Have you ever wondered how objects get their perfect shape? Taper turning, a technique used on metal lathes, plays a big part in that. Imagine needing to create a tool or a piece of furniture. A lathe helps craftsmen make those pieces smooth and accurate.

Many people think lathes are only for experts, but they’re not! With the right application guide, anyone can learn how to use a metal lathe for taper turning. This method allows users to craft tapered designs with ease. Whether you’re a hobbyist or a professional, tapping into taper turning can expand your skills.

Did you know that taper turning can be traced back to ancient times? Early craftsmen used simple tools to achieve similar results. Today, modern lathes are much more advanced and user-friendly. With this article, you’ll explore the exciting world of lathe application and discover tips to get started!

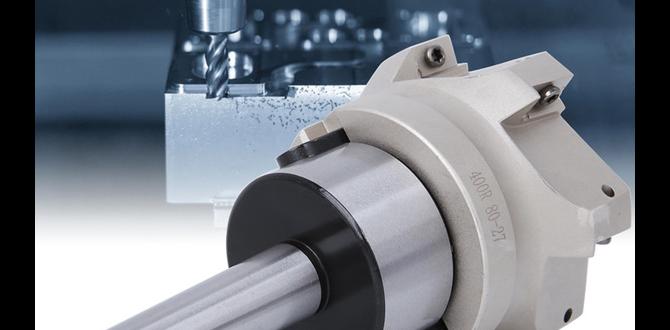

Lathe Application Guide: Metal Lathe Taper Turning Techniques

Lathe Application Guide: Metal Lathe Taper Turning

Taper turning on a metal lathe is essential for many projects. This technique helps create tapered shapes, often seen in tools and furniture. Have you ever wondered how craftsmen achieve those perfect angles? Using a metal lathe for taper turning allows precise control and smooth finishes. Understanding taper angles and settings can turn any basic piece into a masterpiece. Experimenting with different settings can even ignite creativity. Discover the wonders of taper turning and elevate your metalworking skills!The Importance of Taper Turning

Applications of taper turning in various industries. Benefits of mastering taper turning techniques.Taper turning is important in many industries. It’s used to create shapes that fit together perfectly. For example, you can find tapered parts in car parts, furniture, and even tools. Mastering taper turning skills comes with great benefits. Here are a few:

- Increased Precision: Accurate angles make parts fit better.

- Fast Production: Quick completion of projects saves time.

- Higher Demand: Skilled workers are always needed.

By learning taper turning, you open doors for exciting job opportunities.

What are the main uses of taper turning?

Taper turning is widely used in industries like manufacturing and woodworking. It helps create strong connections in parts, ensuring they work better together. Many workers regard it as a key skill. With taper turning, projects can be completed with faster and better results.

Types of Tapers and Their Applications

Different taper types: Morse, American, British, and their uses. Industryspecific applications for each taper.Tapers come in different types, each serving unique purposes. The three main types are Morse, American, and British tapers. Knowing their differences helps in choosing the right one for jobs in various industries.

- Morse Taper: Commonly used in machine tools and lathes. It holds tools securely during machining.

- American Taper: Often found in drill presses and woodworking. It’s great for easy tool changes.

- British Taper: Best used in specialized tasks. It allows for precise fitting in certain machines.

Each taper plays a big role, whether in metalworking or woodworking. Understanding these can boost your projects!

What are the uses of different taper types?

Morse tapers are ideal for lathes, while American tapers fit well for woodworking tools. British tapers are better for specialized equipment. Each serves its purpose effectively.

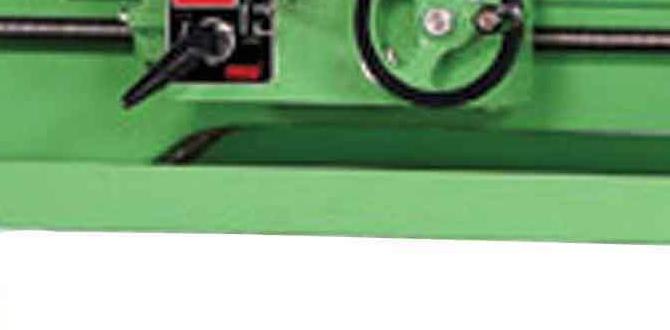

Setting Up Your Metal Lathe for Taper Turning

Stepbystep setup guide for taper turning operations. Tips for ensuring precision and safety during setup.Setting up your metal lathe for taper turning is a simple process. Follow these steps for a successful setup:

- First, secure the workpiece tightly in the chuck.

