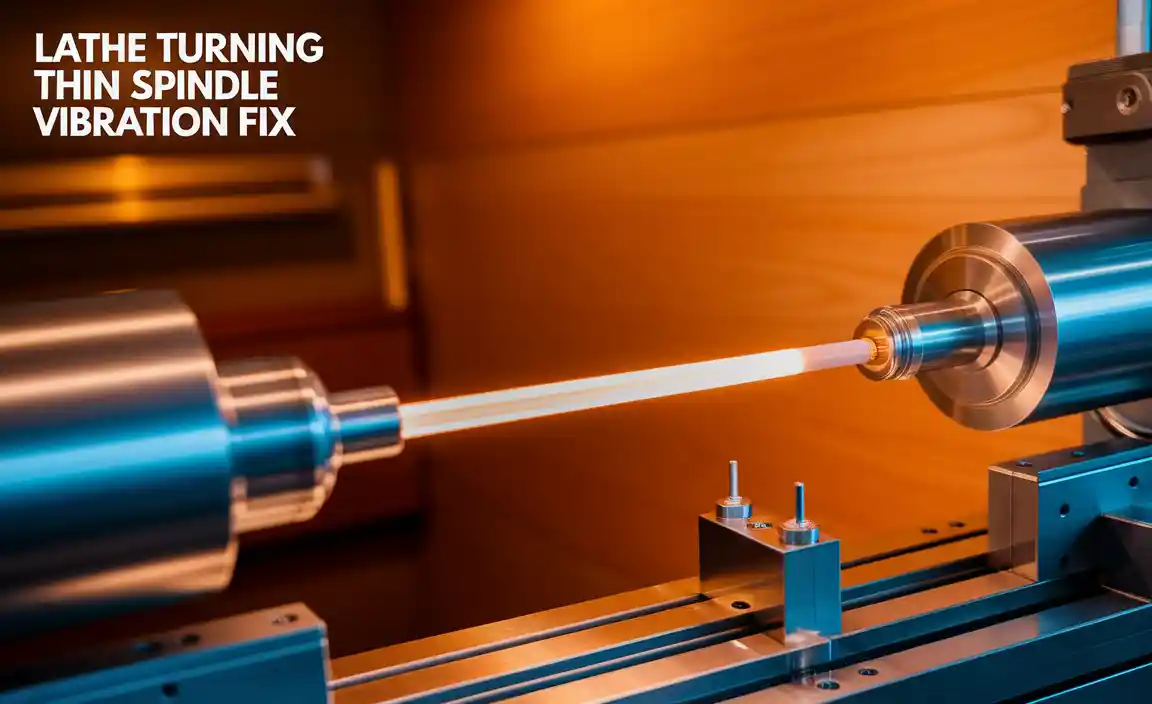

Have you ever heard strange noises coming from your lathe? It can be frustrating. Many people wonder if it’s normal or something more serious. The backgear shaft might be the culprit behind that annoying sound.

Imagine working on an exciting project, and suddenly, a loud clunk interrupts your focus. It’s enough to make anyone stop in their tracks. But don’t worry! A lathe backgear shaft noise fix can help you get back to enjoying your work.

Did you know that a simple adjustment could silence those pesky sounds? Sometimes, it’s not a big issue. Understanding what causes the noise is the first step to finding a solution.

In this article, we will explore easy ways to fix the lathe backgear shaft noise. By the end, you’ll be ready to tackle the problem head-on and get your lathe running smoothly again.

Lathe Backgear Shaft Noise Fix: Effective Solutions Here

Lathe Backgear Shaft Noise Fix

Is your lathe making annoying noises? You’re not alone! Many users face backgear shaft noise issues. One of the first steps to fix this is to check for loose parts. Tightening bolts can often reduce unwanted sounds. Lubricating the shaft is another effective method. A quick oiling can work wonders! Did you know that worn bearings might be the culprit? Replacing them can lead to a smoother operation. With simple steps, you can easily reduce that frustrating noise and get back to work smoothly!Understanding Lathe Backgear Shaft Noise

Explanation of lathe backgear shaft and its function.. Common causes of noise in backgear shafts..A lathe backgear shaft is an important part of a lathe machine. It helps control the speed of the spindle, allowing you to work on materials smoothly. However, sometimes it can make annoying noises. This noise can come from several sources. Common causes include:

- Worn bearings that need replacing.

