Have you ever watched a metal lathe at work? The way it shapes metal can be quite magical. A lathe is a powerful tool for anyone who loves making things. Whether you’re a beginner or a pro, knowing about lathe applications makes a big difference.

Many people upgrade their metal lathes without knowing how to use them properly. This can lead to mistakes and wasted materials. But what if you had a guide to help you? Imagine turning your hobby into something more exciting and accurate.

In this article, we’ll explore the world of lathes. You will learn how to get the best from your metal lathe upgrade. Let’s dive into tips and tricks that can make you the master of your workshop! Are you ready to discover the secrets of lathe applications?

A Comprehensive Lathe Application Guide For Metal Lathe Upgrade

Lathe Application Guide: Metal Lathe Upgrade

When considering a metal lathe upgrade, it’s vital to know what to expect. Newer lathes offer better precision, speed, and efficiency. They can handle a variety of materials, making them versatile for many projects. A fun fact: the right lathe can reduce your work time by half! Just think, what could you achieve with extra hours? Upgrading your lathe opens up a world of possibilities, enhancing your skills and projects significantly.Understanding Metal Lathes

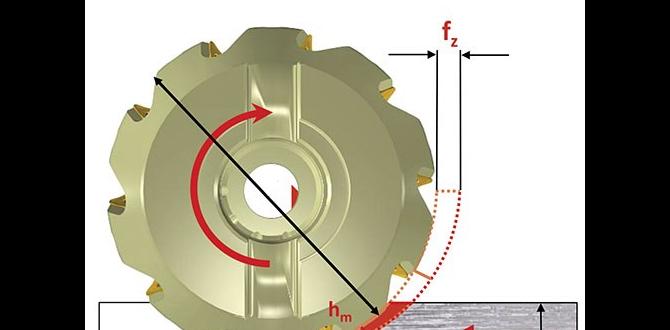

Definition and components of a metal lathe. Key functions and applications in machining.A metal lathe is a machine tool that shapes metal by spinning it against a cutting tool. Think of it like a giant pencil sharpener, but for metal! It has several key parts: a bed, headstock, tailstock, and carriage. Each part works together like a well-rehearsed dance troupe.

The main job of a metal lathe is to create precise shapes and sizes. It can turn, drill, and polish metal pieces. This helps make everything from tiny screws to huge machine parts. It’s like magic, but with metal! When it comes to machining, the possibilities are endless!

| Component | Function |

|---|---|

| Bed | Holds everything in place |

| Headstock | Holds the spinning part |

| Tailstock | Supports the other end |

| Carriage | Moves the cutting tool |

Signs You Need an Upgrade

Performance issues and limitations of older models. Benefits of upgrading for efficiency and precision.| Signs You Need an Upgrade | What to Watch For |

|---|---|

| Performance Issues | If your lathe is moving slower than a sloth on vacation, it’s time for a change. |

| Inaccuracies | Are your pieces looking more like abstract art than precise shapes? That’s a red flag! |

| More Efficiency | Upgrading can save you time—like finishing a book before bedtime! |

| Better Precision | New models can cut with the accuracy of a cat landing on its feet. |

Does your lathe feel more like a dinosaur? Older models often struggle with performance issues. If your machine skips beats, you might be in the Stone Age of metalworking. Upgrading can boost efficiency, making work faster and more enjoyable. Think of it as getting a new toy! Better precision means your projects will turn out just right. Say goodbye to wonky shapes and hello to smooth results!

Assessing Your Current Lathe

Evaluating the condition and capabilities of your existing lathe. Identifying gaps in production and quality.Check your lathe closely to see how well it works. Look for signs of wear or damage. Ask yourself, can it make the parts I need? Next, think about production. Is your lathe keeping up with orders? Is the quality good? Finding these gaps helps you see if you need an upgrade. Consider these points:

- Condition of parts and tools.

- Speed of production.

- Accuracy of cuts.

Improving your lathe can boost your work and make it easier.

Why should I evaluate my existing lathe?

Knowing your lathe’s strengths and weaknesses helps you decide if it needs an upgrade to improve work efficiency and quality.

Key Features to Consider When Upgrading

Essential specifications and technologies to look for. Importance of automation and digital controls.Upgrading a metal lathe is like giving it a superhero makeover! You want to check out the essential specifications first. Look for things like speed control and torque. These can make your work smoother than butter on a hot pancake! Next, think about automation and digital controls. They help you work faster and more accurately. Who doesn’t love a machine that can do some of the thinking for you? Below is a table of key features to consider:

| Feature | Importance |

|---|---|

| Speed Control | Ensures precision |

| Torque | Improves cutting ability |

| Automation | Reduces human error |

| Digital Controls | Increases efficiency |

Just remember, a good upgrade is not just about shiny buttons; it’s about making your work time more fun and productive!

Popular Upgrades and Modifications

Common upgrade options for enhanced performance. Adjustments that improve safety and usability.Upgrading your lathe can boost its performance and make it safer to use. Many machinists choose common upgrades to get better results. Here are some popular options:

- Variable Speed Drives: This allows smoother speed control for different tasks.

