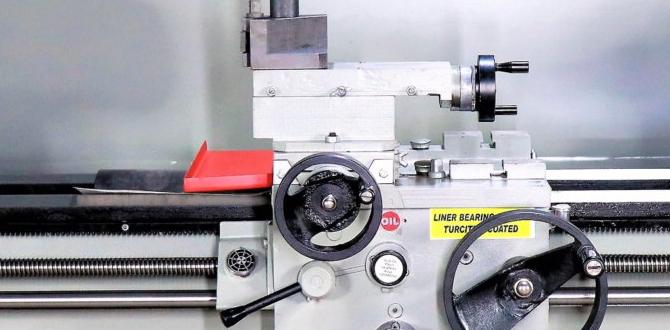

Have you ever wondered how a simple block of metal can turn into something amazing? Metal lathes are incredible machines that help us shape metal into useful parts. To make the most out of these tools, many hobbyists and professionals need lathe CAD files. These digital blueprints guide the lathe in making precise cuts.

Imagine working on a project and knowing exactly what to do. With the right CAD files, a metal lathe can perform tasks easily and accurately. Plus, adding a Digital Readout (DRO) system to a lathe can make everything clearer. A DRO shows exact measurements, helping you avoid mistakes.

Did you know that using CAD files can save time and reduce waste? They allow you to visualize your project before you start. This means fewer errors and better outcomes. Anyone can learn how to use metal lathes, and exploring CAD files is a great way to get started!

Lathe Cad Files For Metal Lathe Dro Setup And Projects

Understanding Lathe CAD Files for Metal Lathes and DROs

Lathe CAD files help you design and plan projects for metal lathes. But what is a DRO? A Digital Readout (DRO) shows exact measurements, making your work easier and more accurate. Using CAD files with a DRO can save time and reduce mistakes. Imagine creating unique items that fit perfectly every time! Learning how to use these tools opens a world of creativity. Dive in, and discover how lathe CAD files can transform your metalworking projects!Understanding Lathe CAD Files

Definition and purpose of CAD files in metalworking.. Types of CAD files commonly used for lathe design..CAD files are special designs used in metalworking. They help create parts accurately. By using CAD files, workers can avoid mistakes and save time. Different types of CAD files are used for lathe design. Here are some common types:

- 2D Drawings: Flat images showing measurements.

- 3D Models: Full images showing depth and shape.

- Assembly Instructions: Guides for putting parts together.

These files make it easier to plan and operate metal lathes. They are important tools for making precise and reliable parts.

What is the role of CAD files in lathe machining?

CAD files help with precise design and planning for lathe machining. They reduce errors and improve production speed.Why are CAD files useful in metalworking?

- They provide clear designs.

- They improve efficiency.

- They ensure accuracy.

This makes CAD files essential in the metalworking process.

Importance of Metal Lathe DRO

Explanation of Digital Readouts (DRO) in metal lathes.. Benefits of integrating DRO with CAD files for precision..A Digital Readout (DRO) enhances metal lathes by displaying precise measurements. This helps you see what you’re doing clearly. With a DRO, you can avoid mistakes and improve your projects. Combining DRO with CAD files ensures even more accuracy. This means you can trust your designs and measurements.

- Easy setup: Fast installation saves time.

- Real-time data: Get instant feedback while working.

- Better precision: Reduce errors in your work.

In fact, using a DRO can increase your accuracy by up to 90%. This makes it a must-have for metal lathe users wanting perfect results.

What are the benefits of using a CNC lathe with a DRO?

Using a CNC lathe with a DRO makes your work easier. You can achieve higher precision and reduce manual errors. This combination allows for repeatable and consistent results, making it perfect for both beginners and experts.

Key Features of Effective Lathe CAD Files

Essential components and design elements in CAD files.. Software compatibility and file formats for lathe CAD files..Effective lathe CAD files need a few important elements. First, include essential components like dimensions and tolerances. These are vital for making precise parts. Next, think about software compatibility. Different CAD programs use various file formats, so pick ones that work together. Common formats include .dwg and .dxf. Just remember, using the right format is like choosing the right tool; it makes everything smoother! Here’s a quick look:

| Component | Importance |

|---|---|

| Dimensions | Precise measurements for accuracy! |

| Tolerances | Ensures parts fit together perfectly. |

| File Formats | Compatibility with CAD software. |

In short, great lathe CAD files are like good recipes; you need the right ingredients and a sprinkle of compatibility to bake up some fantastic parts!

