Have you ever wondered how to keep your lathe running smoothly? Just like a car needs oil, a lathe needs proper lubrication. The lathe back gear is a vital part of this machine. If it isn’t taken care of, it can cause big problems. But don’t worry! Our lathe back gear lubrication guide has got you covered.

Think about this: when was the last time you checked your lathe’s back gear? Many people forget this important task. Neglecting lubrication can lead to wear and tear. This can make your lathe less effective. A simple act can save you time and money!

In this article, we will share easy steps for keeping your lathe back gear in top shape. Did you know that regular lubrication can even extend the life of your machine? It’s true! By following our guide, you can ensure your lathe performs at its best.

Lathe Back Gear Lubrication Guide: Essential Tips For Maintenance

Lathe Back Gear Lubrication Guide

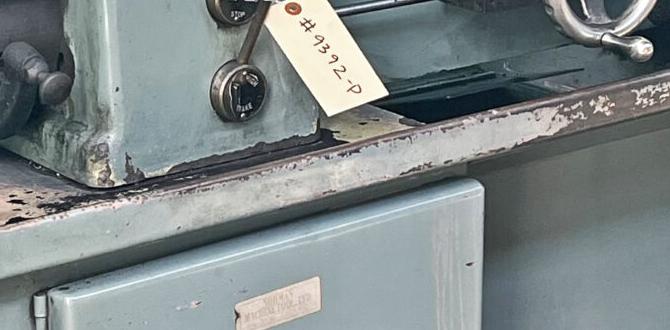

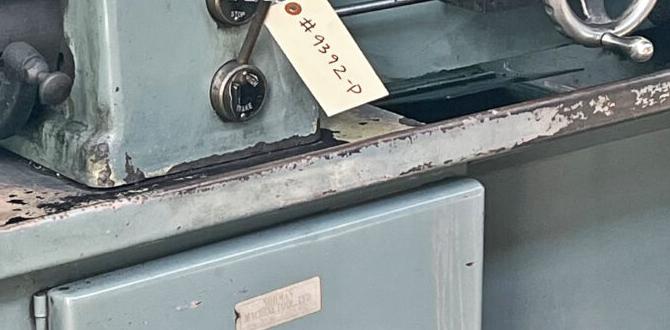

Proper lathe back gear lubrication keeps your machine running smoothly. Did you know that good lubrication can extend the life of your lathe significantly? This guide explains how to choose the right lubricants for your lathe back gear. It also shares tips on how often to lubricate and the best techniques for application. When gears are well-lubricated, they operate quietly and efficiently, making your work easier and more enjoyable.Understanding Lathe Back Gear Mechanism

Explanation of the back gear assembly and its function in a lathe.. Importance of lubrication in ensuring smooth operation and longevity..The back gear assembly is a key part of a lathe. It helps change the speed of the spindle. This means it can go faster or slower, depending on the job. Good lubrication is vital for this assembly. It ensures smooth movement and prevents wear and tear. Without proper oiling, parts may stick or break. Keeping the back gear well-lubricated extends its life. This makes your lathe last longer and work better!

Why is Lubrication Important for the Back Gear?

Lubrication helps the back gear run smoothly and increases its lifespan. Regular oiling stops friction, ensuring that all pieces work together perfectly.

Key Points:

- Prevents wear and tear

- Enhances efficiency

- Reduces noise during operation

Lubrication Frequency and Schedule

Recommended intervals for lubrication based on usage.. Factors influencing the lubrication frequency such as workload and environment..Understanding how often to lubricate your lathe back gear is important. Check the lubrication every week if you use it daily. If you use it less, check once a month. Workload matters too. Heavy usage means more lubrication. Also, remember the environment. Dusty or humid places need more frequent checks. Keeping everything running smoothly makes your work easier and your machine lasts longer.

How often should I lubricate my lathe back gear?

Daily or heavy usage requires weekly lubrication checks. For lighter use, check monthly.

Factors influencing lubrication frequency:

- Workload: More work means more lubrication needed.

- Environment: Humid or dusty areas require more frequent checks.

Step-by-Step Lubrication Process

Detailed guide on how to properly lubricate the back gear.. Common mistakes to avoid during the lubrication process..Lubricating your lathe’s back gear is simple if you follow a few quick steps. First, clean the area to get rid of any dust. Then, apply the right lubricant. Use a light oil for smooth movement, and remember: too much lubricant can make a mess and attract dirt. Avoid overdoing it or skipping the cleaning. The best way to remember? Think of lubrication like putting on lotion: just enough keeps things smooth! Keep your tools happy, and they’ll keep working.

| Common Mistakes | How to Avoid Them |

|---|---|

| Not cleaning before applying oil | Wipe surfaces clean first |

| Using the wrong lubricant | Check guidelines for specific oils |

| Over-lubrication | Use only what’s necessary |

Signs of Inadequate Lubrication

Identifying symptoms and performance issues related to poor lubrication.. Maintenance checks to ensure optimal back gear functionality..When lubrication goes bad, you might notice some strange things. First, listen for odd noises like squeaks or rattles. These sounds can mean your lathe is not getting enough oil. Also, watch for overheating. If it feels hotter than a summer day, that’s a red flag! Check for wear and tear on gears or unusual speed changes. Regular maintenance is key. Keep an eye out and give your lathe some love!

