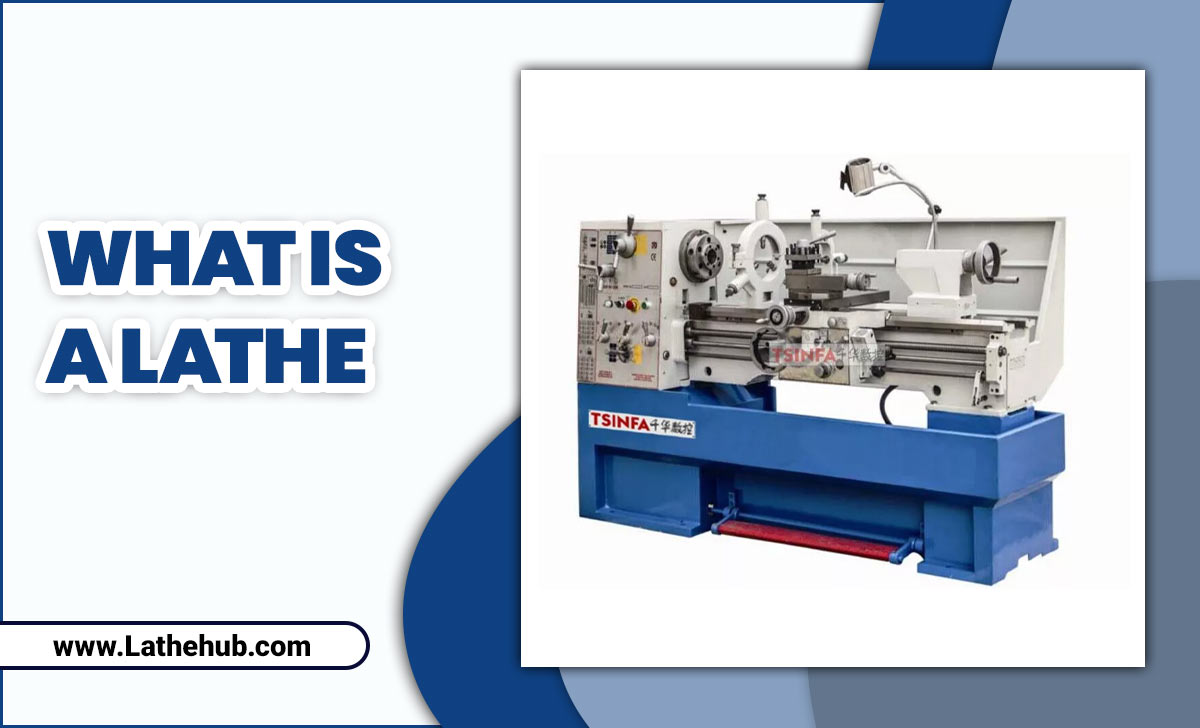

A lathe bed is the foundation of the lathe machine, serving as the base for all its components. It is a critical component in a lathe’s accurate and precise functioning, and understanding its basics is crucial for any machinist or woodworking enthusiast.

The design and construction of the lathe bed play a vital role in determining the overall performance and durability of the machine. Despite its importance, the lathe bed is often overlooked, with more focus given to the spindle, motor, and other visible components.

However, a well-built and properly maintained lathe bed is essential for achieving smooth and accurate cuts, making it a topic of utmost importance for anyone working with a lathe. Here, we will delve into the fundamentals of entire-piece lathe bed construction, material selection, and maintenance, providing you with a comprehensive understanding of this crucial component and its impact on the overall functioning of a lathe bench machine.

