Imagine you have a metal block, and you want to turn it into something useful. Have you ever wondered how people create precise threads on metal? This is where a lathe and its applications come in. A metal lathe is a powerful tool that can transform raw metal into detailed parts.

Thread cutting is one of the coolest things you can do with a lathe. It sounds tricky, right? But with the right guide, anyone can learn how to do it. Whether you’re a beginner or an experienced user, understanding lathe applications can help you make amazing projects.

In this article, we’ll explore the basics of using a metal lathe for thread cutting. You’ll discover tips and tricks that make this process easier. Plus, you’ll learn important techniques to help you create strong, precise threads. So, are you ready to dive in and unlock the exciting world of metalworking?

Lathe Application Guide: Metal Lathe Thread Cutting Techniques

Lathe Application Guide for Metal Lathe Thread Cutting

Have you ever wondered how metal pieces fit together perfectly? That’s where lathe machines come into play! A lathe application guide for metal lathe thread cutting shows you how to create strong and precise threads. By learning the basic techniques, anyone can improve their skills. With the right tools and steps, making threads becomes an exciting challenge. Threads not only hold pieces but also ensure stability in projects. This guide opens a world of creative metalworking opportunities!Understanding Metal Lathes

Definition and purpose of metal lathes. Types of metal lathes and their applications.Metal lathes are fascinating machines that help change raw metal into useful parts. They spin metal pieces really fast, allowing tools to shape them easily. Think of it as a magical turntable but for metal! There are different types of metal lathes, like production lathes for factories and mini lathes for home projects. Each one has special uses, such as making screws, bolts, or cool custom designs! Here’s a quick comparison:

| Type of Lathe | Common Use |

|---|---|

| Engine Lathe | General purposes |

| CNC Lathe | Automated precision work |

| Bench Lathe | Small projects |

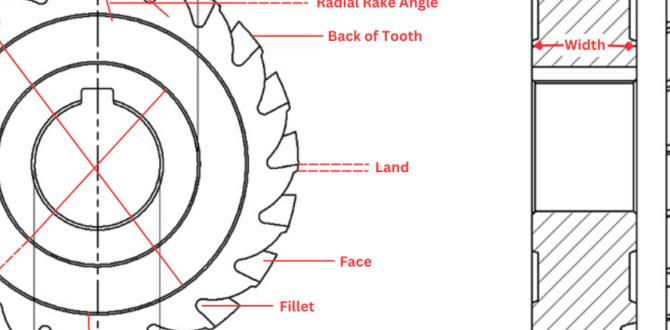

Essential Components of a Metal Lathe

Major parts and their functions. Importance of each component in thread cutting.Metal lathes are like the superheroes of the workshop! Each part has a special job that helps create perfect threads. The bed is the sturdy base. It holds everything steady, so things don’t wobble around like a jelly on a plate! The headstock powers the spindle. It keeps things spinning smoothly, much like a merry-go-round. The tailstock helps support the workpiece and can be moved—just like sliding over to grab your snack. Let’s not forget the carriage, which moves the cutting tool back and forth. Each component plays a vital role in thread cutting, ensuring everything fits and works well together.

| Component | Function |

|---|---|

| Bed | Sturdy base holding everything steady. |

| Headstock | Powers the spindle for smooth spinning. |

| Tailstock | Supports the workpiece and adjusts easily. |

| Carriage | Moves the cutting tool for accurate cuts. |

Setting Up Your Metal Lathe for Thread Cutting

Recommended tools and equipment. Stepbystep setup process for optimal performance.To ace thread cutting on your metal lathe, you need some trusty tools by your side. Gather a cutting tool, calipers for measuring, and a micrometer to check the threads. First, properly set your lathe speed and feed rates for smooth operation. Then, align the cutting tool to your desired angle. Keep your eyes peeled for any wobbling—lathe yoga isn’t a thing! Finally, test with a scrap piece to ensure everything glides like butter. Here’s a quick tool checklist:

| Tools | Purpose |

|---|---|

| Cutting Tool | For cutting the thread |

| Calipers | For measuring sizes |

| Micrometer | For precise thickness checks |

Choosing the Right Materials for Thread Cutting

Common materials suitable for lathe thread cutting. Factors to consider when selecting materials.Choosing the right materials can make a huge difference in thread cutting. Common materials include:

- Steel

- Aluminum

- Brass

These materials are strong and easy to work with. Consider the following factors:

- Strength: Ensure the material can hold up under pressure.

- Machinability: Look for materials that cut easily.

- Cost: Choose materials that fit your budget.

Using the right materials means better threads and a smoother process!

What materials are best for thread cutting?

Steel, aluminum, and brass are excellent choices for thread cutting. These materials balance strength and ease of machining, allowing for effective results during the process.

