Have you ever wondered how metal parts are shaped with such precision? It often starts with lathe CAD files. These digital designs help engineers and hobbyists create incredible items using metal lathe cutting tools. Imagine creating a shiny gear or a detailed bracket right from your computer screen!

Lathe machines spin the metal while cutting tools shape it into the desired form. But what if you want to design something unique? This is where lathe CAD files come in handy. They offer ready-made designs or allow you to craft your own ideas.

Isn’t it amazing how technology can help us build things we only dreamed of? Dive into the world of lathe tools and discover how these files can lead you to endless creativity. Who knows? You might create the next big invention!

Lathe Cad Files: Essential Metal Lathe Cutting Tools

Understanding Lathe CAD Files and Metal Lathe Cutting Tools

Lathe CAD files help in designing metal parts with precision. These files can guide you in creating accurate models for machining. Metal lathe cutting tools play a vital role in shaping materials. They allow you to cut, carve, and refine various surfaces. Did you know that using the right CAD file can save you time and reduce waste? Choosing the proper cutting tools can make your projects easier and more efficient. Discover how these elements can transform your workshop!Understanding Lathe CAD Files

Definition and importance of CAD files in lathe work. Types of CAD files commonly used in metalworking.CAD files act like magic blueprints for lathe work. They help make precise cuts with the right tools and materials. Without these files, metalworking can feel like trying to find your way in the dark—pretty tricky! Common types of CAD files include .dxf and .dwg formats. Each type has its unique flair in metalworking. Using the right one is crucial for success.

| Type of CAD File | Description |

|---|---|

| .dxf | Great for sharing and used widely in metal cutting. |

| .dwg | Popular for detailed designs and better for intricate work. |

Benefits of Using CAD Files for Metal Lathes

Enhanced precision in design and cutting. Efficiency in the manufacturing process.Using CAD files for metal lathes offers great benefits. First, it improves precision in design and cutting. This means parts fit perfectly together, making things work better. Second, it saves time in the manufacturing process. Tools can be used faster and more accurately. This speeds up work. Here are key advantages:

- Improved Accuracy: Designs are exact, reducing errors.

- Faster Production: Tools work quickly, boosting output.

Why are CAD files important?

CAD files help create detailed designs. They ensure everything is made correctly and quickly.How to Create CAD Files for Metal Lathe Cutting Tools

Stepbystep process of designing CAD files. Software options for creating CAD files.Designing CAD files for cutting tools is like making a LEGO masterpiece. First, you gather your ideas and figure out what you need. Then choose software that fits your skill. Popular options include Tinkercad for beginners and Fusion 360 for advanced users. Now comes the fun part: draw your tool shape, add measurements, and tweak it until it’s just right. Want to know if your design is a winner? Go ahead and make a virtual prototype!

| Software | Features | Best For |

|---|---|---|

| Tinkercad | User-friendly, free | Beginners |

| Fusion 360 | Advanced modeling tools | Experienced users |

| SolidWorks | Professional features | Engineers |

Remember, practice makes perfect! So, grab your tools and get started on your next cutting tool design adventure!

Best Practices for Downloading and Using Lathe CAD Files

Tips for finding quality CAD files online. Guidelines for customizing CAD files for specific lathe tools.Finding quality CAD files online can feel like searching for a needle in a haystack. Start by visiting reliable websites that specialize in engineering or machining resources. Look for user reviews to gauge file quality. Always double-check the file format to ensure it fits your lathe’s tools. Customization is key for specific lathe needs. Adjust sizes and features to match your tools. Think of it like tailoring a suit—nobody wants a baggy tuxedo!

| Tips for Finding Quality CAD Files | Customization Guidelines |

|---|---|

| Check user reviews | Adjust dimensions |

| Use trusted sites | Edit file features |

| Look for popular formats | Match your tools exactly |

Top Resources for Metal Lathe CAD Files

Websites and platforms offering free and paid CAD files. Community forums and usergenerated content.Finding top-notch CAD files for metal lathes is easier than you think! You can check out websites like Thingiverse or GrabCAD for free CAD files. If you’re up for spending a few bucks, sites like TurboSquid and CADdetails offer some fancy paid options. Don’t forget to peek into community forums, where users share their creations and tips. It’s like having a workshop full of friends, but without the noise of tools whirring!