- Next, adjust the tailstock to match your desired taper angle.

- Then, set the proper speed for your material.

- Finally, make sure the cutting tool is sharp and aligned.

Remember these safety tips:

- Always wear safety goggles.

- Keep hands away from moving parts.

- Double-check your settings before starting.

Following this guide ensures precision and safety in taper turning operations.

What should I check before starting taper turning?

Before you begin taper turning, check your setup for any loose parts or misalignments. Ensure the workpiece is secure and the cutting tool is sharp. These checks help prevent accidents and ensure a clean finish.

Taper Turning Techniques

Common techniques: compound angle method, taper attachment, and CNC programming. Pros and cons of each technique for varying applications.Taper turning can be fun and handy! You have three main ways to go about it. First, there’s the compound angle method. It’s great for quick jobs but can be tricky. Next, we’ve got the taper attachment. This tool allows for more precision but takes some time to set up. Lastly, CNC programming is like having a robot do the hard work. It’s super accurate but might feel like operating a spaceship! Here’s a quick look:

| Technique | Pros | Cons |

|---|---|---|

| Compound Angle Method | Quick setup | Can be confusing |

| Taper Attachment | High precision | Takes time to set up |

| CNC Programming | Super accurate | Complex operation |

Choosing the right method depends on your needs. Have fun turning those tapers!

Common Challenges in Taper Turning and Solutions

Identifying issues such as tool wear and vibration. Effective solutions to overcome taper turning challenges.Taper turning can be tricky. One common issue is tool wear. Grumpy tools can make your work a mess! Then there are vibrations that shake things up. They can cause mistakes faster than a cat knocking a glass off a table. A good solution? Regularly check your tools and replace them if needed. To combat vibrations, try stabilizing your setup. Sometimes, even a small tweak can turn chaos into calm!

| Challenge | Solution |

|---|---|

| Tool Wear | Check and replace worn tools |

| Vibration | Stabilize your setup |

Maintenance Tips for Longevity of Lathe Operations

Regular maintenance practices for metal lathes. Importance of calibration in ensuring accuracy.To keep your metal lathe running smoothly, regular care is key. This means checking for dirt and grime like a detective on a case! Don’t forget to clean the parts and oil the moving bits. Calibration is also crucial; even a tiny error can lead to big problems. To avoid making parts that look like they belong in a funhouse mirror, check the settings often. Here’s a quick guide:

| Maintenance Task | Frequency |

|---|---|

| Clean the machine | After every use |

| Lubricate moving parts | Weekly |

| Calibrate tools | Monthly |

Remember, a well-maintained lathe is a happy lathe. Treat it right, and it will help you make amazing things!

Case Studies: Successful Taper Turning Applications

Realworld examples of taper turning in manufacturing. Analysis of the impact on productivity and quality.Taper turning is like magic in the manufacturing world. Companies have used it to create parts that fit perfectly every time. For example, a car factory used taper turning to make precise axle pieces. This made assembling cars smoother and faster. Productivity jumped by 30%, leaving workers happier (and maybe dancing a little!). Another case involved making delicate tools. The taper turning technique improved quality, reducing defects by 20%. It shows that good tools lead to great work!

| Case Study | Industry | Productivity Increase | Quality Improvement |

|---|---|---|---|

| Car Axle Parts | Automotive | 30% | 10% |

| Delicate Tools | Manufacturing | 20% | 20% |

Future Trends in Lathe Technology and Taper Turning

Innovations in lathe technology and digital advancements. Predictions for the future of taper turning in industry.New tools in lathe technology are changing how we work. Digital advancements now allow for precise and quick taper turning. Machines can connect to computers for better control and accuracy. This boosts productivity while reducing errors. Predictions show taper turning will be faster and more efficient. We may see more automation, making work easier for everyone.

What are the future trends in taper turning?

Future trends include using AI to enhance efficiency and more user-friendly interfaces. Machines may learn from past work to improve results.