Step-by-Step Thread Cutting Process

Detailed instructions for manual thread cutting. Tips for using CNC lathes in thread cutting.Cutting threads on a lathe can be easy if you follow the steps. First, set your lathe to the right speed for your material. Then, use a proper thread cutting tool. Slowly feed the tool into the material, keeping a steady pace. For manual lathes, use a dial to measure the depth. If using CNC lathes, program the tool path carefully.

Here are some tips for CNC lathe users:

- Double-check your settings before starting.

- Use coolant to keep the tool cool.

- Make test cuts on scrap material first.

With practice, you’ll cut perfect threads every time!

How do I start cutting threads on a lathe?

First, ensure your lathe is secure and your tool is sharp. Follow the manual for settings. Start with a calm pace for best results.

Common Challenges in Thread Cutting and Solutions

Identification of frequent problems. Practical solutions to overcome these challenges.Thread cutting can be tricky. Many beginners face challenges like poor thread quality or incorrect measurements. Here are some common problems and how to fix them:

- Poor thread quality: Check tool sharpness. A dull tool leads to rough threads.

- Wrong thread pitch: Double-check your die or lathe settings. Accuracy is key.

- Irregular thread depth: Keep a steady hand and speed. Fast cutting can mess up depth.

These tips can help improve your thread cutting skills.

What are common problems in thread cutting?

The most common problems are poor thread quality, wrong thread pitch, and irregular thread depth.

What are practical solutions for these issues?

To overcome these issues, remember to maintain tool sharpness, double-check your settings, and keep a steady speed while cutting.

Maintenance Tips for Longevity of Metal Lathes

Routine maintenance practices. Importance of upkeep for thread cutting precision.Taking care of your metal lathe is like giving a puppy a bath—it just makes everything better! Routine maintenance helps keep your lathe in tip-top shape. Regularly clean and lubricate it to avoid rust and ensure smooth operation. Remember, precise thread cutting relies on a well-maintained lathe. Neglecting upkeep can lead to wobbly threads and a not-so-fun time. Aim to check your lathe often. Here’s a quick table with maintenance tips:

| Task | Frequency |

|---|---|

| Clean and oil | Every week |

| Check for wear and tear | Every month |

| Test alignment | Every three months |

Routine care helps your machine last. Remember, a happy lathe makes happy threads!

Safety Practices in Lathe Operations

Essential safety gear and equipment. Best practices to ensure a safe working environment.Keeping safe while using a lathe is as important as making a perfect cut. First, wear protective gear like goggles, gloves, and hearing protection to guard against flying chips and loud noises. It’s like wearing a superhero outfit, but for metalwork!

Organize your workspace. A clean area means fewer chances of accidents. Make sure all tools are in their right spots, and keep a fire extinguisher nearby, because we don’t want sparks to turn into a surprise party. Work in a well-lit space so you can see what you’re doing—you don’t want to play hide and seek with your fingers!

| Essential Safety Gear | Description |

|---|---|

| Safety Goggles | Protects your eyes from dust and debris. |

| Gloves | Keeps your hands safe from cuts. |

| Ear Protection | Reduces the noise from machinery. |

Follow these practices and you’ll be cutting threads safely in no time! Who knew being safe could be this easy and fun?

Innovations in Lathe Technology

Recent advancements in metal lathe applications. Impact of new technologies on thread cutting efficiency.New tools in lathe technology are changing how we make parts. These advancements help machines cut threads better and faster. For example, modern CNC lathes can automatically adjust settings. This means less human error and improved precision. As a result, companies save time and money. The use of smart sensors also boosts efficiency. They detect issues before they become big problems.

What are the benefits of new lathe technology?

New lathe technology offers better speed, accuracy, and less waste. This helps businesses produce high-quality products more efficiently.

Key advantages:

- Improved thread cutting.

- Less manual work needed.

- Fewer mistakes and reworks.

- Time-saving features.

Resources for Further Learning

Recommended books and online courses. Communities and forums for lathe enthusiasts and professionals.If you want to dive deeper into lathe work, there are plenty of resources waiting for you! Books like “Lathe Basics” give great tips on handling materials, and online courses from platforms such as Udemy bring the workshop right to your living room! Don’t forget about communities and forums. Places like Reddit’s r/Machinists are filled with friendly folks ready to help. Join the fun—who knows, you might find your next best friend is a fellow lathe enthusiast!

| Resource Type | Recommended Resources |

|---|---|

| Books | Lathe Basics |

| Online Courses | Udemy Metalworking |

| Communities | Reddit – r/Machinists |

Conclusion

In summary, using a metal lathe for thread cutting is a valuable skill. You can create strong connections for pipes and fasteners. Start by understanding your lathe and practice safe techniques. Explore guides and tutorials for hands-on learning. With patience and practice, you’ll master this useful application and enhance your craftsmanship. Dive into more resources to keep improving!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Thread Cutting:Sure! A metal lathe is a tool that spins metal to shape it. When we cut threads, we make grooves on the metal. These grooves help pieces fit together tightly, like screws. You can create different sizes of threads by changing settings on the lathe. It’s like carving shapes into clay but with metal!