| Resource | Type | Cost |

|---|---|---|

| Thingiverse | Website | Free |

| GrabCAD | Website | Free |

| TurboSquid | Website | Paid |

| CADdetails | Website | Paid |

| Community Forums | Forum | Free |

Common Issues When Working with Lathe CAD Files

Troubleshooting common file conversion problems. Solutions for compatibility issues with different cutting tools.Lathe CAD files can sometimes cause problems. The file might not open or work well with your cutting tools. Here are common issues and solutions:

- File Conversion Problems: Files may not change formats easily. Use programs like AutoCAD or Fusion 360 to help.

- Compatibility Issues: Some cutting tools might not fit all files. Always check tool settings before starting.

- Missing Features: Files may lose details while converting. Always preview your work.

By knowing these problems, you can fix them quickly and keep working smoothly.

What should I do if my lathe CAD file won’t open?

First, check the file format. Make sure your software supports it. If not, try converting it to a different format.

How can I ensure my cutting tools are compatible with my CAD files?

- Always read tool specifications. They tell you what files work best.

- Update your software regularly for the latest features.

The Future of CAD in Metal Lathe Technology

Trends in CAD technology for metalworking. Impact of automation and AI on CAD file usage in lathes.New trends in CAD technology are changing metal lathe work. These tools help create precise designs quickly. Automation and AI are now playing big roles. They make it easier to use CAD files for lathes. This means fewer mistakes and faster production. Imagine a machine that learns as it works! Here are some key points:

- Smart Software: CAD programs now use AI to suggest better designs.

- Faster Production: Machines can now work on their own.

- Improved Accuracy: Less human error means better results.

What does automation in CAD mean for lathes?

Automation in CAD means machines can operate with little human help. This saves time and improves safety.

Conclusion

In conclusion, lathe CAD files are essential for designing metal lathe cutting tools. They help us create precise parts and improve our projects. You can find many resources online to explore these files further. By learning about CAD and cutting tools, we can all become better makers. So, let’s dive in and start creating today!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Cutting Tools:1. What is a lathe? A lathe is a machine that shapes materials like wood or metal. It spins the material while cutting. 2. What are CAD files? CAD stands for Computer-Aided Design. These files help us create and share designs on computers. 3. How do we use lathe cutting tools? We use lathe cutting tools to carve and shape materials. They help make parts for machines or toys. 4. Why are metal lathe tools important? Metal lathe tools are strong. They help us shape hard metals that can be used in many products. 5. Can we find lathe plans online? Yes! We can find lathe plans and CAD files online. They help us understand how to make things with a lathe.

Sure! Please provide the question you would like me to answer, and I’ll be happy to help!

What Types Of Cad Software Are Commonly Used For Designing Lathe Cutting Tools, And What Features Do They Offer?Common CAD software for designing lathe cutting tools includes AutoCAD, SolidWorks, and Fusion 360. These programs help you draw and create 3D models. They offer features like easy drawing tools, 3D design options, and the ability to test how tools will work. You can also change designs quickly and see how they look from different angles. This makes it simple to create and improve cutting tools!

How Can I Find High-Quality Cad Files For Specific Metal Lathe Cutting Tools That Are Compatible With My Cnc Lathe?You can find high-quality CAD files by searching online. Use websites that offer free or paid designs. Look for files made for CNC (Computer Numerical Control) lathes. You can also ask in hobby forums or groups. They often share good resources and tips.