- Loose components that rattle as the machine runs.

- Lack of lubrication, which causes friction.

Fixing these issues can improve performance. Keeping the backgear shaft in good shape helps your lathe run quietly and efficiently.

What should I do if my lathe backgear shaft is noisy?

Check the bearings and lubricate the parts regularly. This action can help reduce noise and maintain your lathe’s efficiency.

Identifying Symptoms of Backgear Shaft Issues

Key indicators of problems related to the backgear shaft.. Differentiating between normal operational sounds and warning signs..Many sounds can hint at trouble with the backgear shaft. You should listen closely when your lathe operates. Some key signs include:

- Unusual rattling noise that wasn’t there before.

- Grinding sounds that feel rough.

- Unsteady vibrations during operation.

Normal sounds may include steady humming or a soft whirl. Understanding the difference is crucial. Knowing these signs can lead to fixing problems early!

What are common symptoms of backgear shaft problems?

Common symptoms include strange noises, vibrations, and difficulty in engaging gears. These can indicate wear or damage that needs attention.

Tools and Materials Needed for Fixing Noise

List of essential tools for diagnosing and repairing backgear shaft noise.. Recommended lubricants and replacement parts to use..To fix backgear shaft noise, you’ll need the right tools and materials. Here are some essentials:

- Wrench set

- Screwdriver set

- Socket set

- Lubricant (like machine oil)

- Replacement bearings

Using good quality lubricants helps reduce noise and wear. It’s also wise to check for worn parts. Replacing them can make your lathe run smoother. Taking these steps will help you fix the noise effectively.

What tools and materials do I need for fixing lathe noise?

Use a wrench set, screwdrivers, and good lubricants to repair noise in the lathe. Check for worn parts like bearings and replace them if needed.

Step-by-Step Guide to Diagnose Backgear Shaft Noise

Instructions for inspecting the backgear shaft and components.. How to test for wear and misalignment..To check the backgear shaft for noise, first, inspect all parts closely. Look for visible damage like cracks or wear. Next, test for wear by examining the gears for smooth movement. Proper alignment is important. Misalignment can cause noise and damage. Follow these steps:

- Check gears and bearings for wear.

- Make sure the shaft is straight.

- Turn it by hand to feel for rough spots.

- Look for unusual sounds during operation.

Doing this can help find problems early. Regular checks keep your equipment running well!

How can I tell if my backgear shaft is worn out?

Look for noise, rough movement, or visible damage. Regular checks can help you catch issues before they become serious!Common Fixes for Lathe Backgear Shaft Noise

Detailed methods for tightening or adjusting components.. Techniques for lubricating the backgear shaft effectively..Fixing lathe backgear shaft noise can be easy. Start by tightening the screws and bolts. Make sure everything is snug. This helps prevent rattling sounds. Next, apply lubricant to the backgear shaft. A few drops of oil can reduce friction. Here are some effective methods:

- Tighten screws securely.

- Check for wear or damage on parts.

- Use the right lubricant for smooth operation.

By following these tips, your lathe can run quieter and smoother.

How to tighten and lubricate the backgear shaft?

Start by tightening all screws and inspecting each part. Then apply lubricant carefully to reduce noise.

Preventive Maintenance Tips for Longevity

Best practices to avoid noise issues in the future.. Suggested maintenance schedule for lathe tools..To keep your lathe in top shape, regular check-ups are key. Start with a fun little routine where you inspect it monthly. Look for worn-out parts and clean any dust bunnies hiding in the machine. Think of it as a spa day for your lathe! To avoid that pesky backgear shaft noise, keep the gears well-lubricated. A good schedule could be:

| Maintenance Task | Frequency |

|---|---|

| Inspect gears | Monthly |

| Lubricate moving parts | Weekly |

| Clean dust | Every session |

This simple plan can help avoid those annoying noises in the future. Remember, a happy lathe makes for a happy workshop!

