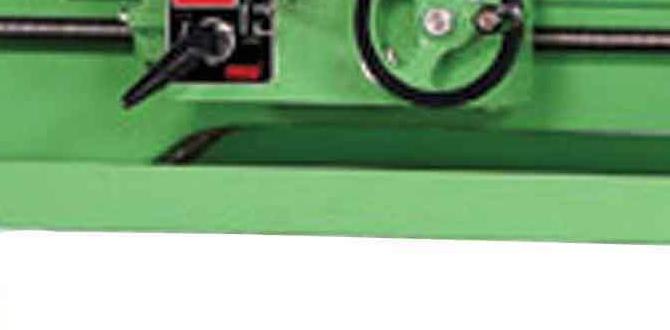

Have you ever wondered how a metal lathe works? These machines are amazing tools that shape metal into all kinds of objects. One important part of using a metal lathe is the control panel. This is where you set your machine to do exactly what you want. But how do you get started?

Thanks to technology, you can find lathe CAD files online. These files help you design and customize your lathe’s control panel. Imagine being able to create a panel that fits your needs perfectly! With the right CAD files, you can turn that dream into reality.

Did you know that using CAD files can save you a lot of time? Instead of guessing or making mistakes, you can use precise designs. This approach makes using a metal lathe even more fun and rewarding.

So, whether you are a beginner or an experienced user, learning about lathe CAD files can take your projects to the next level. Are you ready to dive in and explore how to build your ideal control panel? Let’s get started!

Essential Lathe Cad Files For Metal Lathe Control Panel Design

Lathe CAD Files and Metal Lathe Control Panels

Lathe CAD files help users design precise components for metal lathes. Have you ever wondered how metal parts come to life? A control panel manages lathe operations, making it easier to execute designs. Users learn to import CAD files for quick assembly. This streamlines the process and reduces errors. With the right knowledge, turning raw metal into finished products becomes a fun and creative journey. Knowing how to use CAD files transforms simple ideas into reality.Understanding Metal Lathe Control Panels

Definition and purpose of metal lathe control panels. Common features and functionalities of modern control panels.Metal lathe control panels are like the brains of a metal lathe machine. They help operators control the machine’s movements and settings. Without them, a metal lathe might as well be a confused robot trying to dance! Modern control panels come packed with features. They include digital displays, buttons, and knobs for easy adjustments. Some even have cool touchscreen interfaces. In short, these panels make metal shaping a breeze, and they sure beat using a magic eight ball for guidance!

| Feature | Description |

|---|---|

| Digital Display | Shows settings and measurements clearly. |

| Controls | Buttons and knobs for adjusting speed and feed. |

| Touchscreen | Interactive interface for programming and settings. |

Benefits of Using CAD Files for Metal Lathe Control Panels

Precision and accuracy in designing lathe components. Timesaving advantages of utilizing predesigned CAD files.Using CAD files for metal lathe control panels offers great benefits. First, they bring precision and accuracy to designing parts. This means every component fits perfectly. Second, they save time. Instead of starting from scratch, you can use pre-designed files. This way, you can focus on getting the job done faster. Overall, CAD files make metalworking easier and more efficient.

What advantages do CAD files provide for metal lathe control panels?

CAD files improve design speed and accuracy. They allow for quick adjustments and ensure that all parts fit well together.

Types of CAD Files for Metal Lathes

Formats available: DXF, DWG, and more. Choosing the right CAD file type for your specific lathe model.Many types of CAD files work with metal lathes. Two popular formats are DXF and DWG. These help create drawings and designs easily. You must choose the right file type for your lathe model. Each model has its needs, so use a file that fits best.

- DXF: Great for 2D drawings.

- DWG: Perfect for 2D and 3D designs.

- Other formats include SVG and IGES.

What is the best CAD file for a metal lathe?

The best CAD file for a metal lathe depends on your model and project needs. Always check the lathe manual to select the perfect format.