Sure! Just give me the question you want me to answer, and I’ll be happy to help.

What Are The Essential Tools And Equipment Needed For Threading On A Metal Lathe?To thread on a metal lathe, you need a few important tools. First, you need a threading tool, which helps cut the threads into the metal. You also need a lathe, which is the machine that holds the metal and spins it. A tailstock can help support the other end of the metal while you work. Lastly, don’t forget safety gear like goggles, to protect your eyes!

How Do You Determine The Correct Thread Pitch When Cutting Threads On A Metal Lathe?To find the right thread pitch, first check the size of the screw or bolt you want to match. You can use a thread gauge, which is a tool with different shapes for different threads. Next, measure how many threads are in an inch. This tells you the pitch, or how far along the screw each thread goes. Finally, set your metal lathe to that pitch before you start cutting.

What Steps Should Be Followed To Set Up A Metal Lathe For Cutting External Threads?To set up a metal lathe for cutting external threads, first, secure your workpiece in the lathe. Then, choose the right cutting tool for threads. Next, set the right speeds and feed rate on the machine. After that, adjust the tool to the right position. Finally, test your setup by making a small cut to check the thread.

How Do You Adjust The Cutting Speed And Feed Rate For Optimal Thread Cutting Results On A Metal Lathe?To get the best results when cutting threads on a metal lathe, you need to adjust the cutting speed and feed rate. First, choose a slower cutting speed for hard materials and a faster speed for softer ones. Next, the feed rate should be slower for finer threads and faster for thicker ones. Always check your lathe’s manual for the best settings. Adjusting these helps make cleaner and more precise threads.

What Are Common Troubleshooting Tips For Issues Encountered During Thread Cutting On A Metal Lathe?If you have problems while cutting threads on a metal lathe, check the cutting tool first. Make sure it’s sharp and clean. If the threads look wrong, you might need to adjust the lathe settings. Sometimes, the speed of the lathe can be too fast or too slow. Keep practicing, and you’ll get better!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Thread Cutting:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe is a tool that spins metal to shape it. When we cut threads, we make grooves on the metal. These grooves help pieces fit together tightly, like screws. You can create different sizes of threads by changing settings on the lathe. It’s like carving shapes into clay but with metal!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question you want me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Essential Tools And Equipment Needed For Threading On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To thread on a metal lathe, you need a few important tools. First, you need a threading tool, which helps cut the threads into the metal. You also need a lathe, which is the machine that holds the metal and spins it. A tailstock can help support the other end of the metal while you work. Lastly, don’t forget safety gear like goggles, to protect your eyes!”}},{“@type”: “Question”,”name”: “How Do You Determine The Correct Thread Pitch When Cutting Threads On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right thread pitch, first check the size of the screw or bolt you want to match. You can use a thread gauge, which is a tool with different shapes for different threads. Next, measure how many threads are in an inch. This tells you the pitch, or how far along the screw each thread goes. Finally, set your metal lathe to that pitch before you start cutting.”}},{“@type”: “Question”,”name”: “What Steps Should Be Followed To Set Up A Metal Lathe For Cutting External Threads?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe for cutting external threads, first, secure your workpiece in the lathe. Then, choose the right cutting tool for threads. Next, set the right speeds and feed rate on the machine. After that, adjust the tool to the right position. Finally, test your setup by making a small cut to check the thread.”}},{“@type”: “Question”,”name”: “How Do You Adjust The Cutting Speed And Feed Rate For Optimal Thread Cutting Results On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get the best results when cutting threads on a metal lathe, you need to adjust the cutting speed and feed rate. First, choose a slower cutting speed for hard materials and a faster speed for softer ones. Next, the feed rate should be slower for finer threads and faster for thicker ones. Always check your lathe’s manual for the best settings. Adjusting these helps make cleaner and more precise threads.”}},{“@type”: “Question”,”name”: “What Are Common Troubleshooting Tips For Issues Encountered During Thread Cutting On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you have problems while cutting threads on a metal lathe, check the cutting tool first. Make sure it’s sharp and clean. If the threads look wrong, you might need to adjust the lathe settings. Sometimes, the speed of the lathe can be too fast or too slow. Keep practicing, and you’ll get better!”}}]}