About Lathe Bed

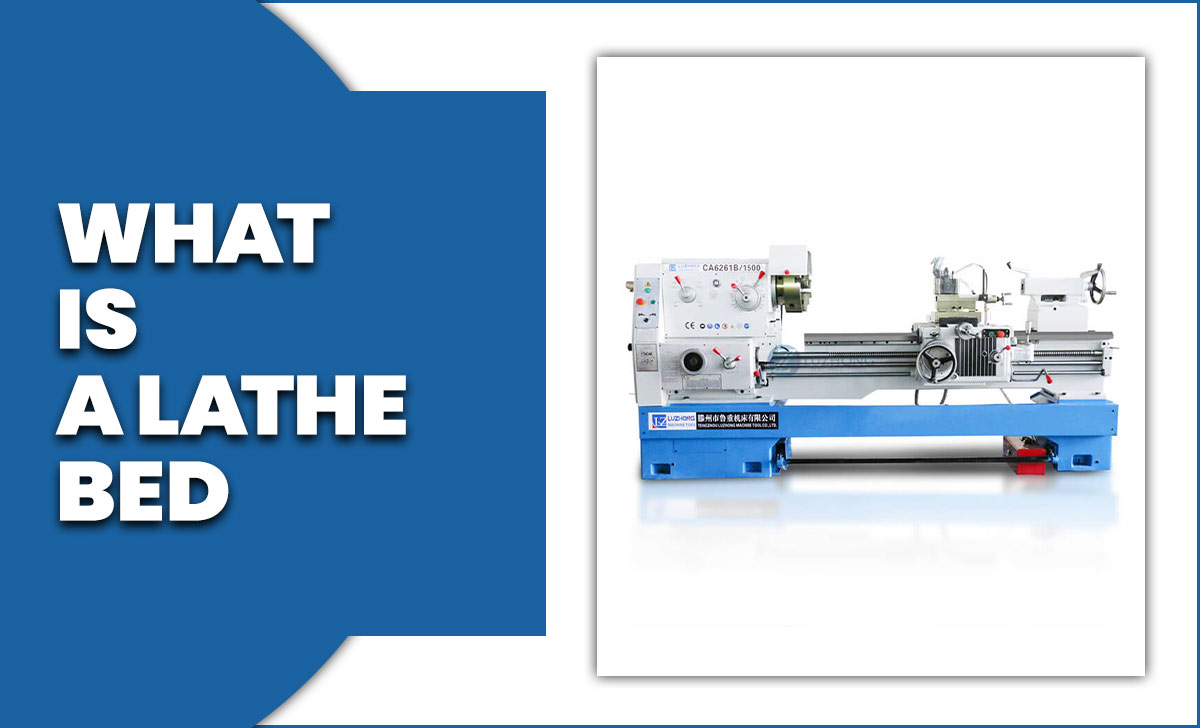

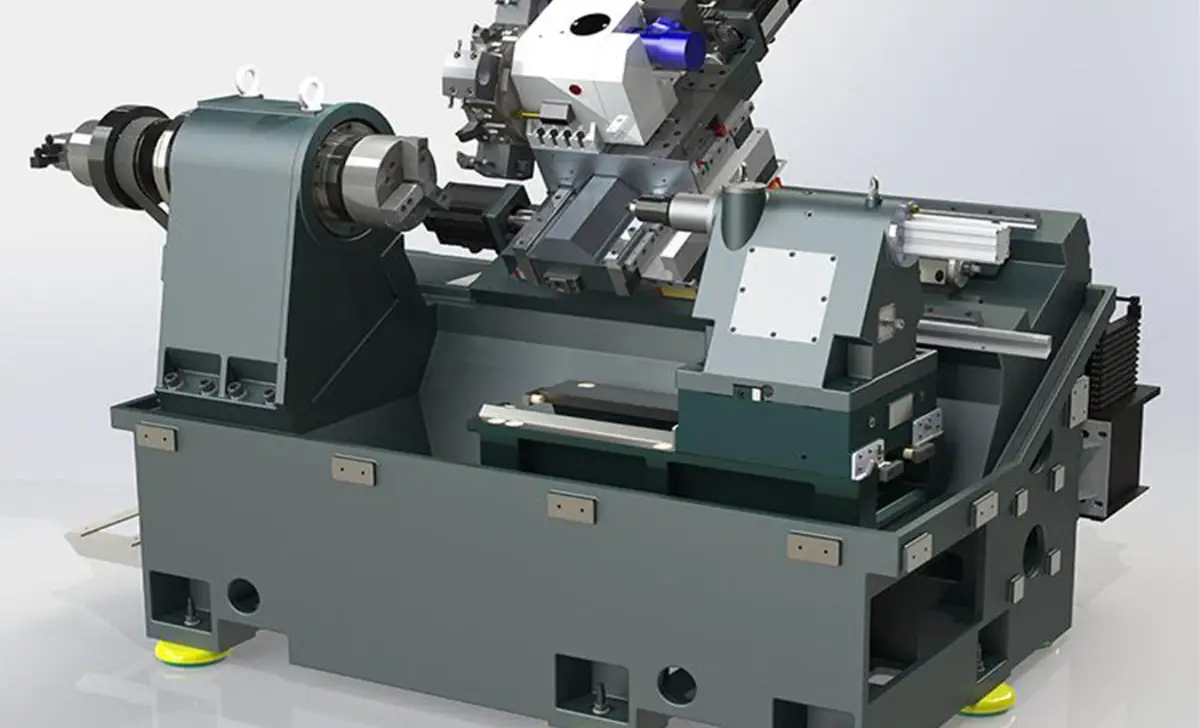

The lathe bed is a crucial component of a lathe machine. It is a long and rigid horizontal base that supports and holds various parts of the lathe, such as the headstock, tailstock, and carriage. Typically, manufacturers use cast iron or steel to ensure stability and durability for the bed.