How to Source Quality CAD Files for Metal Lathe Control Panels

Recommended platforms and repositories for CAD files. Tips for verifying the quality and compatibility of CAD files.Finding the right CAD files can feel like searching for a needle in a haystack. Luckily, there are friendly platforms like GrabCAD and Thingiverse where you can hunt for quality metal lathe control panel designs. Always double-check the files with your software to avoid mismatches. One bad file could lead to a CNC disaster—and we don’t want that! For peace of mind, look for files with positive reviews or comments. Trust me, a little research goes a long way!

| Platform | Description |

|---|---|

| GrabCAD | Select from thousands of CAD files, and read real user reviews! |

| Thingiverse | A treasure trove of user-generated designs, perfect for hobbyists! |

Design Considerations when Creating Custom Control Panels

Essential components to include in your design. Safety features and ergonomics in metal lathe control panels.Creating a custom control panel for a metal lathe is fun and important. First, include essential components like buttons, switches, and displays. These help users operate the lathe easily. Next, safety features are a must! Bright emergency stop buttons and clear labels can save the day. Also, think about ergonomics. The right height and spacing keep users comfy while they work. Who wants sore arms, right? Here’s a quick look at some key design elements:

| Component | Importance |

|---|---|

| Buttons | Easy control |

| Labels | Clear instructions |

| Emergency Stops | Safety first! |

Remember, a well-designed control panel keeps you safe and working happily. Happy lathe-ing!

Troubleshooting Common Issues with CAD Files in Lathe Operations

Identifying common glitches and errors. Solutions and preventative measures for smoother operations.Lathe operations can face some common problems. Glitches in CAD files often lead to errors in machine performance. Identifying these mistakes is key. Look out for incorrect dimensions or missing parts. To fix these issues:

- Double-check your CAD files for accuracy.

- Ensure your file is in the correct format.

- Update software regularly to avoid bugs.

Prevent problems by testing your files before production. This way, you can enjoy smoother operations and better results.

What are common issues with CAD files in lathe operations?

Common issues include dimension errors, corrupted files, and compatibility problems between software. Regular checks and updates help minimize these challenges.

Future Trends in Metal Lathe Control Panel Designs

Innovations in technology affecting CAD designs. Predictions for the evolution of metal lathe control panels in industry.Exciting changes are coming for metal lathe control panels! Innovations in CAD technology are transforming how these designs are created. Imagine a control panel that is so easy to use, even a squirrel could operate it. Well, maybe not. But advanced software is allowing for smarter and more user-friendly layouts. Predictions suggest that future control panels will be sleek, feature touch screens, and connect wirelessly. Industry experts believe this will boost efficiency and precision, leading to higher productivity.

| Technology Trends | Future Features |

|---|---|

| Advanced CAD tools | User-friendly interfaces |

| IoT connectivity | Wireless controls |

| Smart functionalities | Interactive touch screens |

As the saying goes, “If you can’t make it simple, you probably don’t understand it well enough.” The future looks bright for metal lathe control panels!

Conclusion

In conclusion, lathe CAD files are essential for designing metal lathe control panels. They help you create accurate, detailed designs. By using these files, you can improve your projects and make your work easier. We encourage you to explore more about CAD software and metal lathes to enhance your skills. Take the next step in your learning journey!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Control Panels:Sure! Here are some questions about lathe CAD files and metal lathe control panels: 1. What are CAD files? CAD means Computer-Aided Design. They are digital drawings that help us plan and build machines. 2. How do we use CAD files for lathes? We use CAD files to show how to make parts on a lathe. 3. What is a control panel on a metal lathe? A control panel is where you push buttons and turn knobs to run the lathe. 4. Why are control panels important? They help us control how fast and how much the lathe cuts into the metal. 5. Can we create our own CAD files? Yes, we can use special computer programs to make our own CAD files for lathes.

Sure! Please provide the question you want me to answer.

What File Formats Are Commonly Used For Cad Designs Of Metal Lathe Control Panels?For CAD (Computer-Aided Design) designs of metal lathe control panels, we often use formats like DXF and DWG. DXF stands for Drawing Exchange Format, and it helps share drawings easily. DWG is another popular format made by Autodesk for design files. We can also use PDF files to share designs that everyone can see. These formats help us work together on projects.

