: “What Maintenance Steps Are Necessary To Keep A Quick Change Tool Post Functioning Smoothly Over Time? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a quick change tool post working well, we should clean it regularly. You should wipe off dust and dirt after using it. Oil the moving parts so they can move easily. Check the screws and tighten them if they feel loose. This will help it last a long time!”}},{“@type”: “Question”,”name”: “How Can A Quick Change Tool Post Increase Production Efficiency In A Metalworking Environment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A quick change tool post helps you switch tools faster when you’re working with metal. That means you spend less time looking for tools and more time making parts. When you save time, you can create more items in a day. This makes your work easier and helps everyone be more productive.”}}]}