When to Seek Professional Help

Signs that indicate the need for professional repair services.. Resources for finding qualified technicians..Noticing odd noises from your lathe? This could mean it’s time to call in the pros. If you hear strange grinding or clunking sounds, these are signs that something may be wrong. Also, if your machine vibrates more than a dance party, that’s a red flag. For help, you can search online for qualified technicians or ask local hardware stores for recommendations. A well-maintained lathe means less downtime and more fun!

| Signs You Need Help | Where to Find Technicians |

|---|---|

| Strange Noises | Online Reviews |

| Unusual Vibrations | Local Hardware Stores |

| Moving Parts Sticking | Industry Forums |

Conclusion

To fix lathe backgear shaft noise, first check for wear and tear. Lubricate moving parts regularly to keep them running smoothly. Tighten loose components to reduce rattling sounds. You can also replace worn parts if needed. By following these steps, you improve performance and extend your lathe’s life. For more tips, explore user manuals or online resources. Happy lathing!FAQs

What Are The Common Signs That Indicate A Lathe Backgear Shaft Is Noisy And May Need Adjustment Or Repair?If your lathe backgear shaft is noisy, you might notice strange sounds like grinding or rattling. You may also feel vibrations when it runs. Sometimes, there can be a smell of burning, or you might see oil leaks. If you notice these signs, it’s a good idea to check if it needs fixing or adjusting.

How Can I Properly Diagnose The Source Of Noise Coming From The Backgear Shaft On My Lathe?To find the noise from the backgear shaft on your lathe, start by turning off the machine. Check for loose parts or dirt around the backgear area. You can also listen closely while gently turning the gears. If you still hear noise, check the oil level and add more if it’s low. If nothing seems wrong, ask someone who knows about lathes for help.

What Maintenance Steps Can I Take To Prevent Noise Issues With The Backgear Shaft On My Lathe?To prevent noise with the backgear shaft on your lathe, you should check for loose parts. Tighten any screws or bolts you find. Next, keep the shaft clean and free of dust. You can also add some oil to help it move smoothly. Finally, check the gears for wear and replace them if needed.

Are There Any Specific Lubricants Or Products Recommended For Reducing Noise In A Lathe Backgear Mechanism?Yes, you can use special lubricants to help reduce noise in a lathe backgear. Look for products like lithium grease or oil made for machines. These help the parts move smoothly and quietly. Always follow the instructions on the product for the best results. Regularly checking and adding lubricant is also important.

What Are The Potential Consequences Of Not Addressing Noise Problems In A Lathe Backgear Shaft?If we ignore noise problems in a lathe backgear shaft, it can lead to bigger issues. The machine might break down, making it stop working. This can waste our time and money on repairs. The noise could also mean parts are wearing out faster, which is not good. Overall, fixing noise quickly helps keep the lathe running well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Lathe Backgear Shaft Is Noisy And May Need Adjustment Or Repair? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your lathe backgear shaft is noisy, you might notice strange sounds like grinding or rattling. You may also feel vibrations when it runs. Sometimes, there can be a smell of burning, or you might see oil leaks. If you notice these signs, it’s a good idea to check if it needs fixing or adjusting.”}},{“@type”: “Question”,”name”: “How Can I Properly Diagnose The Source Of Noise Coming From The Backgear Shaft On My Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the noise from the backgear shaft on your lathe, start by turning off the machine. Check for loose parts or dirt around the backgear area. You can also listen closely while gently turning the gears. If you still hear noise, check the oil level and add more if it’s low. If nothing seems wrong, ask someone who knows about lathes for help.”}},{“@type”: “Question”,”name”: “What Maintenance Steps Can I Take To Prevent Noise Issues With The Backgear Shaft On My Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To prevent noise with the backgear shaft on your lathe, you should check for loose parts. Tighten any screws or bolts you find. Next, keep the shaft clean and free of dust. You can also add some oil to help it move smoothly. Finally, check the gears for wear and replace them if needed.”}},{“@type”: “Question”,”name”: “Are There Any Specific Lubricants Or Products Recommended For Reducing Noise In A Lathe Backgear Mechanism? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can use special lubricants to help reduce noise in a lathe backgear. Look for products like lithium grease or oil made for machines. These help the parts move smoothly and quietly. Always follow the instructions on the product for the best results. Regularly checking and adding lubricant is also important.”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of Not Addressing Noise Problems In A Lathe Backgear Shaft? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If we ignore noise problems in a lathe backgear shaft, it can lead to bigger issues. The machine might break down, making it stop working. This can waste our time and money on repairs. The noise could also mean parts are wearing out faster, which is not good. Overall, fixing noise quickly helps keep the lathe running well.”}}]}