Imagine you’re in a workshop, surrounded by buzzing machines and shining metal parts. You’re about to create something amazing, but where do you start? This is where lathe CAD files come into play. They are like blueprints for your metal lathe carriage. With these files, you can design, modify, and build with precision.

Did you know that using CAD files can save you time and effort? They help you visualize your project. Instead of guessing, you have a clear view of what your metal lathe carriage should look like. This makes the entire process much smoother and more enjoyable.

Whether you’re a beginner or a pro, having the right plans is essential. Lathe CAD files are useful tools that can unlock your creativity. So, what will you create next? Let’s explore how you can harness these files to bring your ideas to life!

Lathe Cad Files: Metal Lathe Carriage Design Resources

Lathe CAD Files for Metal Lathe Carriage

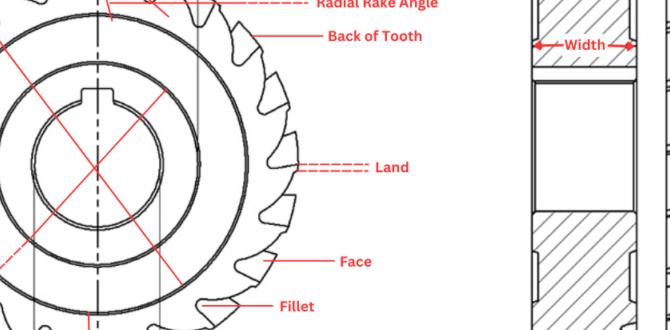

Lathe CAD files for a metal lathe carriage help makers design better tools. These files show detailed drawings, making it easier to create parts. Have you ever thought about how important precision is in metalworking? With CAD files, you can improve accuracy and speed up your projects. Plus, these files are often shared online, making them accessible for everyone. Learning about CAD files opens up new possibilities for your metal lathe projects.Understanding Lathe CNC Technology

Definition of CNC lathes and their applications. Benefits of using CAD files in metal lathe operations.CNC lathes are machines that make precise cuts in metal and other materials. They work automatically, which means you can sit back and relax while they do the hard work. These machines are great for creating parts for cars, airplanes, and even toys! Using CAD files with metal lathes makes everything smoother and faster. You can design what you need on a computer and send it straight to the lathe. It’s like giving the machine a treasure map!

| Benefits of CAD Files | Impact on Metal Lathe Operations |

|---|---|

| Precision | Reduces errors and waste |

| Speed | Quicker setup time |

| Flexibility | Easily modify designs |

In summary, CNC lathes make metalworking easier and more fun. With CAD files, you can be a metal wizard, creating amazing things with just a few clicks! Who knew machines could be this cool?

Types of Lathe CAD Files Available

Common formats for CAD files (e.g., .DWG, .DXF). Differences between 2D and 3D CAD files for lathe components.There are several types of CAD files that help in designing lathe components. The most common file formats include .DWG and .DXF. These make sharing designs easy, like trading snacks at school! Now, let’s talk about the differences. 2D CAD files show flat views, like drawing on paper. Meanwhile, 3D CAD files add depth, making designs pop out! Imagine looking at a flat pizza and then a 3D one with toppings! Below is a quick comparison:

| Type | Description |

|---|---|

| 2D CAD | Shows height and width, but no depth. |

| 3D CAD | Displays all dimensions, including depth! |

Understanding these formats can help you create the perfect designs for your metal lathe carriage. Happy designing!

Importance of Carriage Design in Metal Lathes

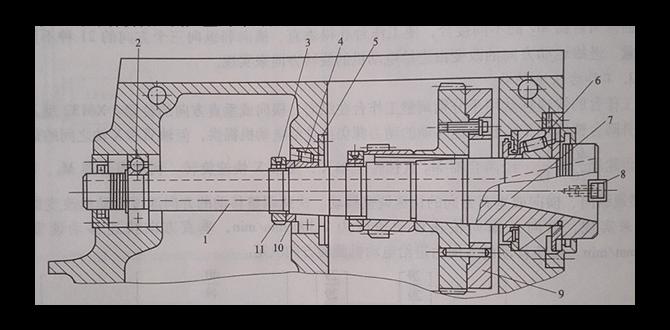

Role of the carriage in lathe functionality. Key design features to consider for optimal performance.The carriage is a key part of a metal lathe. It helps move tools along the workpiece. This movement is crucial for shaping and cutting metals. Good carriage design improves precision and control. Think of it as the guide that keeps everything on track!

Key design features include:

- Stability: A stable carriage reduces vibration.

- Ease of use: Smooth movement helps the operator work better.

- Material strength: Strong materials ensure durability.

Investing in a well-designed carriage can make your lathe perform at its best. Quality design reduces wear and tear, leading to longer tool life.

Why is carriage design important?

The carriage design is essential for accuracy in metal lathes. It directly influences how well the lathe shapes materials.

Where to Find Quality Lathe CAD Files

Popular online repositories for CAD files. How to assess the quality and accuracy of CAD files.Finding good CAD files for your lathe can make your work easier. Many people share their designs online. Here are some popular places you can check:

- Thingiverse

- GrabCAD

- MyMiniFactory

- CADBlocksFree

To ensure quality and accuracy, look for files with good reviews. Check the number of downloads. Files with clear pictures or descriptions are often better. Always download the ones with recent updates. This way, you get the best designs for your needs.

How can I tell if a CAD file is good?

Look for positive reviews and a high number of downloads. Read comments to see if others had good experiences.

How to Customize Lathe CAD Files

Software options for editing CAD files. Steps for modifying existing files to fit specific lathe models.Customizing CAD files for your lathe can be exciting! Many software programs help you edit these files. Popular options include Autodesk Fusion 360 and FreeCAD. These tools are user-friendly and powerful.