It provides a stable platform for moving the cutting tool and workpiece during turning operations. The bed’s design and construction are vital in determining the lathe’s accuracy and precision. Maintaining the bed’s flatness and alignment is important to ensure optimal performance and consistent results in lathe machining.

Material Used In Making A Lathe Bed

A lathe bed is an important component of a lathe machine. It serves as the foundation and support for other parts of the lathe. The material used in making a lathe bed is crucial in determining the machine’s stability and durability. People commonly make lathe beds from cast iron or steel.

Cast iron is often preferred due to its excellent vibration-dampening properties, which help achieve smoother and more accurate machining. On the other hand, steel offers high strength and rigidity, making it suitable for heavy-duty applications. The choice of material depends on factors such as the size and weight of the workpiece, desired precision, and the intended use of the lathe machine.

Distinguishing Types Of Lathe Beds

Commonly used in machining, there are several types of lathe beds. One such type is the flatbed, which features a flat, broad surface for the carriage and tailstock to move along. This design provides stability and rigidity, making it suitable for heavy-duty work. Another type is the v-bed, which has a v-shaped groove that guides the carriage and tailstock.

This design allows for precise and smooth movement, making it ideal for precision machining. There is also the gap bed, which includes a removable section to accommodate larger workpieces. This type provides versatility and flexibility for machining a variety of sizes. Understanding the different types of lathe beds is essential in choosing the most suitable one for specific machining needs. Some types of Lathe Beds:

Flat Bed Type

One of the most common types of lathe beds is the flatbed type. As the name suggests, the flatbed lathe provides a horizontal surface for the carriage, tailstock, and headstock. Metal crude lathes commonly use this type of lathe bed, known for its ability to handle larger workpieces.

The length of the flatbed lathe determines its capacity, making it suitable for turning larger workpieces with precision. It also accommodates steady rests, tool rests, and tailstock, facilitating the machining of workpieces with accuracy.