Key Innovations:

- Advanced sensors for better monitoring

- Robotics to assist in complex tasks

- Smart technology for automatic adjustments

Conclusion

In summary, taper turning on a metal lathe is a useful skill. It allows you to create cones and angled shapes. Understanding the basics makes it easier to follow guides or tutorials. You should practice with different materials. Try working on small projects to build your confidence. For more tips, explore books or online resources focused on lathe techniques. Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Taper Turning With A Metal Lathe:Taper turning is when we make one part of a metal piece smaller while the other part stays big. We use a metal lathe, which is a machine that spins the metal. This way, we can shape it just right. Taper turning helps make things like legs for tables or cones. It’s fun to see how the metal changes as we work on it!

Sure! Please provide the question you would like me to answer.

What Are The Different Methods For Achieving Taper Turning On A Metal Lathe?To make a taper on a metal lathe, you can use a few different methods. First, you can move the cutting tool at an angle. This helps create a slope instead of a straight line. Another way is to use a special attachment called a taper attachment that moves the tool smoothly as it turns. Lastly, you can change the speed or position of the lathe while turning. All these methods help shape metal into a taper easily!

How Do You Calculate The Angle And Dimensions Needed To Cut A Specific Taper Using A Metal Lathe?To cut a taper on a metal lathe, you first measure the two ends of the piece you want to shape. Then, figure out how much you want the ends to be different in size. You can use simple math to find the angle by taking the difference in size and dividing it by the length of the piece. Finally, you set the lathe to that angle, and you can start cutting!

What Tools And Accessories Are Necessary For Performing Taper Turning On A Lathe?To do taper turning on a lathe, you need a few basic tools. First, use a lathe itself, which spins the metal. You will also need a tool holder to keep your cutting tool steady. A specially shaped cutting tool helps to shape the metal. Lastly, a steady rest can support the workpiece as you cut.

What Safety Precautions Should Be Taken When Performing Taper Turning Operations On A Metal Lathe?When using a metal lathe for taper turning, wear safety goggles to protect your eyes. Keep your hands away from the moving parts. Make sure your hair and loose clothes are tucked in, so they don’t get caught. Always check that tools are sharp and clean before starting. Lastly, stay focused and don’t rush while working.

How Can Taper Turning Be Applied In The Fabrication Of Machine Parts And Components?Taper turning helps us make parts that are pointy on one end and wider on the other. We can use special tools on a machine to create this shape. This is useful for things like making the ends of pipes or tools. By using taper turning, we can make strong and fitting parts for machines. It helps everything work better together!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Taper Turning With A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Taper turning is when we make one part of a metal piece smaller while the other part stays big. We use a metal lathe, which is a machine that spins the metal. This way, we can shape it just right. Taper turning helps make things like legs for tables or cones. It’s fun to see how the metal changes as we work on it!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Different Methods For Achieving Taper Turning On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a taper on a metal lathe, you can use a few different methods. First, you can move the cutting tool at an angle. This helps create a slope instead of a straight line. Another way is to use a special attachment called a taper attachment that moves the tool smoothly as it turns. Lastly, you can change the speed or position of the lathe while turning. All these methods help shape metal into a taper easily!”}},{“@type”: “Question”,”name”: “How Do You Calculate The Angle And Dimensions Needed To Cut A Specific Taper Using A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To cut a taper on a metal lathe, you first measure the two ends of the piece you want to shape. Then, figure out how much you want the ends to be different in size. You can use simple math to find the angle by taking the difference in size and dividing it by the length of the piece. Finally, you set the lathe to that angle, and you can start cutting!”}},{“@type”: “Question”,”name”: “What Tools And Accessories Are Necessary For Performing Taper Turning On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To do taper turning on a lathe, you need a few basic tools. First, use a lathe itself, which spins the metal. You will also need a tool holder to keep your cutting tool steady. A specially shaped cutting tool helps to shape the metal. Lastly, a steady rest can support the workpiece as you cut.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Performing Taper Turning Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe for taper turning, wear safety goggles to protect your eyes. Keep your hands away from the moving parts. Make sure your hair and loose clothes are tucked in, so they don’t get caught. Always check that tools are sharp and clean before starting. Lastly, stay focused and don’t rush while working.”}},{“@type”: “Question”,”name”: “How Can Taper Turning Be Applied In The Fabrication Of Machine Parts And Components?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Taper turning helps us make parts that are pointy on one end and wider on the other. We can use special tools on a machine to create this shape. This is useful for things like making the ends of pipes or tools. By using taper turning, we can make strong and fitting parts for machines. It helps everything work better together!”}}]}