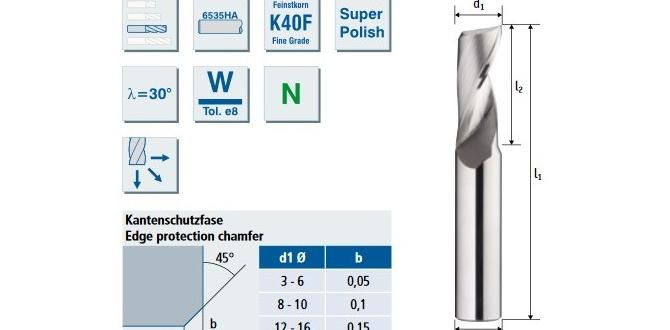

What Factors Should Be Considered When Designing Cad Models For Metal Lathe Cutting Tools To Ensure Optimal Performance And Durability?When designing CAD models for metal lathe cutting tools, you should think about the shape and size. The tool should fit well and be easy to hold. We must also choose strong materials so the tools last a long time. It’s important to think about how the tool will cut, like how sharp it is. Finally, we should check how heat will affect the tool during use.

Are There Any Online Platforms Or Repositories Where I Can Download Free Or Paid Cad Files For Various Metal Lathe Attachments And Accessories?Yes, you can find CAD files online for metal lathe attachments. Websites like Thingiverse and GrabCAD offer free files. You can also check Etsy for paid designs. Just search for what you need, and download it!

How Do Different Cutting Tool Geometries And Materials Represented In Cad Files Affect Machining Performance On A Metal Lathe?Different cutting tool shapes and materials can change how well we cut metal on a lathe. If a tool has a sharp edge, it cuts better and wears down less. Tough materials like carbide last longer than softer ones. CAD files help us see and choose the best tools for our projects, which makes our work easier and faster.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Cutting Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “1. What is a lathe? A lathe is a machine that shapes materials like wood or metal. It spins the material while cutting. 2. What are CAD files? CAD stands for Computer-Aided Design. These files help us create and share designs on computers. 3. How do we use lathe cutting tools? We use lathe cutting tools to carve and shape materials. They help make parts for machines or toys. 4. Why are metal lathe tools important? Metal lathe tools are strong. They help us shape hard metals that can be used in many products. 5. Can we find lathe plans online? Yes! We can find lathe plans and CAD files online. They help us understand how to make things with a lathe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Types Of Cad Software Are Commonly Used For Designing Lathe Cutting Tools, And What Features Do They Offer?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common CAD software for designing lathe cutting tools includes AutoCAD, SolidWorks, and Fusion 360. These programs help you draw and create 3D models. They offer features like easy drawing tools, 3D design options, and the ability to test how tools will work. You can also change designs quickly and see how they look from different angles. This makes it simple to create and improve cutting tools!”}},{“@type”: “Question”,”name”: “How Can I Find High-Quality Cad Files For Specific Metal Lathe Cutting Tools That Are Compatible With My Cnc Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find high-quality CAD files by searching online. Use websites that offer free or paid designs. Look for files made for CNC (Computer Numerical Control) lathes. You can also ask in hobby forums or groups. They often share good resources and tips.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Designing Cad Models For Metal Lathe Cutting Tools To Ensure Optimal Performance And Durability?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing CAD models for metal lathe cutting tools, you should think about the shape and size. The tool should fit well and be easy to hold. We must also choose strong materials so the tools last a long time. It’s important to think about how the tool will cut, like how sharp it is. Finally, we should check how heat will affect the tool during use.”}},{“@type”: “Question”,”name”: “Are There Any Online Platforms Or Repositories Where I Can Download Free Or Paid Cad Files For Various Metal Lathe Attachments And Accessories?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can find CAD files online for metal lathe attachments. Websites like Thingiverse and GrabCAD offer free files. You can also check Etsy for paid designs. Just search for what you need, and download it!”}},{“@type”: “Question”,”name”: “How Do Different Cutting Tool Geometries And Materials Represented In Cad Files Affect Machining Performance On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different cutting tool shapes and materials can change how well we cut metal on a lathe. If a tool has a sharp edge, it cuts better and wears down less. Tough materials like carbide last longer than softer ones. CAD files help us see and choose the best tools for our projects, which makes our work easier and faster.”}}]}