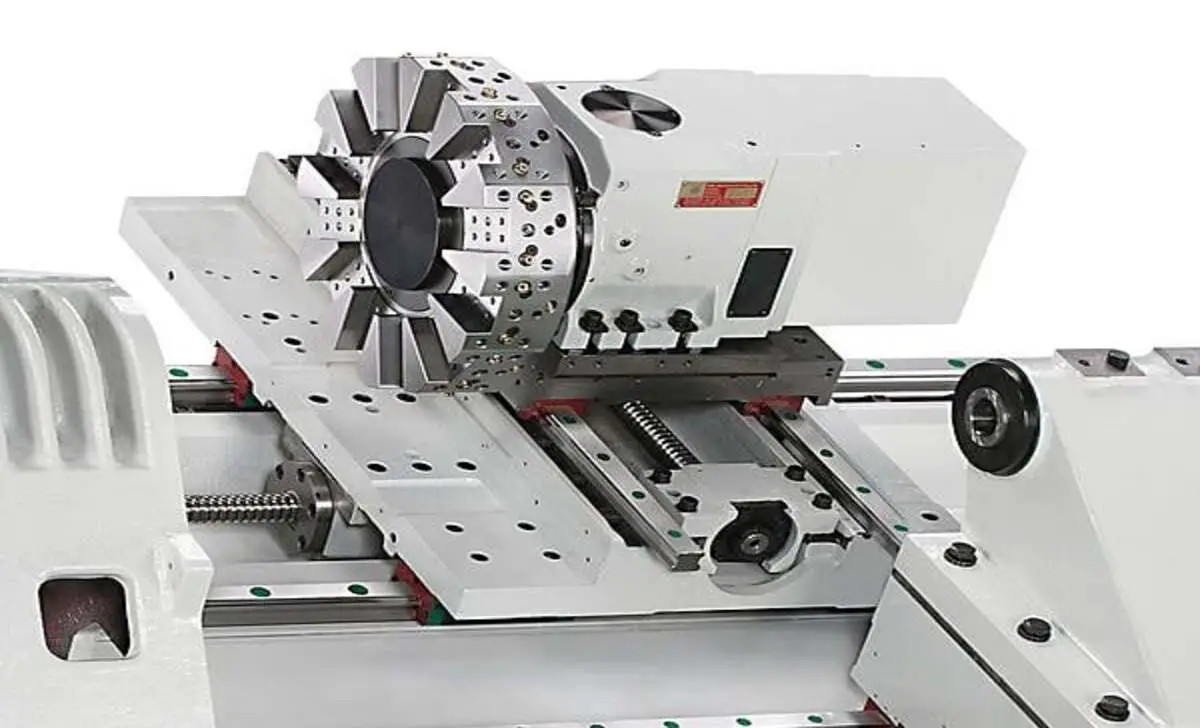

Slant Bed Type

Another type of lathe bed is the slant bed type. Unlike the flat bed lathe, the slant bed lathe offers a sloped surface, which enhances the removal of chips and swarf during machining. This innovative design improves the precision and efficiency of turning operations.

The operator positions the tooling on a slant bed lathe at an angle, allowing for better contact with the workpiece. Moreover, the slant bed lathe features a threaded rod, enabling power feed for smoother machining. The conjunction of the lead screw and feed rod promotes precise threading and machining operations, making the slant bed lathe a popular choice for precision machining.

Gap Bed Type

The gap bed lathe is another type of lathe bed that offers flexibility and versatility for machining operations. It incorporates a removable section, creating a gap between the lathe headstock and tailstock. This gap allows longer workpieces with larger diameters to be turned, expanding the machining capabilities of the lathe.

The gap bed lathe is particularly useful when threading long shafts or cylinders. Its versatility extends to the turning of chuck and spindles of different diameters. Machinists can work on a wide range of workpieces with the gap bed lathe, making it a valuable tool in various industries.

Components Of A Lathe Bed

Craftsmen carefully craft irregular pieces to ensure maximum stability and durability for the lathe bed. Each piece, known as a carriage gib, is meticulously designed to fit perfectly into the carriage and keep it aligned during operation. The lathe bed is a critical component of a lathe machine and is significant in ensuring precise and accurate machining operations. We mount all other lathe components on the foundation, including the headstock, tailstock, and carriage.

The lathe bed typically comes from high-quality cast iron, chosen for its exceptional rigidity and vibration-dampening properties. This ensures stability and minimizes potential distortion during machining operations, allowing consistent and precise results. The bed is carefully machined to provide a flat and smooth surface, essential for the smooth movement of the carriage along its length.

The Carriage

The carriage is an integral part of the lathe bed, housing the cross slide, tool post slide, and other components essential for machining operations. It moves longitudinally and crosswise, allowing for precise tool movement during turning.

The tool post slide and apron, part of the carriage, facilitate the accurate positioning of cutting tools for machining. In conjunction with the apron, the lever controls feed and threading operations. Additionally, the carriage features a power feed mechanism, enabling automatic tool movement and enhancing machining efficiency.

The Headstock

The headstock is another crucial component of the lathe bed, holding the spindle, chuck, and bearings. It provides the rotational motion required for turning workpieces. The lathe headstock’s rigidity and precision ensure accurate and stable workpiece rotation.

The bearings and spindle design are vital in minimizing runout and ensuring the turning, facing, and drilling of workpieces with precision. The machine taper present in the headstock accommodates different tooling, expanding the lathe’s machining capabilities.

The Tailstock

Completing the trio of key components, the tailstock of the lathe bed offers support and stability to the workpiece during machining operations. It contains the tailstock spindle, quill, and live center, which are crucial for workpiece alignment and support. The lead screw, feed rod, and handwheel of the tailstock enable precise adjustment and positioning of the workpiece.

Moreover, steady rests can be attached to the tailstock, facilitating accurate machining of long workpieces and shafts. In conjunction with the headstock and carriage, the tailstock provides the necessary components for turning, milling, and drilling operations.

Care And Maintenance Of Lathe Beds

One of the key features of a lathe bed is its length, which determines the maximum length of workpieces that can be accommodated. Longer beds allow for machining larger workpieces and provide increased support, minimizing any potential deflection during heavy cutting operations. Some lathe beds have specific designs with removable sections, allowing for greater flexibility in accommodating workpieces of varying lengths. Here are the Care and Maintenance of Lathe Beds:

- Keep the lathe bed clean and free from debris.

- Regularly lubricate the lathe bed to ensure smooth movement.

- Inspect the bed for any signs of wear or damage and address them promptly.

- Avoid placing heavy objects on the lathe bed to prevent warping or bending.

- Use a cover or protective coating to prevent corrosion on the lathe bed.

- Check the alignment of the lathe bed regularly to maintain accuracy in machining.