How Can I Customize A Cad File For A Metal Lathe Control Panel To Fit My Specific Machine’S Interface?To customize a CAD (Computer-Aided Design) file for your metal lathe control panel, you start by opening the file in a CAD program. Next, look at your machine’s buttons and screens. You can move, add, or change parts in the drawing to match what you see on your lathe. Finally, save your changes and make sure to test everything before using it. This way, your panel will work perfectly with your machine!

What Are The Typical Components That Should Be Included In A Cad Design For A Metal Lathe Control Panel?In a CAD design for a metal lathe control panel, you should include buttons, switches, and lights. Buttons let you start, stop, or change the machine settings. Switches can turn power on and off. Lights show if the machine is running or if there’s a problem. You might also design a screen to show information.

Are There Any Open-Source Resources Or Libraries Where I Can Find Existing Cad Files For Lathe Control Panels?Yes, you can find open-source resources for CAD files. Websites like GitHub and Thingiverse are good places to start. You can search for “lathe control panel” there. These sites let you download designs for free. Happy exploring!

What Software Options Are Available For Designing And Modifying Cad Files Specifically For Metal Lathe Control Panels?You can use several software options to design and change CAD files for metal lathe control panels. Some popular ones are AutoCAD and SolidWorks. TinkerCAD is also a good choice because it’s easy to use. These programs help you create shapes and plans for your projects. You can learn how to use them through online tutorials and practice.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Control Panels:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions about lathe CAD files and metal lathe control panels: 1. What are CAD files? CAD means Computer-Aided Design. They are digital drawings that help us plan and build machines. 2. How do we use CAD files for lathes? We use CAD files to show how to make parts on a lathe. 3. What is a control panel on a metal lathe? A control panel is where you push buttons and turn knobs to run the lathe. 4. Why are control panels important? They help us control how fast and how much the lathe cuts into the metal. 5. Can we create our own CAD files? Yes, we can use special computer programs to make our own CAD files for lathes.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What File Formats Are Commonly Used For Cad Designs Of Metal Lathe Control Panels?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For CAD (Computer-Aided Design) designs of metal lathe control panels, we often use formats like DXF and DWG. DXF stands for Drawing Exchange Format, and it helps share drawings easily. DWG is another popular format made by Autodesk for design files. We can also use PDF files to share designs that everyone can see. These formats help us work together on projects.”}},{“@type”: “Question”,”name”: “How Can I Customize A Cad File For A Metal Lathe Control Panel To Fit My Specific Machine’S Interface?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To customize a CAD (Computer-Aided Design) file for your metal lathe control panel, you start by opening the file in a CAD program. Next, look at your machine’s buttons and screens. You can move, add, or change parts in the drawing to match what you see on your lathe. Finally, save your changes and make sure to test everything before using it. This way, your panel will work perfectly with your machine!”}},{“@type”: “Question”,”name”: “What Are The Typical Components That Should Be Included In A Cad Design For A Metal Lathe Control Panel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a CAD design for a metal lathe control panel, you should include buttons, switches, and lights. Buttons let you start, stop, or change the machine settings. Switches can turn power on and off. Lights show if the machine is running or if there’s a problem. You might also design a screen to show information.”}},{“@type”: “Question”,”name”: “Are There Any Open-Source Resources Or Libraries Where I Can Find Existing Cad Files For Lathe Control Panels?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can find open-source resources for CAD files. Websites like GitHub and Thingiverse are good places to start. You can search for lathe control panel there. These sites let you download designs for free. Happy exploring!”}},{“@type”: “Question”,”name”: “What Software Options Are Available For Designing And Modifying Cad Files Specifically For Metal Lathe Control Panels?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use several software options to design and change CAD files for metal lathe control panels. Some popular ones are AutoCAD and SolidWorks. TinkerCAD is also a good choice because it’s easy to use. These programs help you create shapes and plans for your projects. You can learn how to use them through online tutorials and practice.”}}]}