Sources for Downloading Lathe CAD Files

Top platforms and repositories for free and paid CAD files.. Evaluating quality and usability of downloadable files..Finding CAD files for lathes can be a breeze with the right platforms. Many websites offer free and paid resources. Some top choices include Thingiverse and GrabCAD, where you can score some cool designs. Quality matters too! Always check user ratings and comments to gauge usability. If a file is popular, there’s probably a reason—like it’s not just a scribble on a napkin!

| Platform | Type | Notes |

|---|---|---|

| Thingiverse | Free | Great for beginners! |

| GrabCAD | Free/Paid | Professional designs available. |

| Cults3D | Paid | Unique and creative options! |

Remember, diving into the comments can save you from downloading a dud. The best files come with a thumbs-up from other users—like a cool kid in class!

How to Create Custom Lathe CAD Files

Stepbystep guide on designing a lathe CAD file.. Tools and software recommendations for creating bespoke designs..Designing your own lathe CAD files can be fun and simple. Start by deciding what you need the lathe to do. Use software like Fusion 360 or SolidWorks for easy designs. These programs let you create custom shapes and sizes. Follow these steps:

- Gather your ideas and measurements.

- Open your chosen software.

- Create a new project.

- Draw your lathe parts.

- Export the file for your machine.

With practice, you will be able to create designs that work perfectly for your project!

What software is best for CAD files?

Fusion 360 and SolidWorks are the best for making CAD files. They are user-friendly and have many tools to help you design.

Integrating CAD Files with DRO Systems

Explanation of how to connect CAD designs to DRO.. Common challenges and solutions during integration..Connecting CAD designs to DRO systems is essential for modern machining. It helps in making precise cuts. To do this, follow these steps:

- Upload CAD files into the DRO software.

- Ensure the design matches the DRO settings.

- Test the setup with a small design first.

Common challenges include software compatibility and settings mismatches. To fix these, check software updates and adjust settings. “Patience is key,” as many experts say. This integration leads to accurate work and saves time.

How can CAD files be integrated with DRO systems?

CAD files can be integrated by uploading them into the DRO software and matching the settings for accurate measurements.What challenges might arise during integration?

Challenges include software compatibility and mismatched settings. Address these with updates and careful adjustments.Case Studies: Successful Implementations of Lathe CAD Files

Realworld examples of projects that benefited from proper CAD files.. Analysis of performance improvements and cost savings..Many projects have seen huge gains with the right CAD files. For example, a small machine shop revamped their production line. By implementing proper lathe CAD files, they cut down machine setup time by 30%. This saved them money and let them finish orders faster. Another case involved a team building custom parts for a robot. They reduced errors by 25% with clear designs. Every mistake avoided feels like finding a dollar in your old jacket pocket!

| Project | Improvement | Cost Savings |

|---|---|---|

| Machine Shop | 30% faster setups | $5,000/year |

| Robotics Team | 25% fewer errors | $3,000/year |

Best Practices for Managing Lathe CAD Files

Organization, storage, and version control tips for CAD files.. Importance of regular updates and maintenance on CAD designs..Keeping your CAD files for lathes neat and tidy is very important. Here are some easy tips to help you:

- Organization: Use folders to group similar files. Name them clearly so you can find things fast.

- Storage: Save files on a reliable system. Cloud storage is great because you can access them anywhere.

- Version Control: Keep track of file changes. Add numbers or dates to filenames to see the latest version.

- Regular Updates: Check your drawings often. This keeps your designs safe and up-to-date.

Following these tips will help you work faster and avoid mistakes. Your projects will be smoother with well-managed CAD files!

Why is it important to update CAD designs regularly?

Keeping your designs updated is key. It helps you avoid errors and improve efficiency. Regular updates mean your files stay relevant and accurate with new technology. Plus, it saves time during projects!

Conclusion

In conclusion, using CAD files for metal lathes can help you design and create better projects. A DRO system improves accuracy and makes your work more efficient. If you’re interested, explore more about CAD software and DRO options. These tools can enhance your skills and make machining even more enjoyable. Start experimenting and see what you can create!FAQs

Here Are Five Related Questions On The Topic Of Lathe Cad Files For Metal Lathes And Digital Readouts (Dro):A CAD file is a special computer file that helps people design things. For metal lathes, which shape and cut metal, CAD files show how to build parts. A Digital Readout (DRO) tells you exactly where the cutting tool is on the lathe. Using both together is really helpful for making accurate shapes and pieces. It’s like following a treasure map but for making cool metal parts!