- Avoid excessive heat or moisture exposure to prevent warping or rusting of the bed.

- Follow manufacturer guidelines for specific care and maintenance instructions.

Upgrading Or Replacing A Lathe Bed

Another important aspect of the lathe bed is its overall design and construction. It should have adequate rigidity and stiffness to withstand the forces generated during machining operations. Additionally, the bed should be properly aligned and leveled to ensure the accuracy of the lathe machine. Any misalignment or unevenness can lead to inaccuracies in the machined parts. Here are Upgrading or Replacing a Lathe Bed:

- Determine the condition of the current lathe bed and evaluate if it is worth upgrading or if it should be replaced.

- Research and compare the cost of upgrading the lathe bed versus purchasing a new one.

- Consider your lathe projects’ specific needs and requirements when choosing the best option.

- Consult with experts or experienced individuals for advice and recommendations.

- If upgrading, ensure the new bed is compatible with your lathe model and properly install it.

- If replacing, choose a high-quality lathe bed that suits your needs and is within your budget.

Troubleshooting Common Issues With Lathe Beds

The lathe bed is a critical component of a lathe machine and is crucial to its overall performance and accuracy. Made from high-quality materials like cast iron or steel, the lathe bed provides a robust and stable platform for various machining operations.

Its main purpose is to support and align the other major parts of the lathe, including the headstock, tailstock, and carriage, ensuring smooth and precise movements during turning operations. Here are Troubleshooting Common Issues with Lathe Beds:

- Uneven wear on the lathe bed

- Excessive vibration during operation

- Difficulty in achieving accurate and consistent cuts

- Loose or misaligned components causing instability

- Limited range of movement on the lathe bed

- Difficulty in adjusting or locking the lathe bed in position

- Rust or corrosion on the lathe bed surface

- Inadequate lubrication leads to increased friction and wear

How Does A Lathe Bed Influence Your Work?

One key aspect of the lathe bed is its length, which determines the maximum length of the workpiece that can be accommodated. Longer beds are often preferred for handling larger workpieces or performing operations requiring extended machining capabilities. Additionally, the lathe bed may feature a gap section, which allows for machining larger-diameter workpieces that cannot fit on the standard length of the bed. Here are Lathe Bed Influence Your Work:

- The lathe bed provides a stable and rigid platform for the lathe machine.

- It helps to absorb vibrations and maintain accuracy during the turning process.

- The lathe bed’s quality and design can affect the machine’s overall performance and precision.

- A sturdy and well-machined lathe bed ensures smooth movement of the carriage and tailstock.

- The length and width of the lathe bed determine the maximum size of the workpiece that can be accommodated.

- A properly aligned lathe bed is crucial for achieving accurate and consistent results.

Conclusion

Understanding the different types of lathe beds and their components is essential for anyone involved in machining. The material used in making a lathe bed is significant in its stability and durability. Whether it’s a flatbed, slant bed, or gap bed type, each has advantages and applications.

Regular care and maintenance of lathe beds ensure optimal performance and longevity. Upgrading or replacing a lathe bed can enhance your work efficiency and precision. Troubleshooting common issues can save time and prevent costly repairs. Ultimately, the design and quality of a flat-way lathe bed greatly influence the accuracy and quality of your workpiece. So, choose wisely and create masterpieces with confidence.

Frequently Asked Questions

1.What Is A Turning Lathe Bed Made Of?

Ans: Turning lathe beds typically come with cast iron or steel, with cast iron being more common due to its ability to dampen vibrations and provide stability. Steel lathe beds may be handy for larger machines that require more strength.

2.Is A Lathe Bed Usually Made Of Cast Iron?

Ans: Lathe beds are typically cast iron, known for its durability and stability. This material ensures the bed can bear the weight of the workpiece and provide stability during machining.

3.What Angle Is A Lathe Bed?

Ans: The angle of a lathe spindle bed can vary depending on the manufacturer and model. Typically, lathe slide beds have an angle of 45 degrees or 60 degrees. The angle of the lathe headstock spindle bed has specific designs to provide stability, rigidity, and support for the workpiece during machining.

4.What Does A Gap Bed Lathe Do?

Ans: A gap bed inexpensive lathe double features a removable section of the bed, creating a gap between the lathe from scratch headstock and tailstock. This gap allows for turning larger-diameter workpieces or workpieces with irregular pieces shapes.

5.What Is A Lathe Bed Handy For?

Ans: A lathe bed is a crucial component of a lathe machine. It serves as the foundation and support for the various parts of the lathe. The bed typically has strong, rigid materials such as cast iron to ensure stability and precision.