- Upgraded Tool Holders: Better holders support a wider range of tools.

- Enhanced Work Lighting: Good lighting helps you see fine details clearly.

Making adjustments can also improve safety. Adding guards keeps hands away from moving parts. Non-slip handles make it easier to grip and control the tools. These upgrades help everyone work safer and smarter.

What are the best lathe upgrades?

Your best upgrades include variable speed drives, upgraded tool holders, and enhanced work lighting. These options increase performance while ensuring safety. Consider what fits your needs before starting your upgrade journey!

Budgeting for Your Upgrade

Estimating costs associated with different models. Costbenefit analysis of potential upgrades.When upgrading your lathe, it’s important to understand costs. Start by estimating the price of different models. Look at features that each one offers. This helps you choose wisely. A cost-benefit analysis compares what you pay and the benefits gained. Consider these points:

- Initial cost: What you pay upfront.

- Operating costs: Ongoing expenses like power and maintenance.

- Features: What extra tools or uses you gain.

- Longevity: How long the lathe lasts.

Knowing this helps you decide if the upgrade is worth it.

What should I consider when planning a lathe upgrade?

You should think about features, costs, and future use. Will the upgrade help your projects? How much will you use it? Investing wisely means getting the best value for your money.

Tips for Transitioning to a New Lathe

Best practices for installation and setup. Training and adaptation for operators.Changing to a new lathe can be exciting but challenging. Start by following best practices for setup. Make sure to read the manual carefully. Check all parts are secure and correctly installed. This ensures safety and efficiency.

Next, train your operators. They should understand the new features and controls. Hands-on practice helps everyone adjust smoothly. Regular discussions can build confidence and improve skills.

Remember, transitioning takes time. Be patient and supportive while your team learns the new machine.

What are essential tips for operators during the transition?

Training should include hands-on experience, regular check-ins, and step-by-step instruction on new features.

- Encourage questions from operators.

- Use simple language when explaining features.

- Allow time for practice and mistakes.

Maintenance Tips for Upgraded Lathes

Routine care and upkeep to ensure longevity. Troubleshooting common issues postupgrade.Taking care of your upgraded lathe is like giving it a warm hug! Regular check-ups help it last longer. Keep it clean and lubricated. Dust and grime are like a bad haircut; they just ruin everything! Check for loose bolts and worn belts regularly. If something feels off, like a strange noise, don’t ignore it! Here’s a quick troubleshooting table to help you.

| Issue | Possible Cause | Solution |

|---|---|---|

| Strange noises | Loose parts | Tighten screws and bolts |

| Inconsistent cuts | Dull tools | Sharpen or replace blades |

| Vibration | Unbalanced load | Rebalance the workpiece |

Following these tips means your lathe will work like a charm. Remember, a little love goes a long way! ✨

Conclusion

In summary, upgrading your metal lathe can greatly enhance your projects. We learned about key features, tools, and techniques for better performance. Remember to research specific upgrades that fit your needs. You can also explore guides online for detailed instructions. This will help you work smarter and achieve amazing results in your metalworking projects. Happy lathing!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Upgrading A Metal Lathe For Better Applications:Upgrading a metal lathe can help you make better and cooler shapes from metal. You might want to add a stronger motor for more power. A better tool holder can also help you switch tools easily. Remember, a good upgrade makes your machine last longer and work better. All of this makes your projects more fun and easier to complete!

Sure! Just ask your question, and I’ll give you a short and simple answer.

What Are The Key Features To Consider When Upgrading A Metal Lathe For Enhanced Performance?When upgrading a metal lathe, think about the motor power. A stronger motor helps cut faster. You should also consider the size of the lathe. A bigger work area lets you make larger items. Don’t forget about adding better tools. High-quality tools can make your cuts smoother and more precise.

How Can Incorporating Cnc Technology Into A Metal Lathe Improve Precision And Efficiency In Machining Tasks?Using CNC, which stands for Computer Numerical Control, makes metal lathes smarter. It helps you create exact shapes and sizes. Machines can work faster and make fewer mistakes. This means you can finish jobs quicker and better. Overall, CNC technology makes the work easier and more precise!

What Are The Advantages Of Adding A Quick-Change Tool Post To A Standard Metal Lathe Setup?A quick-change tool post helps you change tools faster on a metal lathe. This means you spend less time switching and more time working. It’s also easier to use, so you can make better parts. With more tools ready to go, your projects can be finished quicker and with great results!

How Does Upgrading To A Larger Swing And Bed Length On A Metal Lathe Affect The Types Of Projects That Can Be Completed?Upgrading to a larger swing and bed length on a metal lathe means you can work with bigger pieces of metal. This lets you make larger projects, like big tools or parts for machines. You can also create more complex shapes because you have more space. With a bigger lathe, we can be more creative and take on tougher jobs!

What Are The Most Effective Ways To Enhance The Safety Features Of An Upgraded Metal Lathe?To make an upgraded metal lathe safer, you can do a few things. First, always wear safety glasses to protect your eyes. Second, add covers or guards to moving parts. This keeps your hands and clothes safe. Finally, keep the work area clean and organized. A tidy space helps you avoid accidents.