Follow these simple steps to modify existing files for your specific lathe model:

- Open the CAD software.

- Import your existing file.

- Make changes to fit your lathe dimensions.

- Save your work and export the new file.

Now you’re ready to create or modify lathe projects!

What are the best software options for CAD editing?

Great software options for CAD editing include Autodesk Fusion 360, FreeCAD, and SolidWorks. These tools make it easy to customize your designs.

Best Practices for Using Lathe CAD Files

Tips for integrating CAD files into your workflow. Common mistakes to avoid when working with CAD files.Using CAD files can make your lathe projects a breeze! First, always check the file for errors before you start. You don’t want to surprise your machine with a design blunder. Think of it as looking before you leap—safety first!

Sometimes, people forget to adjust the file scale. This can lead to parts that are too big or too small. Yikes! Remember, those settings are there for a reason. And finally, keep backups of your files. Losing work is like losing your lunch money—definitely not cool.

| Tip | Common Mistake |

|---|---|

| Check for errors | Ignoring file issues |

| Adjust the scale | Using wrong dimensions |

| Keep backups | Not saving properly |

By following these tips, you’ll become a CAD whiz in no time. Soon, you’ll be the one giving advice, and who knows? Maybe one day, you’ll even write a manual called “Lathe CAD Files for Dummies.” No offense taken, right?

Case Studies: Successful Applications of Lathe CAD Files

Realworld examples of improved lathe performance. Impact of quality CAD files on production efficiency.Companies using lathe CAD files often see cool results. Take, for example, a small machine shop. They improved lathe performance by 25% after switching to high-quality CAD files. This means they could make more parts in less time. That’s like finding extra fries in your bag! Quality CAD files help streamline the production process, leading to fewer mistakes. Less time fixing errors means more time for donuts in the break room! Here’s a quick look at the impact:

| Case Study | Performance Improvement | Production Efficiency |

|---|---|---|

| Small Machine Shop | 25% | Higher |

| Large Manufacturing Company | 30% | Increased |

| Tech Startup | 20% | Optimized |

These examples show how powerful lathe CAD files can be. They aren’t just pictures on a screen; they’re game-changers that make things faster and better!

Future Trends in Lathe CAD Technology

Innovations in CAD software for metal lathes. The role of automation and AI in reducing human error.New ideas in CAD software are making magic happen for metal lathes. Imagine drawing your designs with a few clicks, like doodling on your tablet. These programs now help users create detailed lathe CAD files quickly and easily. Plus, with automation and AI stepping in, human mistakes are becoming rare. It’s like having a superhero sidekick that makes sure every cut is perfect. Soon, lathes may not just turn metal but also make us breakfast. How about metal pancakes, anyone?

| Innovation | Benefit |

|---|---|

| Advanced CAD tools | Faster design process |

| Automation | Less human error |

| AI Assistance | Improved accuracy |

FAQs About Lathe CAD Files

Addressing common questions from users. Providing expert insights and solutions.Many users have questions about lathe cad files. Here are some common ones, with clear answers to help you understand better:

What are lathe CAD files?

Lathe CAD files are digital plans used for designing parts on a lathe machine. They help in making precise cuts and shapes.

How can I use these files?

You can open these files in CAD software. This allows you to customize designs before machining them.

Common Questions:

- What software do I need?

- Any CAD software such as AutoCAD or SolidWorks will work great!

- Where can I find more files?

- Many websites offer free or paid CAD files.

Understanding lathe cad files helps you make better parts easily! Don’t hesitate to explore and ask more questions.

Conclusion

In summary, lathe CAD files for a metal lathe carriage are vital for creating precise parts. They help you design and customize your projects effectively. Understanding these files can boost your metalworking skills. We encourage you to explore CAD software and practice creating your own designs. Keep learning and experimenting to improve your craftsmanship!FAQs

What Are The Best Practices For Creating Cad Files For A Metal Lathe Carriage Design?When you create CAD files for a metal lathe carriage, start by drawing clear and simple shapes. Use straight lines and easy-to-read measurements. Make sure to save your work often, so you don’t lose anything. Check your design for mistakes before you finish. Lastly, keep your files organized in folders for easy access later.

How Can I Modify Existing Cad Files Of A Metal Lathe Carriage To Fit My Specific Machine Requirements?To change CAD files of a metal lathe carriage, first, open the files in a CAD program. You can then adjust the sizes or shapes to fit your machine. Use tools like the line or shape tool to make changes. Be sure to save your new file so you don’t lose your work. Finally, check that your changes will work with your metal lathe before using it.

What Software Is Recommended For Designing And Manipulating Cad Files For Metal Lathe Carriages?For designing and changing CAD files for metal lathe carriages, you can use software like AutoCAD or SolidWorks. These programs help you draw and plan your designs easily. They have tools to make your work neat and accurate. You can also try free options like Tinkercad if you’re just starting out. They’re fun to use and help you learn!

Are There Any Online Resources Or Repositories Where I Can Find Downloadable Cad Files For Various Metal Lathe Carriage Designs?Yes, you can find downloadable CAD files online! Websites like Thingiverse and GrabCAD have many designs. You can search for metal lathe carriage files there. Just type in what you need, and you’ll see many options. Enjoy building!

What Factors Should I Consider When Selecting Materials For A Metal Lathe Carriage Based On Cad Designs?When choosing materials for a metal lathe carriage, think about strength. You want something that can hold up under pressure. Also, consider weight; lighter materials can help with movement. Look for resistance to wear and tear, so it lasts longer. Lastly, make sure the material is easy to work with for your designs.