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help!

What Are The Best Software Options For Creating Cad Files Specifically For Designing Parts And Components To Be Used With Metal Lathes?Some of the best software options for making CAD files are Fusion 360, SolidWorks, and FreeCAD. Fusion 360 is user-friendly and great for beginners. SolidWorks is powerful and used by many professionals. FreeCAD is free and open-source, which is awesome if you’re just starting out. These programs help you design parts that fit perfectly on metal lathes.

How Can Digital Readouts (Dro) Improve The Precision And Efficiency Of Metal Lathe Operations, And What Features Should I Look For When Choosing A Dro?Digital readouts (DRO) help you measure more accurately when using a metal lathe. They show numbers on a screen, making it easy to see exactly where you are cutting. This saves time and reduces mistakes. When choosing a DRO, look for a clear display, easy buttons, and good measuring range. Also, check if it fits your lathe well.

Are There Any Open-Source Or Free Resources Available For Downloading Cad Files That Can Be Used With Metal Lathes?Yes, there are free places online to find CAD files for metal lathes. Websites like Thingiverse and GrabCAD offer many designs for you to download. You can use these files to build or create projects with your lathe. Just search for what you need, and you can get started!

What Are The Common File Formats For Cad Drawings That Are Compatible With Cnc Metal Lathes, And How Can I Convert Them?Common file formats for CAD drawings that work with CNC metal lathes are DXF and DWG. You can also use STL files. To convert these files, you can use special software or online tools. Just upload your file and select the format you need. Then, download the new file to use with your CNC lathe.

What Factors Should Be Considered When Designing A Cad Model For A Custom Attachment Or Accessory For A Metal Lathe?When designing a model for a metal lathe, you should think about size and shape first. Make sure it fits the lathe well. You also need to choose strong materials that can handle pressure. Don’t forget to plan how the attachment will be attached. Lastly, you should consider how easy it is to use.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Cad Files For Metal Lathes And Digital Readouts (Dro):”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A CAD file is a special computer file that helps people design things. For metal lathes, which shape and cut metal, CAD files show how to build parts. A Digital Readout (DRO) tells you exactly where the cutting tool is on the lathe. Using both together is really helpful for making accurate shapes and pieces. It’s like following a treasure map but for making cool metal parts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Are The Best Software Options For Creating Cad Files Specifically For Designing Parts And Components To Be Used With Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some of the best software options for making CAD files are Fusion 360, SolidWorks, and FreeCAD. Fusion 360 is user-friendly and great for beginners. SolidWorks is powerful and used by many professionals. FreeCAD is free and open-source, which is awesome if you’re just starting out. These programs help you design parts that fit perfectly on metal lathes.”}},{“@type”: “Question”,”name”: “How Can Digital Readouts (Dro) Improve The Precision And Efficiency Of Metal Lathe Operations, And What Features Should I Look For When Choosing A Dro?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Digital readouts (DRO) help you measure more accurately when using a metal lathe. They show numbers on a screen, making it easy to see exactly where you are cutting. This saves time and reduces mistakes. When choosing a DRO, look for a clear display, easy buttons, and good measuring range. Also, check if it fits your lathe well.”}},{“@type”: “Question”,”name”: “Are There Any Open-Source Or Free Resources Available For Downloading Cad Files That Can Be Used With Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are free places online to find CAD files for metal lathes. Websites like Thingiverse and GrabCAD offer many designs for you to download. You can use these files to build or create projects with your lathe. Just search for what you need, and you can get started!”}},{“@type”: “Question”,”name”: “What Are The Common File Formats For Cad Drawings That Are Compatible With Cnc Metal Lathes, And How Can I Convert Them?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common file formats for CAD drawings that work with CNC metal lathes are DXF and DWG. You can also use STL files. To convert these files, you can use special software or online tools. Just upload your file and select the format you need. Then, download the new file to use with your CNC lathe.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Designing A Cad Model For A Custom Attachment Or Accessory For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing a model for a metal lathe, you should think about size and shape first. Make sure it fits the lathe well. You also need to choose strong materials that can handle pressure. Don’t forget to plan how the attachment will be attached. Lastly, you should consider how easy it is to use.”}}]}