| Warning Signs | What to Do |

|---|---|

| Unusual Noises | Check lubrication levels |

| Overheating | Inspect for oil leaks |

| Gear Wear | Replace or lubricate |

Maintenance Tips for Back Gear Longevity

Additional maintenance practices beyond lubrication.. Tools and equipment for effective maintenance of lathe back gears..To keep back gears happy, check for dirt and grime. Clean them often with a soft brush. A tidy lathe is a happy lathe! Also, don’t forget to examine for cracks or any loose parts. Tighten screws and bolts to keep everything snug. Using the right tools makes this job even easier.

| Tool | Purpose |

|---|---|

| Soft Brush | Cleaning dust and debris |

| Screwdriver | Tightening loose parts |

| Oil Can | Applying lubricant |

Think of it like brushing your teeth—do it regularly to avoid bigger problems later! Don’t let your gears suffer in silence; a little care goes a long way. So, grab your tools and let’s keep those back gears humming like a happy kitten!

Common Questions and Myths About Back Gear Lubrication

Addressing frequently asked questions regarding lubrication.. Debunking common misconceptions in lathe maintenance..Many people wonder about lathe back gear lubrication. One common question is, “How often should I lubricate my lathe?” The answer is: frequently! Regular lubrication keeps your machine running smoothly. Another myth claims that more oil means better performance. Nope! Too much oil can lead to gunk buildup, which is like giving your lathe a sticky donut instead of a fresh one. Always follow the manufacturer’s guidance for best results. Keep your lathe happy, and it will keep you happy!

| Myth | Truth |

|---|---|

| More oil is better | Too much oil can cause problems. |

| Lubrication is only needed when it’s loud | Regular lubrication prevents loud noises. |

Conclusion

In summary, proper lubrication of your lathe back gear is essential for smooth operation and longevity. Use high-quality oils to reduce wear and noise. Regular checks can prevent problems before they start. We encourage you to read more about lubrication techniques and maintain your lathe for the best performance. Taking these steps keeps your machine running smoothly and safely.FAQs

What Types Of Lubricants Are Recommended For Lathe Back Gear Lubrication?For lathe back gear lubrication, you can use certain oils. Look for gear oil or motor oil. These oils help keep the gears running smoothly. Make sure the oil is thick enough to stick and protect the gears well. Always check the machine manual for any special recommendations!

How Often Should The Back Gear Of A Lathe Be Lubricated To Ensure Optimal Performance?You should lubricate the back gear of a lathe every time you use it. This helps keep it running smoothly. If you use the lathe a lot, check the gear regularly. Always follow your lathe’s instructions for the best care. Taking care of it will make it last longer!

What Are The Signs That Indicate The Back Gear Of A Lathe Is Not Properly Lubricated?If the back gear of a lathe isn’t getting enough oil, you might notice a few signs. First, it can make strange noises, like grinding or squeaking. You might also see it getting very hot when you use it. Lastly, the movements may feel rough or not smooth at all. If you see these signs, it’s time to add more oil!

Can Improper Lubrication Of The Lathe Back Gear Lead To Mechanical Failure, And If So, How?Yes, if you don’t put enough oil on the lathe back gear, it can break. The gears need oil to move smoothly. Without it, they can get too hot and wear out. This can cause parts to break or stop working correctly. Always check and add oil to keep everything running well!

What Is The Correct Procedure For Lubricating The Back Gear On Different Types Of Lathes?To lubricate the back gear on a lathe, you first need to turn off the machine and unplug it for safety. Then, use a clean cloth to wipe away any old grease or dirt. Next, apply a few drops of the right oil to the moving parts. Finally, turn the gears by hand to spread the oil evenly. Always check the machine’s instructions for more details!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Types Of Lubricants Are Recommended For Lathe Back Gear Lubrication? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For lathe back gear lubrication, you can use certain oils. Look for gear oil or motor oil. These oils help keep the gears running smoothly. Make sure the oil is thick enough to stick and protect the gears well. Always check the machine manual for any special recommendations!”}},{“@type”: “Question”,”name”: “How Often Should The Back Gear Of A Lathe Be Lubricated To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should lubricate the back gear of a lathe every time you use it. This helps keep it running smoothly. If you use the lathe a lot, check the gear regularly. Always follow your lathe’s instructions for the best care. Taking care of it will make it last longer!”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate The Back Gear Of A Lathe Is Not Properly Lubricated? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the back gear of a lathe isn’t getting enough oil, you might notice a few signs. First, it can make strange noises, like grinding or squeaking. You might also see it getting very hot when you use it. Lastly, the movements may feel rough or not smooth at all. If you see these signs, it’s time to add more oil!”}},{“@type”: “Question”,”name”: “Can Improper Lubrication Of The Lathe Back Gear Lead To Mechanical Failure, And If So, How? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, if you don’t put enough oil on the lathe back gear, it can break. The gears need oil to move smoothly. Without it, they can get too hot and wear out. This can cause parts to break or stop working correctly. Always check and add oil to keep everything running well!”}},{“@type”: “Question”,”name”: “What Is The Correct Procedure For Lubricating The Back Gear On Different Types Of Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To lubricate the back gear on a lathe, you first need to turn off the machine and unplug it for safety. Then, use a clean cloth to wipe away any old grease or dirt. Next, apply a few drops of the right oil to the moving parts. Finally, turn the gears by hand to spread the oil evenly. Always check the machine’s instructions for more details!”}}]}